Anti-suspension device, system and method based on shield segment

A technology of shield segment and suspension device, which is applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of not conforming to the tunnel, the floating of the ring segment deviates from the original positioning, etc., so as to enhance the integrity and ensure the compactness. Effects of uniformity and uniformity, safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

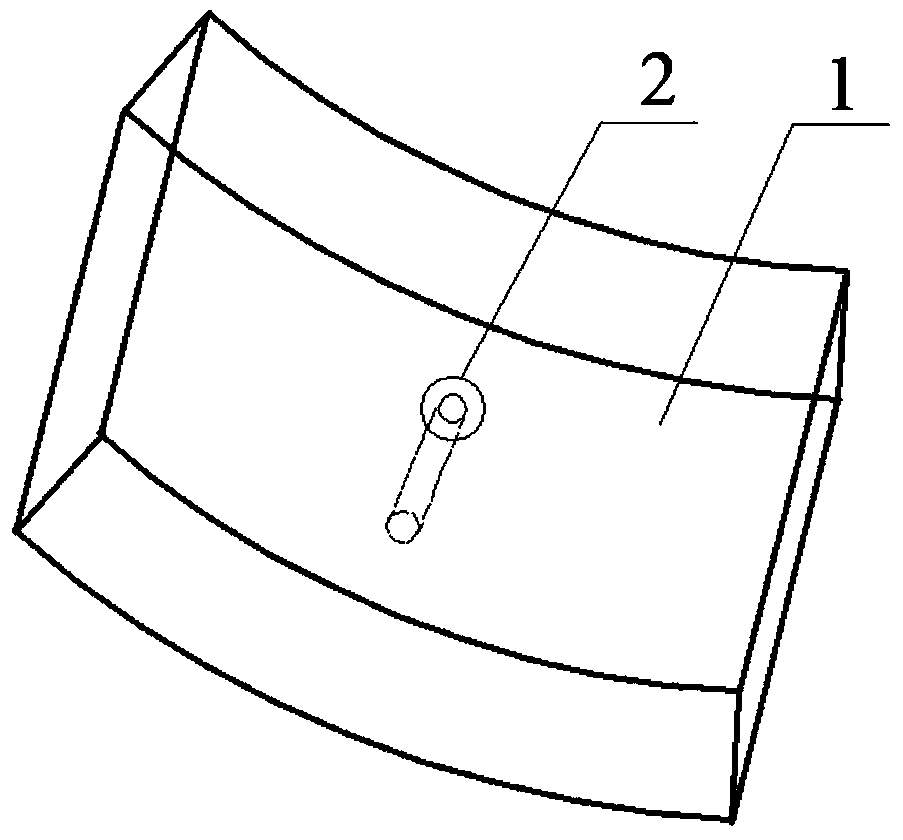

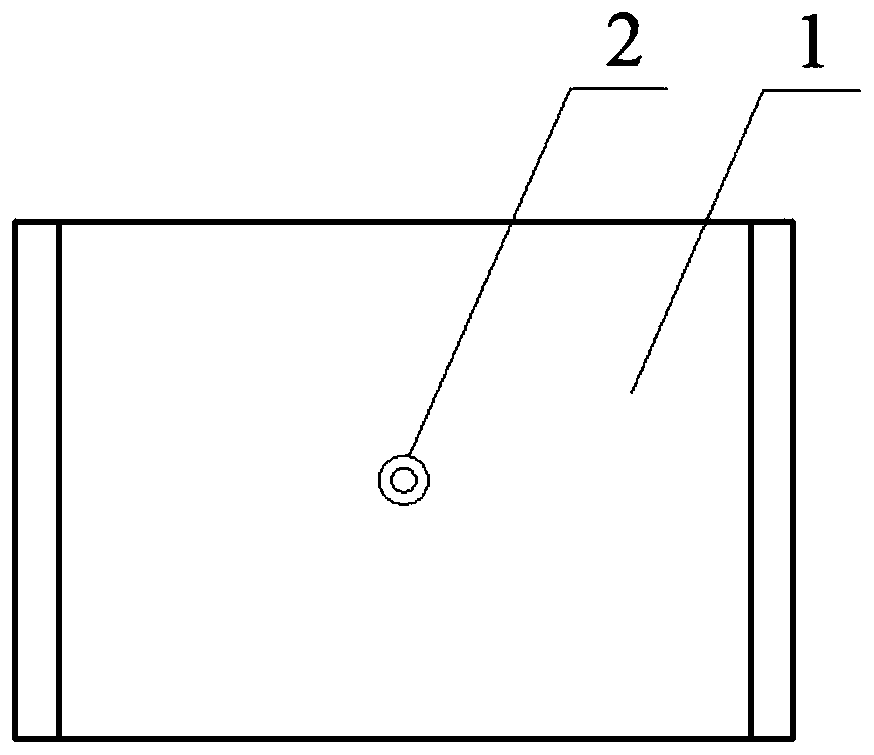

[0030] Attached below Figure 1-Figure 6 The present invention is described in detail, specifically, the structure is as follows:

[0031] This embodiment provides an anti-suspension device based on a shield segment, including a shield segment 1 and anchoring grouting bolts 3 , and the shield segment 1 is provided with a bolt hole 2 for inserting the anchoring grouting bolt 3 .

