Measuring device for injection hole pressure of engine fuel oil injection system

A technology of fuel injection system and measuring device, which is applied in the direction of fuel injection device, engine test, measuring device, etc., can solve the problem of difficult measurement of pressure chamber, and achieve the effect of controllable geometric size and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

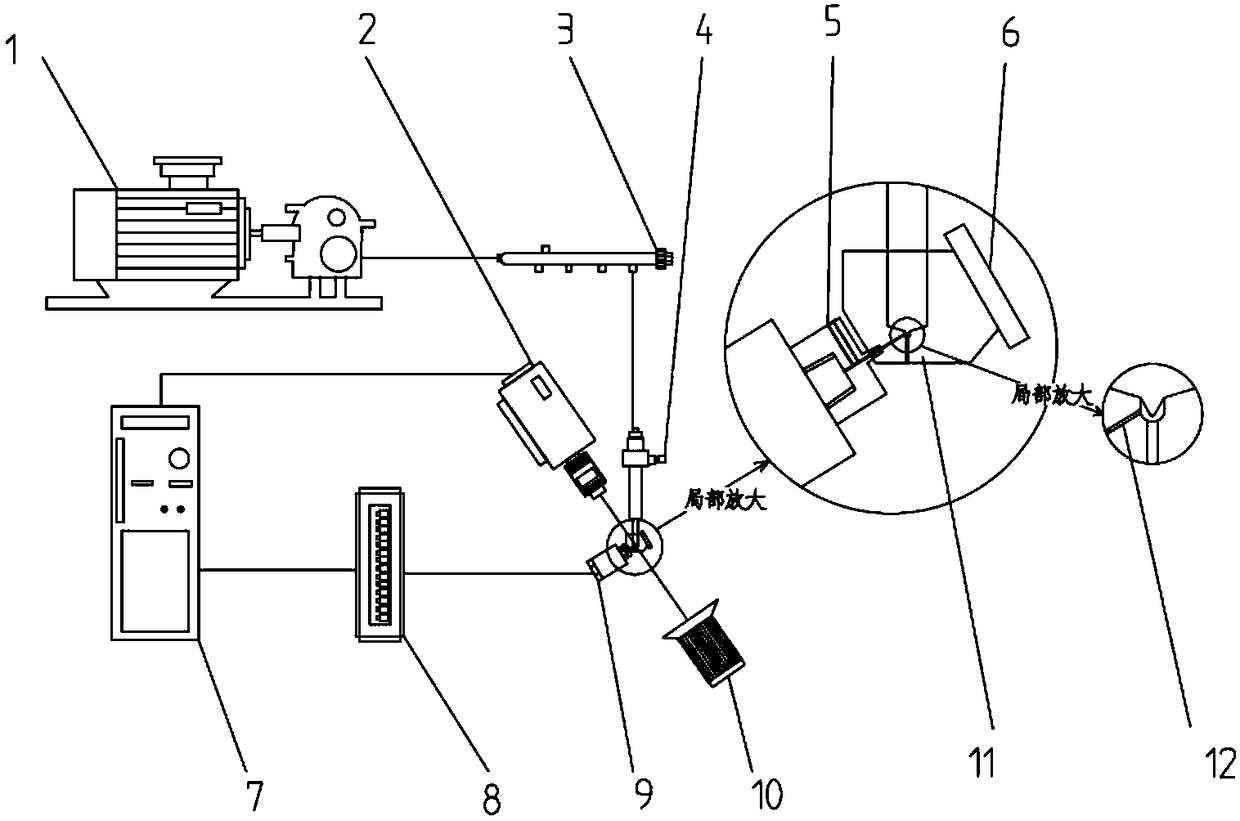

[0034] This embodiment provides a measuring device for the nozzle pressure of the engine fuel injection system, see the attached figure 1 , including: high-pressure fuel supply module, fuel injection module, pressure acquisition module and picture acquisition module;

[0035] The high-pressure fuel supply module includes: a high-pressure pump 1 and a high-pressure common rail 3; the output end of the high-pressure pump 1 is connected to the input end of the high-pressure common rail 3 through a pipeline, the high-pressure pump 1 is used to pressurize the fuel, and the high-pressure common rail 3 Used to ensure the stability of fuel injection pressure;

