Method for preparing butt-welding elbow through molding of stainless steel composite steel plate

A composite steel plate and stainless steel technology, which is applied to other manufacturing equipment/tools, welding media, manufacturing tools, etc., can solve the problems of expensive stainless steel, etc., and achieve the effects of easy geometric size, prevention of peeling, and high shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] (1) Blanking, according to the size of the elbow, select the appropriate steel plate blanking to make a blank;

[0026] (2) Pressing, pressing the blank through the forming die at room temperature or heating several times to reach the elbow forming size; the heating condition is: the blank is placed in a heating furnace for heating, and heated to the range of 930±20℃ Pressing inside; cold pressing process can also be used;

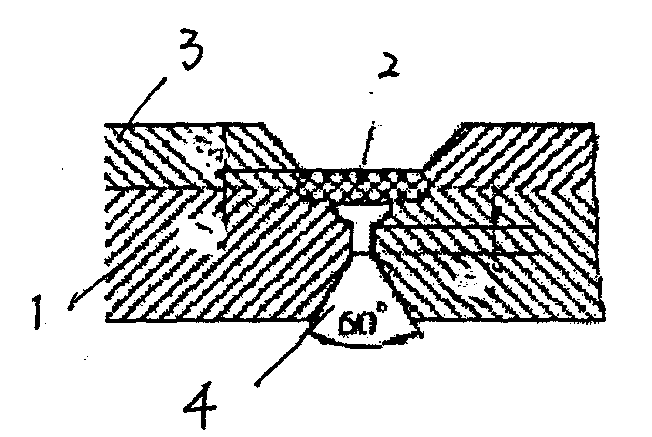

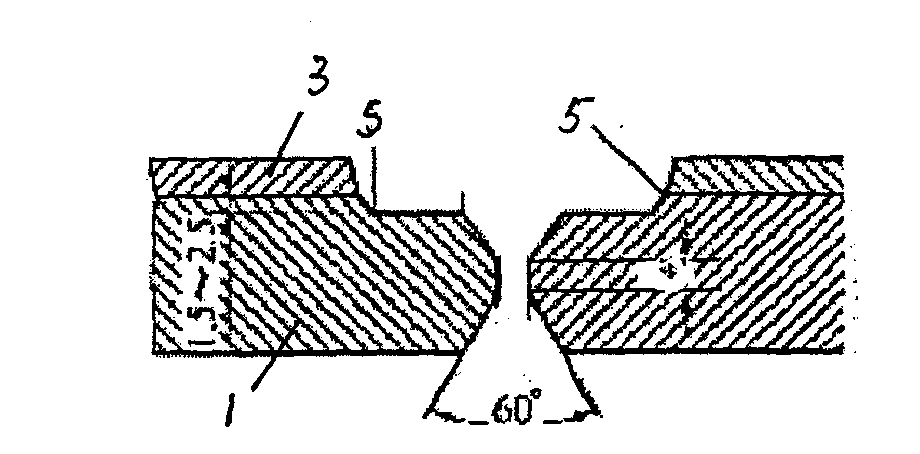

[0027] (3) Welding, select different welding processes for welding according to different materials;

[0028] (4) Heat treatment, normalizing the hot-pressed elbow at 910±10℃; or annealing the cold-pressed elbow at 610±10℃.

[0029] (5) Machining, the rough elbow is processed into a finished elbow.

[0030] (6) Inspection, through its appearance, geometric dimensions, performance inspection and various non-destructive inspections, it becomes a standard finished product.

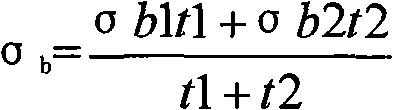

[0031] Press forming: According to the size of the elbow, select the appropriate steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com