Manufacturing method of surface modified artificial skull prosthesis

A technology of surface modification and production method, which is applied in the field of biomedical materials, can solve problems such as unsatisfactory cross-linking effect, failure to comprehensively consider soft tissue bonding performance, and the effect of low radiation dose, so as to avoid excessive water loss rate , easy to implement, and improve the effect of combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 of the present invention provides a method for making a surface-modified artificial skull prosthesis, comprising the following steps in order:

[0036] Step S1 uses a 3D printer to print the solid PEEK skull restoration;

[0037] Step S2 Use a movable handle louver and sandpaper to polish the solid PEEK skull prosthesis until there are no obvious burrs and scratches, and then place it in 90% concentrated sulfuric acid for 1 minute in a water bath at 100°C to corrode the surface to form an etched surface. holes, the diameter of the pits is distributed in the range of 0.01-0.1mm; then ultrasonically cleaned in deionized water for 5 minutes, repeated 3 times; then placed in 75% ethanol for 5 minutes, finally taken out and placed in a sterile glass petri dish, room temperature Transfer to biosafety box after drying;

[0038] Step S3 Prepare a type I collagen solution with a concentration of 0.8 mg / mL in PBS buffer in a biosafety box, immerse the PEEK skull rep...

Embodiment 2

[0042] Embodiment 2 of the present invention provides a method for making a surface-modified artificial skull prosthesis, comprising the following steps in order:

[0043] Step S1 uses a 3D printer to print the solid PEEK skull restoration;

[0044] Step S2 Use a movable handle louver and sandpaper to polish the solid PEEK skull prosthesis until there are no obvious burrs and scratches, and then place it in 90% concentrated sulfuric acid for 1 minute in a water bath at 100°C to corrode the surface to form an etched surface. holes, the diameter of the pits is distributed in the range of 0.01-0.1mm; then ultrasonically cleaned in deionized water for 5 minutes, repeated 3 times; then placed in 75% ethanol for 5 minutes, finally taken out and placed in a sterile glass petri dish, room temperature Transfer to biosafety box after drying;

[0045] Step S3 Use PBS buffer solution to prepare type I collagen solution with a concentration of 1.2 mg / mL in the biosafety box, immerse the P...

Embodiment 3

[0049] Embodiment 3 of the present invention provides a method for making a surface-modified artificial skull prosthesis, comprising the following steps in order:

[0050] Step S1 Use a 3D printer to print a solid PEEK skull restoration;