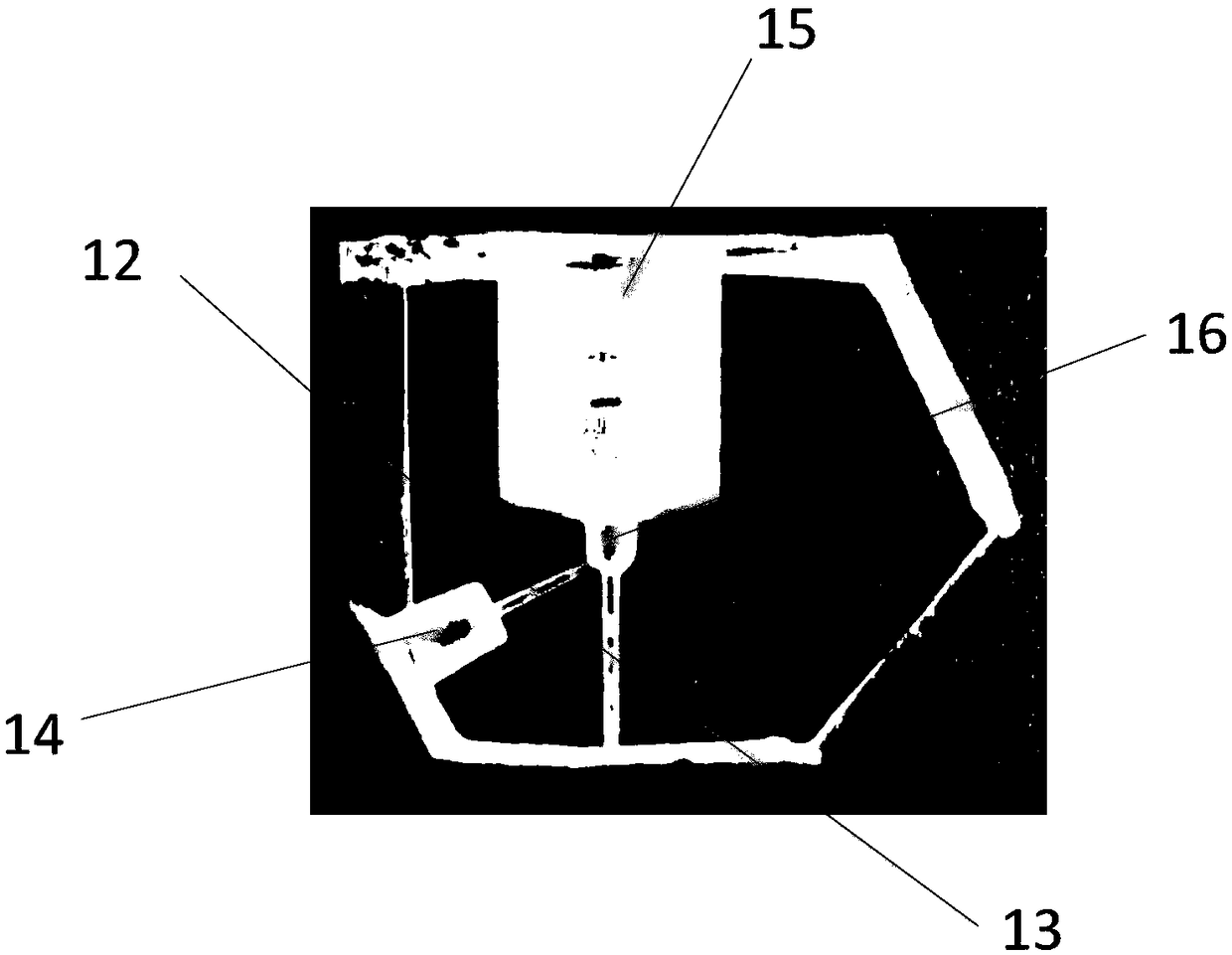

[0036] The fuel injection module includes: a fuel injector 4 and a visual panel 11; see the attached figure 2 , the visible plate 11 is processed with a mounting hole 15 matched with the oil outlet end of the injector 4 and a circular through hole coaxial with the mounting hole 15 and communicated with the circular through ho...

