Nanoparticle-graphene-foamed nickel composite material with bionic structure, and preparation method thereof

A nanoparticle and composite material technology, applied in the field of nanoparticle-graphene-nickel foam composite material and its preparation, can solve the problem of two-dimensional structure catalysts easy to accumulate, low effective surface area, uneven distribution of reduced metal particles, poor cycle performance, etc. problems, to achieve the effect of enriching redox sites, increasing the effective surface area, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A kind of preparation method of the CoNiP nanoparticle-graphene-nickel foam composite material of biomimetic structure concrete steps are as follows:

[0062] Step 1) Preparation of the graphene-nickel foam composite carrier with a skeleton-skin structure, the nickel foam with a size of 2 × 4cm is washed repeatedly with acetone, 6mol / L hydrochloric acid solution, ethanol and deionized water, and the washed Nickel foam is placed in a graphene oxide suspension with a concentration of 3mg / mL under the conditions of a water bath temperature of 60-80°C and a water bath time of 24-30h for soaking in a water bath, and then washed and dried to obtain a skeleton-skin structure. Graphene-nickel foam composite carrier, denoted as Ni / GF;

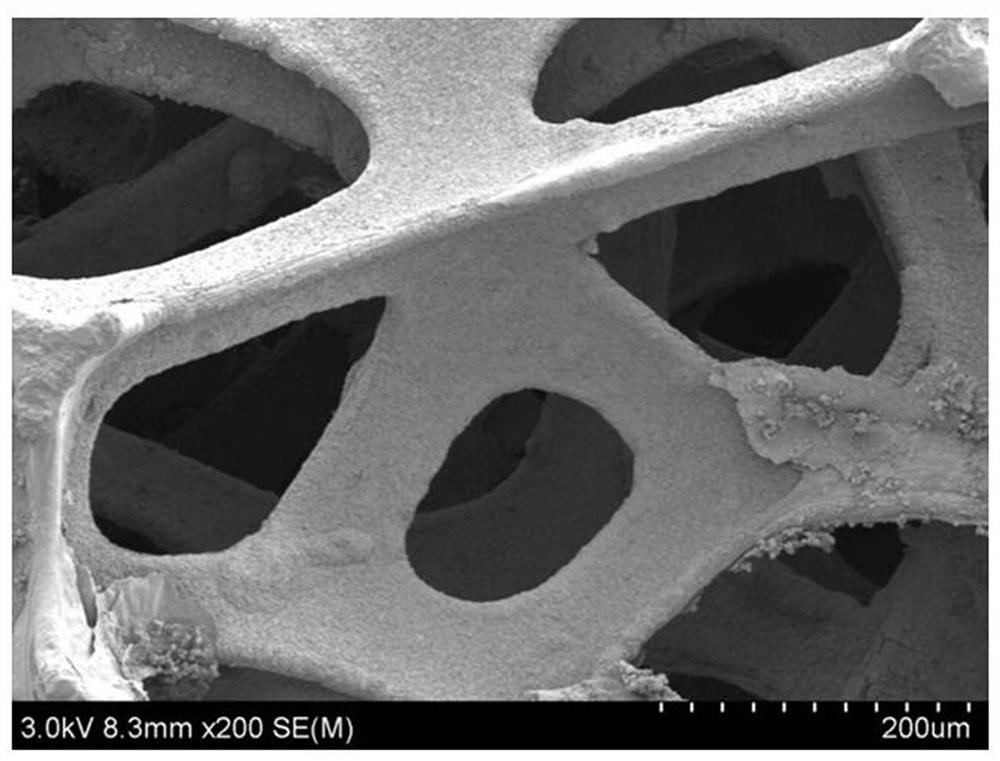

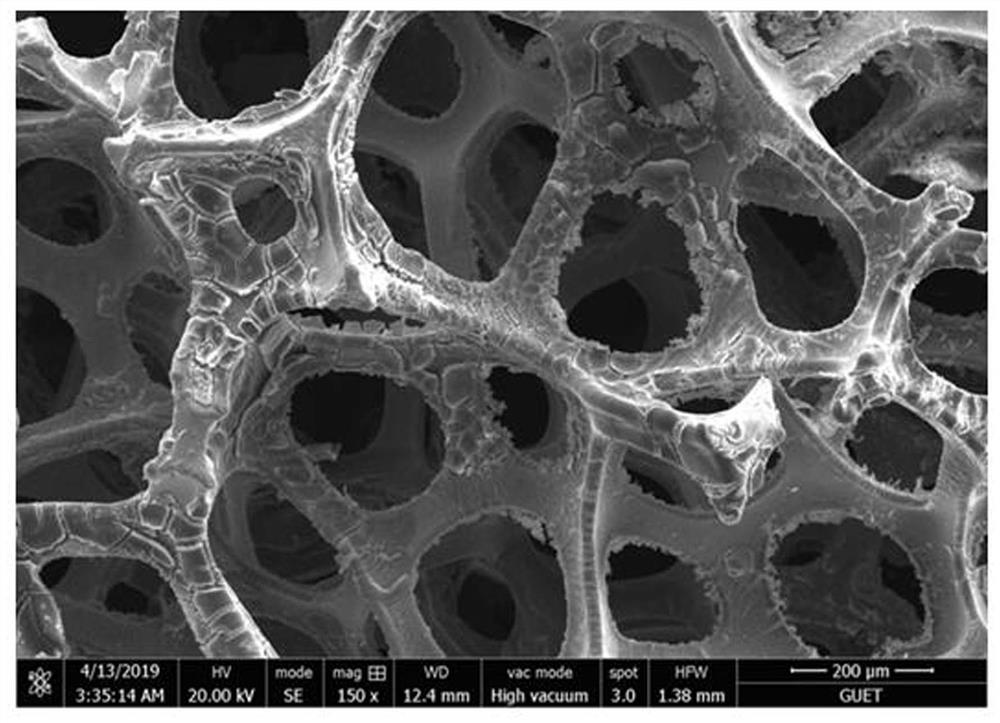

[0063] In order to prove that the Ni / GF obtained in step 1 has a skeleton-skin structure, SEM tests were carried out on the washed nickel foam and graphene-nickel foam composite supports. Test results such as figure 1 with figure 2 as shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com