Method for synthesizing silver oxide semiconductor thin-film material through room temperature in-situ control

A thin-film material and semiconductor technology, which is applied in the field of in-situ controlled synthesis of silver oxide semiconductor thin-film materials at room temperature, can solve the problems of complex reaction process, only powder generation, high energy consumption, etc., and achieves controllable reaction process, convenient operation and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation: Clean the ITO conductive glass with detergent and deionized water for 20 minutes, and then use concentrated ammonia water (25% by mass) / hydrogen peroxide (30% by mass) / deionized water (volume ratio: 1: The mixed solution of 2:5) was treated at 80°C for 30 minutes, and finally ultrasonically cleaned with deionized water for 20 minutes. The treated ITO conductive glass was dried at 80°C and stored in a clean desiccator for later use. Using the DC magnetron sputtering method to sputter a layer of simple silver thin film layer with a thickness of 60nm on the ITO conductive glass substrate, the thickness of the silver layer is controlled by the film thickness monitor (FTM), and the obtained ITO conductive glass with the simple silver thin film layer is stored in Store in a desiccator.

[0043] 2. Reaction steps: Control the reaction conditions, that is, keep the temperature at 10°C and keep the relative humidity at 30%. Put the ITO conductive glass with the s...

Embodiment 2

[0045] 1. Preparatory work: adopt the same method as in Example 1 to sputter a thin film of silver with a thickness of 100 nm on the ITO conductive glass substrate.

