Preparation method of zirconium dioxide modified layered porous vermiculite loaded nickel-based catalyst

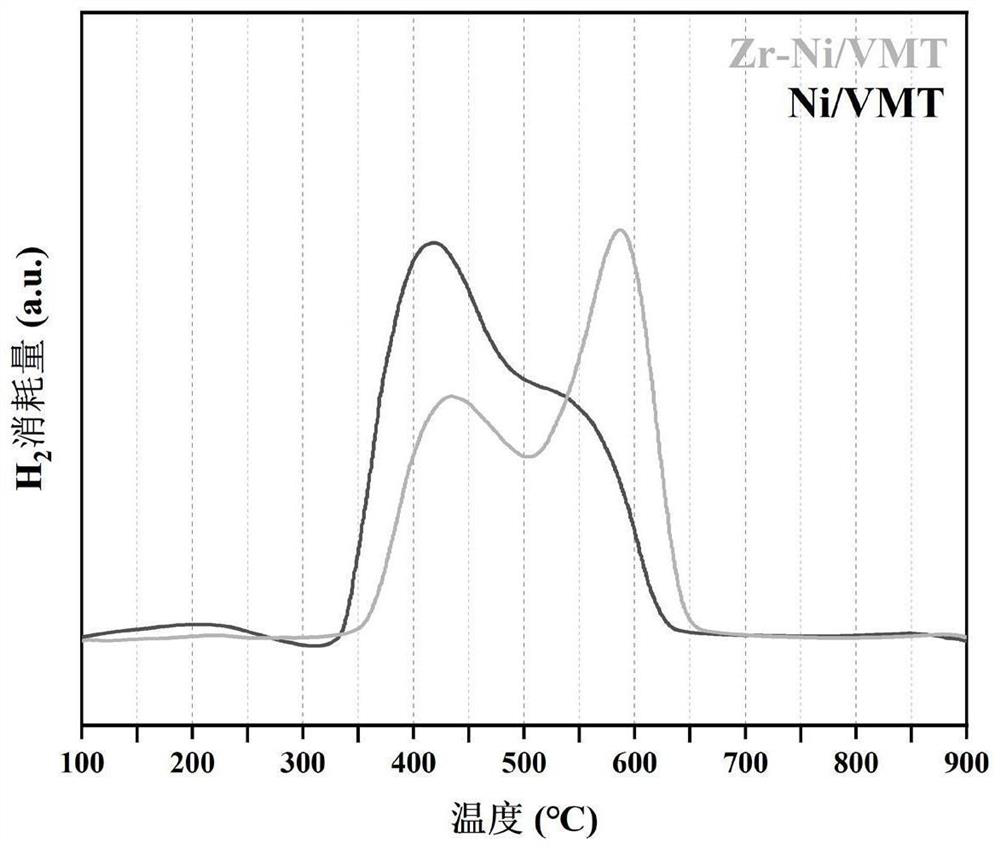

A technology of zirconium dioxide and modified layer is applied in the field of preparation of zirconium dioxide-modified layered porous vermiculite-supported nickel-based catalyst, and can solve the problems of affecting the diffusion of reaction gas and products, reducing reaction activity, blocking pores and the like, Achieve the effect of improving adsorption and activation ability, strong resistance to metal agglomeration, and inhibiting sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Preparation of acidified two-dimensional layered porous vermiculite: Mix 10g of ball-milled commercial expanded vermiculite (100 mesh) with 200mL3mol / L hydrochloric acid solution to prepare a suspension with a solid-to-liquid ratio of 1:20. 3mol / L hydrochloric acid is Prepared by dissolving 50mL of 36-38% concentrated hydrochloric acid in 150mL of deionized water. The suspension was vigorously stirred and refluxed at 800 rpm at 80°C for 4 hours; the obtained bright yellow precipitate was filtered and washed with deionized water until the filtrate was neutral, and the obtained solid was dried overnight at 100°C. The vermiculite powder carrier treated with 3mol / L hydrochloric acid was obtained.

