Patents

Literature

86results about How to "Play an anchoring role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

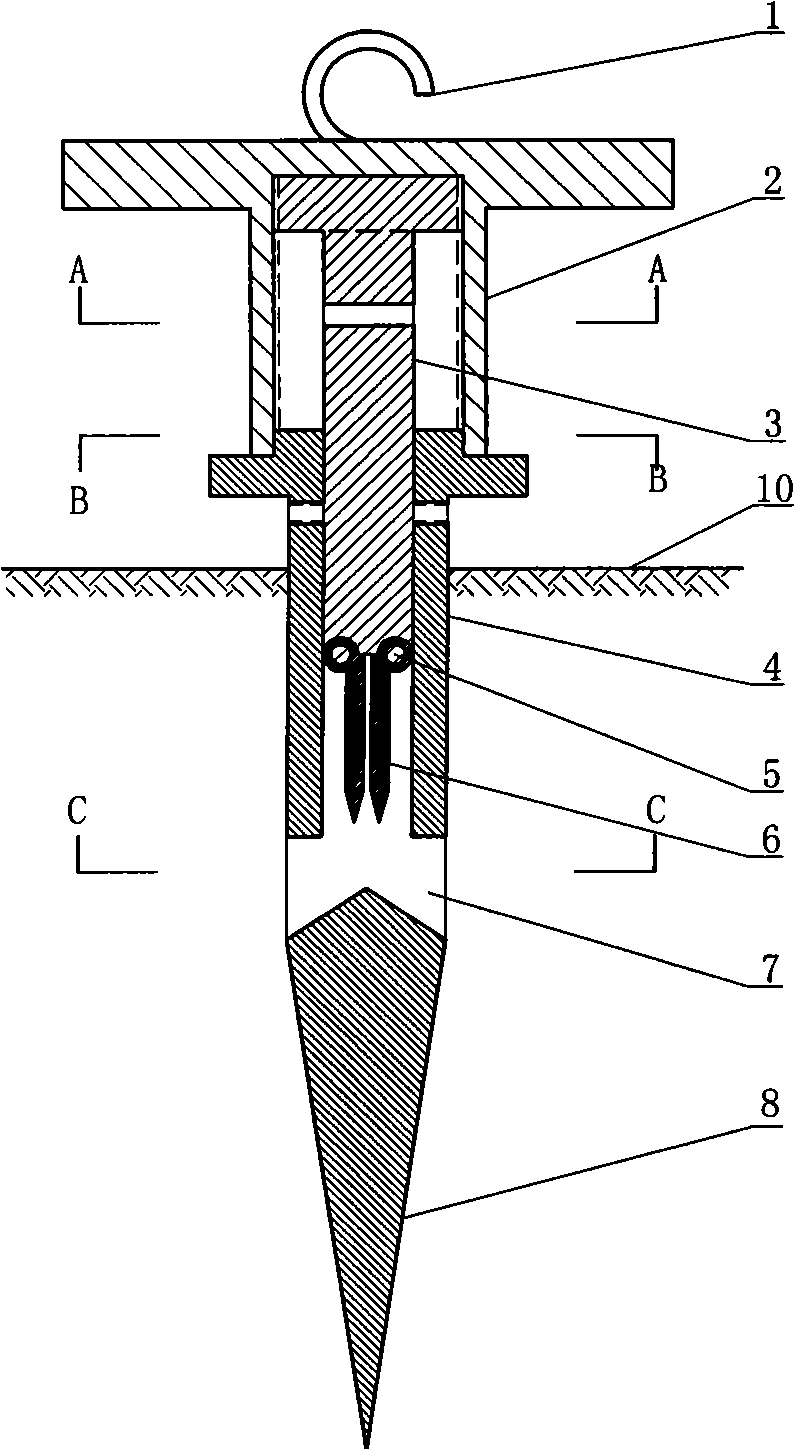

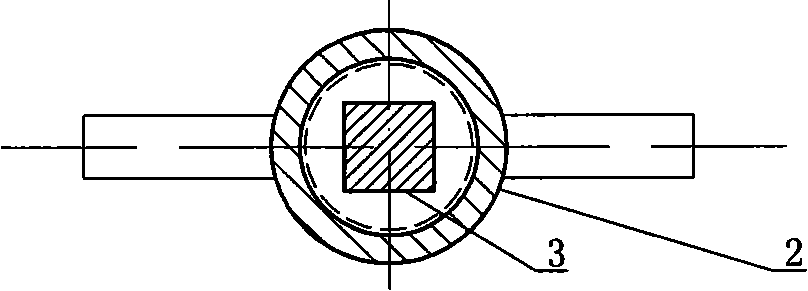

Press-extending type anchor

The invention relates to tent accessories, in particular to a companding type ground anchor. The ground anchor is composed of a draw hook, an inner blind nut, a round head square column, a loop bar, rotating shafts, riveted plates, side hole, a nail and a positioning screw. A square hole is formed inside the loop bar; two rectangular openings are respectively formed on the both sides of the middle part of the loop bar; and the upper top surface of the nail in the space where the rectangular openings on the both sides of the middle part of the loop bar are intersected with the vertical square hole inside the loop bar is an upward edge formed by two left and right symmetrical inclined surfaces. Two rotating shafts are arranged at the bottom end of the round head square column, and each rotating shaft is sleeved with one riveted plate. The part under the circular cylinder of the round head square column is positioned in the square hole of the loop bar, and forms the movable fit with the loop bar; and the inner blind nut is sleeved on the circular cylinder at the top end of the round head square column, and is combined with the circular cylinder through threads. The ground anchor has the advantages of very firm anchoring, convenient disassembly and high integrity.

