Defect repair welding process of stainless steel composite board coating

A composite plate and stainless steel technology, applied in the field of metal welding, can solve problems such as difficulty in quality control, and achieve the effect of ensuring the height of the base weld, avoiding cracks, and ensuring the quality of cladding welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

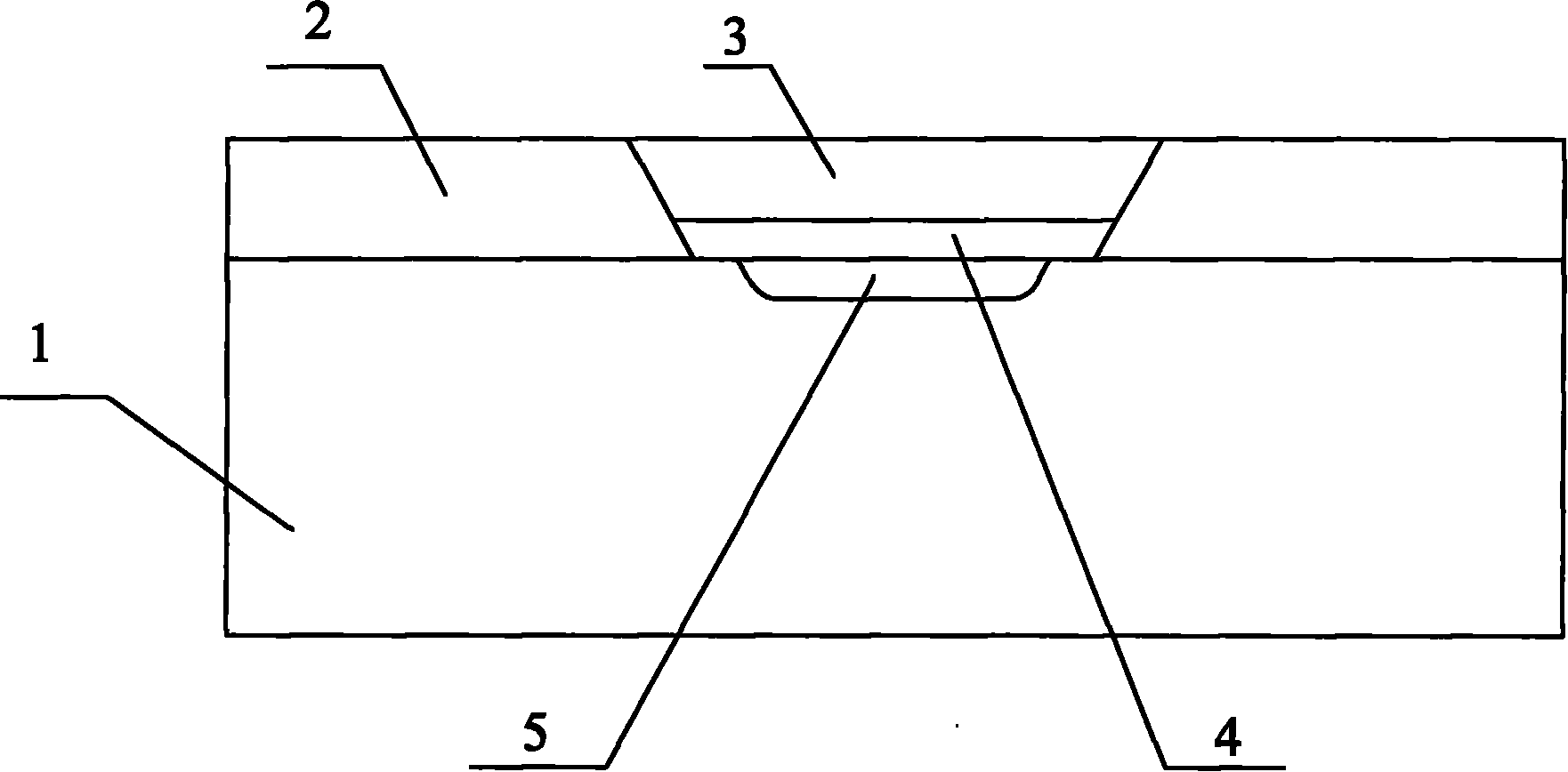

[0025] Refer to attached figure 1 :

[0026] Stainless steel clad plate, the base material 1 is 16MnR, which meets the strength and rigidity requirements of the equipment, and the cladding material 2 is 0Cr13Al stainless steel, which meets the acid resistance requirements of the medium. During the manufacturing process, cracks appeared on the cladding side, so the method of overlay welding was used for repair welding. The specific steps are:

[0027] First remove the defective cladding material with a removal length of 100mm and a width of 30mm; then dig down the base material by 1mm and the width is less than the width of the cladding material 2, so that a step is formed between the base material 1 and the cladding material 2. The length is 3 mm to avoid cracks at the interface between the base material 1 and the cladding material 2. At the same time, the metal of the base weld 5 can be welded to be flush with the step to ensure the height of the base weld 5. At the same ti...