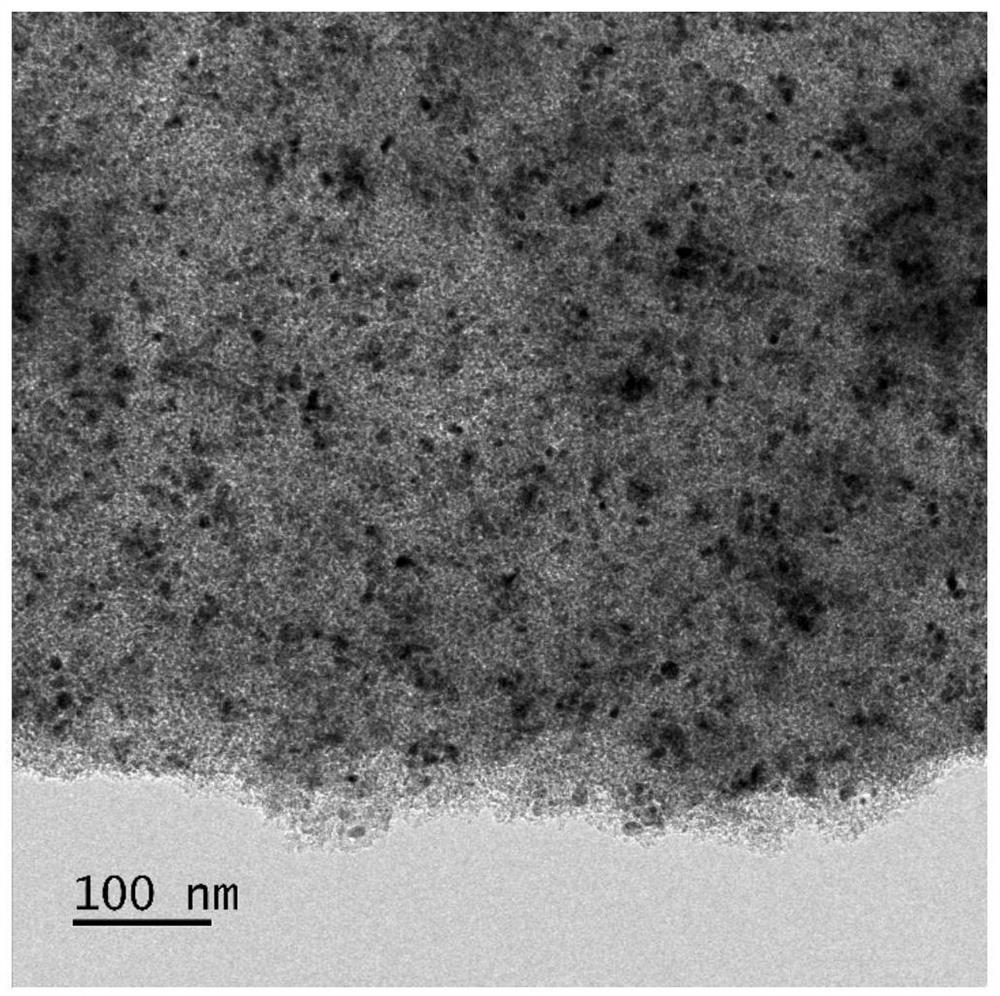

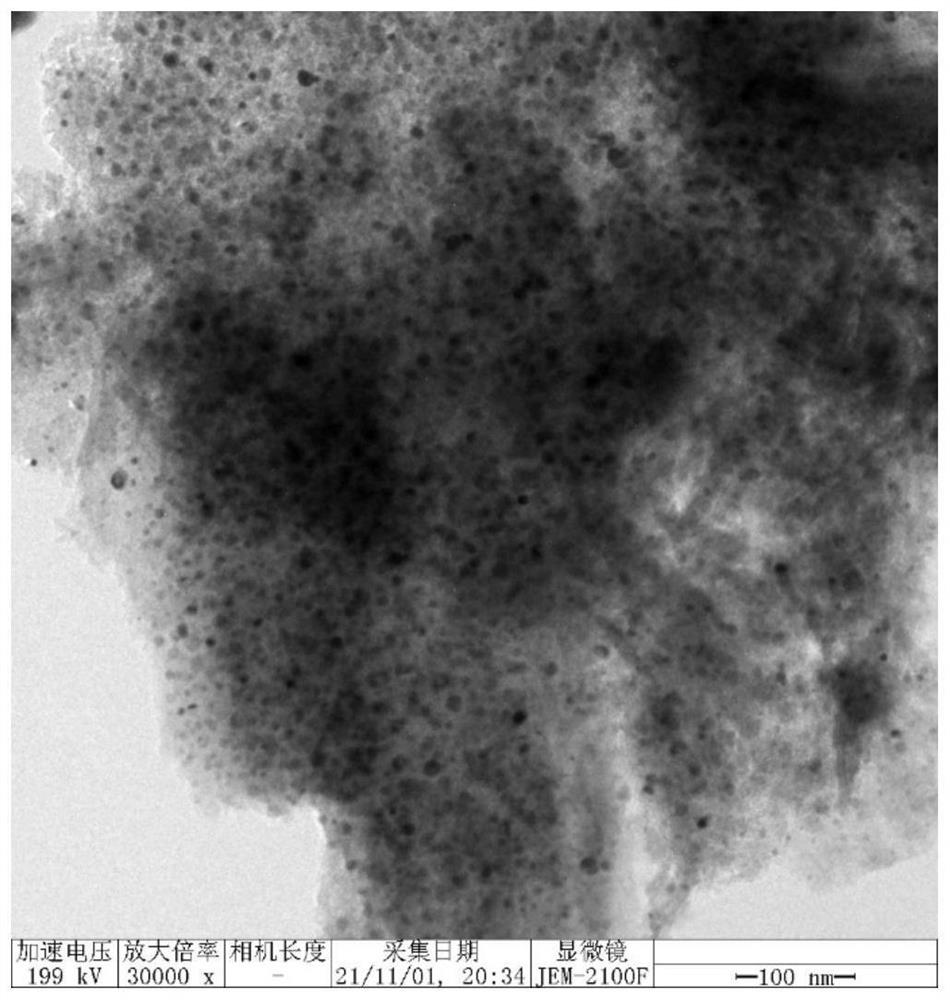

[0039] Preparation of zirconia-modified layered porous vermiculite-supported nickel-based catalyst: Take 1 g of the acid-treated vermiculite powder carrier prepared above, vacuum-dry at 80° C. to remove water vapor in the channels, and test the water absorption. The specific step...

Embodiment 2

[0042] Preparation of acidified two-dimensional layered porous vermiculite: Mix 10g of ball-milled commercial expanded vermiculite (100 mesh) with 200mL3mol / L hydrochloric acid solution to prepare a suspension with a solid-to-liquid ratio of 1:20. 3mol / L hydrochloric acid is Prepared by dissolving 50mL of 36-38% concentrated hydrochloric acid in 150mL of deionized water. The suspension was vigorously stirred and refluxed at 80°C for 4 hours; the obtained bright yellow precipitate was filtered and washed with deionized water until the filtrate was neutral, and the obtained solid was dried at 100°C overnight to obtain a 3mol / Vermiculite powder carrier after L hydrochloric acid treatment.

[0043] Preparation of zirconia-modified layered porous vermiculite-supported nickel-based catalyst: Take 1 g of the acid-treated vermiculite powder carrier prepared above, vacuum-dry at 80° C. to remove water vapor in the channels, and test the water absorption. The specific steps are: under...

Embodiment 3

[0046] Other steps are the same as in Example 1, changing the firing temperature to 450°C. The catalyst activity test conditions were the same as in Example 1, and the conversion rates of methane and carbon dioxide were 68% and 70% respectively. Rapid inactivation at 750°C, the reason for inactivation may be that the calcination temperature is too low and the active center does not form a strong interaction with the carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com