Owner:CHENGDU JUNFENG TECH DEV

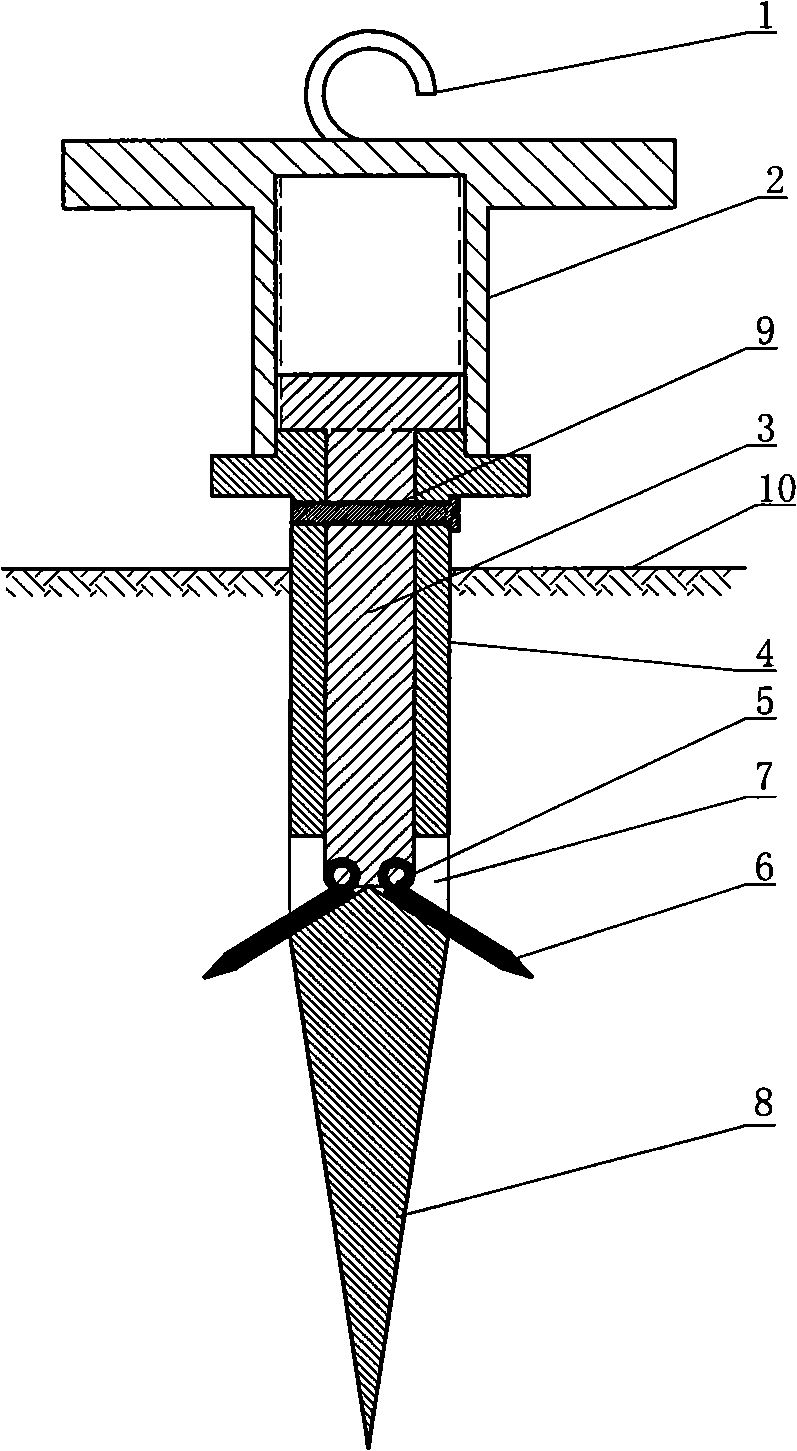

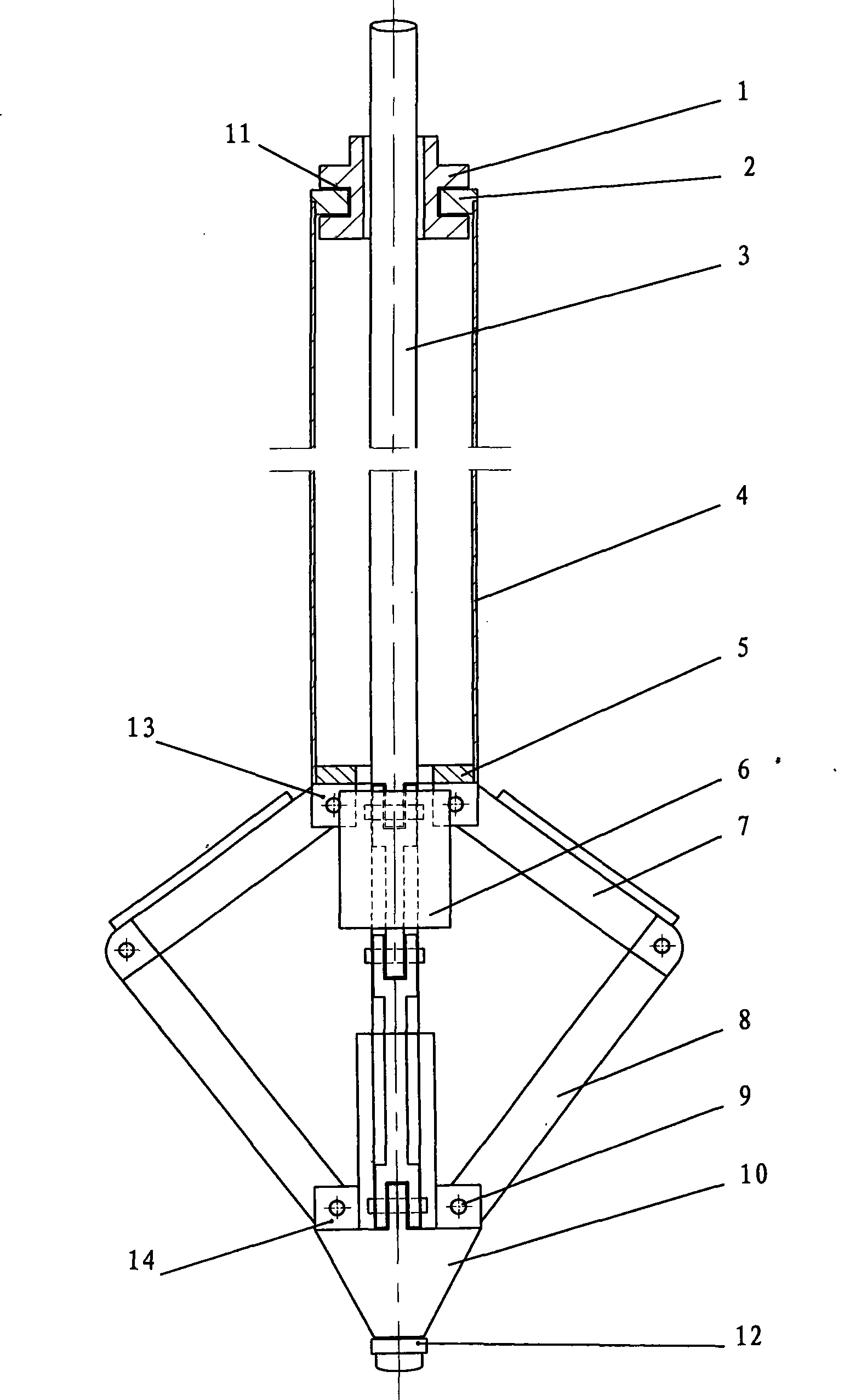

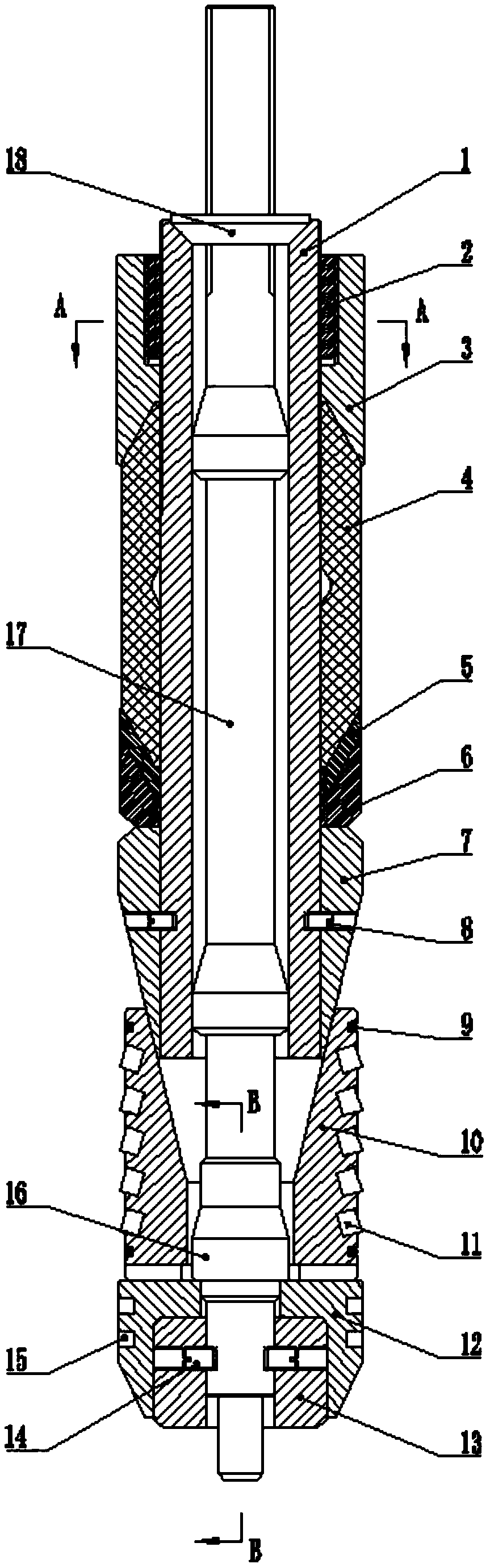

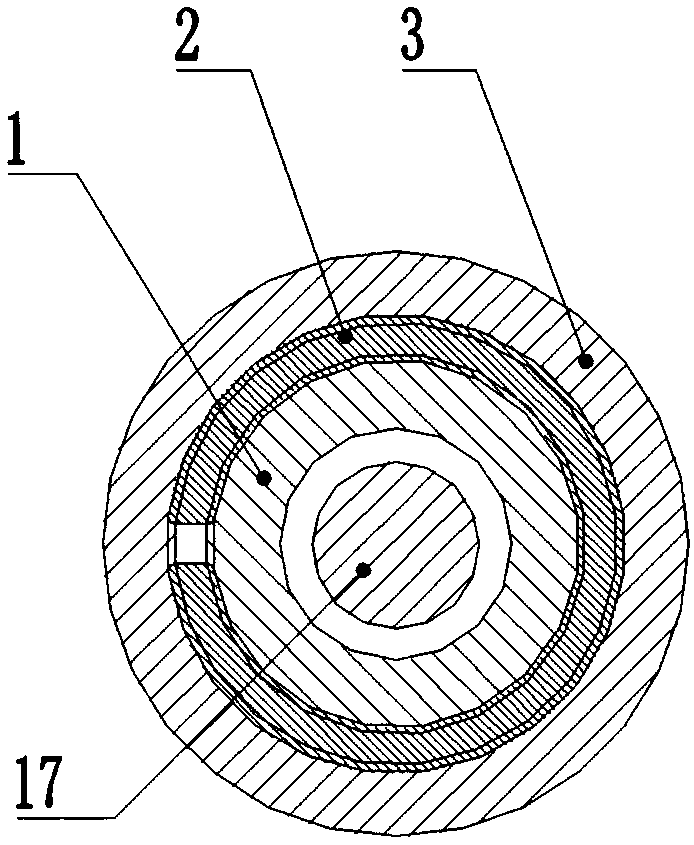

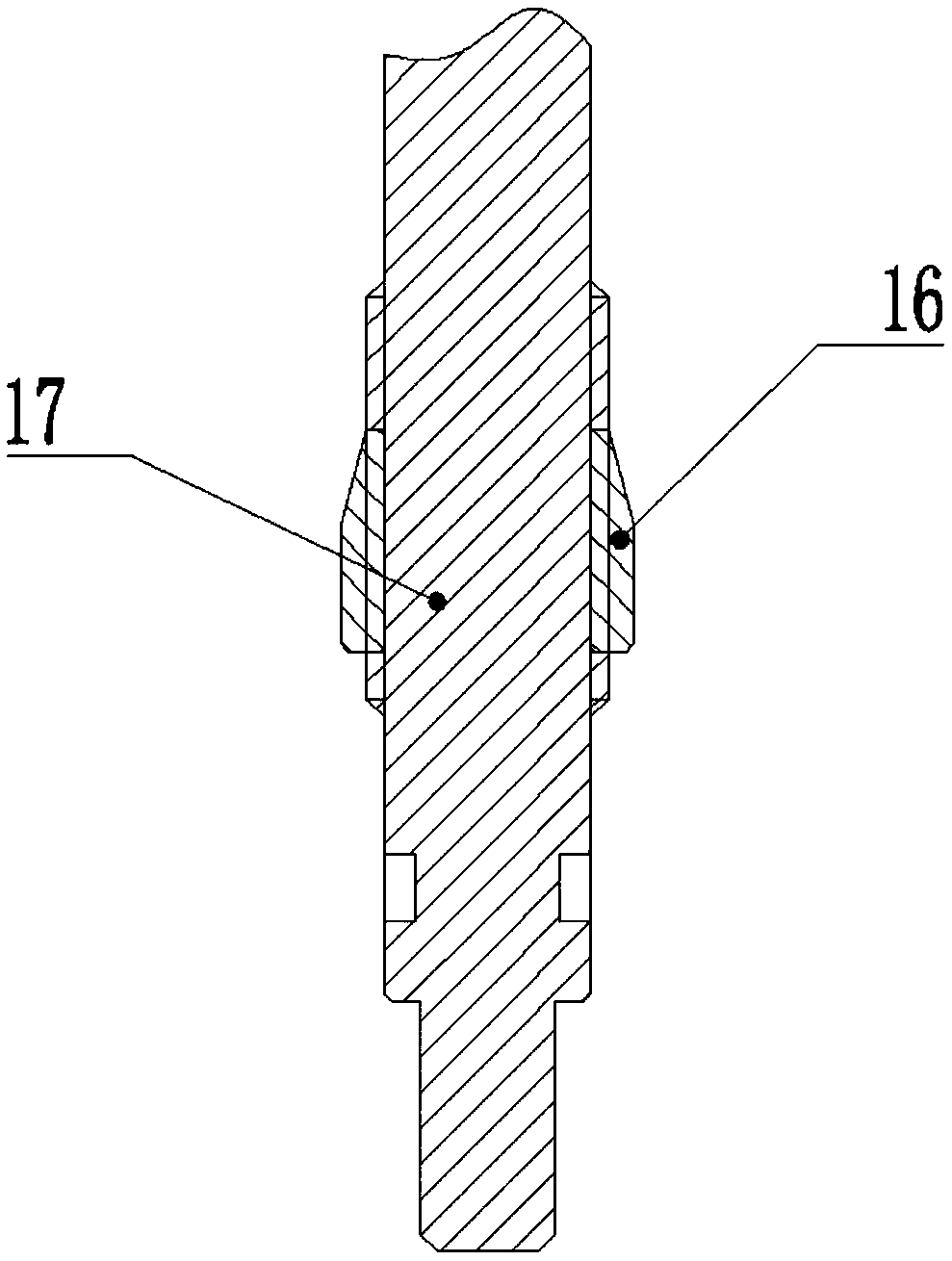

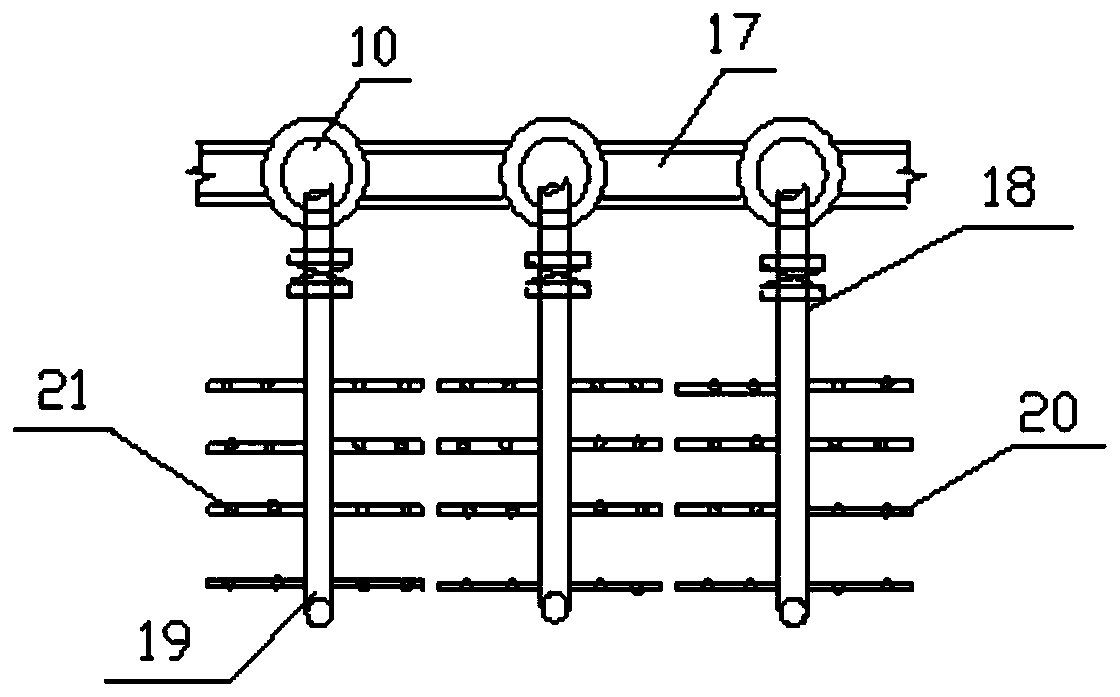

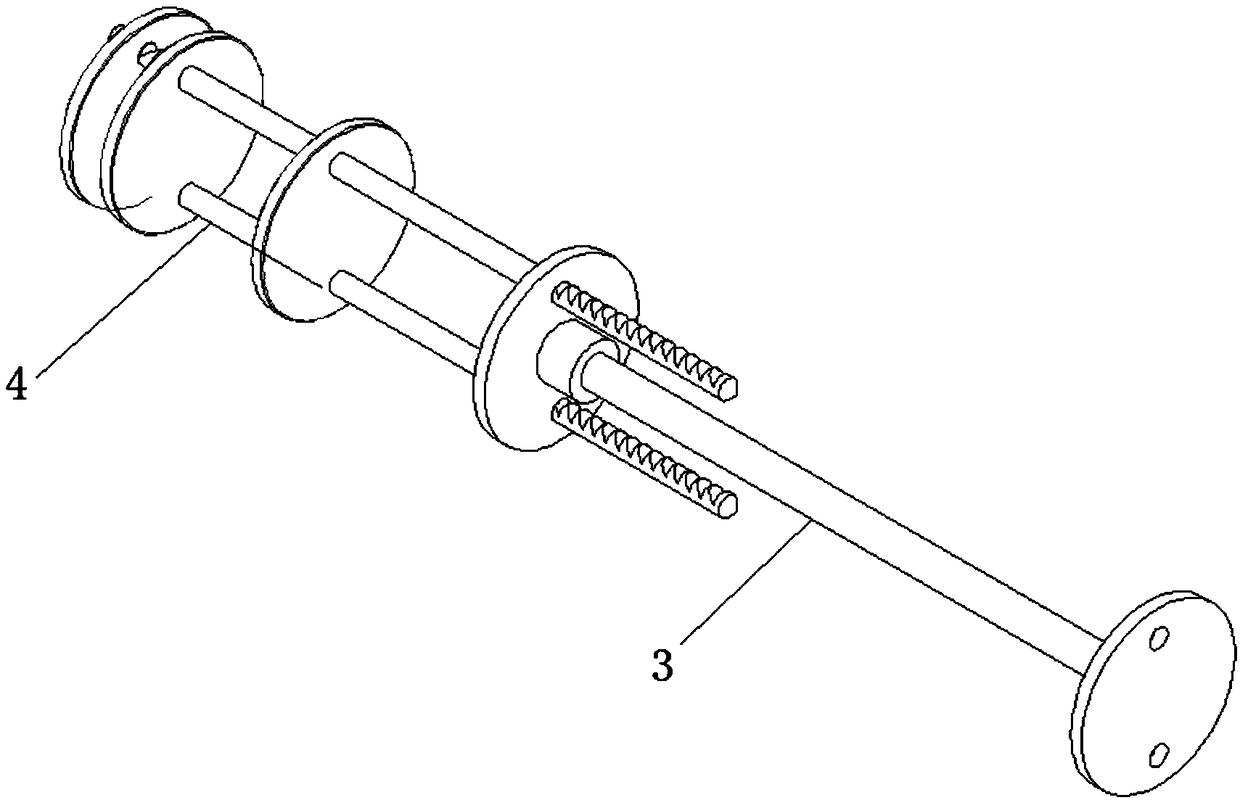

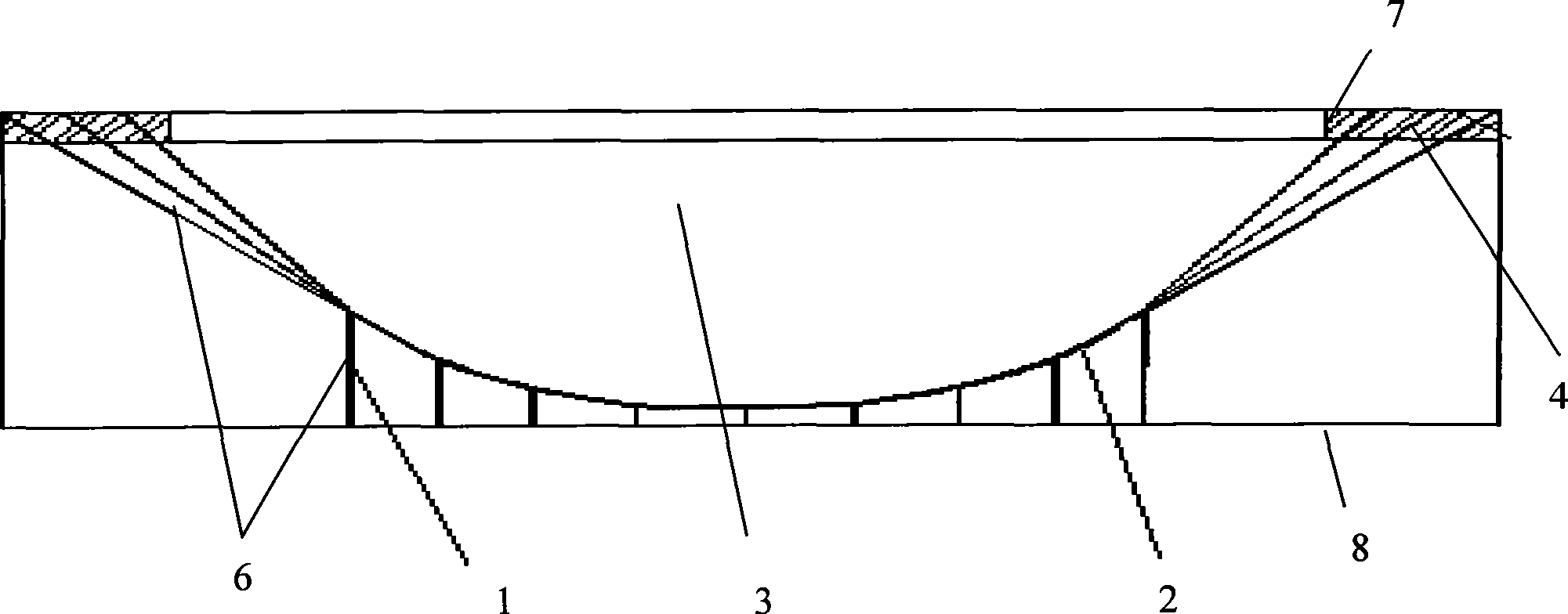

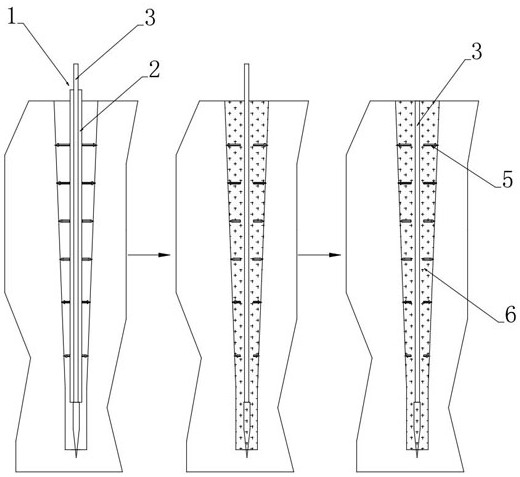

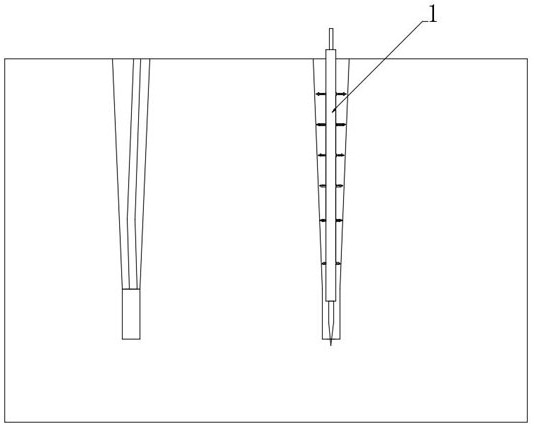

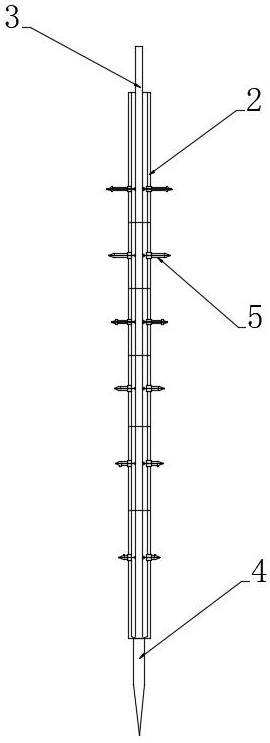

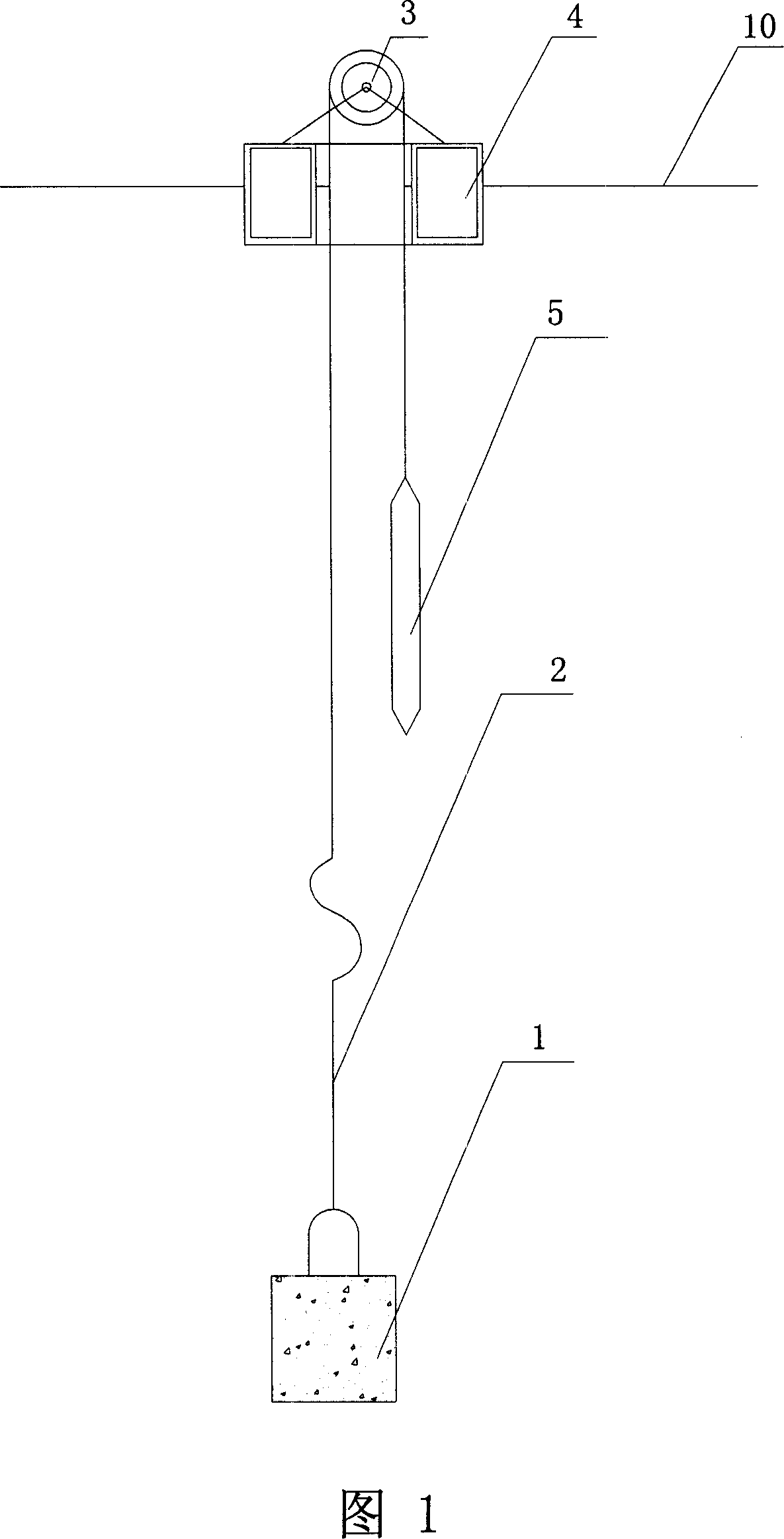

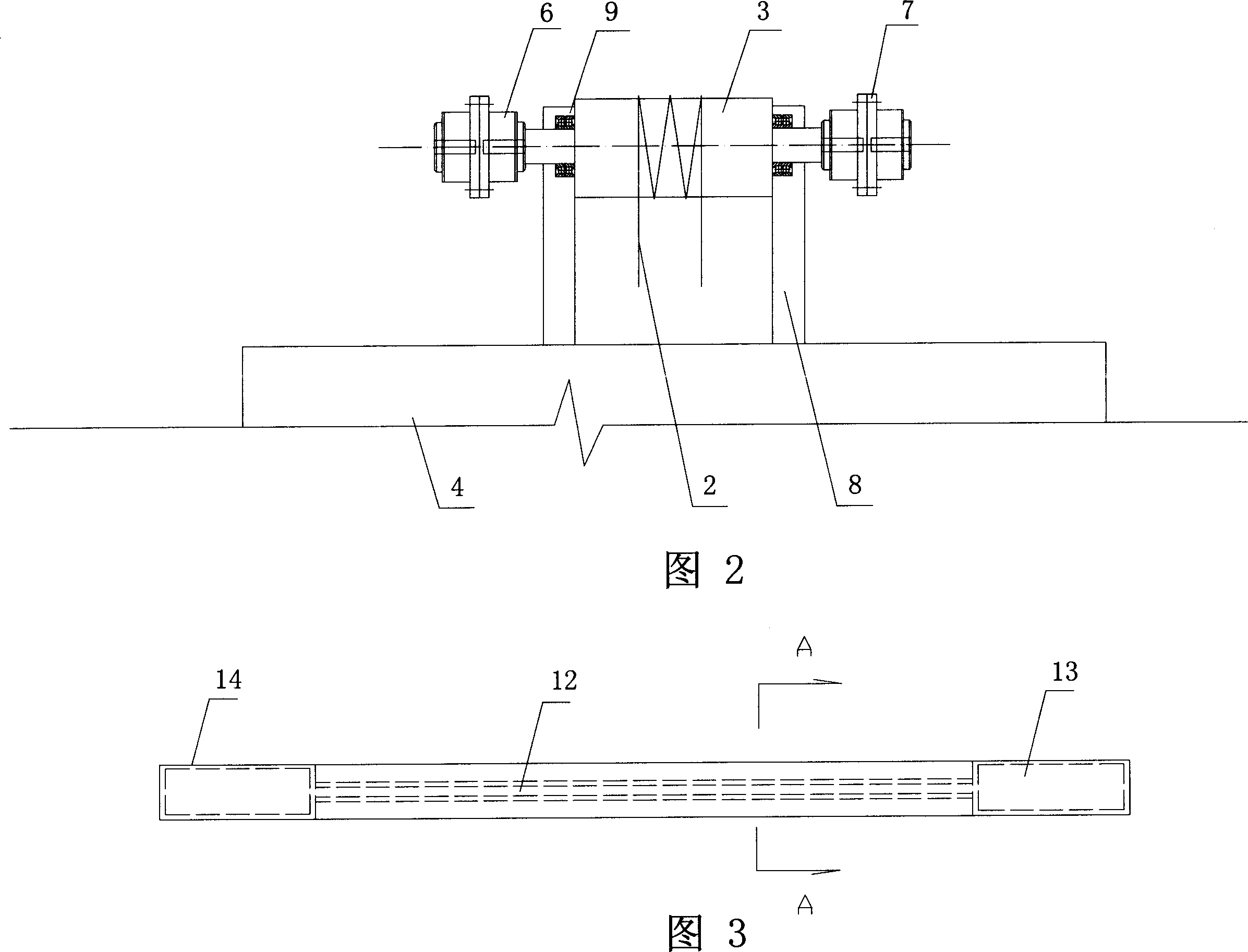

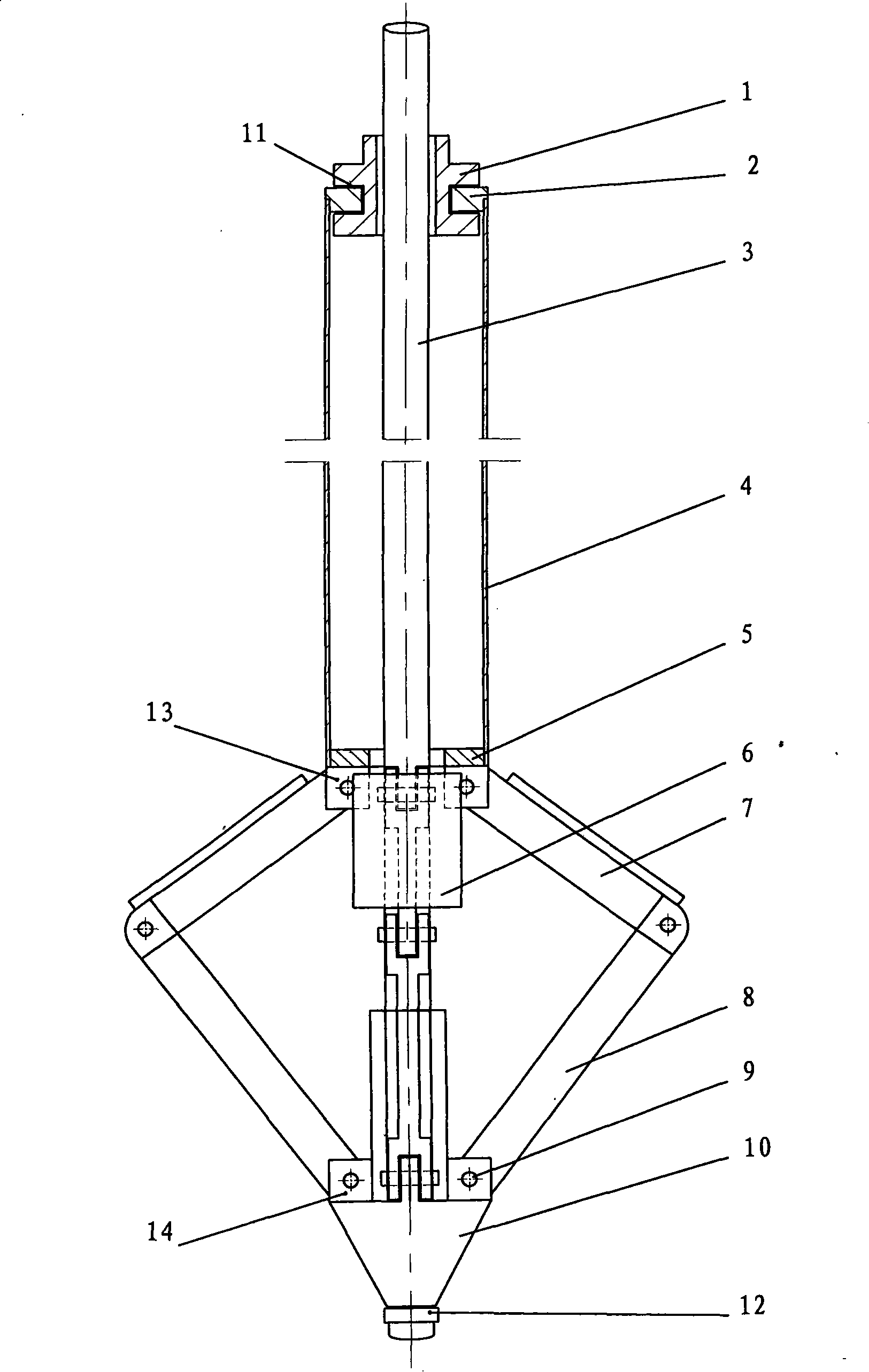

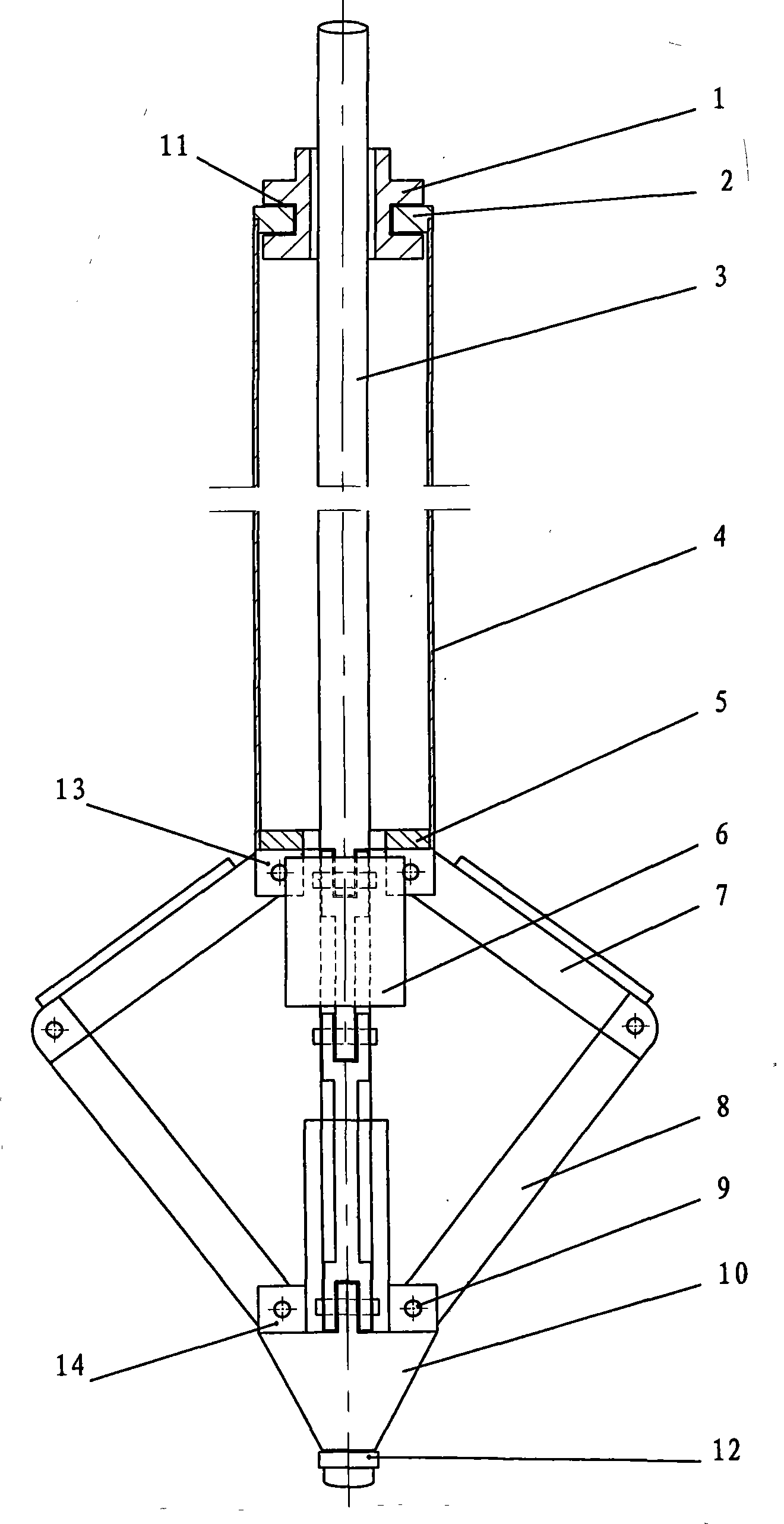

Recoverable anchor rod

InactiveCN101469541ASave underground spaceReduce underground environmental pollutionBulkheads/pilesAnchoring boltsSteel tubeUnderground space

The invention relates to a recovery type anchor bar, comprising an outer sleeve steel pipe, a screw rod disposed in the outer sleeve steel pipe along the axial direction, an upper cover board fixed on the top of the outer sleeve steel pipe, a regulation nut disposed at center of the upper cover board, a lower cover board fixing on the bottom end of the outer sleeve steel pipe, an anchor cone disposed right under the lower cover board, and a plurality of upper connection boards disposed on bottom end of the lower cover board, wherein the upper portion of the screw rod is attached to the regulation nut through a screw thread, the lower portion of the screw rod is attached to the anchor cone. Each upper connection boards is hinged to the top of an upper pulling rod, bottom end of each upper pulling rod is hinged to the top of a lower pulling rod, bottom end of each lower pulling rod is respectively attached to the anchor cone through a pin. Object of the invention is to provide a recovery type anchor bar which is high in shearing resistance capacity, underground space saving, underground environment pollution-free, and steel saving.

Owner:YANTAI UNIV

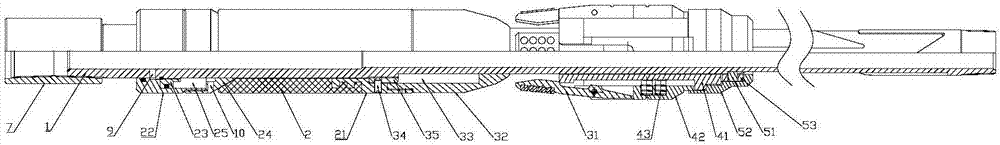

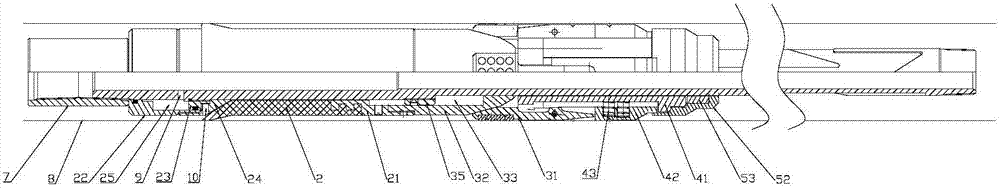

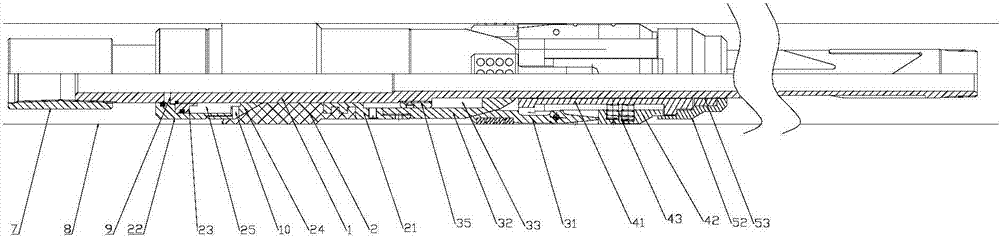

Small-sized soluble bridge plug

The invention relates to a small-sized soluble bridge plug. The small-sized soluble bridge plug comprises a central pipe and a compression sleeve sleeving the upper end of the central pipe and used for compressing a rubber cylinder; a limited C-shaped ring is sandwiched between the compression sleeve and the central pipe; the compression sleeve and the limited C-shaped ring are clamped and fixed by threads; the outer side wall of the central pipe is provided with a thread-like continuous protrusion along the compressed traveling direction of a compression assembly; the inner wall of the limited C-shaped ring is provided with a thread-like continuous groove engaged with the thread-like continuous protrusion. Compared with a traditional double-slip bridge plug, the matched structure of the compression sleeve and the limited C-shaped ring is fixed without expansion produced by relative movements of two components of an existing slip assembly, a setting stroke is greatly decreased, and setting by cable pumping is allowed; in addition, due to the omittion of one slip assembly, the use area on the central pipe is saved, rubber cylinder lengthening design is allowed, and accordingly the expansion degree of the rubber cylinder and improvement of setting capability with expansion increase are ensured.