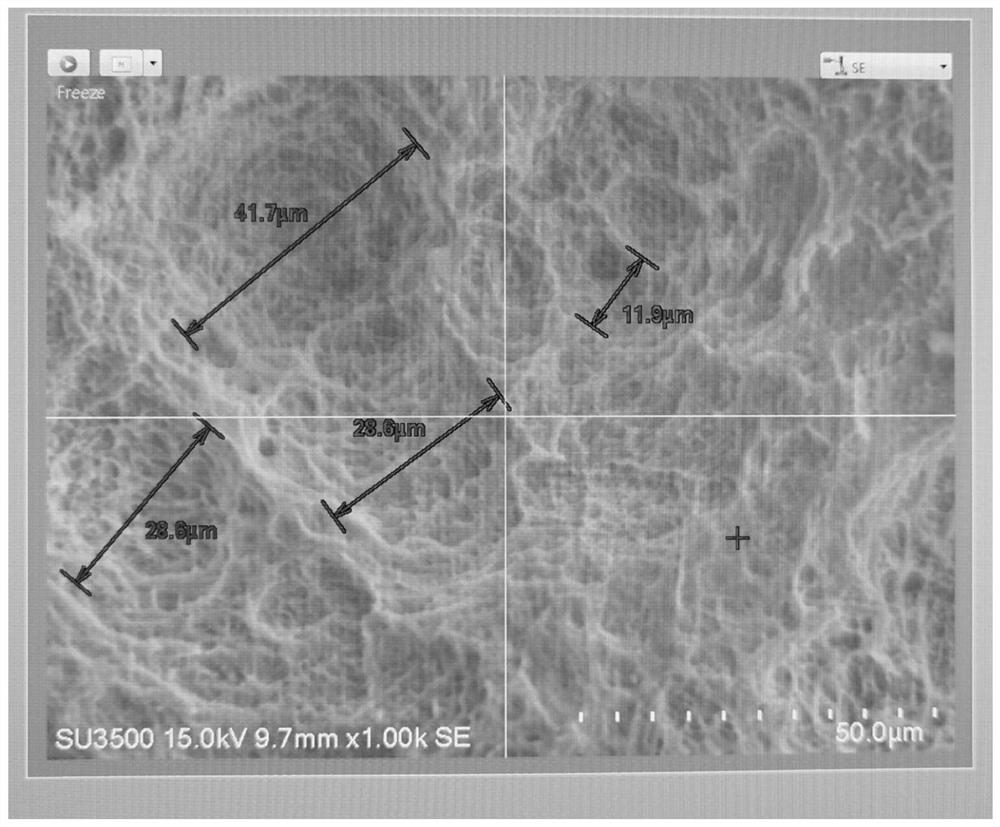

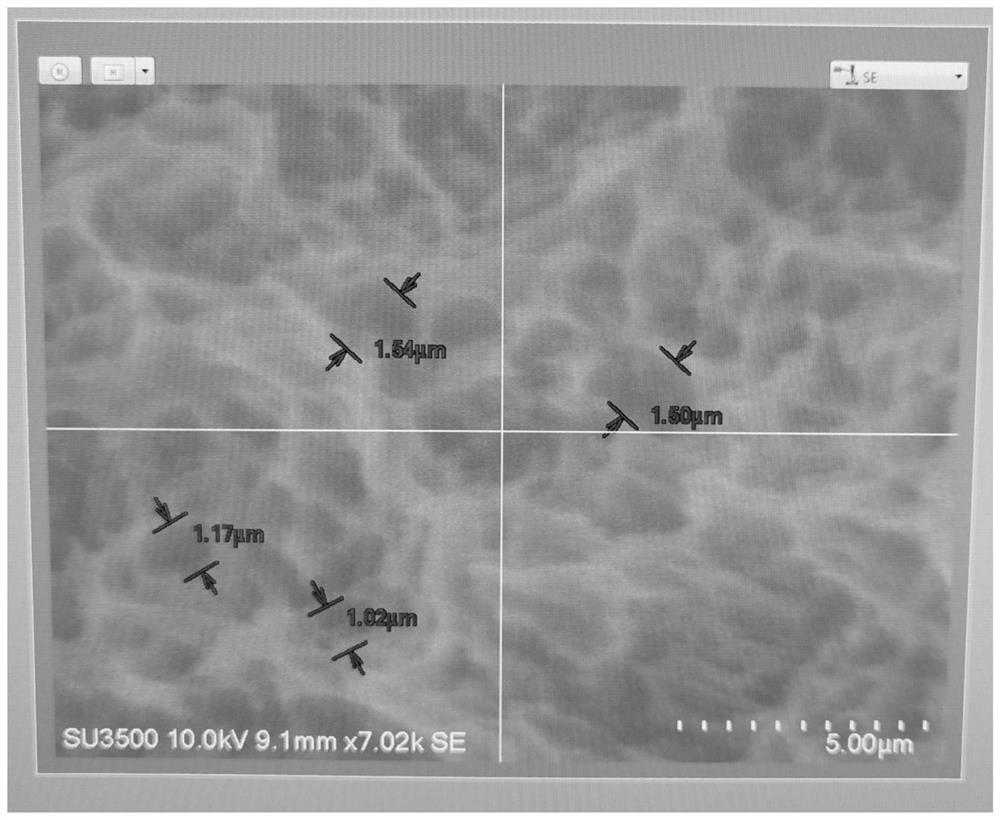

[0051] Step S2 Polish the solid PEEK skull prosthesis with a movable louver and sandpaper until there are no obvious burrs and scratches, and then place it in 90% concentrated sulfuric acid in a water bath at 100°C for 1 minute to corrode the surface, and the surface corrodes to form corrosion pits. The diameter distribution of the pits is 0.01-0.1mm (such as figure 1 shown); then ultrasonically cleaned in deionized water for 5 minutes, repeated 3 times, then placed in 75% ethanol for 5 minutes, finally removed and placed in a sterile glass petri dish, dried at room temperature and transferred to a biological safety box;

[0052] Step S3 Prepare a type I collagen solution with a concentration of 1 mg / mL in PBS buffer in a biosafety box, imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com