Embedded anchoring type concrete crack repairing process

A crack repair and concrete technology, used in building maintenance, construction, building construction, etc., can solve the problems of lack of repair strength, shedding of repair parts, and high-strength bonding of repair materials not easy to crack ends, so as to improve mechanical strength, improve The effect of joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

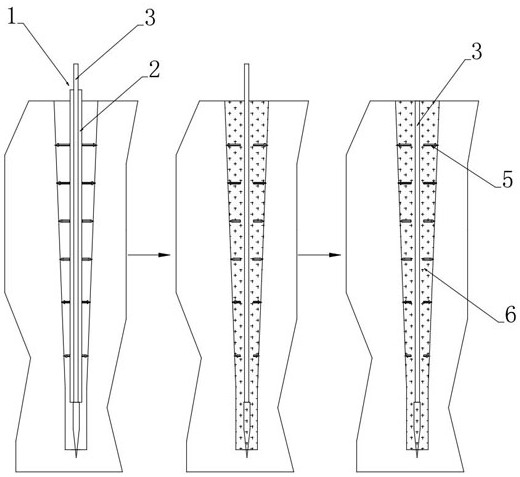

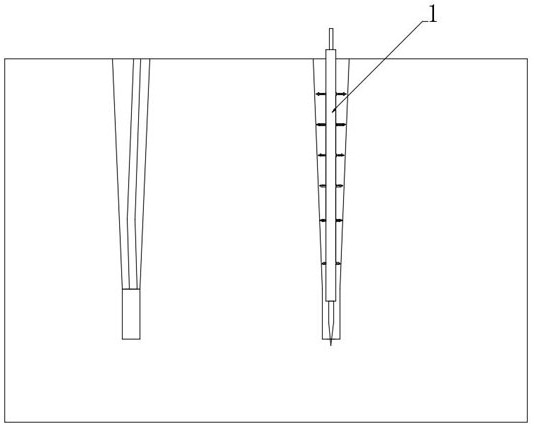

[0044] see Figure 1-4 , a pre-embedded anchor type concrete crack repair process, comprising the following steps:

[0045] S1. Opening the repairing cavity along the concrete crack position, the repairing cavity is preferably a V-shaped structure, and cleaning the repairing cavity;

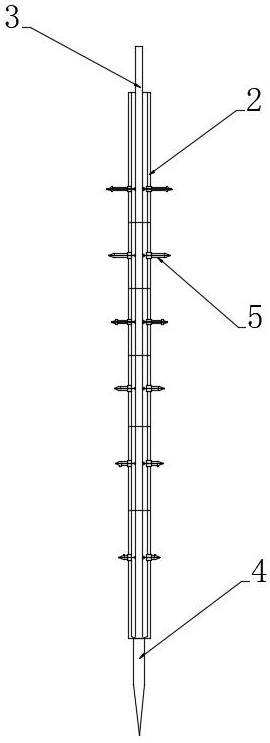

[0046] S2. Put the repair rod 1 into the repair groove cavity. The repair rod 1 is composed of the outer insertion rod 2 and the inner embedded rod 3 nested inside and outside. The bottom end of the inner embedded rod 3 is fixedly connected with a tapered material guide part 4 , the outer wall of the outer insertion rod 2 is provided with a plurality of transverse anchor rods 5 whose inner ends are bonded to the outer wall of the inner pre-embedded rod 3, and the bottom end of the repair rod 1 is inserted into the inner bottom of the repair cavity;

[0047] S3. Inject the preheated crack repairing agent into the repairing cavity through the internal pre-embedded rod 3. The crack repairing agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com