Owner:四川长宁天然气开发有限责任公司 +1

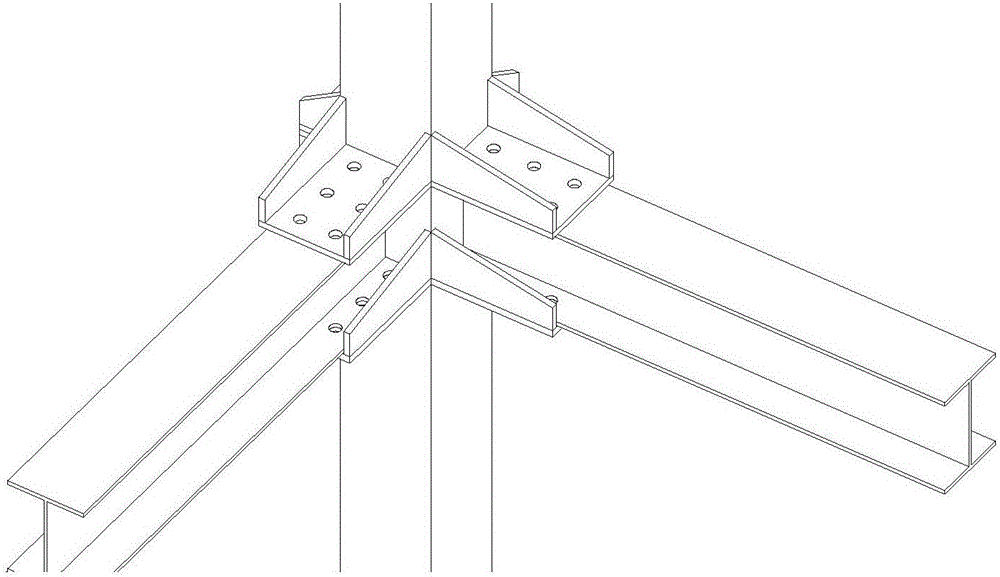

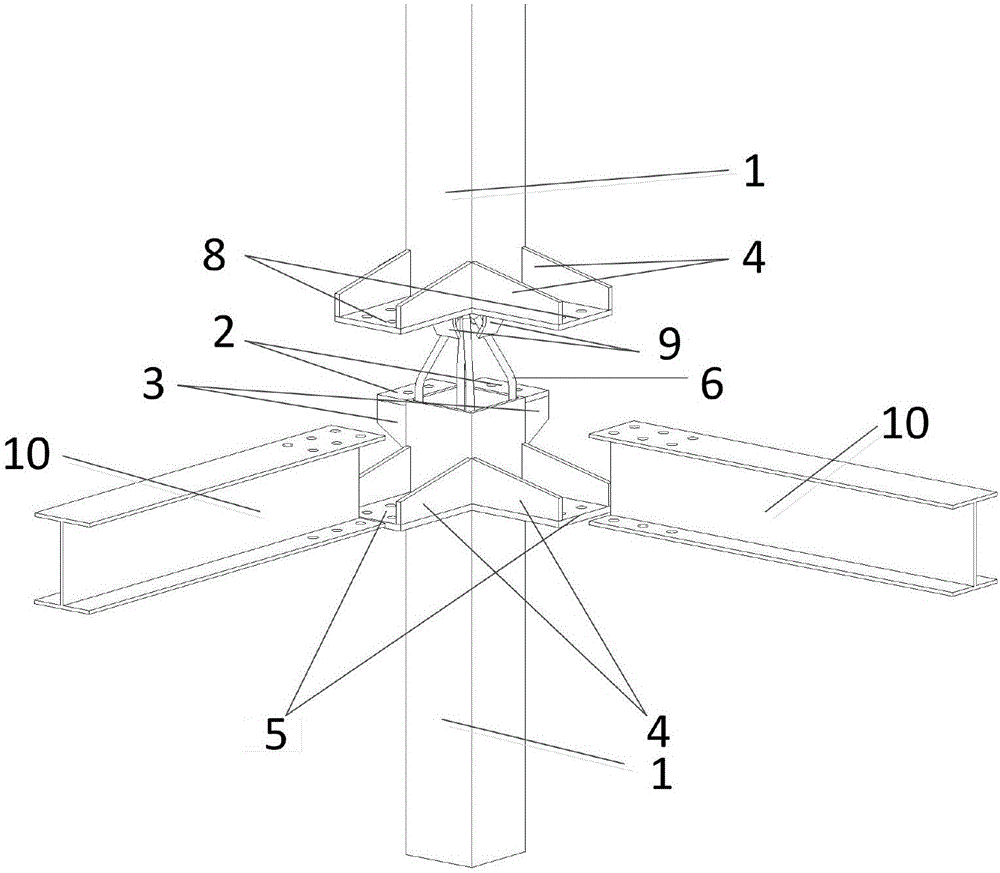

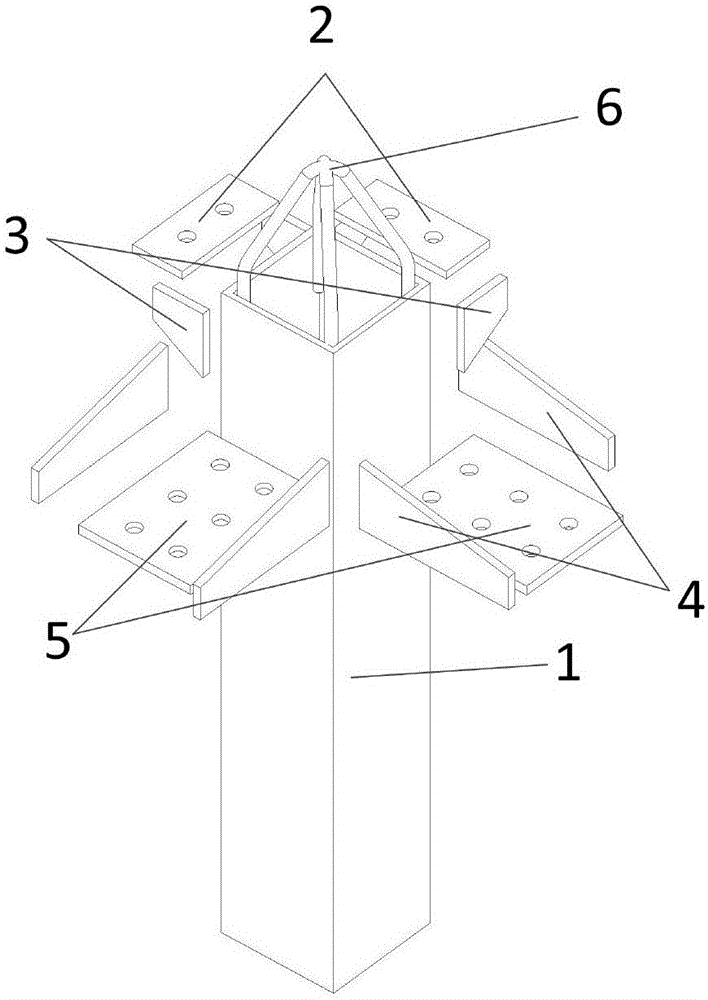

Node connection device of assembly-type steel structure beam pillar

InactiveCN106812214AIncrease rigid connectionPlay an anchoring roleBuilding constructionsFriction forceBolt connection

A node connection device of an assembly-type steel structure beam pillar belongs to the technical field of structure engineering. An upper pillar and a lower pillar are manufactured through welding of square tube pillars, pillar top flange plates, pillar bottom flange plates, long ribs, short ribs, supporting plates, cover plates, hanging hooks and bending plates at a plant, and beams are welded by H-shaped steel beams at the plant; and the form of pillars is not limited to corner pillars, and can also be applied to lateral pillars and middle pillars. According to the invention, all the welding work is completed at the plant, the hanging hooks and bending plates play a role in insertion and guidance during hoisting of the upper pillars and lower pillars, so the hanging difficulty of the upper and lower pillars is reduced, and accuracy corresponding to bolt holes is increased; and when concrete pouring in the pillars is needed, the hanging hooks and bending plates also play a role in anchoring, so rigid connection of nodes could be enhanced. Due to existence of the cover plate, supporting plate and reinforced rib of the pillar, the supporting plate and the cover plate could have very strong building-in effects toward beam ends, so bolt connection will bear pull force and friction force; the bolt utilization rate is increased; and consumption of bolts is reduced under the same bearing force.

Owner:BEIJING UNIV OF TECH

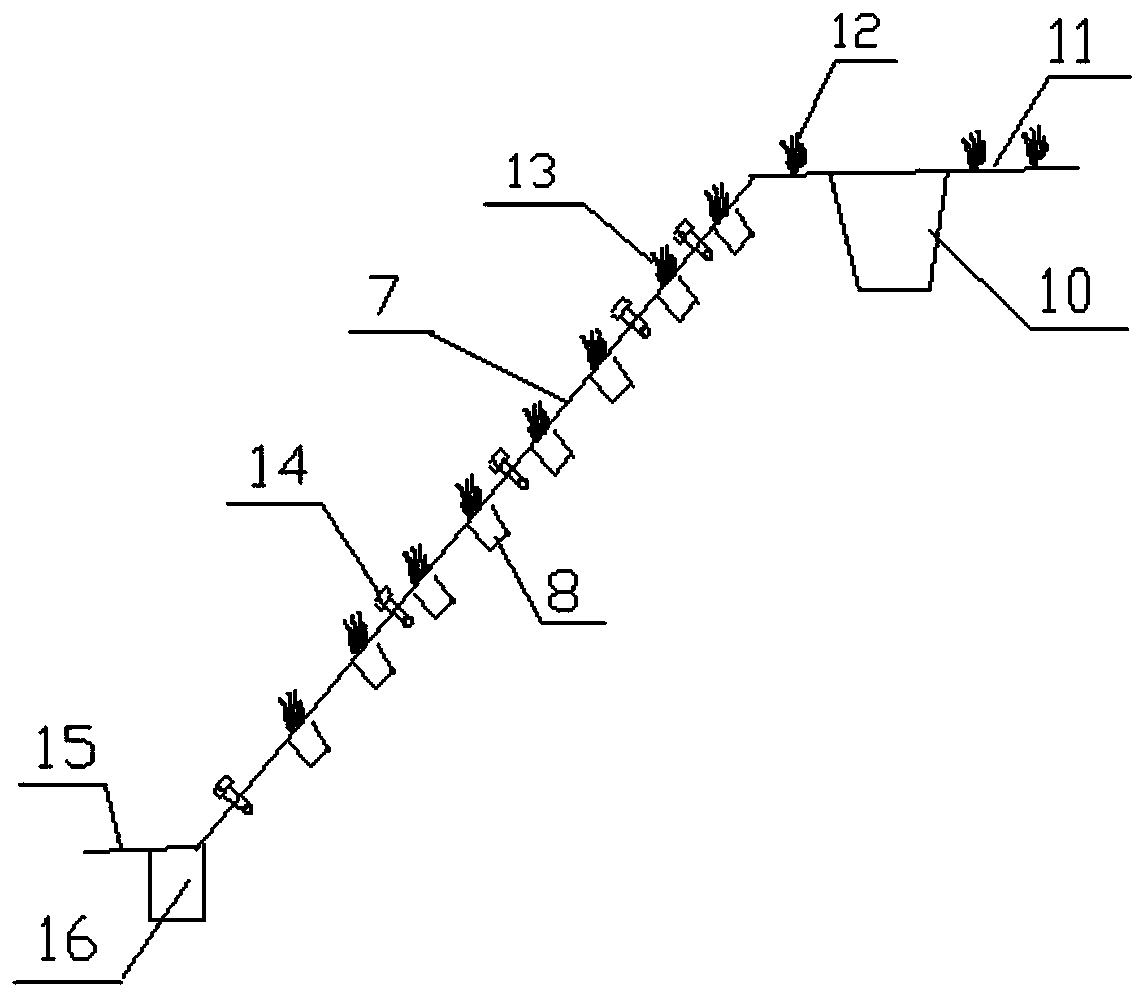

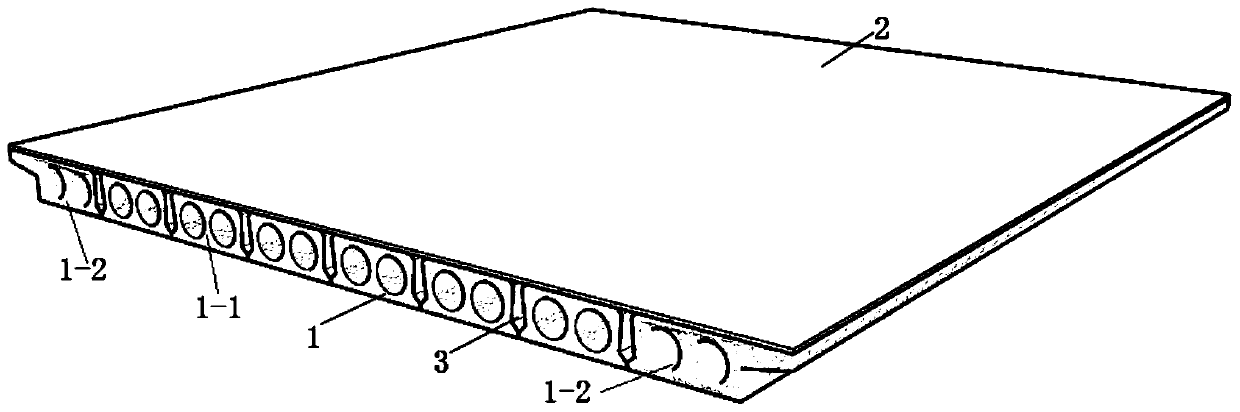

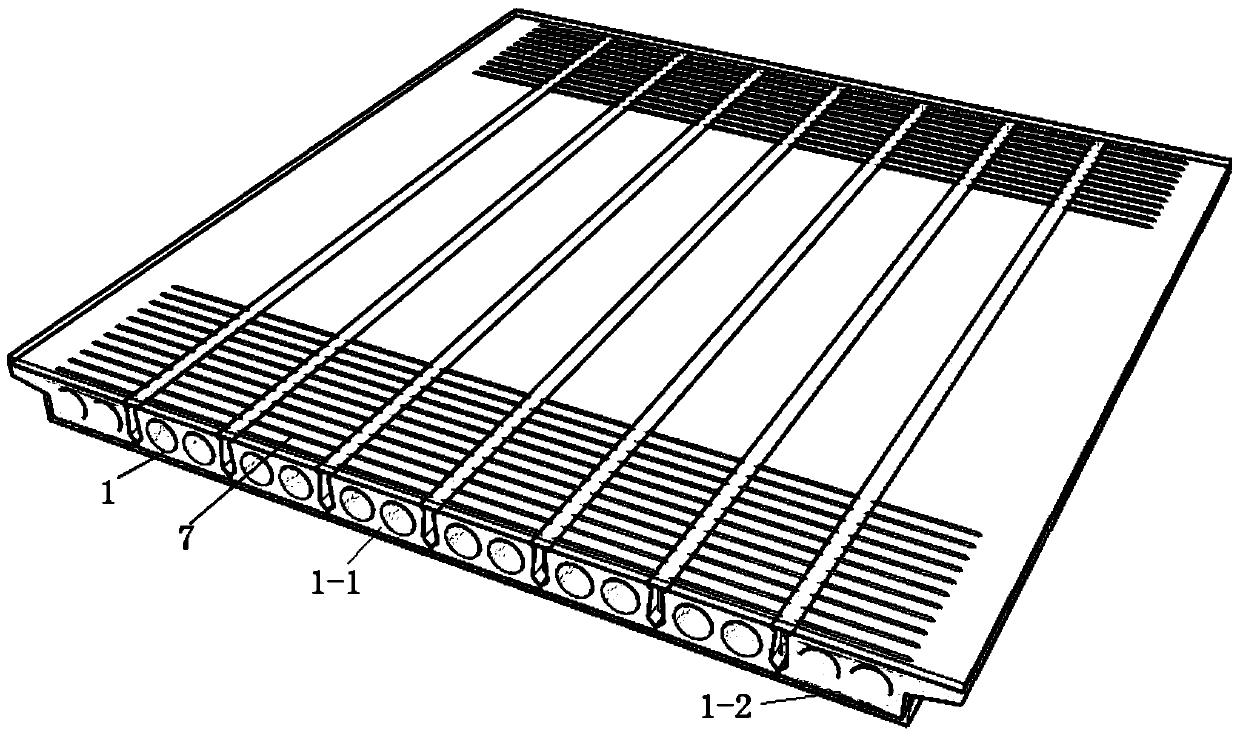

High-steep hard slope greening system and application method thereof

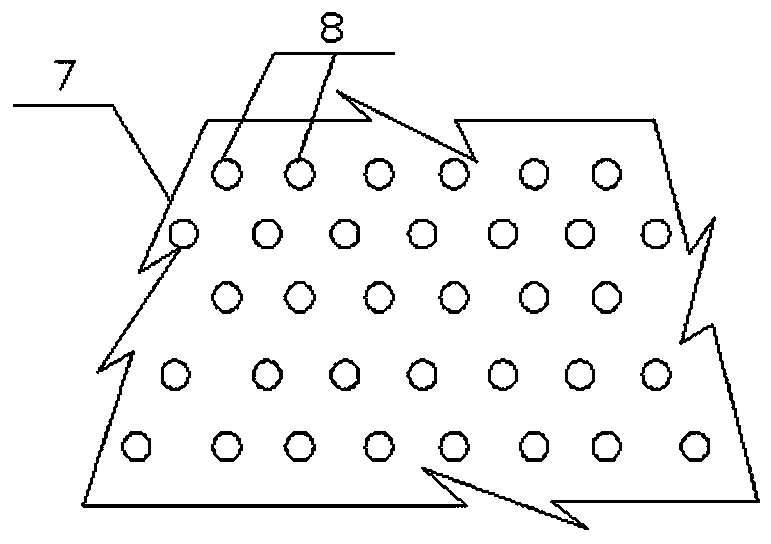

InactiveCN110278804AGuaranteed long-term growthExchangeClimate change adaptationWatering devicesVegetationPlant roots

The invention provides a high-steep hard slope greening system and an application method thereof. The high-steep hard slope greening system comprises a plurality of holes formed in a hard slope surface. Ecological cylinders are arranged in the holes. Each ecological cylinder is filled with an ecological medium for planting plants. A spray-irrigation water supply system is arranged on the upper side of the slope surface. A water intercepting ditch is formed in the bottom of the slope surface. The spray-irrigation water supply system supplies water and waters the plants in the ecological cylinders. The water intercepting ditch is used for drainage of the greening system. Ecological repairing and greening are conducted on the hard slope through the multi-layer porous ecological cylinders, the advantages of a vegetation base material and the porous ecological cylinders are sufficiently used, by locally forming pores in the slope surface and placing the slope protection ecological cylinders, the long-term growth conditions are provided for vegetations, and the ecological repairing requirement of the rocky slope surface and hard slope surface is met. The disturbance of the slope protection ecological cylinders on the slope surface is small, meanwhile the potential adverse effects of the vegetation long-term growth requirement and the plant root system on the slope surface are considered, and the high-steep hard slope greening landscape can be effectively kept.

