Method and device for precisely rolling and forming cylindrical gear

A cylindrical gear, a precise technology, applied in the direction of gears, other household appliances, household appliances, etc., can solve the problems of difficult tooth filling, limited forming ability, large deformation resistance, etc., to improve internal organization and mechanical properties, increase productivity and Product performance and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

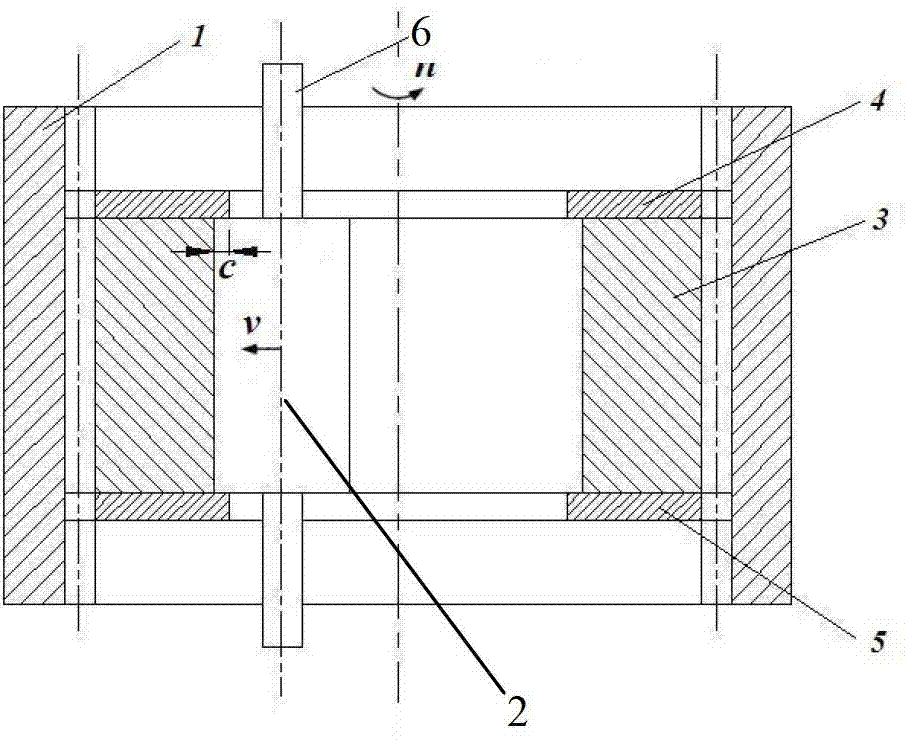

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0027] The precision roll forming method of cylindrical gear of the present invention comprises the following steps:

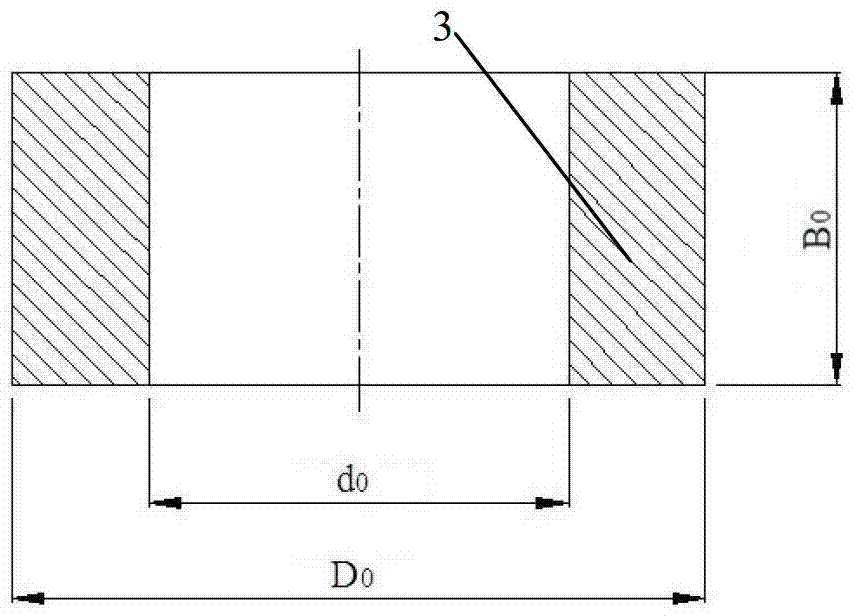

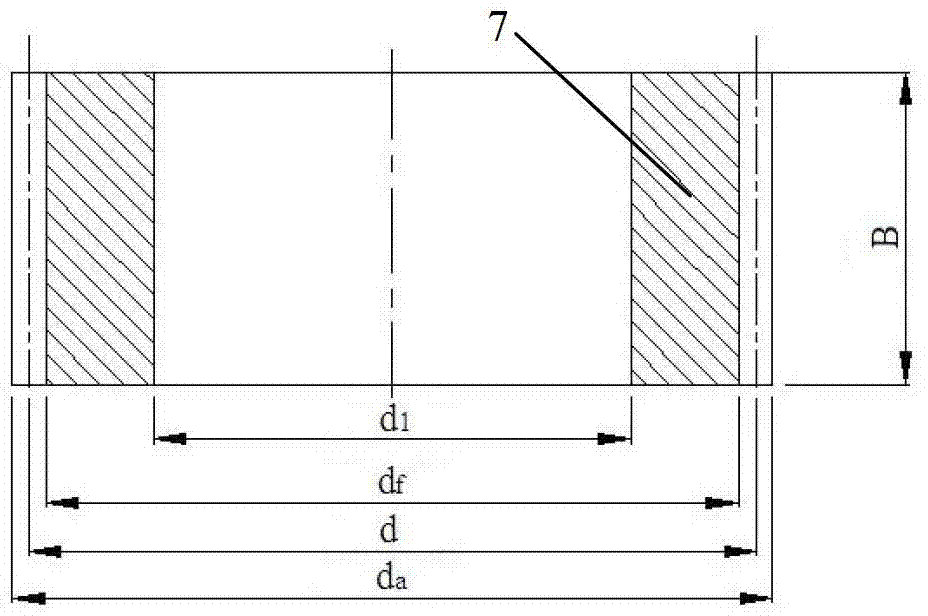

[0028] S1, obtain the ring-shaped blank 3, such as figure 1 , figure 2 As shown, the height B of blank 3 0 Equal to the axial height B of the cylindrical gear 7 and the outer diameter D of the blank 3 0 Equal to the diameter d of the dedendum circle of the cylindrical gear 7 f . Inner diameter of blank 3 Wherein A is the end surface area of the cylindrical gear 7 . In a preferred embodiment of the present invention, the dedendum circle diameter d of the spur gear 7 f =52.80mm, index circle diameter d=60.00mm, addendum circle diameter d a =66.00mm, inner hole diameter d 1 =42.80mm, height B=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com