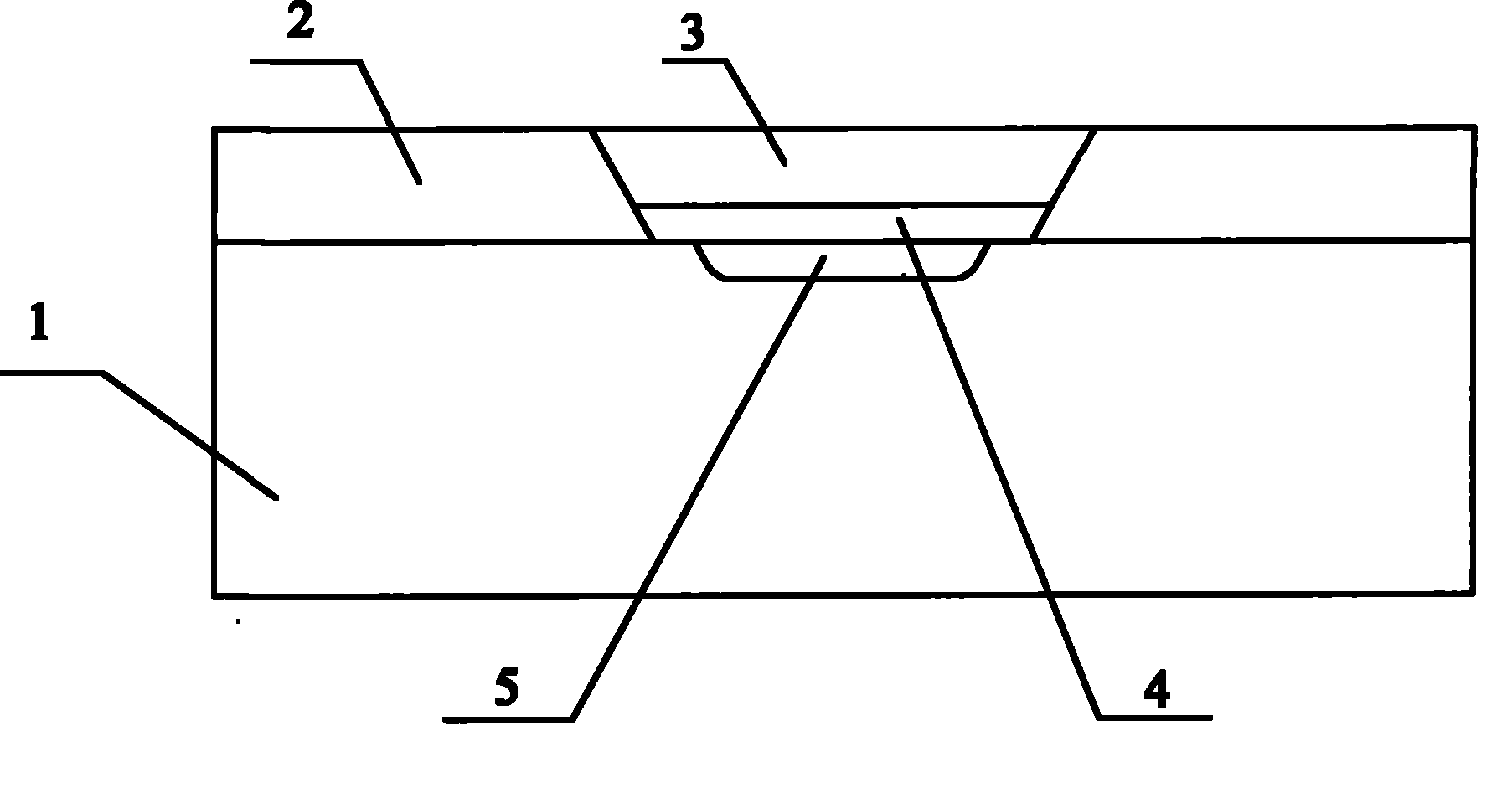

Embodiment 2

[0029] Stainless steel clad plate, the base material 1 is 16MnR, which meets the strength and rigidity requirements of the equipment, and the cladding material 2 is 0Cr13Al stainless steel, which meets the acid resistance requirements of the medium. During the manufacturing process, cracks appeared on the cladding side, so the method of overlay welding was used for repair welding. The specific steps are:

[0030]First remove the defective cladding material, the removal length is 150mm, and the width is 50mm; then the base material is dug down by 3mm, and the width is smaller than the filling width of the cladding material 2, so that a step is formed between the base material 1 and the cladding material 2. The length is 5mm to avoid cracks at the interface between the base material 1 and the cladding material 2. At the same time, the metal of the base weld 5 can be welded to be flush with the step to ensure the height of the base weld 5. At the same time, when welding the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com