Owner:CHINA FIRST METALLURGICAL GROUP

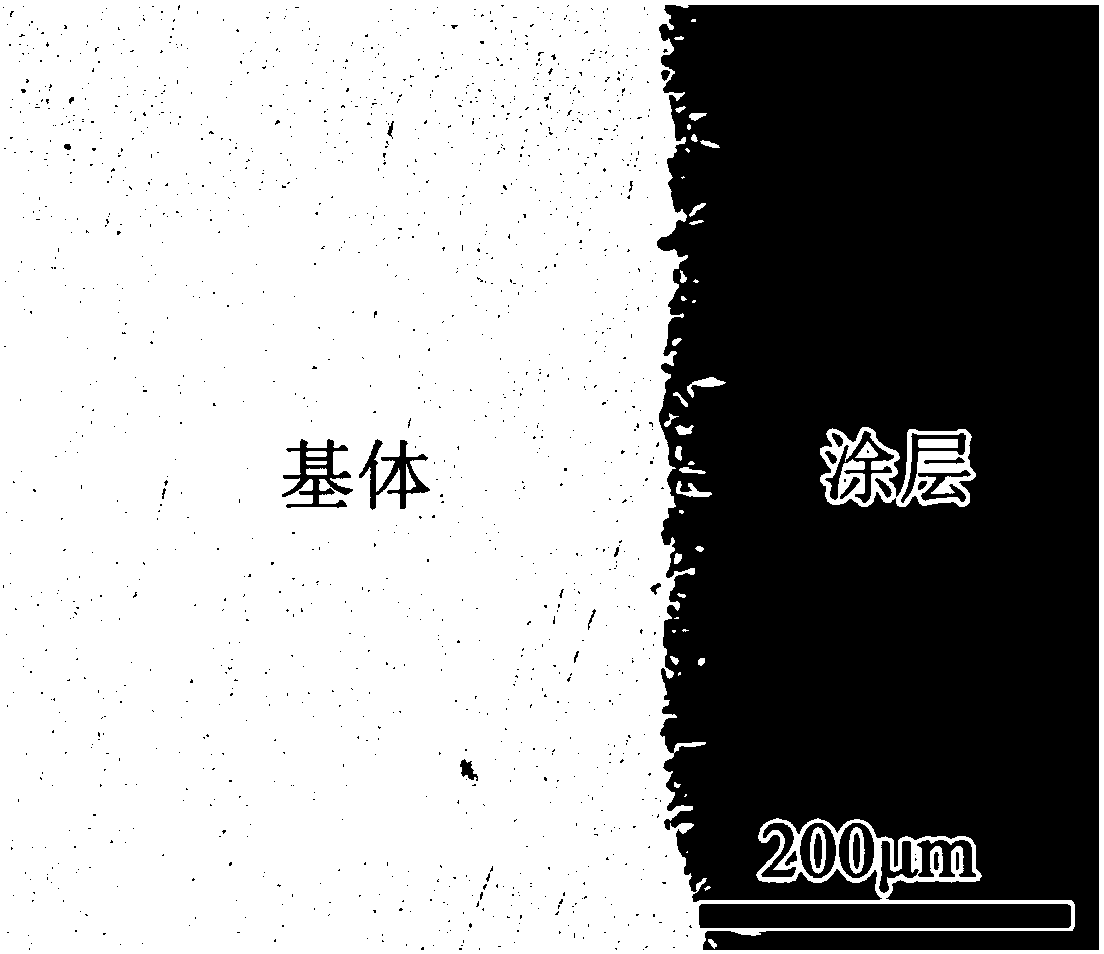

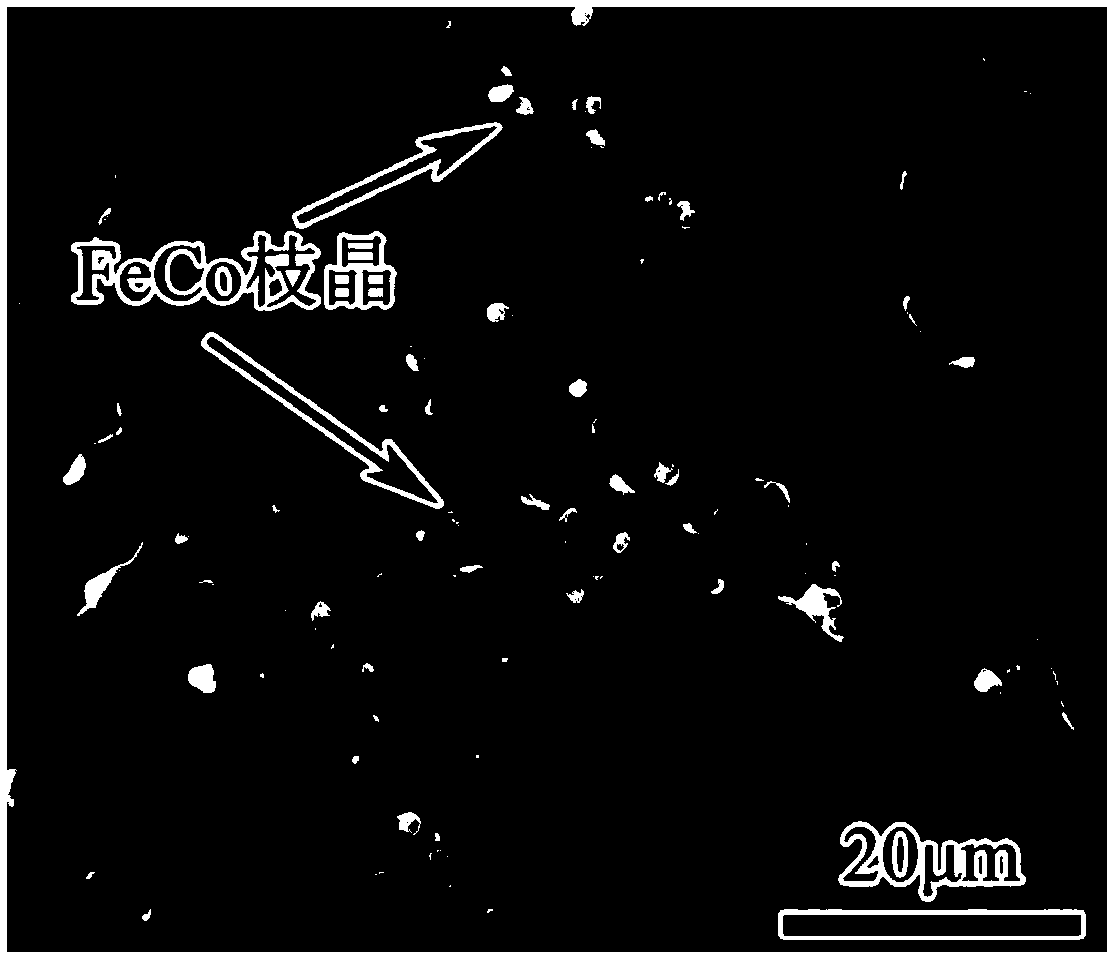

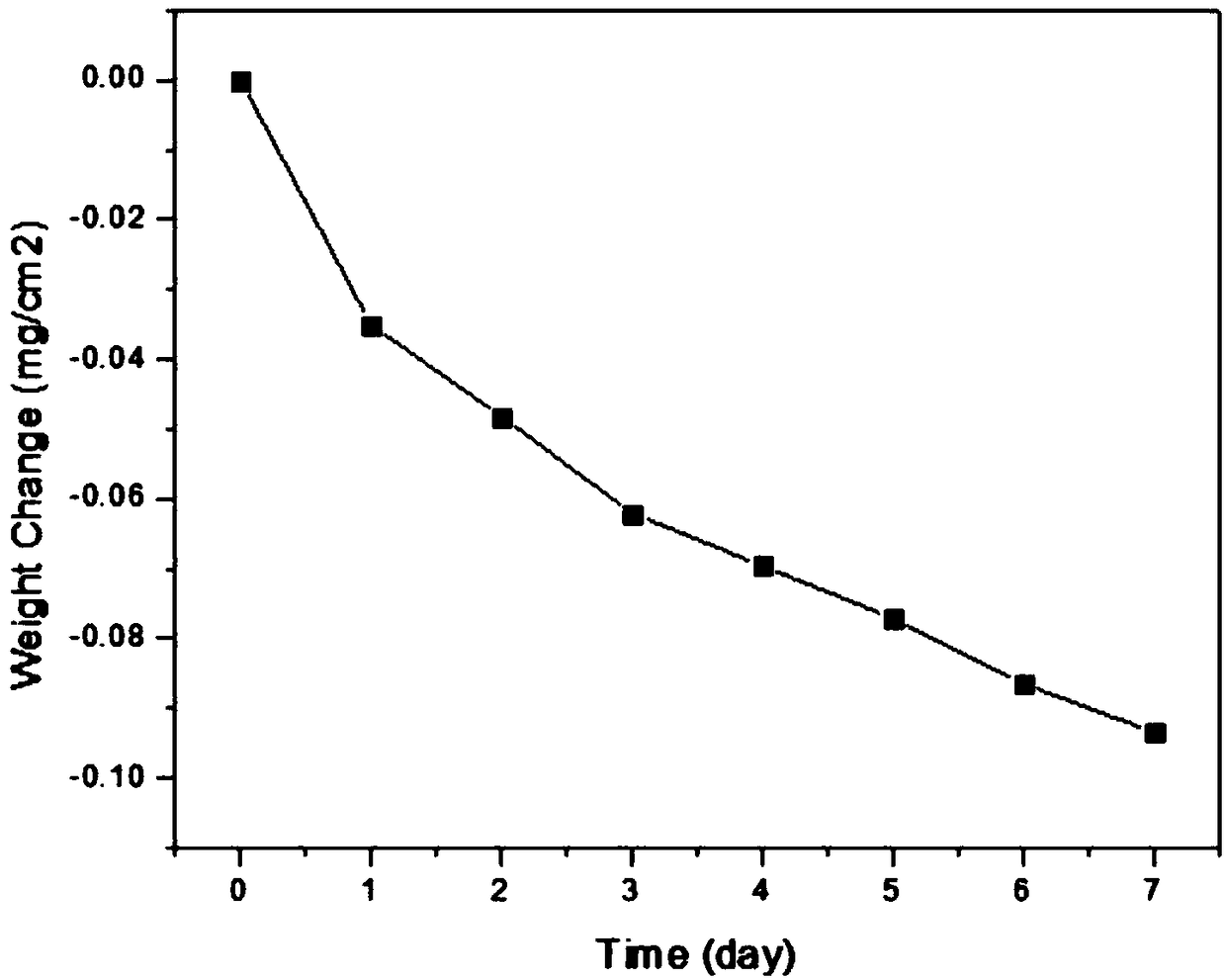

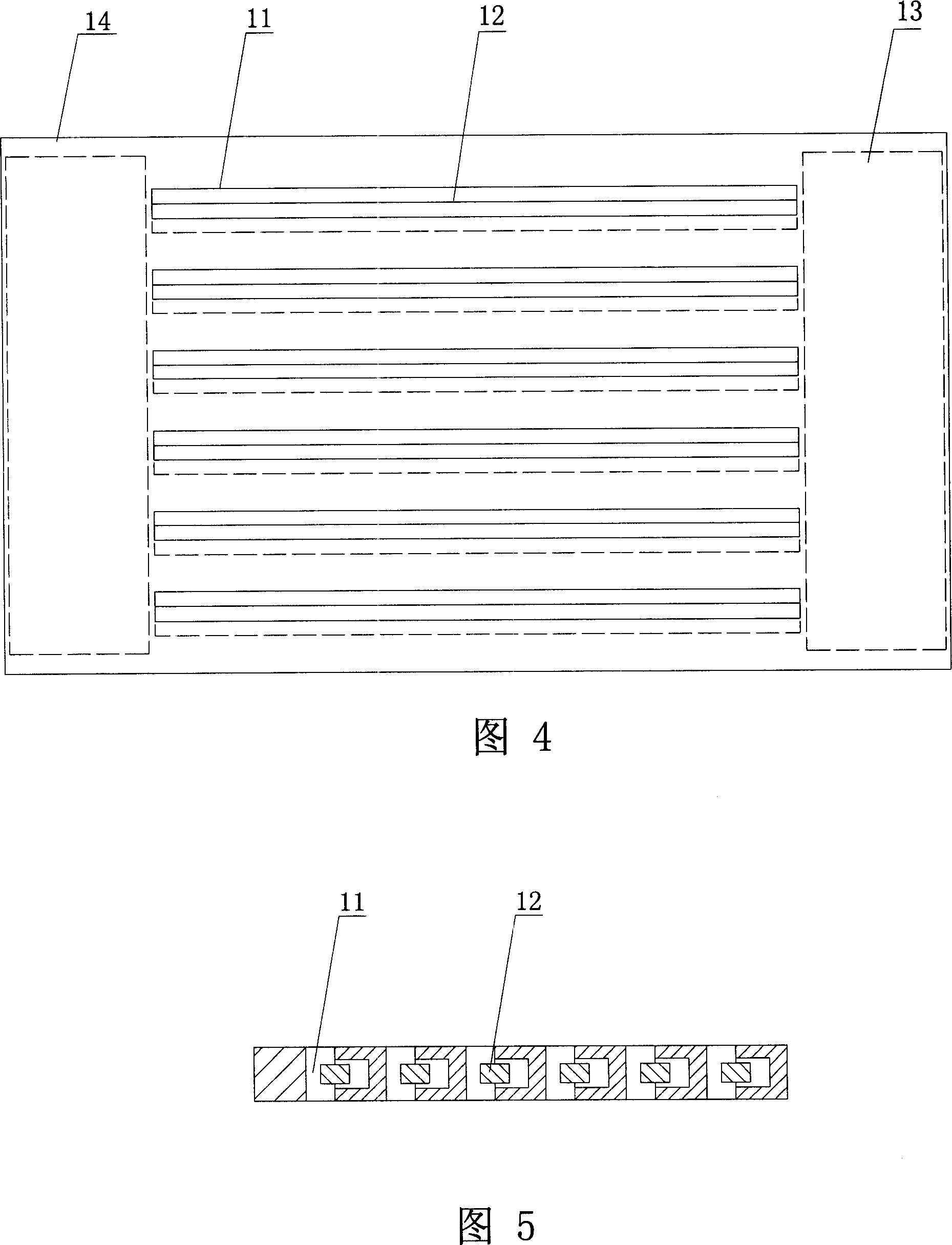

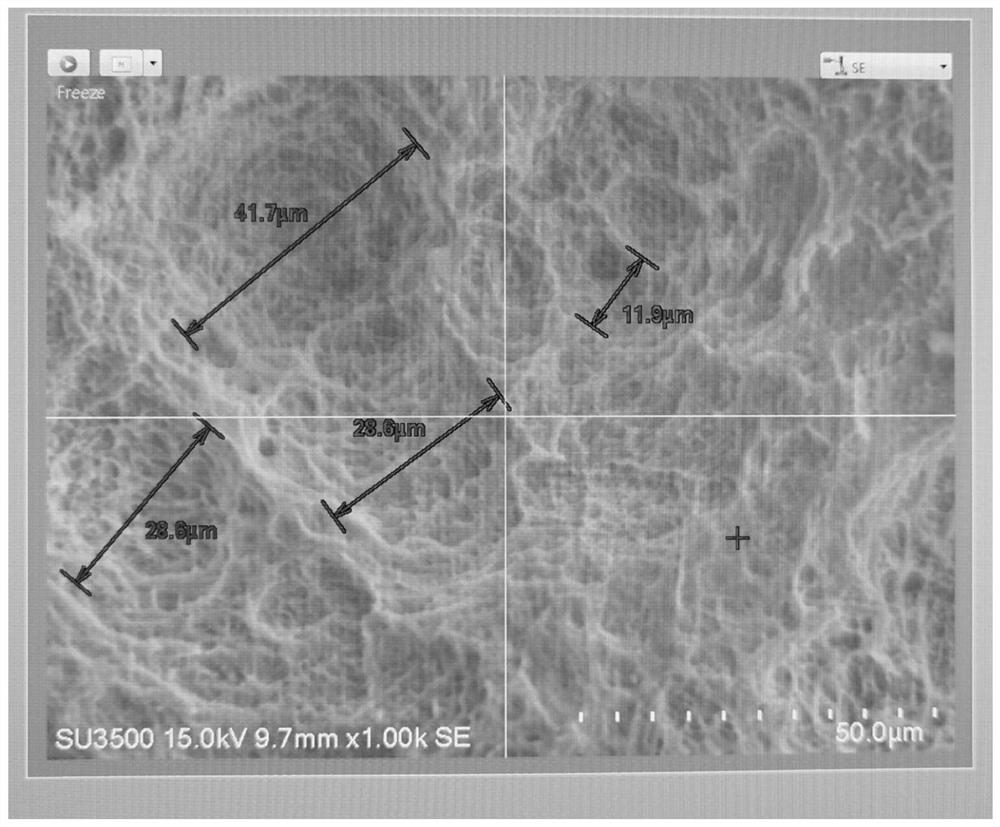

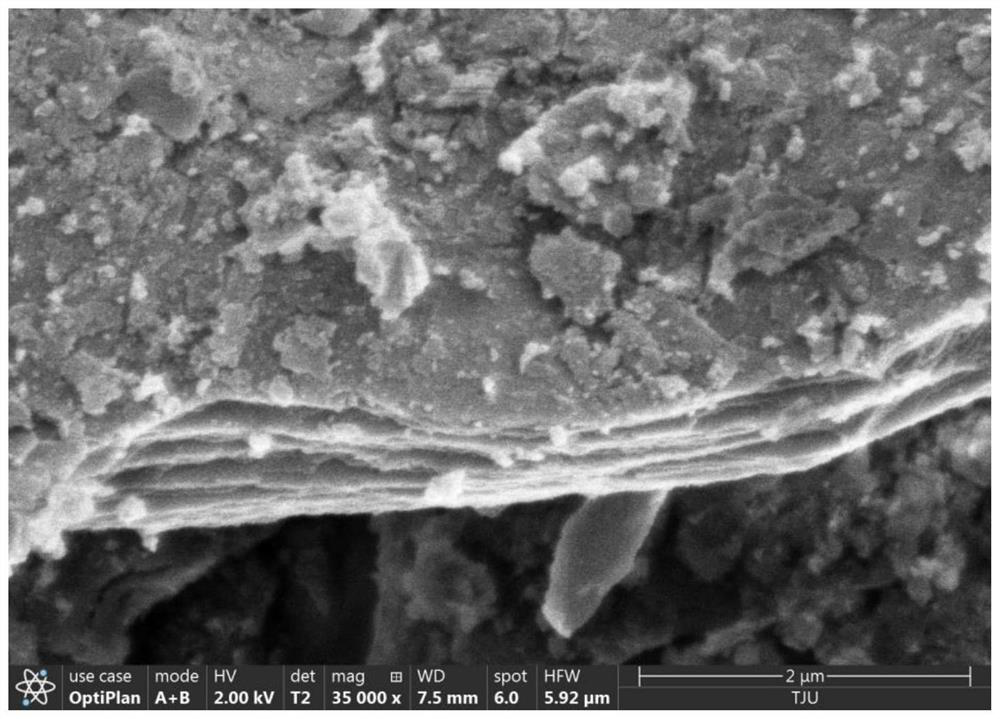

Enamel coating with function of resisting sulfuric acid and hydrochloric acid dew point corrosion and preparation technology thereof

ActiveCN108409138AThe preparation process is non-toxicNo pollution in the processMetallic materialsBoron trioxide

The invention relates to the field of inorganic protection coatings, and particularly provides an enamel coating with the function of resisting sulfuric acid and hydrochloric acid dew point corrosionand a preparation technology thereof. The enamel coating can serve as Q235 steel, BTC1 steel, 304 stainless steel and other metal material parts. Micron oxide particles are uniformly dispersed and distributed in an enamel glaze substrate parent phase, wherein enamel glaze is formed by mixing and melting the analytical pure raw materials (such as: silicon dioxide, aluminum sesquioxide, diboron trioxide, sodium oxide, potassium oxide, nickel oxide, cobalt oxide and calcium fluoride) at the high temperature and water quenching, and the micron oxide particles are one or arbitrary combination of analytical pure aluminum sesquioxide, silicon dioxide, titanium dioxide and zirconium dioxide. The enamel coating is prepared from the raw materials which can be purchased in the market directly, and the preparation technology is free of toxicity and pollution in the process, and conforms to the energy-saving and environment-friendly development trend. The enamel coating is compact and free of pores, has higher strength, fracture toughness, good binding force with a steel substrate and a matched coefficient of thermal expansion.

Owner:NORTHEASTERN UNIV

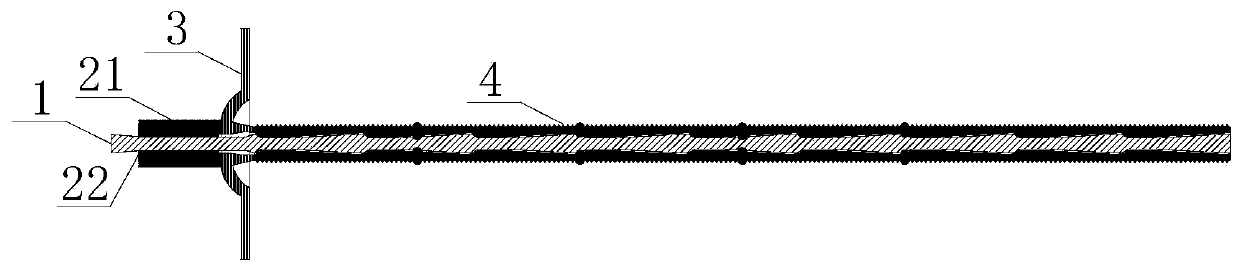

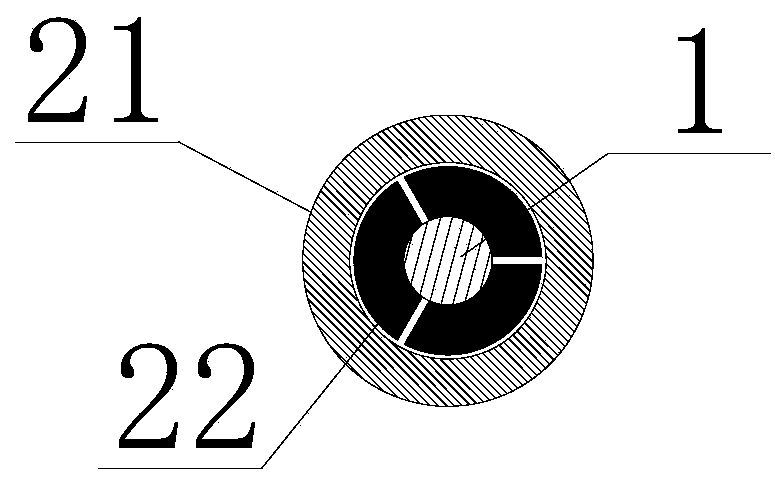

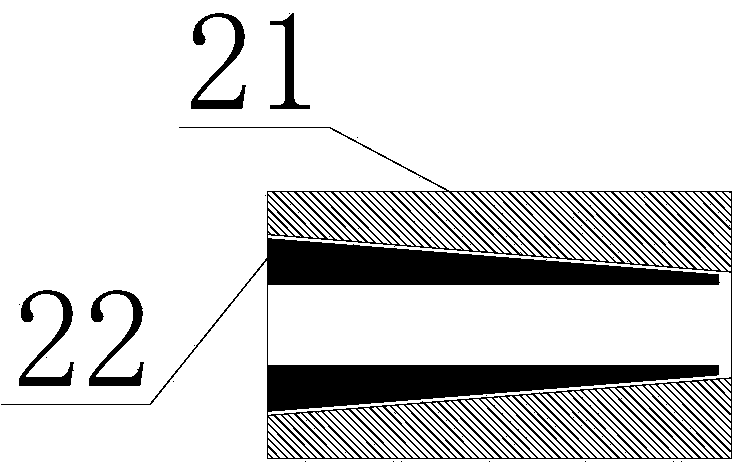

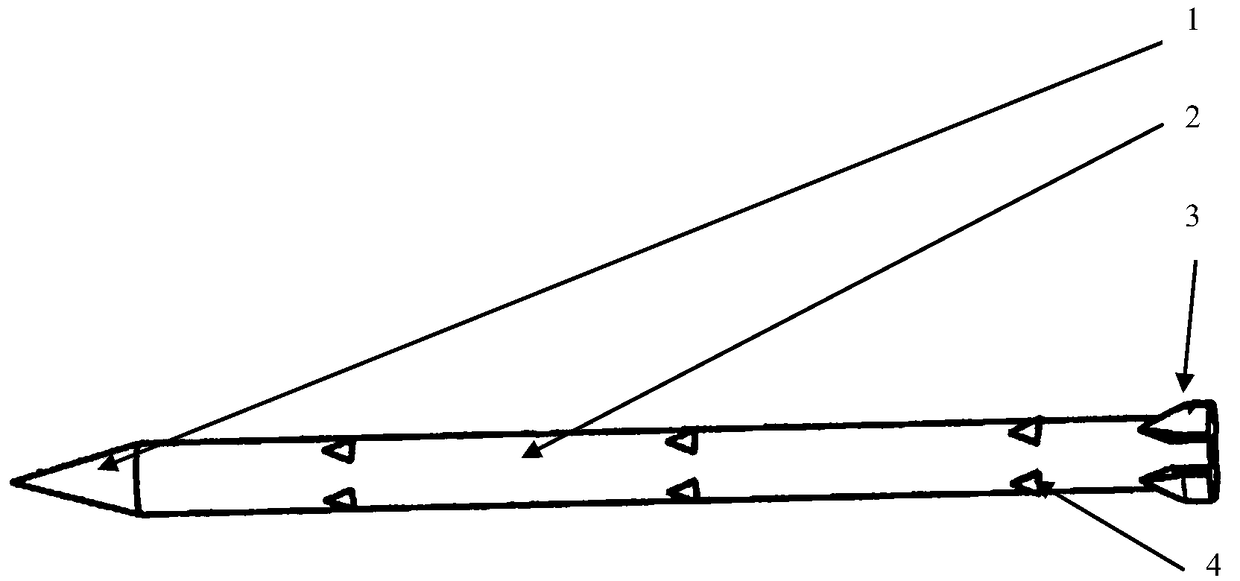

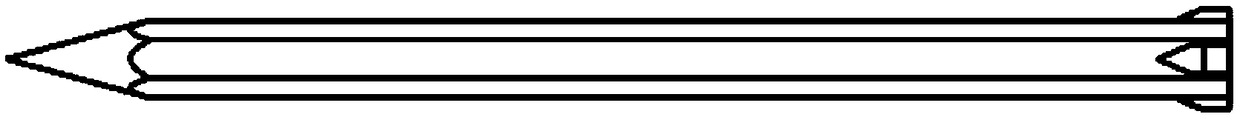

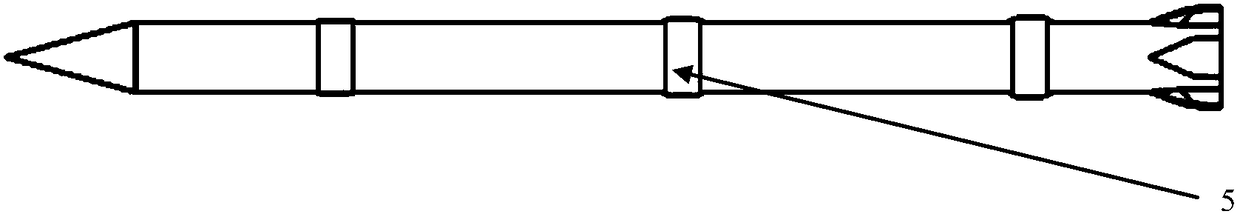

High-stress impact burst roadway anchor rod, design method and work method

ActiveCN110578542AImprove adaptabilityIncrease anchoring forceSpecial data processing applicationsBulkheads/pilesEngineeringHigh stress

The invention provides a high-stress impact burst roadway anchor rod, a design method and a work method. The anchor rod is suitable for being used under a coal mine. The anchor rod comprises a joint-like anchor rod body, an anchor rod tail lock, a force transmitting tray and a sleeve. Protrusions are arranged on the joint-like anchor rod body at intervals. A thread is arranged at the tail end of the joint-like anchor rod body. The force transmitting tray and the anchor rod tail lock are sequentially arranged on the thread. The sleeve is arranged outside the joint-like anchor rod body. A metalpipe provided with a penetration seam in the axial direction is adopted as the sleeve. A fine thread is arranged on the outer side of the metal pipe. An inner concave structure matched with the protrusions on the joint-like anchor rod body is arranged in the metal pipe. The anchor rod has the advantages that anchoring force is high, pre-tightening force is high, and the overall anchoring effect isnot influenced by local breakage, and the anchor rod can effectively avoid the problems that the anchoring condition of a current common anchor rod is rigorous, the whole loses efficacy easily due tolocal breakage, the allowable deformation amount is small, and the anchor rod cannot adapt to high stress, large deformation, strong impact dynamic pressure and rock crushing engineering environments.

Owner:CHINA UNIV OF MINING & TECH

Method for repairing slope vegetation

The invention relates to a dome repairing method that drills some deep holes on the dome by jack hammer or drilling machine, adds mixture vegetation in it and plants climbing plant on it, and uses the haulm of the plants to cover the dome. The method has little engineering work load, and the nutritive layer is not easy to be swept away, and it could also fix the dome.