Embodiment 2

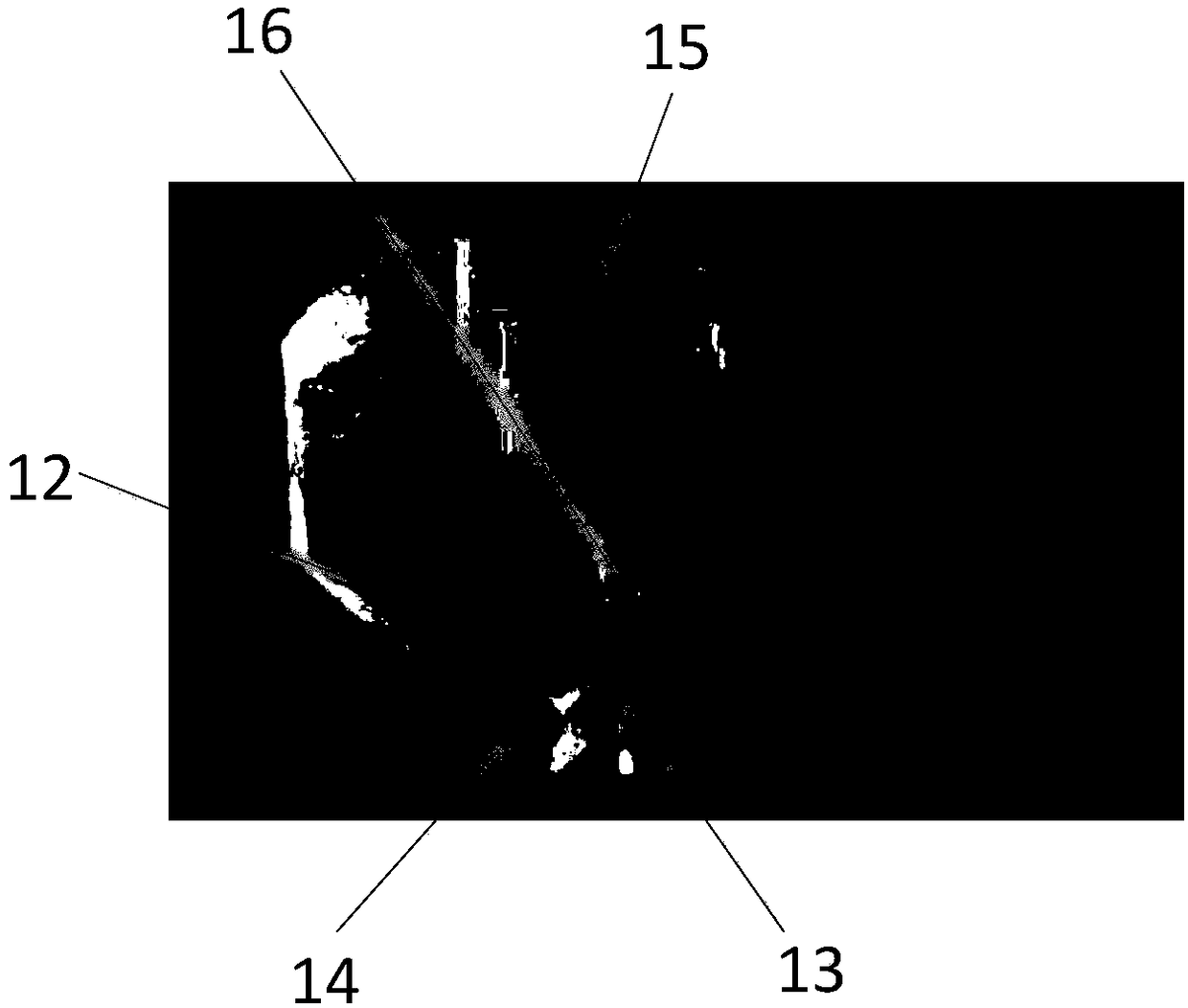

[0045] This embodiment provides another measuring device for the nozzle pressure of the engine fuel injection system, see the attached image 3 , except that one end of the pressure acquisition channel 12 communicates with the conical frustum hole 14 and the other end communicates with the nozzle 13, the rest of the components and connections are the same as in Embodiment 1 for measuring the pressure in the nozzle 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com