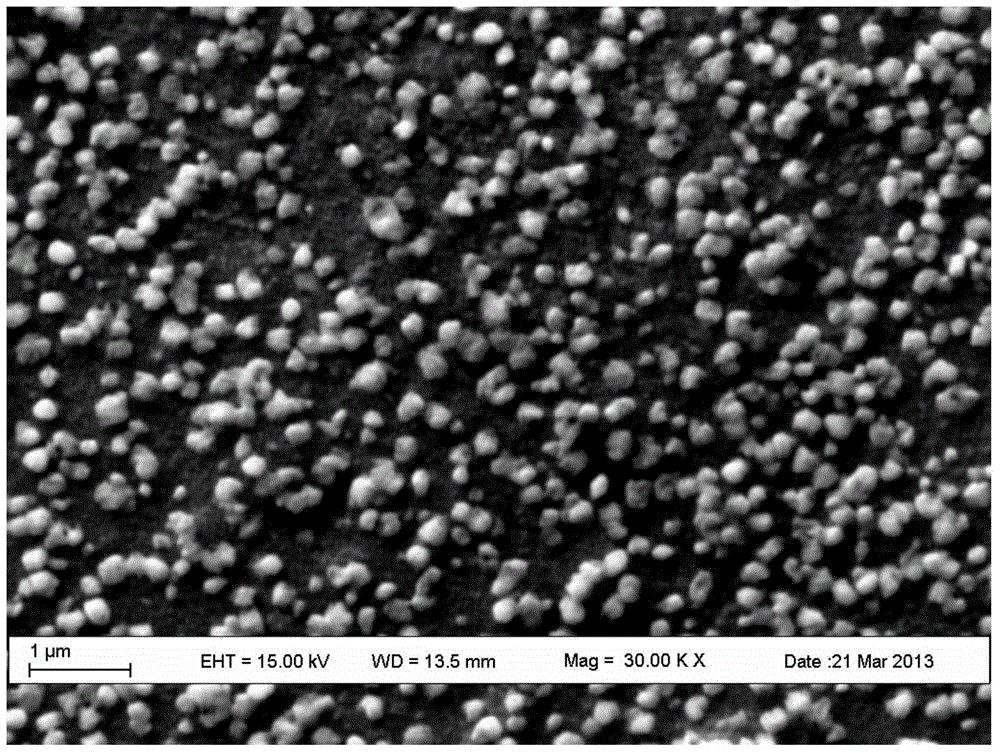

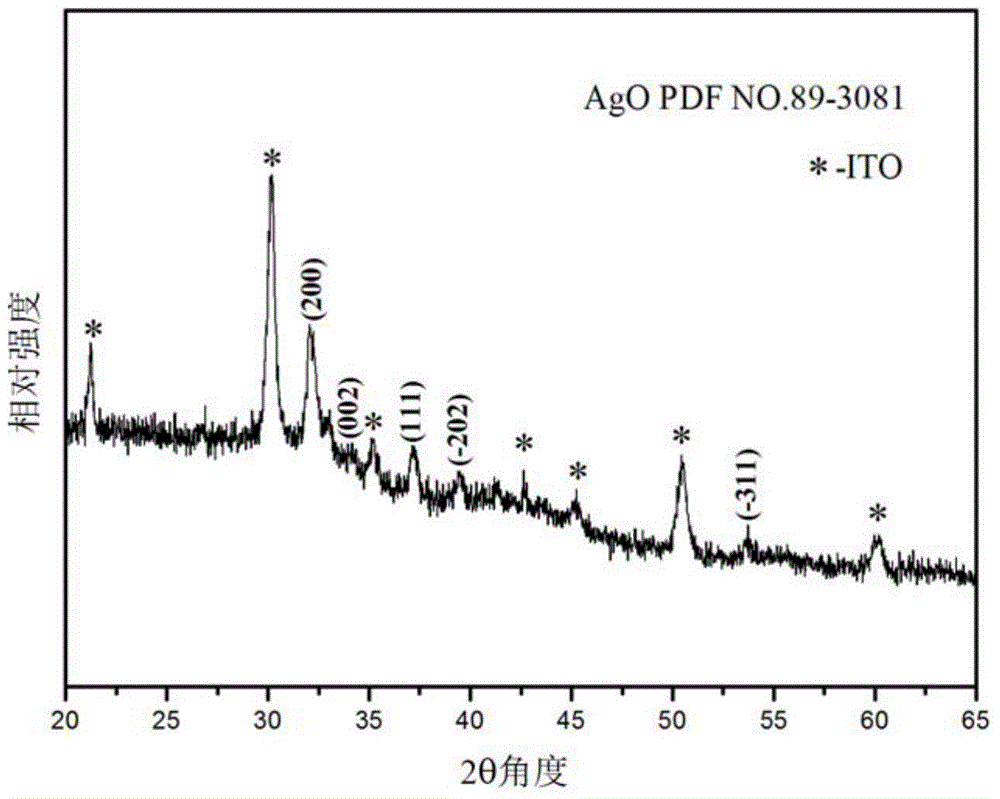

[0046] 2. Reaction steps: Control the reaction conditions, that is, keep the temperature at 22°C and keep the relative humidity at 40%. Put the above-mentioned ITO conductive glass covered with a simple silver film layer directly into the UV-O 3 The reactor is UV-O 3 Washing machine, by UV-O 3 The reactor is UV-O 3 The air inlet of the cleaning machine feeds 5L of oxygen into the reactor, and then the UV-O 3 The inlet and outlet of the reactor are sealed. After 80 minutes of reaction, the sample was taken out, and the obtained product was a brown-gray film. The obtained ITO conductive glass with silver oxide film is put into a desiccator for preservation. image 3 SEM photographs of the obtained samples. Figure 4 The XRD pattern of the obtained sample is obtained through XRD characterization: the AgO semic...

Embodiment 3

[0048] 1. Preparatory work: adopt the same method as in Example 1, sputter a thin film of simple silver with a thickness of 100 nm on the ITO conductive glass substrate.

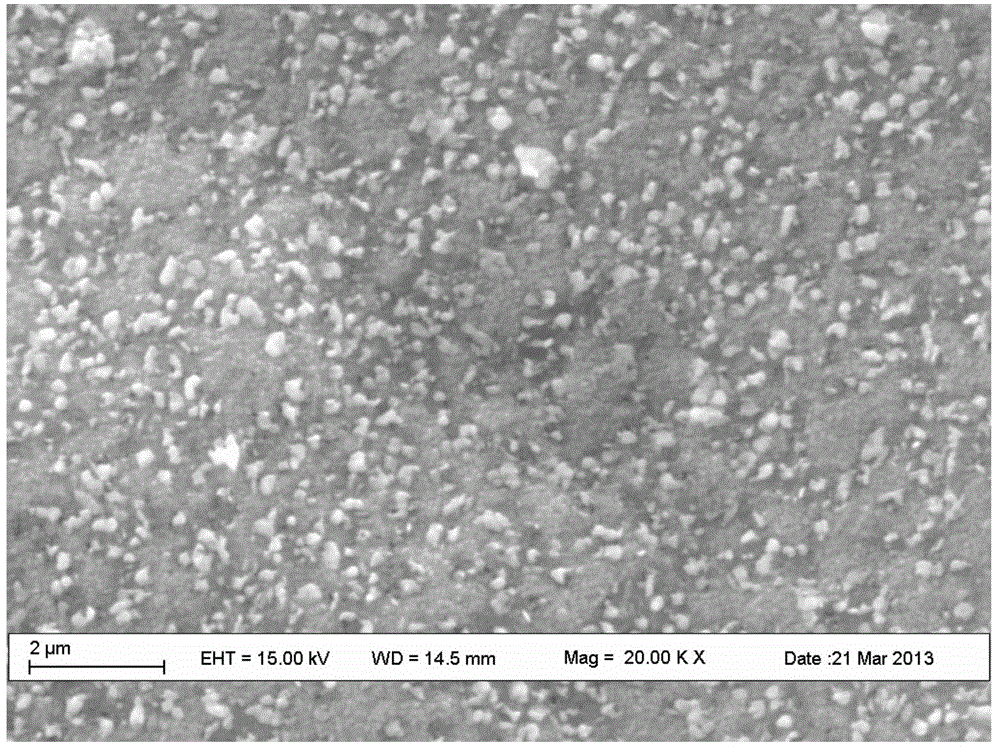

[0049] 2. Reaction steps: Control the reaction conditions, that is, keep the temperature at 22°C and keep the relative humidity at 50%. Put the above-mentioned ITO conductive glass covered with a simple silver film layer directly into the UV-O 3 The reactor is UV-O 3 Washing machine, by UV-O 3 The reactor is UV-O 3 The air inlet of the washing machine is fed into the reactor with oxygen, and then the air inlet and the air outlet of the reactor are sealed, and the sample is taken out after 80 minutes of reaction, and the obtained product is a brown-gray film. The obtained ITO conductive glass with silver oxide film is put into a desiccator for preservation. Figure 5 SEM photographs of the obtained samples. Figure 6 It is the XRD figure of gained sample, obtains through XRD characterization: what the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com