Owner:CHINA THREE GORGES UNIV +2

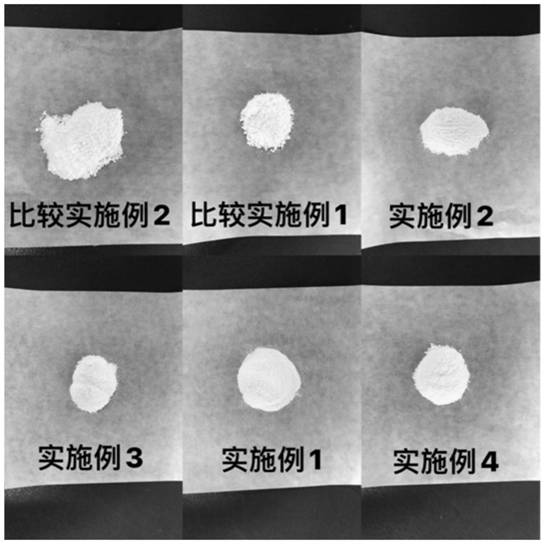

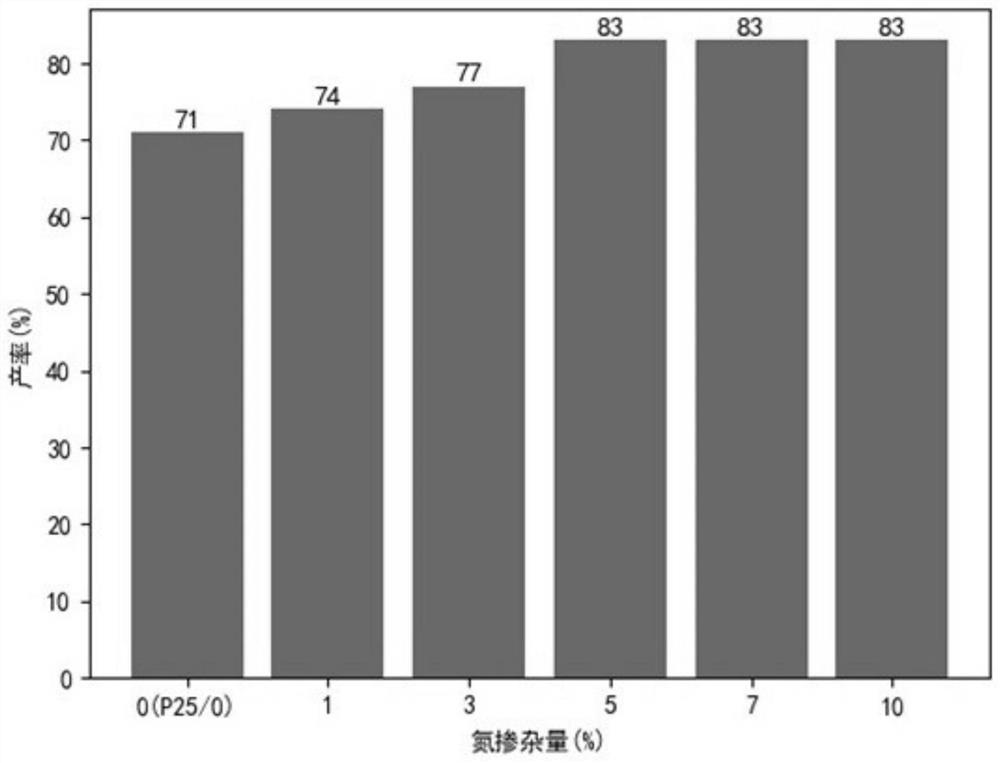

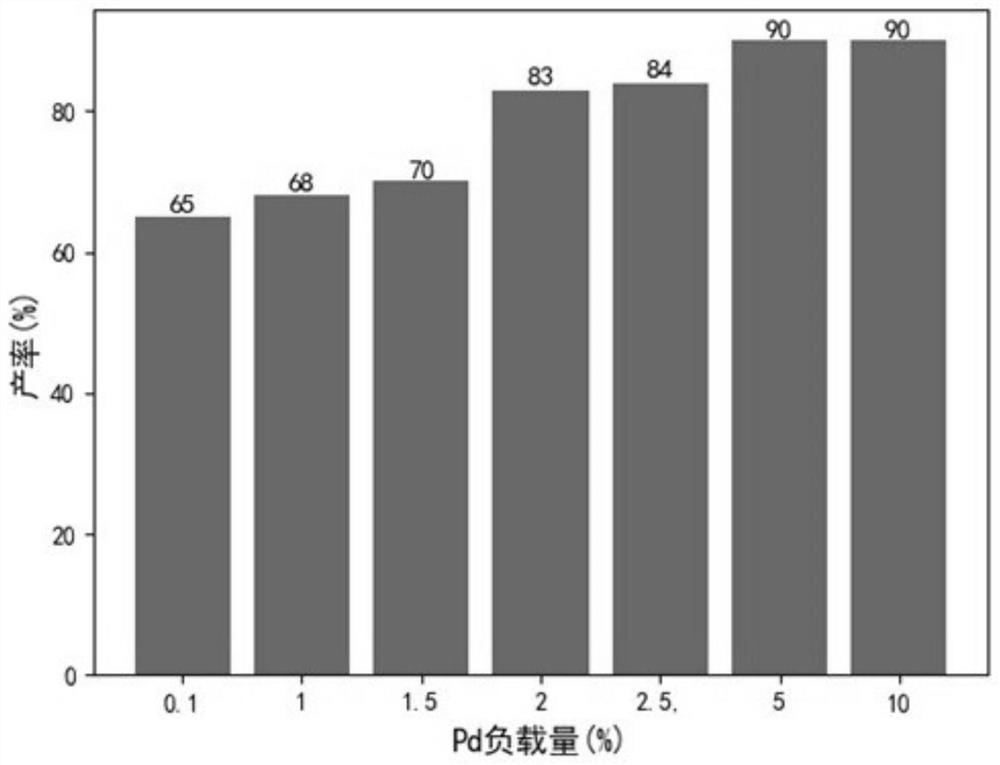

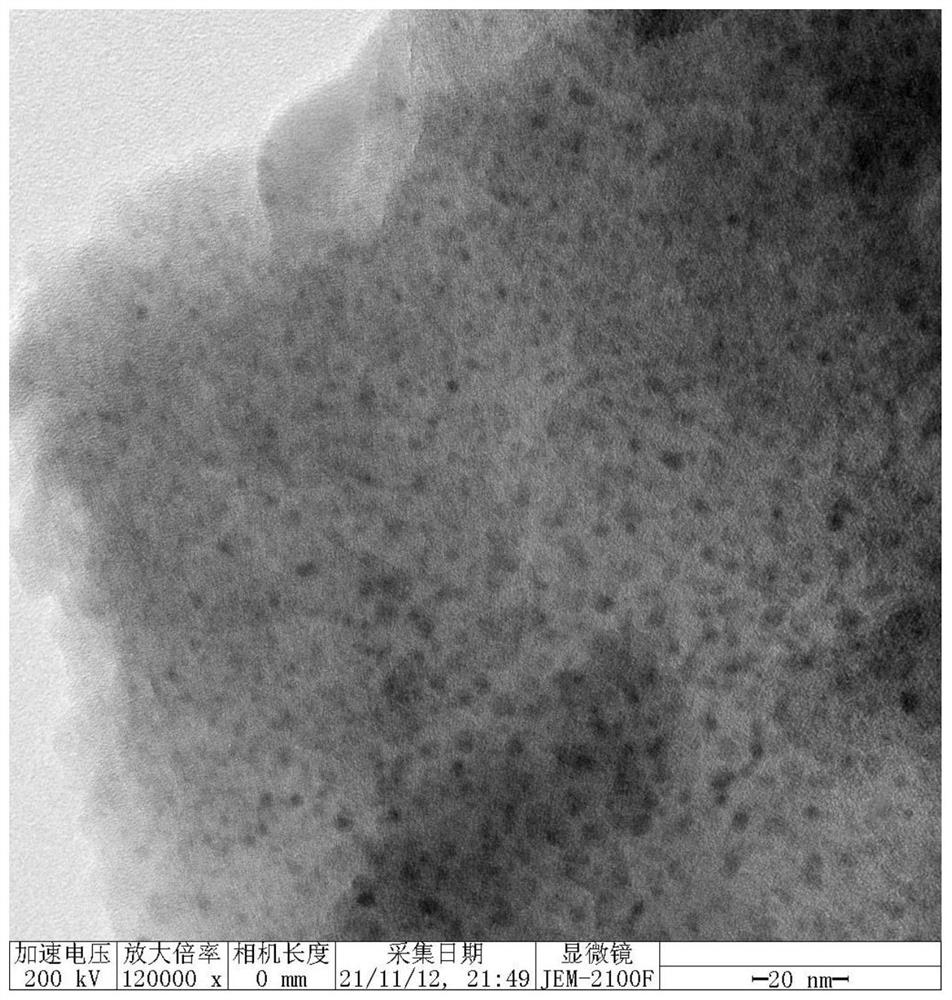

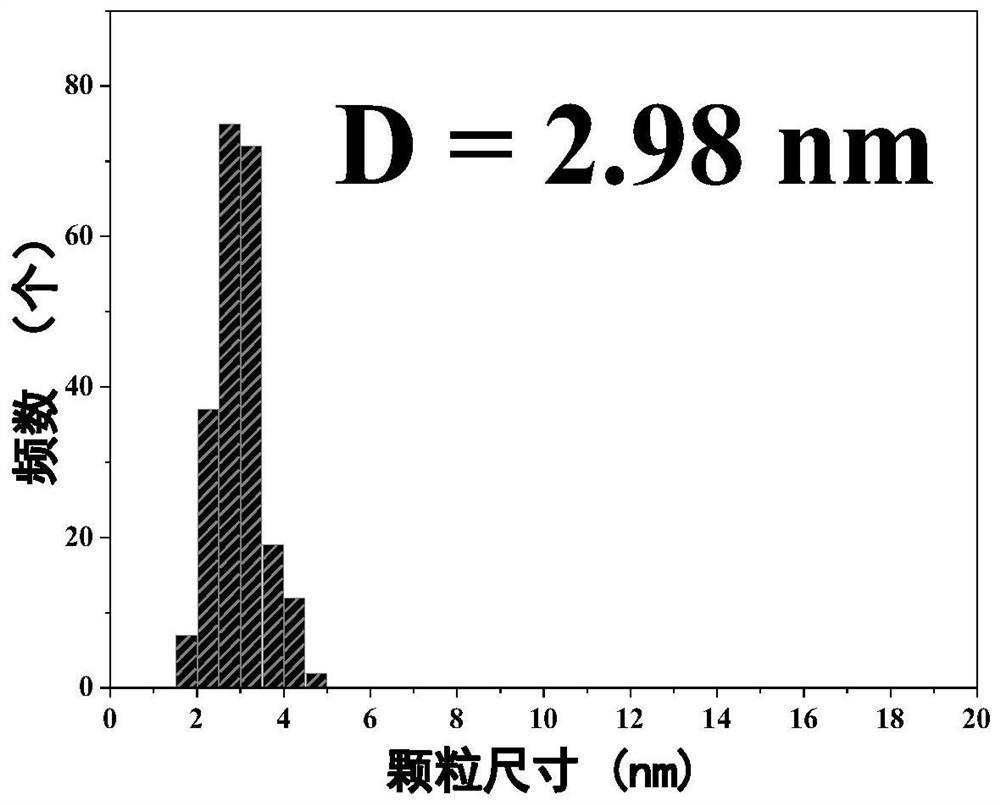

Nitrogen-doped titanium dioxide supported palladium catalyst for TADBIW hydrogenolysis debenzylation and preparation and application of catalyst

ActiveCN112844439AHigh yieldImprove catalytic performanceOrganic chemistryPhysical/chemical process catalystsPtru catalystPhysical chemistry

The invention relates to a nitrogen-doped titanium dioxide supported palladium catalyst for TADBIW hydrogenolysis debenzylation and preparation and application of the catalyst. The catalyst takes nitrogen-doped titanium dioxide as a carrier and palladium as an active component, the palladium is supported on the carrier, the doping amount of nitrogen is 0-10 wt.%, but not 0,of the total amount of the carrier, and the loading amount of the palladium is 0.1-10 wt.% of the total amount of the catalyst. The preparation method specifically comprises the following steps: (a) adding a titanium precursor into a solvent, stirring, adding a nitrogen source to form a mixture, stirring until the mixture is completely hydrolyzed, aging, and carrying out post-treatment to obtain a nitrogen-doped titanium dioxide carrier; and (b) adding the nitrogen-doped titanium dioxide carrier obtained in the step (a) into a solvent, stirring, adding a palladium precursor, stirring, adding a precipitator, adjusting the pH value to be alkaline, and performing post-treatment to obtain the nitrogen-doped titanium dioxide supported palladium catalyst. Compared with the prior art, the catalyst provided by the invention has the characteristics of high hydrogenolysis debenzylation reaction activity, high yield, high selectivity, good stability and the like.

Owner:SHANGHAI UNIV OF ENG SCI

Graphene-modified polyester glass fiber reinforced plastic material and preparation method thereof

InactiveCN105504733AImprove bending abilityImprove tensile propertiesBuilding insulationsPolyesterDecomposition

The invention discloses a graphene-modified polyester glass fiber reinforced plastic material. After low-temperature pretreatment is carried out on glass fibers through a physical method, the bending property, tensile property and interlaminar shear property of the glass fibers are improved. Through high-temperature treatment, oxidative decomposition of original gel on the surfaces of the glass fibers is achieved, and thus moisture stored and adsorbed by the glass fibers is removed. Graft modification is carried out on the surfaces of the glass fibers with materials such as porous carbon nanotubes through a chemical method, hole structures are formed, chain segments of some high polymers enter the holes when the glass fibers are compounded with a matrix, and an effect like anchoring is achieved. Thus, the bonding force between interfaces of the glass fibers and the polymers is increased, the impact resistance of the product is increased, and the obtained glass fiber reinforced plastic material has the advantages of being low in brittleness, large in toughness, low in formaldehyde content, large in tensile strength and the like.

Owner:WUHU EDISON AUTOMATION EQUIP

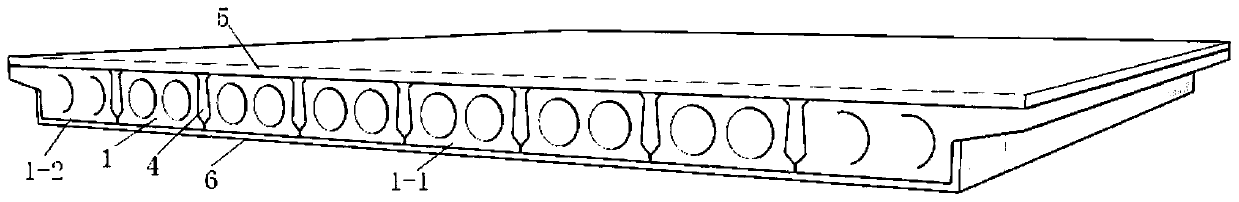

Wide hollow slab oblique section shearing resistance reinforcing method

ActiveCN110747754AImprove the shear bearing capacity of the inclined sectionEnhanced shear capacity of oblique sectionsBridge erection/assemblyBridge strengtheningMesh reinforcementEngineering

The invention discloses a wide hollow slab oblique section shearing resistance reinforcing method. The method comprises the steps that original concrete paving, bituminous concrete paving and hinge joints on a hollow slab bridge are removed; a plurality of drilled holes are formed in edges of center sills and edge beans of the hollow slab bridge correspondingly; a plurality of stirrups are arranged on the center sills and the edge beams in a sleeved mode in the positions of the drilled holes correspondingly, and oblique bend bars are connected between the stirrups; oblique bend bars are connected in the positions, located at webs of the edge beams, between the stirrups sleeved with the edge beams correspondingly; steel bars are embedded in bottom plates of the center sills and the edge beams correspondingly according to a preset spacing; concrete is used for pouring the spaces and joints between the center sills, so that new hinge joints are formed; a ribbed steel mesh is arranged on the upper surfaces of the center sills and the edge beams, and then new concrete paving is formed through pouring; and concrete is poured at the bottoms of the center sills and the edge beams and websof the edge beams correspondingly, and reinforcing is completed. By means of the method provided by the invention, secondary erected stirrups and the oblique bend bars can be utilized for reinforcinga hollow slab on the premise that the cost is reduced, and a good reinforcing effect can be achieved.

Owner:CHANGAN UNIV

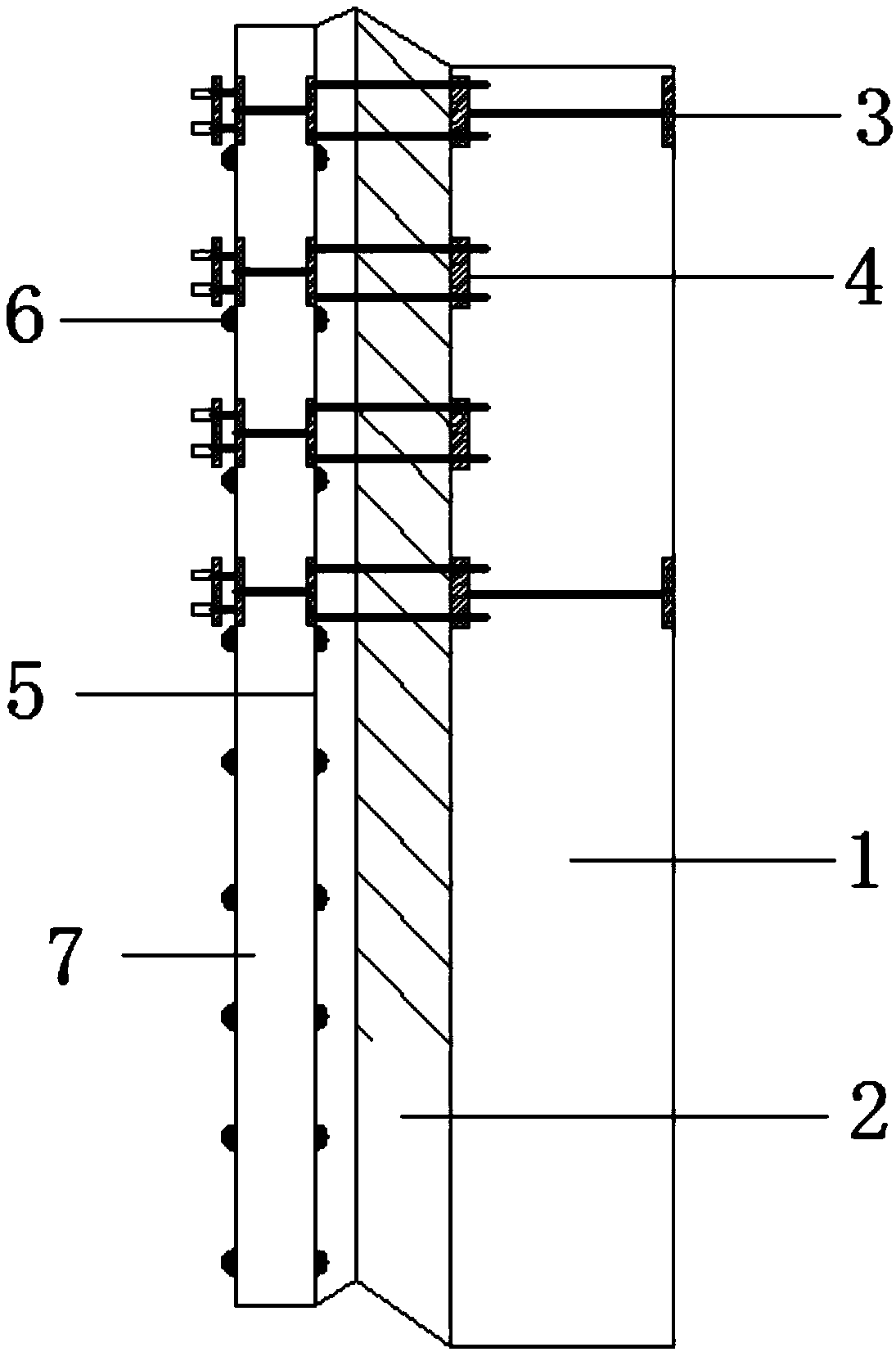

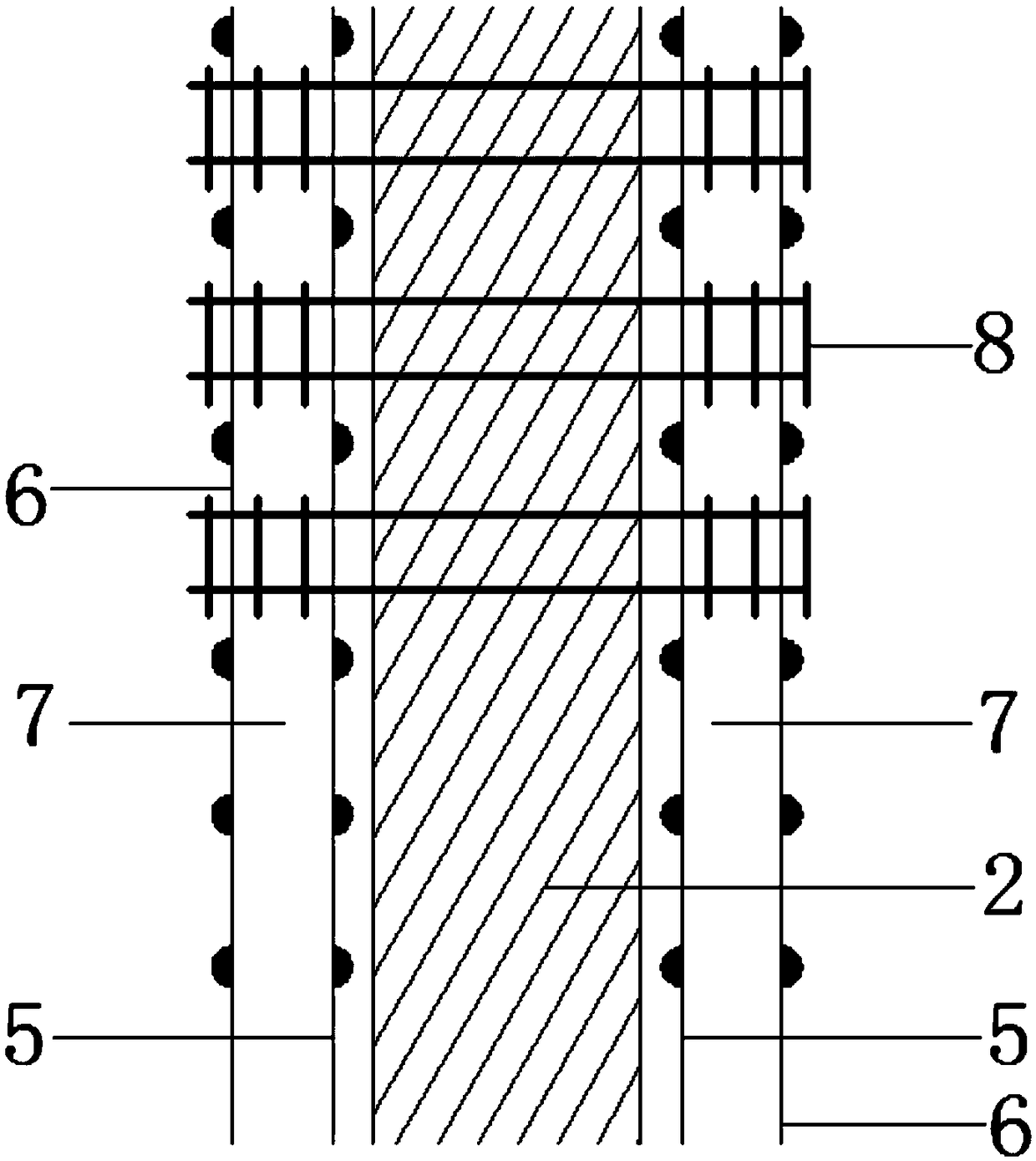

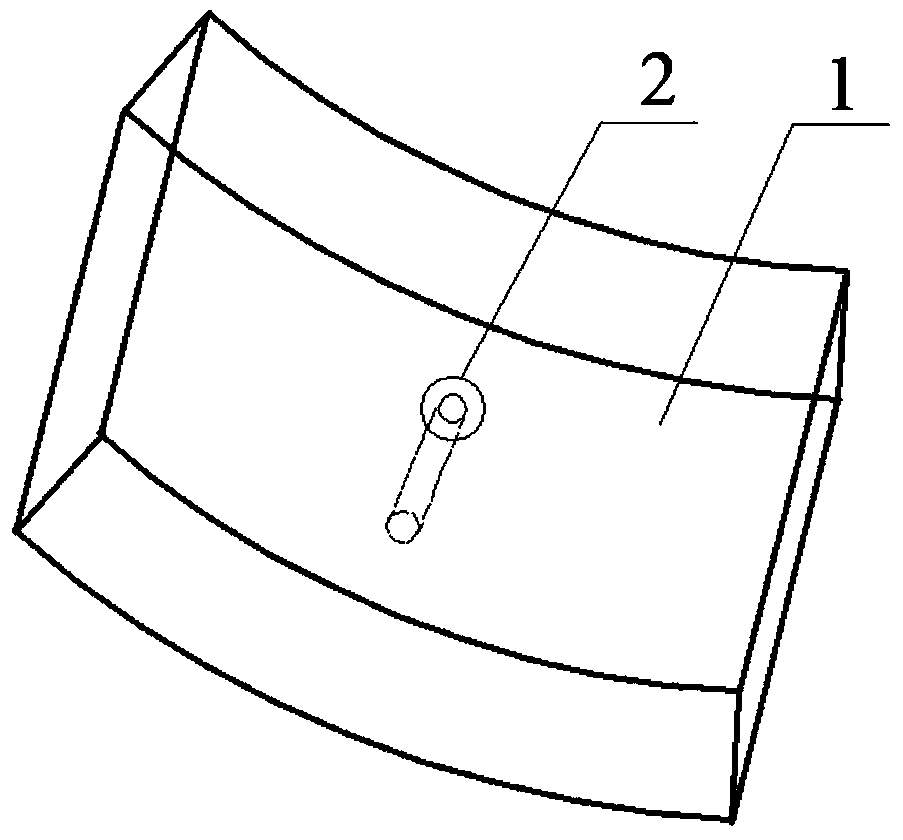

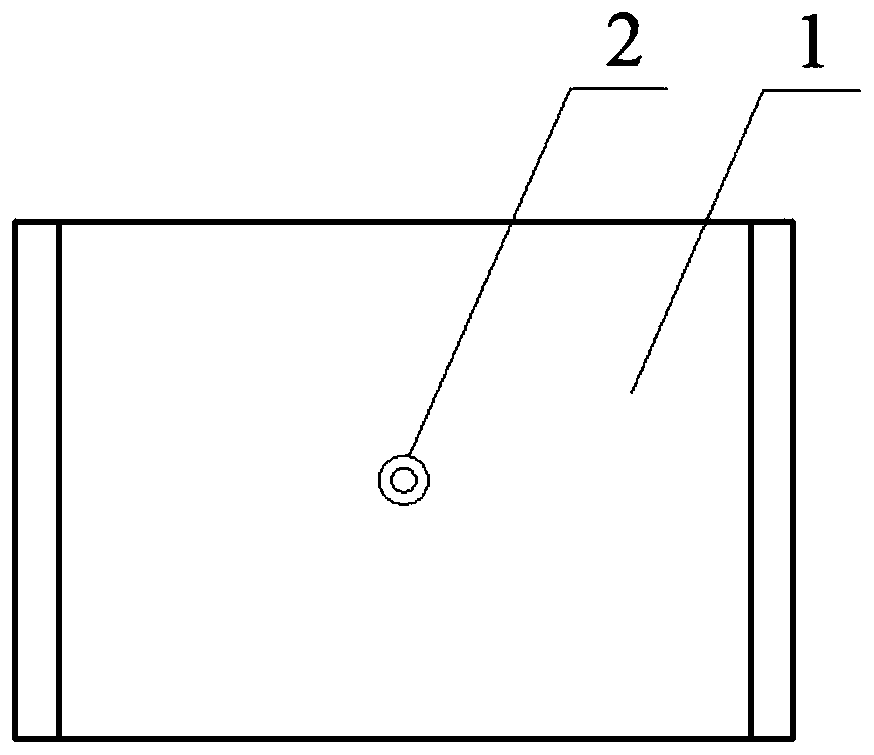

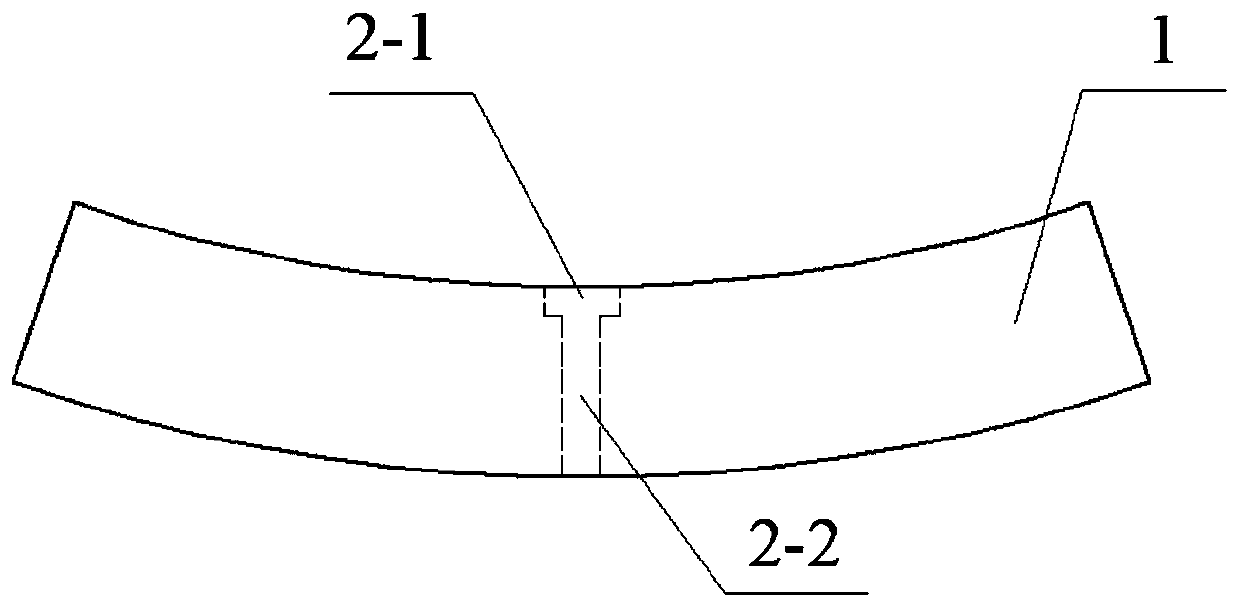

Modeling grid structure thermal insulation wall and construction method

PendingCN108915128AGuaranteed stabilityAvoid sheddingWallsHeat proofingThermal insulationScrew thread