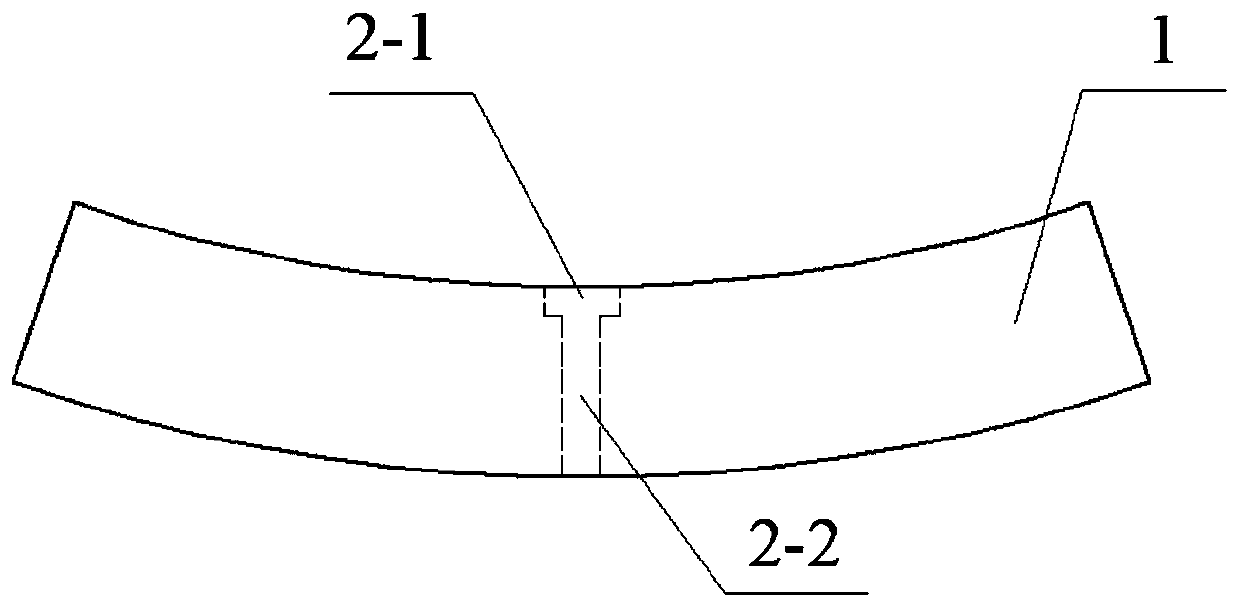

[0032] like image 3 As shown, the bolt hole 2 is located at the center of the shield segment 1, so that the force on the shield segment 1 is relatively uniform. The bolt hole 2 includes a first round hole 2-1 and a second round hole 2-2 arranged coaxially, and the diameter of the first round hole 2-1 is larger than the diameter of the second round hole 2-2. The second round hole 2-2 is provided with an internal thread.

[0033] like Figure 4 As shown, a grouting hole 3-4 is reserved in the center of the anchoring grouting bolt 3 for inserting a grouting pipe, and the grouting hole 3-4 runs throu...

Embodiment 2

[0038] This embodiment provides an anti-suspension system based on shield segments, such as Figure 8 As shown, it includes a plurality of anti-suspension devices described in Embodiment 1, and a plurality of shield segments 1 are assembled together to form a ring structure. In this embodiment, six shield segments 1 form a ring, and since the bolt hole 2 is located at the center of the end shield segment 1, the force on the shield segment 1 is relatively uniform, and the overall structure of the shield segment 1 is enhanced sex.

[0039] like Figure 7 As shown, a waterproof gasket 6 is provided between the anchoring grouting bolt 3 and the bolt hole 2 to prevent groundwater behind the shield segment 1 from flowing into the tunnel along the reserved bolt hole 2 . In this embodiment, the waterproof gasket 6 is a rubber gasket. It can be understood that in other embodiments, the waterproof gasket 6 can also use other waterproof materials.

Embodiment 3

[0041] This embodiment provides a construction method of an anti-suspension system based on a shield segment, specifically as follows:

[0042] After the shield segment 1 is assembled into a ring, the shield machine continues to drive forward, and the anchor grouting bolt 3 is driven through the bolt hole 2, and a waterproof gasket 6 is added between the anchor grouting bolt 3 and the shield segment 1. After the installation of the anchoring grouting bolt 3 is completed, the grouting pipe is inserted into the bottom of the bolt through the grouting hole 3-4, and the grouting pipe is connected to the grouting instrument. The fiber quick-setting liquid 5 is injected through the grouting pipe, and the polymer film 4 rapidly expands to the surrounding under the action of the grouting pressure, increasing the contact area with the surrounding rock 7 .

[0043] When the surrounding rock 7 is weak soil, part of the anchoring grouting bolts 3 will enter the soil. At this time, the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com