Sample plate positioning detecting method for Airbus complicated titanium alloy forged pieces

A technology for titanium alloys and forgings, which is applied in the auxiliary detection of complex special forgings and the detection of complex forgings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described in detail below by specific examples

[0018] Introduction to forgings: Forging number: SID546352.200; Material: Tc4; Features: single fan mold, thin web, more arc profiles, high ribs on both sides.

[0019] The specific detection steps are as follows:

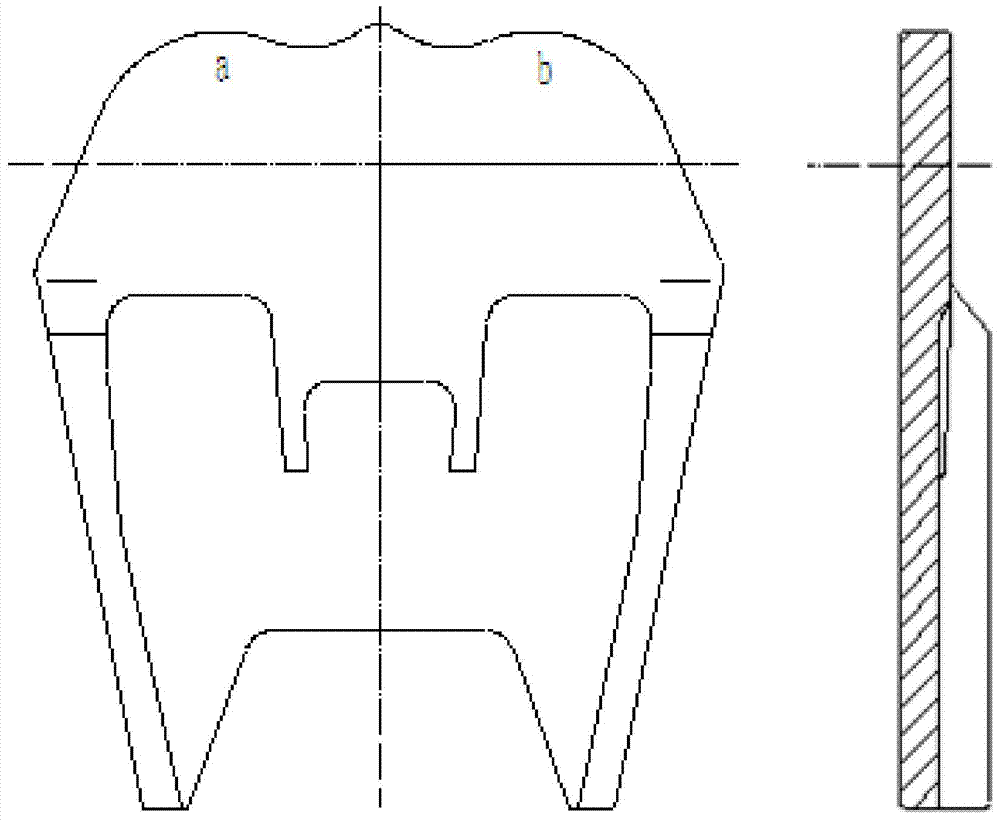

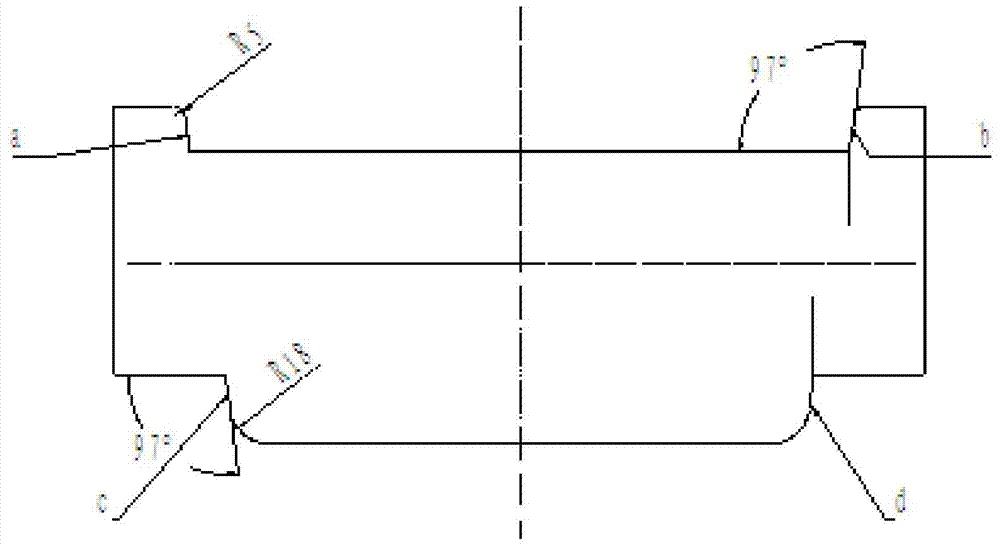

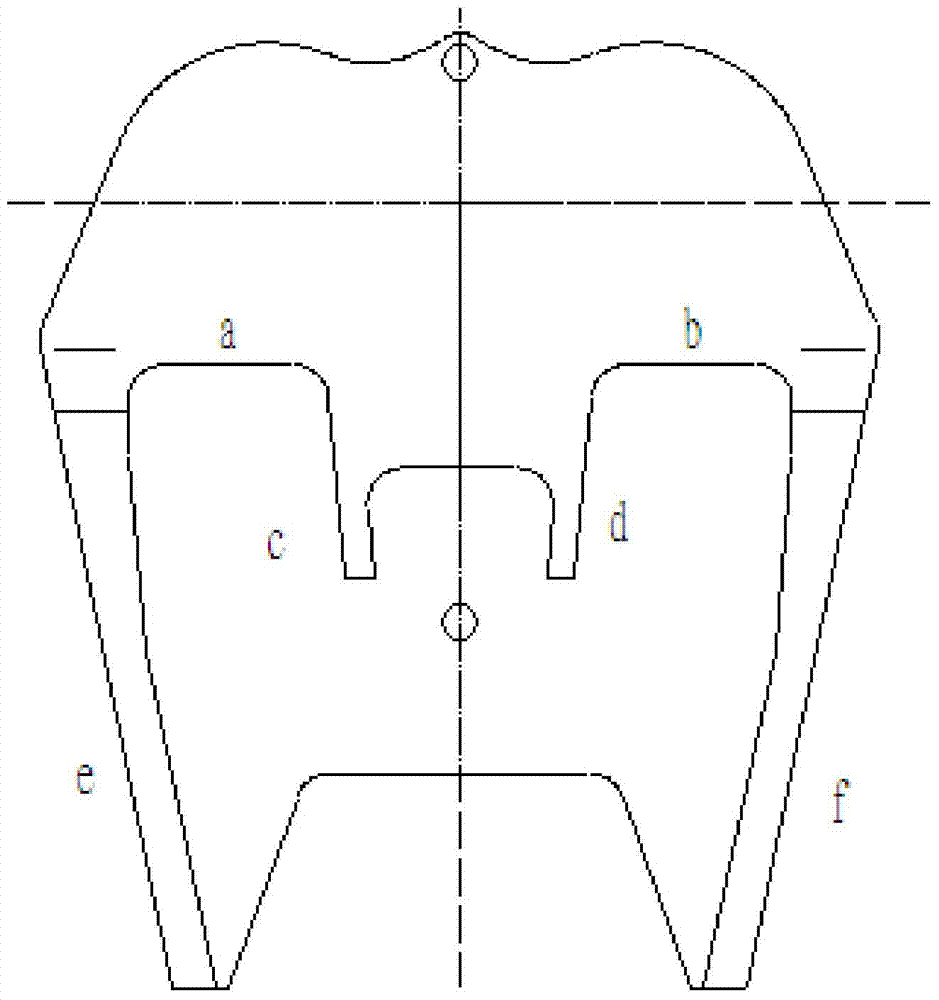

[0020] In the first step, use the two arc tips (see figure 1 a and b as shown) and the high-reinforcement shape design and positioning templates on both sides (see figure 2 ). Use the template to directly align and determine the center line:

[0021] use figure 2 Position the two inclined planes a and b in the middle, and use a marking needle to directly draw the center of the upper part of the forging according to the center position of the sample; the lower part uses figure 2 The two slopes in middle c and d are positioned on the inner side of the rib, and the center of the lower part of the forging is directly drawn according to the center position of the sample with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com