The invention discloses a modeling grid structure thermal insulation wall and a construction method. The modeling grid structure thermal insulation wall comprises a shear wall and a filler wall, wherein a thermal insulation board is arranged on an outer layer of the shear wall; two layers of steel wire meshes are arranged on the outer side of the thermal insulation board of the shear wall, and twolayers of steel wire meshes are arranged on the inner side and the outer side of a thermal insulation board of the filler wall; the steel wire meshes comprise fixed steel wire meshes and anti-crack steel wire meshes, the fixed steel wire meshes are arranged outside the thermal insulation boards, the anti-crack steel wire meshes are arranged on outer layers of the fixed steel wire meshes, and thefixed steel wire meshes and the anti-crack steel wire meshes are connected by adopting mesh-frame-type connecting pieces; supporting pieces are installed at the inner side ends of the mesh-frame-typeconnecting pieces, and the supporting pieces are arranged on the mesh-frame-type connecting pieces in a penetrating mode; and the supporting pieces are connected to the inner sides of the mesh-frame-type connecting pieces through screw threads or clamping grooves in a fastening mode. The modeling grid structure thermal insulation wall and the construction method have a simple production process, agood thermal insulation effect, good fireproof performance, no falling off, fast construction progress and capability of maintaining the same technological life as a building.

Owner:陈红庆

Beam strengthening method

InactiveCN101532277APlay a protective effectReduce slackBridge erection/assemblyBridge strengtheningMesh reinforcementEngineering

The invention relates to a beam strengthening method. The method comprises the following steps: firstly, chiseling a beam top anchorage groove on the top surface of a beam end, obliquely boring along the direction of two sides of a beam rib, and paving a positioning groove for fixing a prestressed steel wire buddle and a positioning tension sleeve along a beam web; mounting an anchorage plate; polishing the lateral surfaces and a bottom surface of a beam, and roughening a strengthening surface; mounting the steel wire buddle and the tension sleeve, namely arranging the positioning tension sleeve in the positioning groove of the positioning tension sleeve, threading the steel wire buddle from the anchorage plate at one end of the beam, placing the steel wire buddle into the positioning groove, then threading out the steel wire buddle from the anchorage plate at the other end of the beam, tightening the steel wire buddle and temporarily fixing the steel wire buddle by a rolling anchorage head; tensioning the steel wire buddle by using a tensioning jack or a winch at one end of the steel wire buddle, anchoring the steel wire buddle when reaching a design value, and then casting and sealing the wire buddle by concrete; implanting a pin into a beam body; after positioning and setting out a reinforcing steel bar on the beam body, binding reinforcement mats on the surface of the beam, and partially spot-welding the reinforcement mats; painting an interface agent; and plastering composite mortar. The method is active, ultra-strong and durable, can well overcome the main defects of the prior strengthening technology, and has strong effectiveness and economy.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

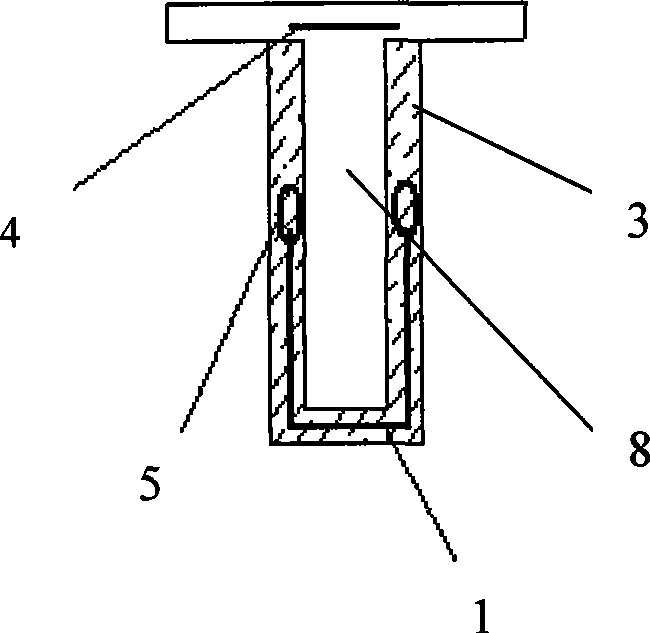

Packer and use method thereof

InactiveCN107143303AAdvantages of useOvercome the problem of insufficient loadingSealing/packingEngineeringMechanical engineering

The invention provides a packer and a use method thereof. The packer comprises a center tube and a first seat seal mechanism, a second seat seal mechanism and an anchoring mechanism which are arranged on the outer side of the center tube in sequence in a sleeving mode; the first seat seal mechanism comprises a rubber cylinder and an extrusion part, the lower end of the rubber cylinder is fixed to a first cone through a rubber cylinder support, and the upper end of rubber cylinder can slide on the outer wall of the center tube in a limiting mode through the extrusion part; the second seat seal mechanism is provided with a slip and the first cone, and the first cone can be fixedly inserted into the slip in a matched mode; the anchoring mechanism comprises a stable part and a clamping part, the stable part comprises a centralizer, and a centralizer base is connected with the slip base. The packer and the use method thereof are suitable for a composite seat seal packer of a highly-deviated well, and the requirement of oil extraction production is met.

Owner:DRILLING TECH DEV CO LTD OF TIANJIN DAGANG OILFIELD PETROLEUM ENG INST +1

Embedded anchoring type concrete crack repairing process

PendingCN112177376AImprove connection strengthHigh mechanical strengthBuilding repairsEngineeringStructural engineering

The invention discloses an embedded anchoring type concrete crack repairing process, and belongs to the technical field of concrete repairing. A repairing rod is inserted into a repairing groove cavity, a plurality of transverse anchoring rods with the inner ends bonded with inner embedded rods are distributed on the end wall of an outer inserting rod from bottom to top, after a heated crack repairing agent is injected into the repairing groove cavity through the inner embedded rods, the inner embedded rods are heated to enable the inner ends of the transverse anchoring rods to be separated from the inner embedded rods and the outer inserting rod in sequence, a plurality of transverse anchoring rods are embedded into the crack repairing agent, the outer tip ends of the transverse anchoringrods are inserted into the repairing groove cavity to achieve the anchoring effect, then the outer inserting rod is pulled out upwards, secondary material injection is carried out, a concrete supplementing layer is formed in the crack repairing cavity, the inner embedded rods, a conical material guide part and the plurality of transverse anchoring rods are embedded into the repairing groove cavity, and the multiple transverse anchoring rods are distributed up and down, so that the transverse bonding degree between the concrete supplementing layer and the repairing groove cavity and the overall mechanical strength are effectively enhanced to a certain extent.

Owner:高洋

Wheel cable type sea wave energy conversion apparatus

InactiveCN101000030AStrong wind and wave resistanceCompact structureMachines/enginesEngine componentsSea wavesEngineering

Owner:卢国林

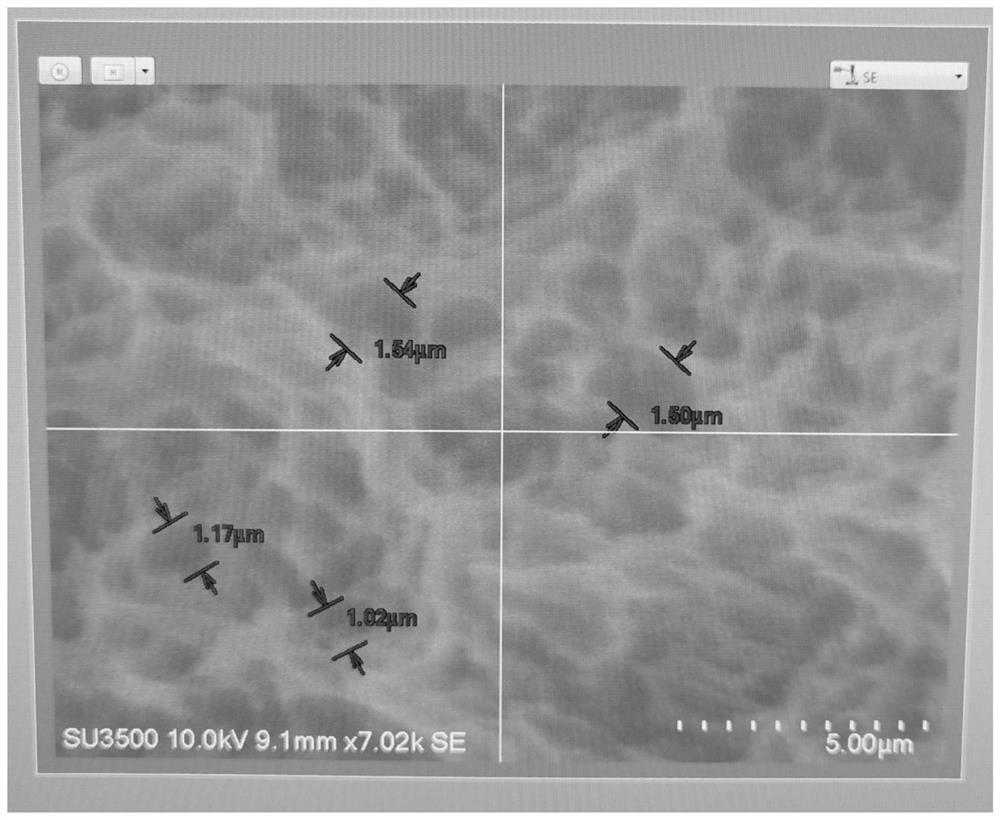

Manufacturing method of surface modified artificial skull prosthesis

PendingCN113633438AHigh water lossImprove adhesionSkull3D printingCollagen cross linkingComputer printing

The invention provides a manufacturing method of a surface modified artificial skull prosthesis, which comprises the following steps: 1, printing a solid PEEK skull prosthesis by using a 3D printer; 2, pretreating the PEEK skull prosthesis; 3, adsorbing and fixing type I collagen on the surface of the PEEK skull prosthesis through a physical effect to form a collagen adsorption layer; 4, carrying out crosslinking on the type I collagen by adopting Co-60 irradiation; and finally carrying out freeze vacuum drying. According to the method, the binding property of the PEEK material and the subcutaneous tissue can be remarkably improved, meanwhile, a chemical cross-linking agent is not used, the biocompatibility is good, the steps are relatively simple, and water resources are saved.

Owner:NINGBO CIBEI MEDICAL TREATMENT APPLIANCE

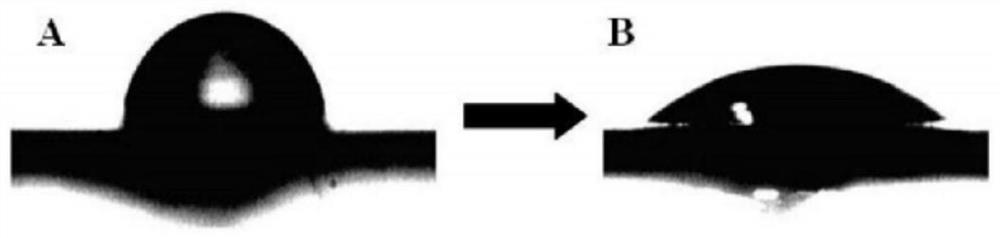

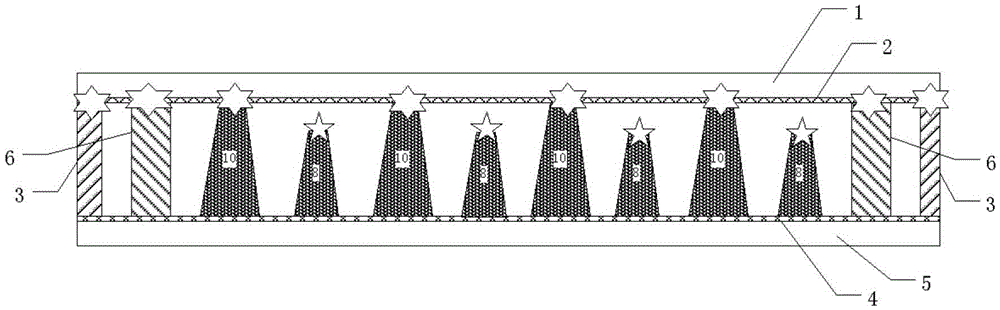

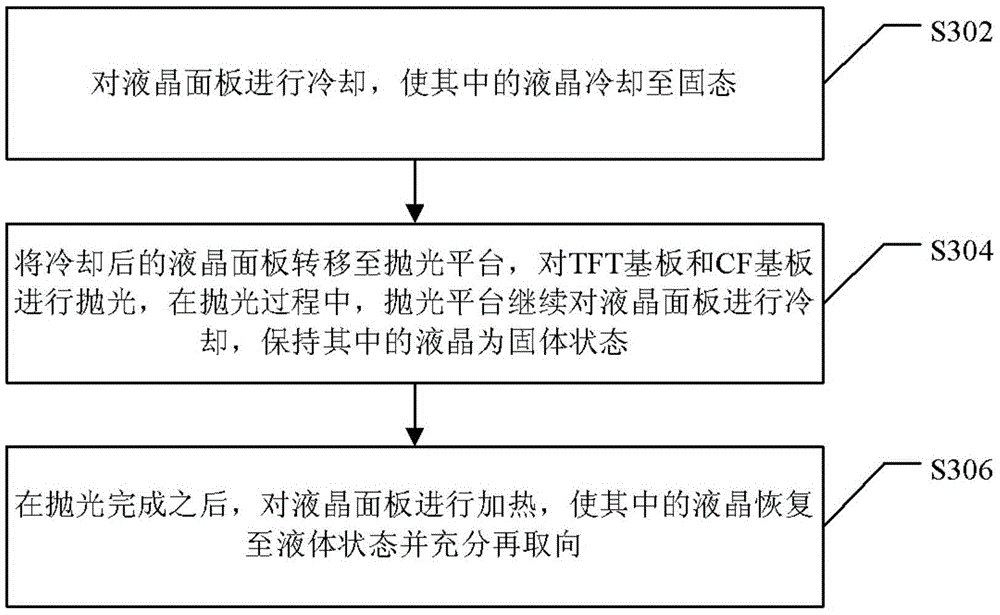

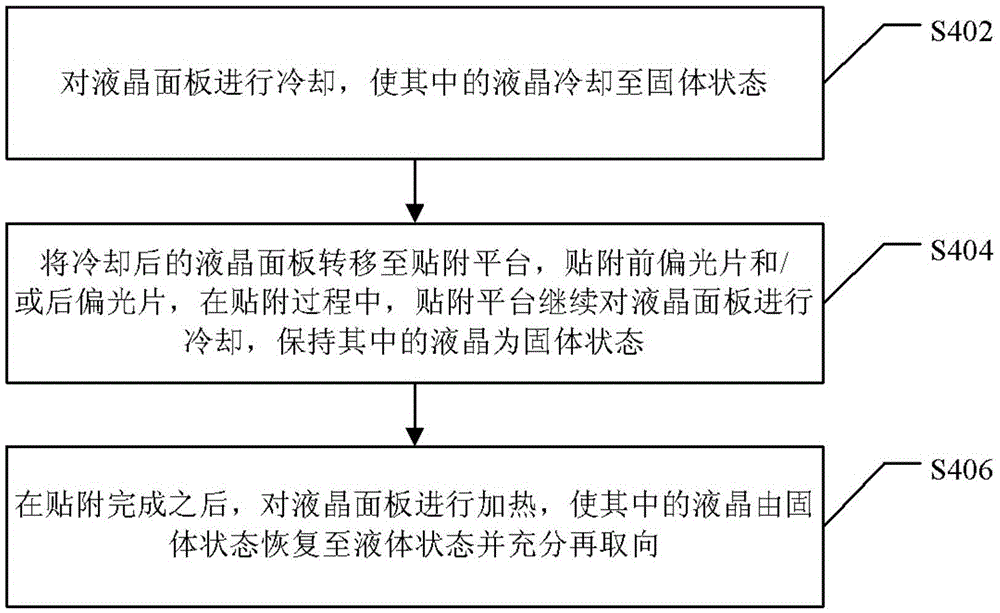

Manufacturing method of liquid crystal display device

InactiveCN105607327AImprove stress resistanceAvoid breakingNon-linear opticsLiquid-crystal displayStress point

The invention provides a manufacturing method of a liquid crystal display device. In the manufacturing method, before a liquid crystal panel is treated, liquid crystals in the liquid crystal panel are turned into solid states, so that the pressure resistance of the liquid crystal panel can be greatly improved, and damage to the liquid crystal panel due to the pressure in the treatment process can be prevented. Furthermore, before the liquid crystal panel is polished, the liquid crystals therein are cooled to solid states, the solid liquid crystals achieve an effect of anchoring photoresistance columns in a closed space, and then the friction force on stress points at the top ends of panel sealants and the photoresistance columns is changed from dynamic sliding friction force into static friction force, so that the sliding resistance of the surface of the liquid crystal panel is improved, the probability of PI debris in the polishing process is reduced, and the risk of Zara can be also reduced.

Owner:BOE TECH GRP CO LTD +1

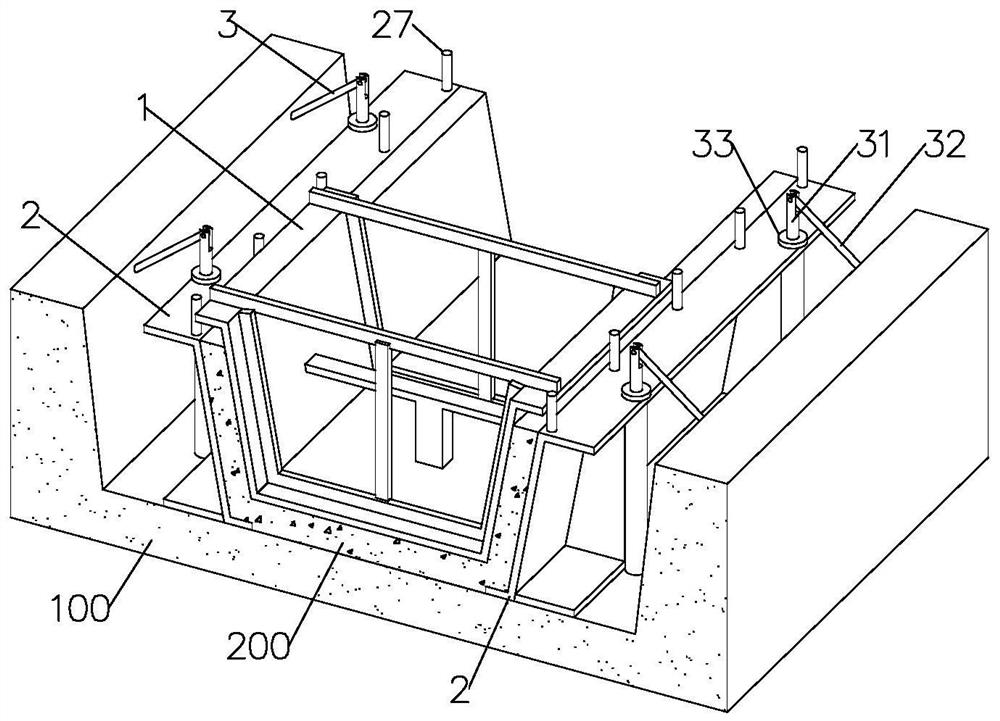

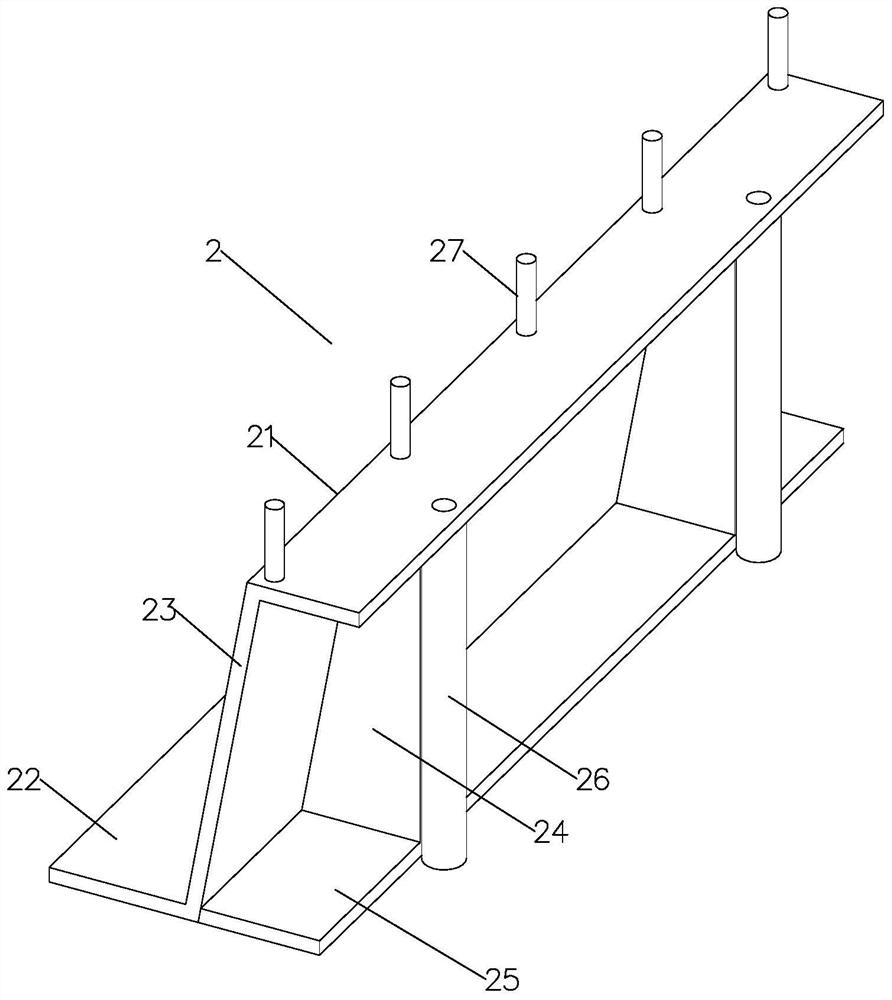

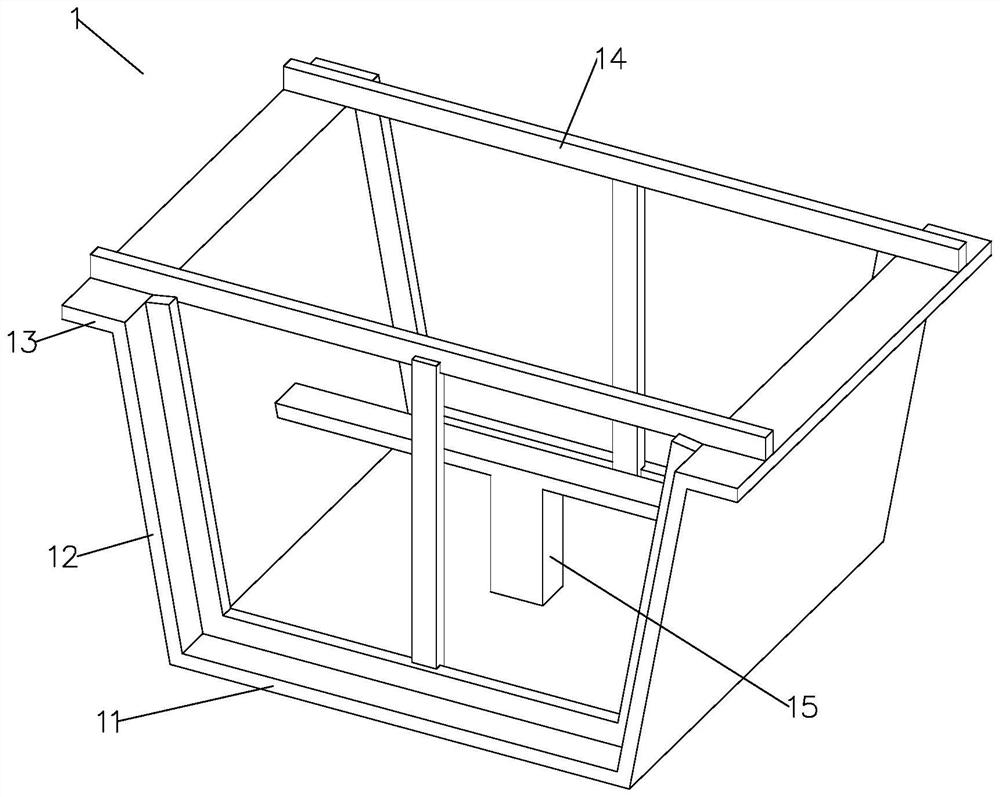

Construction method of cast-in-place drainage ditch

ActiveCN112814116AReduce installation stepsEasy to removeClimate change adaptationSewer pipelinesStructural engineeringDrainage ditch

The invention relates to the technical field of drainage engineering, and particularly relates to a construction method of a cast-in-place drainage ditch. The construction method comprises the following steps that a groove is excavated; the groove is leveled; a bottom die is installed, the bottom die is divided into a left part and a right part, the two parts of the bottom die are fixed to the bottom of the groove, and the bottom of the groove supports the bottom surfaces of the two parts of the bottom die; concrete is poured, specifically, the concrete is poured between the two parts of the bottom die, and the concrete flows downwards along the side walls of the two parts of the bottom die and is converged between the two parts of the bottom die; a pressing die is installed, specifically, the pressing die squeezes the concrete at the bottom of the bottom die, so that the concrete is used for filling between the side wall of the bottom die and the side wall of the pressing die, and shaping is carried out; the die is removed, specifically, after a drainage ditch main body starts to be hardened, the pressing die is removed, and after maintenance is completed, the bottom die is removed; and the groove is backfilled, specifically, after the die is removed, slurry supplementing or sand and stone backfilling is carried out at the bottom of the drainage ditch main body, and then the groove is backfilled and compacted. According to the construction method, the construction efficiency of the urban cast-in-place drainage ditch is improved, and the construction steps are simplified.

Owner:安徽仁成建设工程有限公司

Conductive fiberglass reinforced plastic material and manufacturing method thereof

The invention discloses a conductive fiberglass reinforced plastic material. After ultralow temperature pretreatment is performed on fiberglass through a physical method, the bending resistance and the tensile property of the fiberglass are improved; through high temperature treatment, an original sizing material on the surface of the fiberglass is oxidized to be decomposed, and then water stored and adsorbed in the fiberglass is removed; the surface of the fiberglass is grafted with a modified porous carbon nano tube material through a chemical method; a hole structure is achieved, when the fiberglass is composited with a matrix, chain segments of some high polymers enter holes, a similar anchoring effect is achieved, the binding force betrween the fiberglass and a polymer interface is enhanced, the impact resistance of the product is improved, and the prepared fiberglass reinforced plastic material has the advantages of being good in mechanical property, corrosion resistance and electromagnetic shielding effect.

Owner:WUHU EDISON AUTOMATION EQUIP

Recoverable anchor rod

InactiveCN101469541BReduce pollutionWill not develop impactAnchoring boltsBulkheads/pilesArchitectural engineeringScrew thread

The invention relates to a recovery type anchor bar, comprising an outer sleeve steel pipe, a screw rod disposed in the outer sleeve steel pipe along the axial direction, an upper cover board fixed on the top of the outer sleeve steel pipe, a regulation nut disposed at center of the upper cover board, a lower cover board fixing on the bottom end of the outer sleeve steel pipe, an anchor cone disposed right under the lower cover board, and a plurality of upper connection boards disposed on bottom end of the lower cover board, wherein the upper portion of the screw rod is attached to the regulation nut through a screw thread, the lower portion of the screw rod is attached to the anchor cone. Each upper connection boards is hinged to the top of an upper pulling rod, bottom end of each upper pulling rod is hinged to the top of a lower pulling rod, bottom end of each lower pulling rod is respectively attached to the anchor cone through a pin. Object of the invention is to provide a recovery type anchor bar which is high in shearing resistance capacity, underground space saving, underground environment pollution-free, and steel saving.

Owner:YANTAI UNIV

Production process of garment fabric added with graphene

ActiveCN111519436AWell mixedHigh bonding strengthFibre mixingBiochemical treatment with enzymes/microorganismsPolymer scienceEngineering

The invention discloses a production process of garment fabric added with graphene. The production process comprises the steps that with synthetic fiber raw materials and viscose fiber raw materials used as raw materials, a card sliver is obtained through blending, opening, mixing and carding; the card sliver is dip-dyed in a copper chloride and graphene solution to obtain a dip-dyed card sliver;drawing and weaving are carried out; and finally, the fabric is obtained after water scrubbing. According to the production process, the shortcoming of the prior art is overcome, and the durability ofthe graphene synthetic fiber fabric is improved.

Owner:合肥克拉伦斯科技有限公司

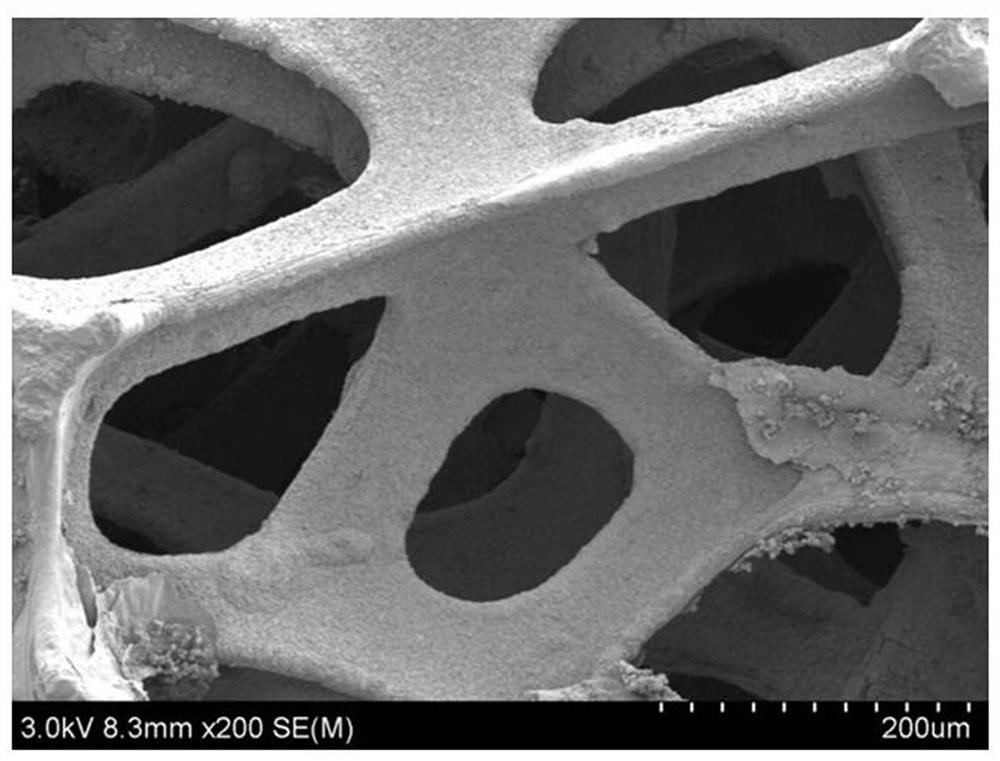

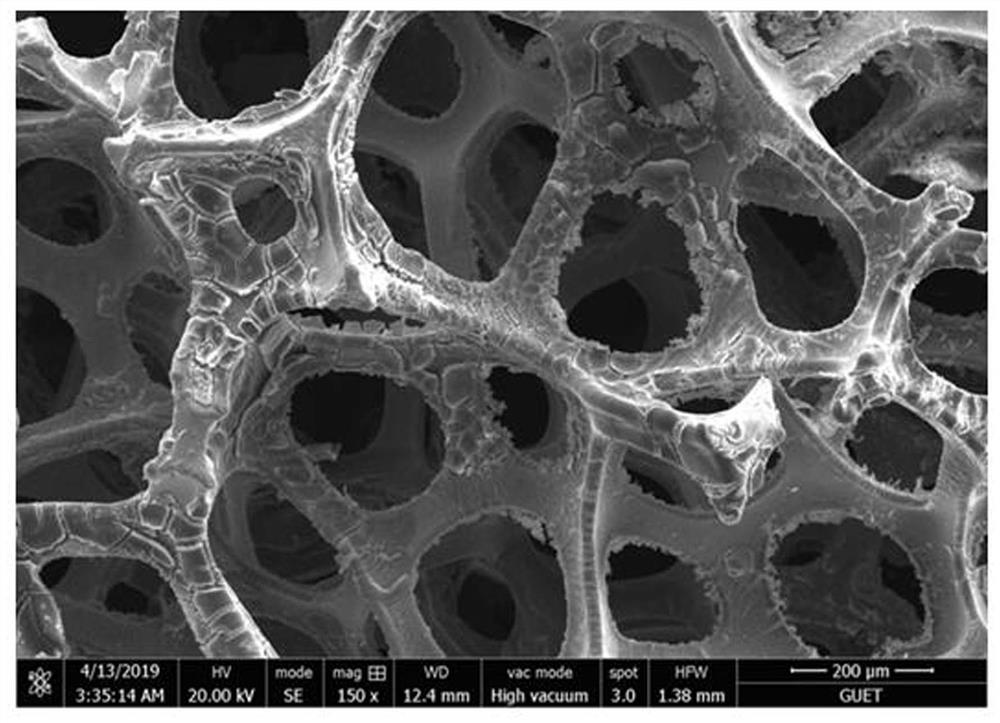

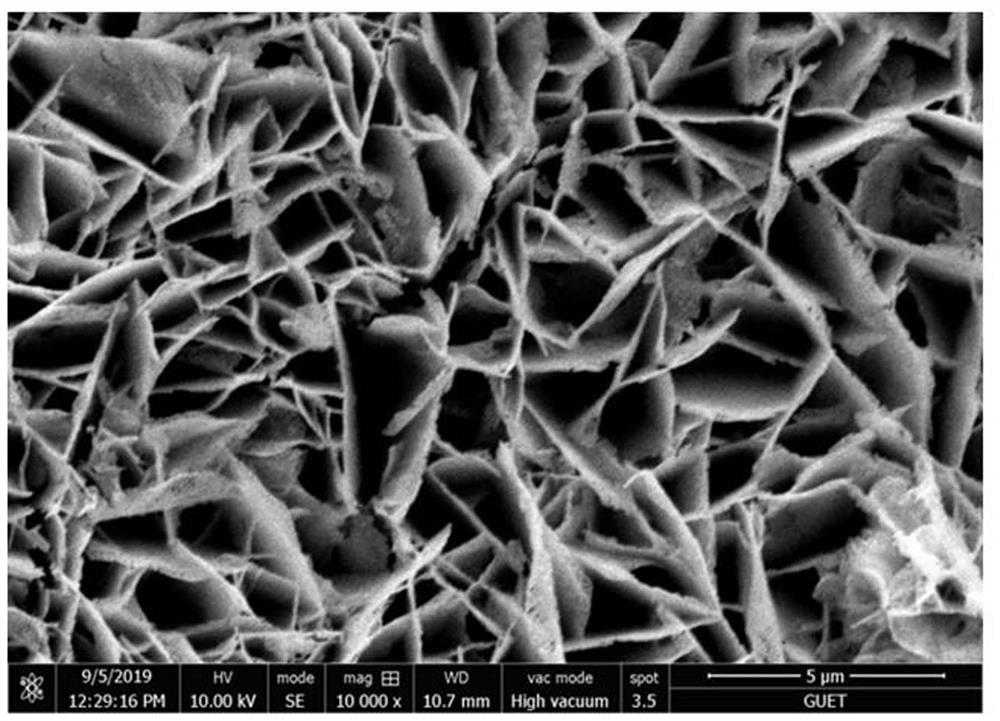

Nanoparticle-graphene-foamed nickel composite material with bionic structure, and preparation method thereof

InactiveCN111604072ASpread evenlyIncrease the effective surface areaPhysical/chemical process catalystsHydrogen productionPtru catalystHydrogen desorption

The invention discloses a nanoparticle-graphene-foamed nickel composite material with a skeleton-skin-hair bionic structure. Foamed nickel plays a role in skeleton, graphene plays a role in skin, nanoparticles play a role in hair, the macroscopic morphology of the composite material is block-shaped, and the nanoparticles are CoNiP nanoparticles and are of a nano-lamellar structure. A preparation method of the composite material comprises the following steps: 1) preparing a graphene-foamed nickel composite carrier with a skeleton-skin structure; 2) preparing a graphene-foamed nickel loaded CoNiprecursor; and 3) carrying out phosphating treatment on the graphene-foamed nickel loaded CoNi precursor. The composite material is used as a catalyst for hydrogen production by hydroboron hydrolysis, the maximum hydrogen production rate is 6681.34 mL.min<-1>g<-1>, the hydrogen desorption amount is 100% of a theoretical value, the activation energy Ea is 31.2 kJ.mol<-1>, the effects of producinghydrogen as required and immediately controlling the start and stop of the reaction can be achieved, and 74.8% of the initial catalytic activity is still retained after 15 times of recovery / reuse.

Owner:GUILIN UNIV OF ELECTRONIC TECH

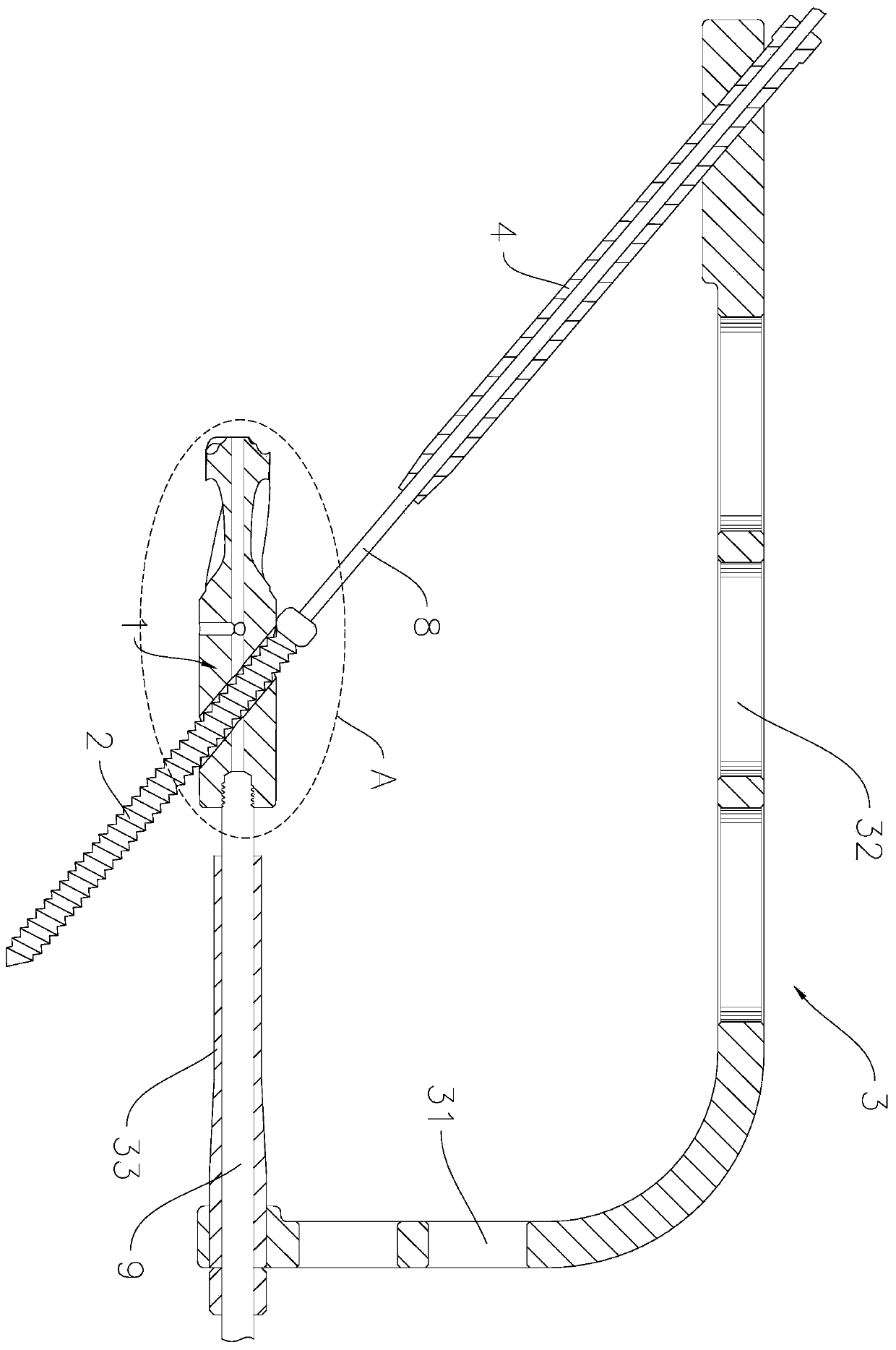

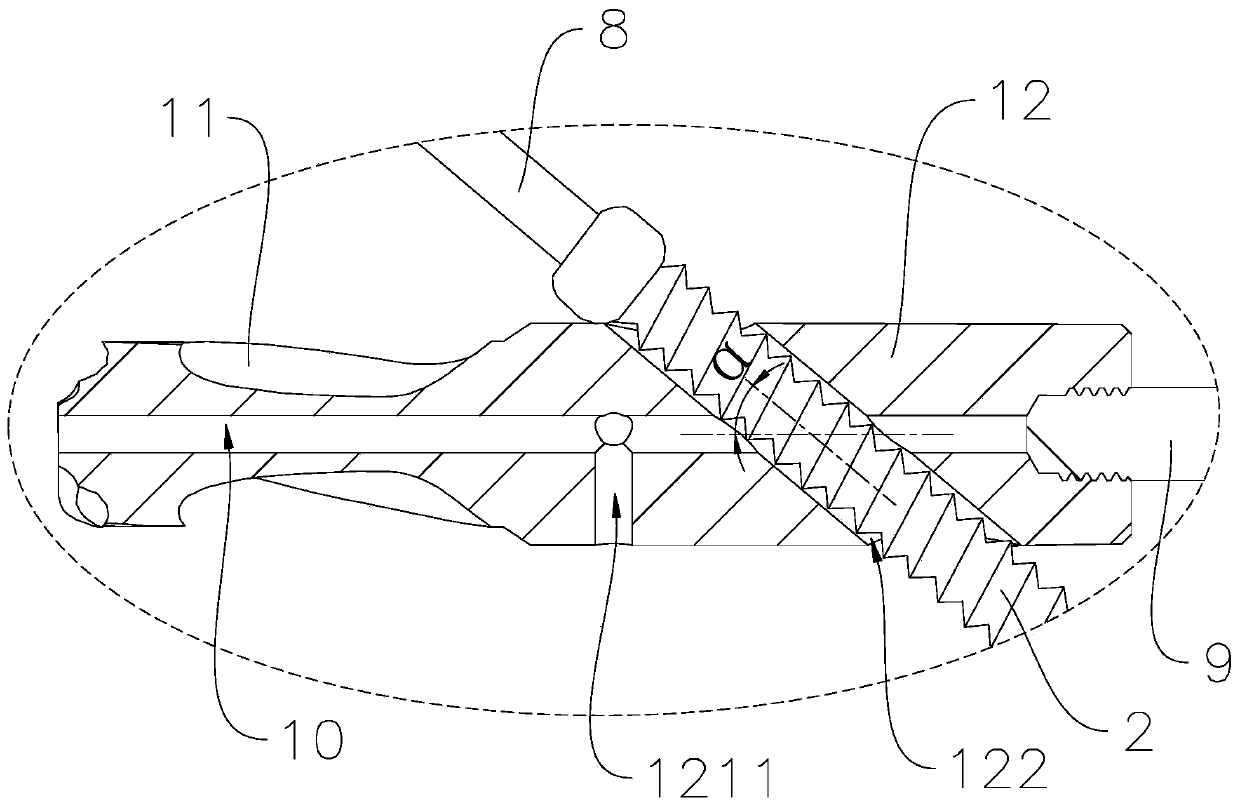

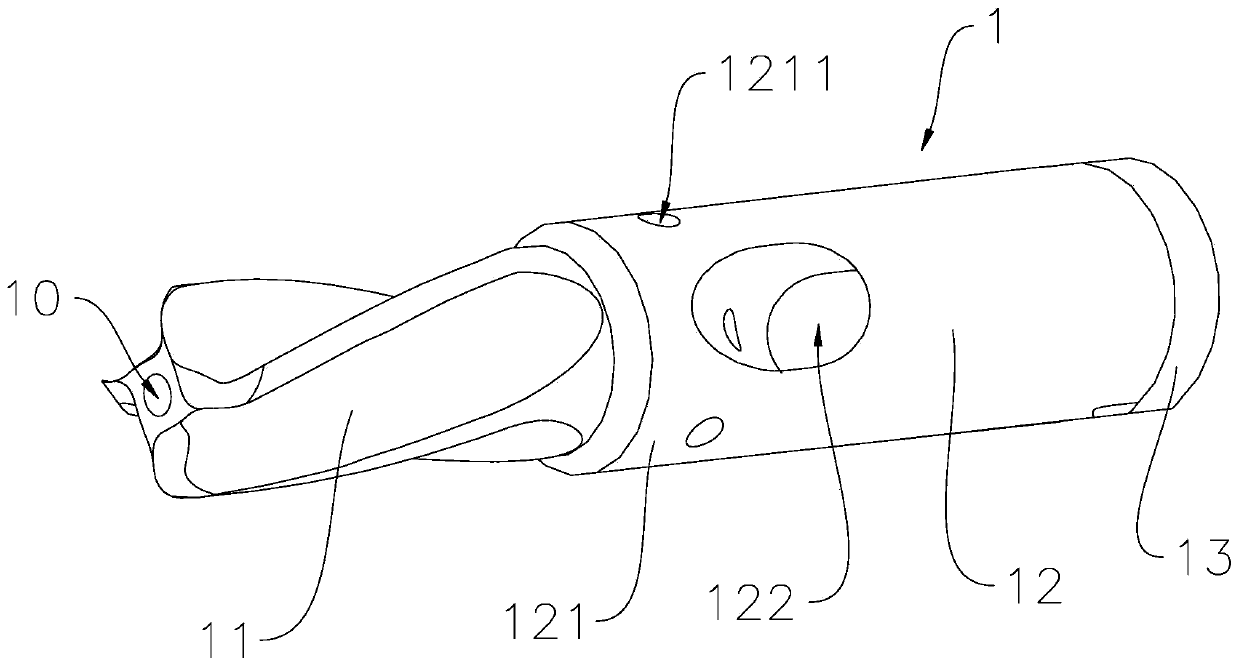

Novel unilateral locking lumbosacral vertebrae axial fusion internal fixing system

PendingCN111184564APlay an anchoring roleEffective anti-rotational stabilityInternal osteosythesisIntervertebral discGonial angle

The invention belongs to the technical field of medical devices, and in particular relates to a novel unilateral locking lumbosacral vertebrae axial fusion internal fixing system. The system includesan axial screw, a unilateral locking screw and a positioner; a through hole 1 is arranged in the axial screw, the axial screw includes a spiral part, a columnar part and a tail cap arranged in sequence, the connection position of the columnar part and the spiral part is provided with a transition part, the side wall of the transition part is provided with a plurality of through holes 2, the through hole 1 communicates with the outside through the through holes 2, the columnar part is provided with a through hole 3, the angle between the axis of the through hole 3 and the axis of the through hole 1 is alpha, and the angle of the alpha is the same as the angle of a complementary angle of an intervertebral disc angle of lumbar 5 sacral 1; the exterior of the unilateral locking screw has a threaded structure, and the interior has a hollow structure; the positioner is in the shape of a fishhook(right) and includes a horizontal part and a long vertical part and a short vertical part perpendicular to the horizontal part, the short vertical part has a hollow structure, so that a screw connector can conveniently pass through the hollow structure to be connected to the columnar part of the axial screw, a through hole 4 is arranged in the end part of the long vertical part, so that the unilateral locking screw can conveniently pass through the through hole 4 to be inserted into the through hole 3.

Owner:NANHUA HOSPITAL AFFILIATED TO UNIV OF SOUTH CHINA

Anti-suspension device, system and method based on shield segment

InactiveCN111425208AAvoid enteringPrevent floating deviationUnderground chambersTunnel liningFiberPressure - action

The invention discloses an anti-suspension device, system and method based on a shield segment. The technical scheme is that the anti-suspension device comprises the shield segment and an anchoring grouting bolt, and the shield segment is provided with a bolt hole for inserting the anchoring grouting bolt; a grouting hole for inserting a grouting pipe is reserved in the center of the anchoring grouting bolt, the anchoring grouting bolt comprises a bolt main body and a polymer film arranged at the bottom of the bolt main body, fiber rapid hardening liquid is injected through the grouting pipe,and the polymer film can be rapidly expanded under the action of grouting pressure. According to the anti-suspension device disclosed by the invention, a looped shield segment can be effectively positioned and fixed, the position of an original design line is accurately positioned, meanwhile, the grouting compactness can be improved, and it is guaranteed that the grouting thicknesses of the periphery of the back of the looped segment are the same.

Owner:JINAN MUNICIPAL ENG DESIGN & RES INSITITUTE GRP

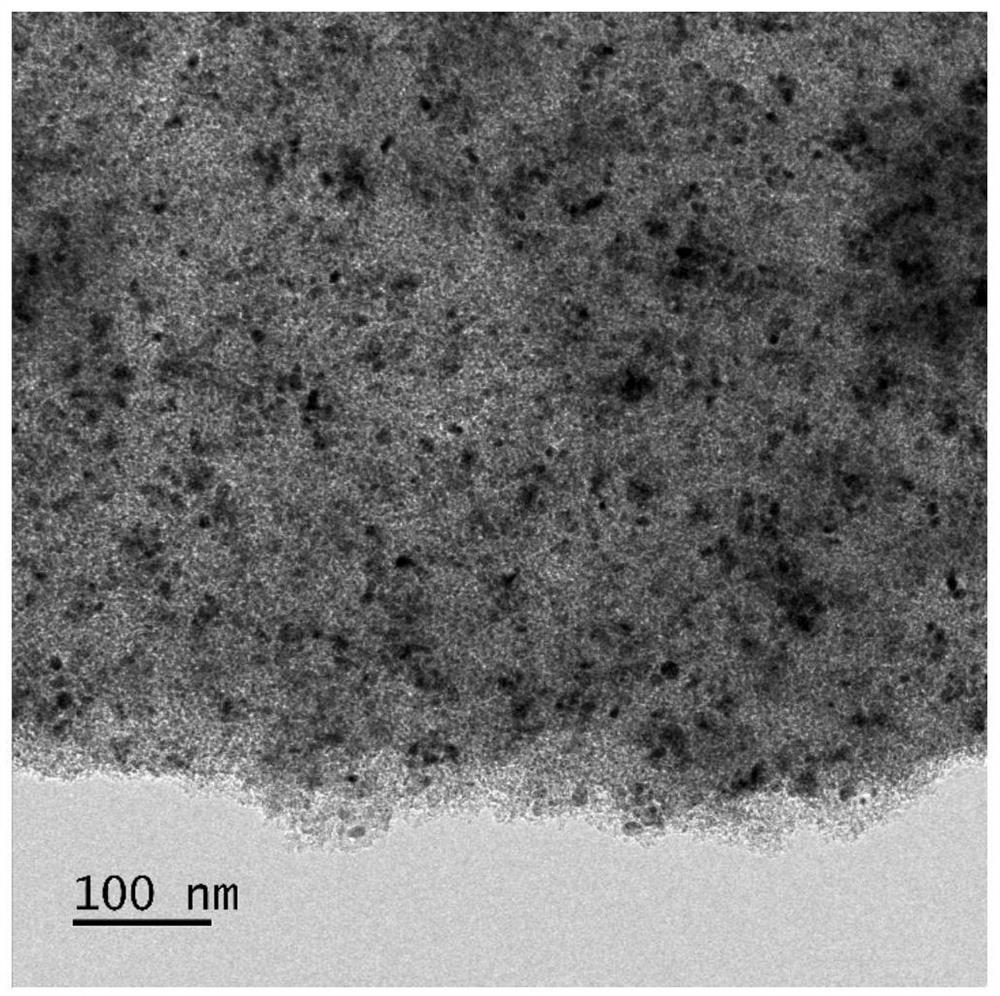

Preparation method of acidified two-dimensional layered vermiculite loaded nickel-based catalyst

PendingCN114308043AGood metal dispersionSmall particle sizeHydrogenMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveRoasting

The invention relates to a preparation method of an acidified two-dimensional layered vermiculite loaded nickel-based catalyst. According to the method, expanded vermiculite is adopted as a carrier, a vermiculite structure in which a layered molecular sieve with a large specific surface area is removed is obtained through treatment in an acid solution, washing and drying, and then the acidified two-dimensional layered vermiculite loaded nickel-based catalyst is prepared through a slightly excessive liquid-phase high-temperature roasting method. The catalyst has the advantages of simple composition, simple preparation process, easy operation, low production cost and the like, and the catalyst prepared without subsequent addition of auxiliaries has the advantages of uniform dispersion of metal particles, small average particle size, high sintering resistance at high temperature, high carbon deposition resistance and the like; the catalyst has a good industrial prospect when applied to methane and carbon dioxide reforming reaction for synthesis gas preparation.

Owner:TIANJIN UNIV

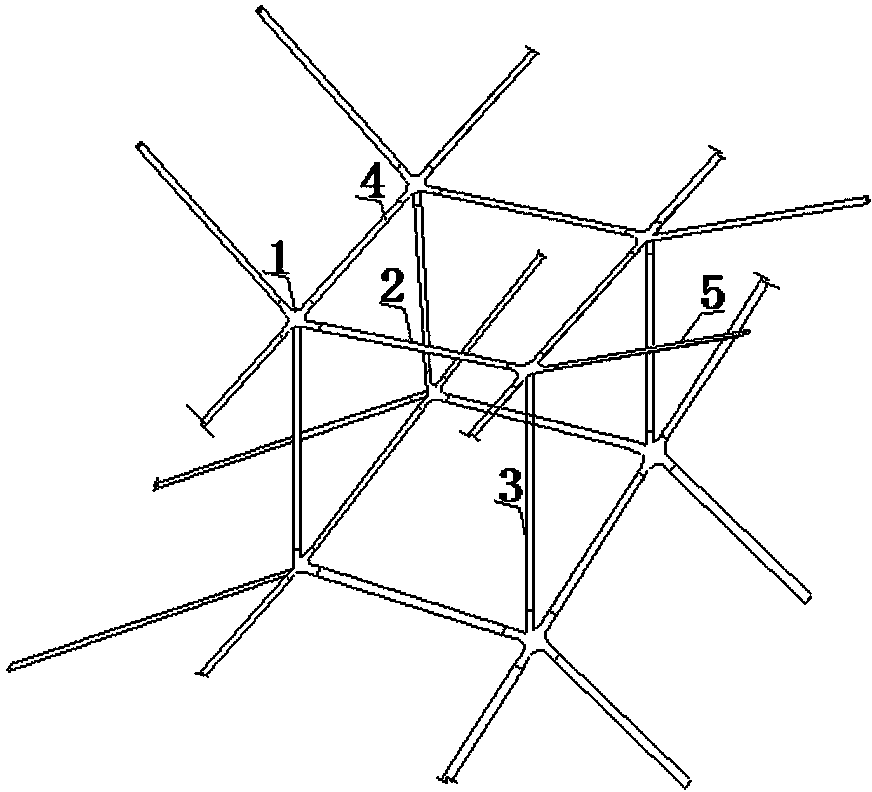

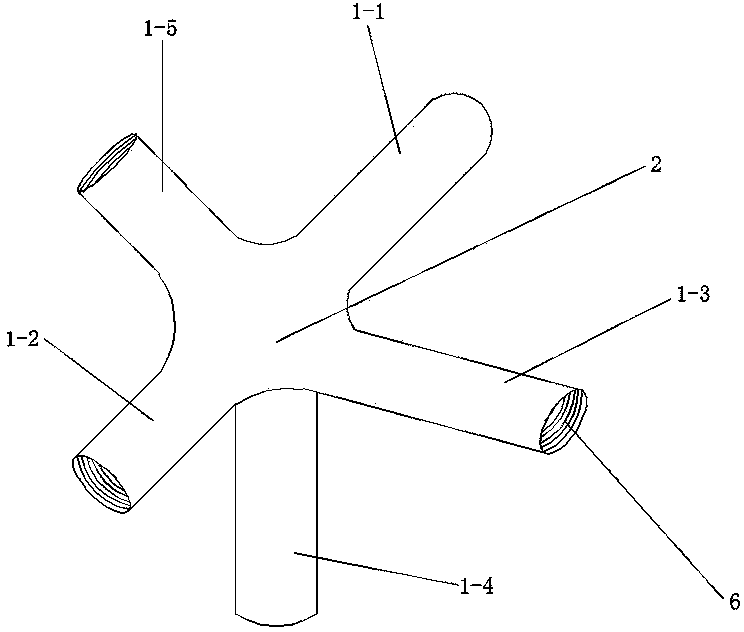

Steel tube truss grouting reinforcing and supporting structure for high-stress weak broken surrounding rocks

InactiveCN104265329APlay an anchoring rolePlay a stabilizing roleUnderground chambersTunnel liningHigh stressControl area

The invention discloses a steel tube truss grouting reinforcing and supporting structure for high-stress weak broken surrounding rocks. The steel tube truss grouting reinforcing and supporting structure comprise five-way connectors, mandrels, assisting rods, shoulder rods and grouting anchor rods. Each five-way connector comprises five communicated ports, and the mandrels, the assisting rods, the shoulder rods and the grouting anchor rods are installed on the five ports and form supports with the five-way connectors as the center. The four supports are connected together to form a square framework structures with the four five-way connector as the top points. Each square framework is provided with a square framework having the same structure with the square framework along two sides of the axial direction of the first ports of the five-way connectors. Every two adjacent square frameworks are integrally connected through the shoulder rods to form a multi-connection structure with the single square frameworks as the base. The steel tube truss grouting reinforcing and supporting structure has the advantages of being large in initial supporting force, high in supporting strength, good in integrity, large in the supporting top control area, strong in surface protection strength, simple and convenient to construct, safe and reliable, and being capable of greatly improving the stability of loose surrounding rocks.

Owner:HUNAN UNIV OF SCI & TECH

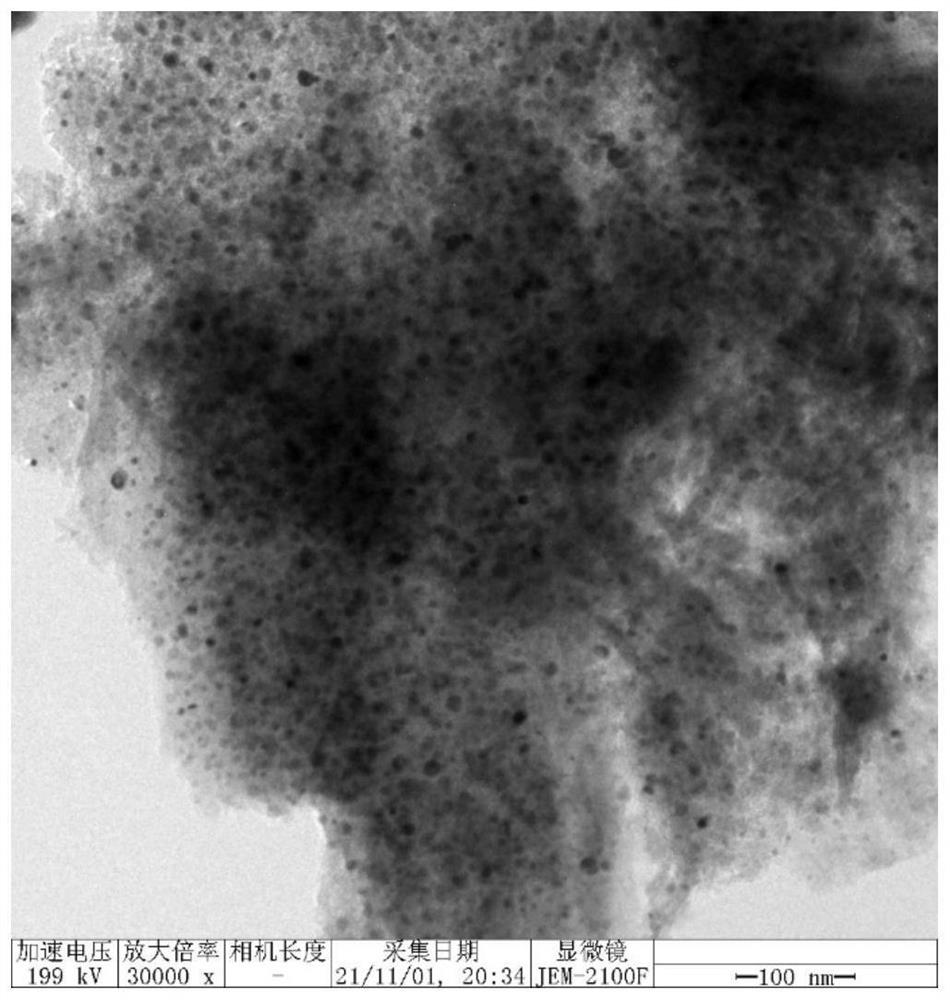

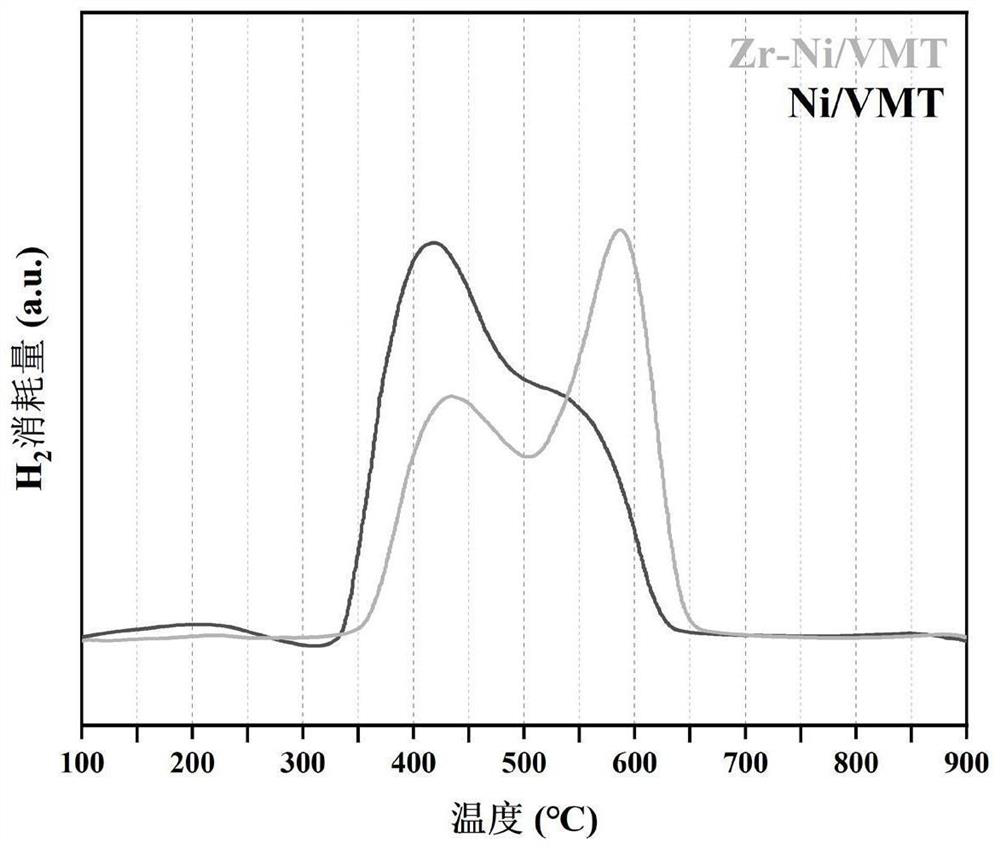

Preparation method of zirconium dioxide modified layered porous vermiculite loaded nickel-based catalyst

PendingCN114272927AImprove stabilityGood dispersionHydrogenMetal/metal-oxides/metal-hydroxide catalystsMolecular sievePtru catalyst

The invention relates to a preparation method of a zirconium dioxide modified layered porous vermiculite loaded nickel-based catalyst. According to the method, acid-treated two-dimensional layered porous vermiculite is taken as a carrier, and zirconium dioxide and nickel metal are anchored in a mesoporous structure of a layered molecular sieve at the same time through a co-initial wet immersion high-temperature reduction method, so that the zirconium dioxide modified layered porous vermiculite loaded nickel-based catalyst rich in Ni-Zr interfaces and a large number of oxygen vacancies is prepared. The preparation method has the advantages that the preparation process is easy to operate, the process energy consumption is low, the preparation method is good in repeatability and the like, the prepared catalyst has the advantages of being small in metal particle, uniform in dispersion, high in reactant adsorption and activation capacity and the like, and the Ni-Zr interface effect and oxygen vacancies rich in the zirconium dioxide auxiliary play a synergistic effect; the prepared catalyst has the advantages of high sintering resistance and carbon deposition resistance at high temperature and the like. The method has a good prospect when being applied to the reaction for preparing the synthesis gas by reforming the methane and the carbon dioxide.

Owner:TIANJIN UNIV

Medical internal fracture fixation needle and medical fracture fixation tool

InactiveCN108852488APromote healingLess discomfortInternal osteosythesisTissue regenerationOsteoblastInternal fixation

The invention discloses a medical internal fracture fixation needle and a medical fracture fixation tool. The medical internal fracture fixation needle is made of biodegradable magnesium or magnesiumalloy materials, and comprises a needle head, a needle body and a needle tail, wherein the needle head is conical so that an internal fixation needle can be inserted into a bone hole; the needle bodyis cylindrical, and a clamping structure is arranged on the needle body, and is used for achieving locking of the needle body after the internal fixation needle is inserted into the bone hole; multiple tail vane structures arranged at intervals are arranged on the surface of the needle tail, the ends, away from the needle tail, of the tail vane structures are pointed, so that the tail vane structures are inserted into the bone hole to achieve the anchoring effect, and a sliding groove for achieving the guiding effect is formed between every two tail vane structures. By means of the medical internal fracture fixation needle and the medical fracture fixation tool, the discomfort of a patient in the application process is reduced while a fixation operation can be conveniently carried out on the patient, and a second operation is avoided; as a degradation product of magnesium and magnesium alloy is alkalescency, stem cells can be better differentiated into osteoblast, generation of new bones is facilitated, and fracture healing is promoted.

Owner:西安卓恰新材料科技有限公司

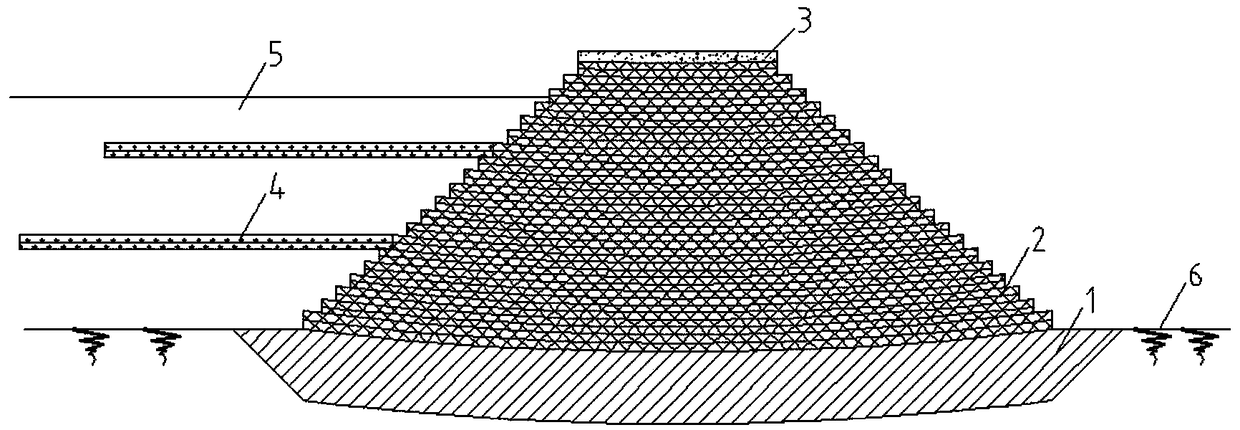

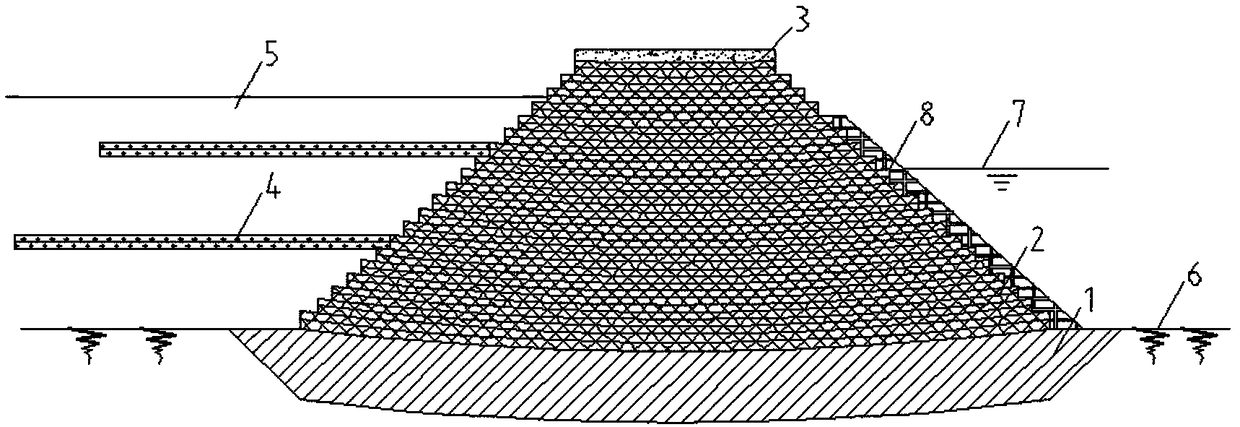

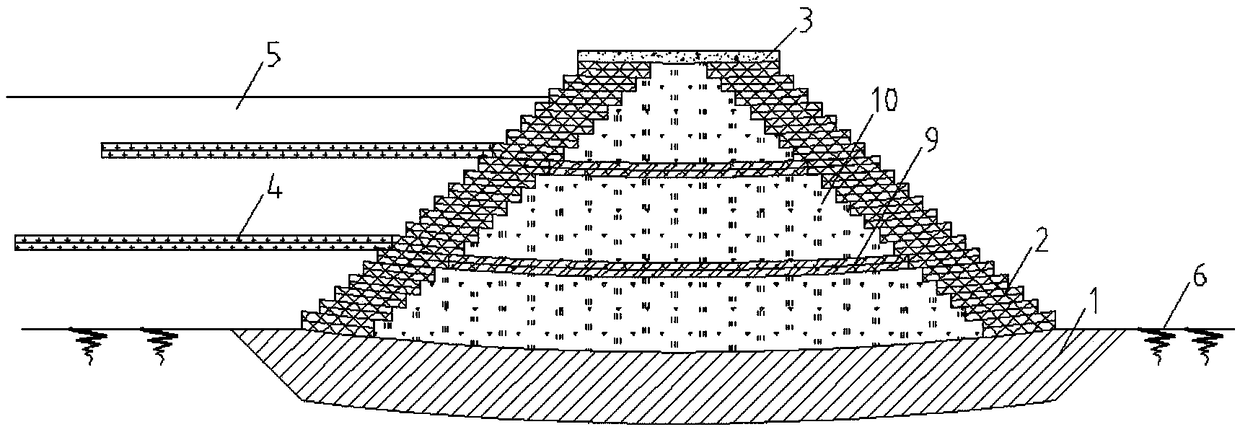

Geocell cofferdam and construction method thereof

PendingCN109056654AImprove integrityImprove adaptabilityLand reclamationSoil preservationGeocellsEngineering

The invention provides a geocell cofferdam, wherein a main body of the earthwork standard room cofferdam is formed by multiply layers of geogrids, and geocells of the geogrids are filled with sand ordetritus or clay to form the cofferdam. The invention further provides another geocell cofferdam, wherein two side slopes are formed by erecting multiple layers of geogrids, and breakwater core soil is filled between two side slopes. According to the invention, the cofferdam slopes have good integrity and sedimentation adaptability, have powerful lateral limitation and high rigidity and can fulfill the aims of enlarging a slope ratio of the slopes, reducing a cofferdam section, reducing material outward transport cost and saving engineering cost.

Owner:HYDRAULIC SURVEY & DESIGN RES INST OF TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com