Geocell cofferdam and construction method thereof

A technology of geocells and construction methods, applied in the field of port engineering, to achieve the effects of reducing the cost of foreign transportation, improving stability, good integrity and settlement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

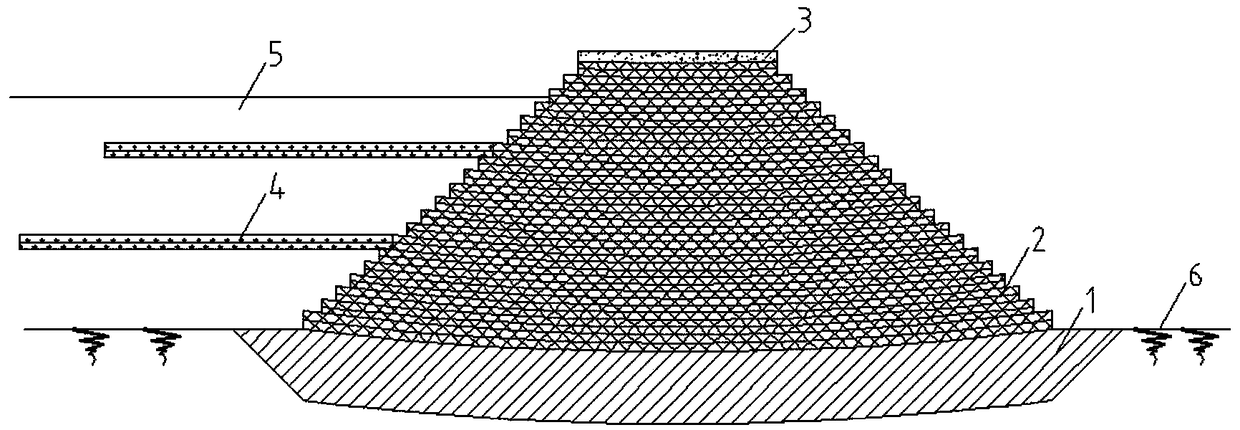

[0034] Embodiment 1 (as figure 1 ):

[0035] The utility model relates to an enclosure of a geocell, the main body of which is a multi-layer geogrid, and the cells of the geogrid are filled with sand, gravel or soil to form an enclosure. Set up inland side tie bars on the inner side slope of the enclosure.

[0036] The construction method is:

[0037] 1. On the completed foundation (according to the actual situation, adopt corresponding foundation treatment measures), lay the geocell filling layer upward in sequence;

[0038] 2. Each layer of geocell retracts inward for a certain distance to form a certain slope;

[0039] 3. When the filling layer of the geocell is laid to a certain height, the filling starts. It is necessary to choose whether to set the inland side tie bar at the same time of filling;

[0040] 4. Alternately carry out the laying and filling of geocell fill layers until the top of the enclosure;

[0041] 5. Each geocell is connected with the upper and low...

Embodiment 2

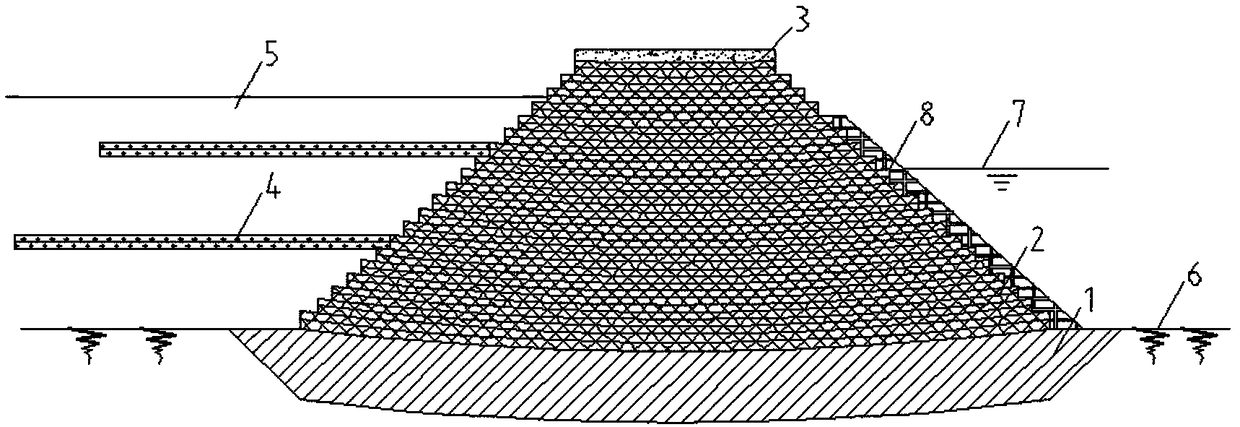

[0043] Embodiment 2 (as figure 2 ):

[0044] The utility model relates to an enclosure of a geocell, the main body of which is a multi-layer geogrid, and the cells of the geogrid are filled with sand, gravel or soil to form an enclosure. Set up inland side tie bars on the inner side slope of the enclosure. Set up the protective surface on the side facing the sea.

[0045] The construction method is:

[0046] 1. On the completed foundation (according to the actual situation, adopt corresponding foundation treatment measures), lay the geocell filling layer upward in sequence;

[0047] 2. Each layer of geocell retracts inward for a certain distance to form a certain slope;

[0048] 3. When the filling layer of the geocell is laid to a certain height, the filling starts. It is necessary to choose whether to set the inland side tie bar at the same time of filling;

[0049] 4. Alternately carry out the laying and filling of geocell fill layers until the top of the enclosure; ...

Embodiment 3

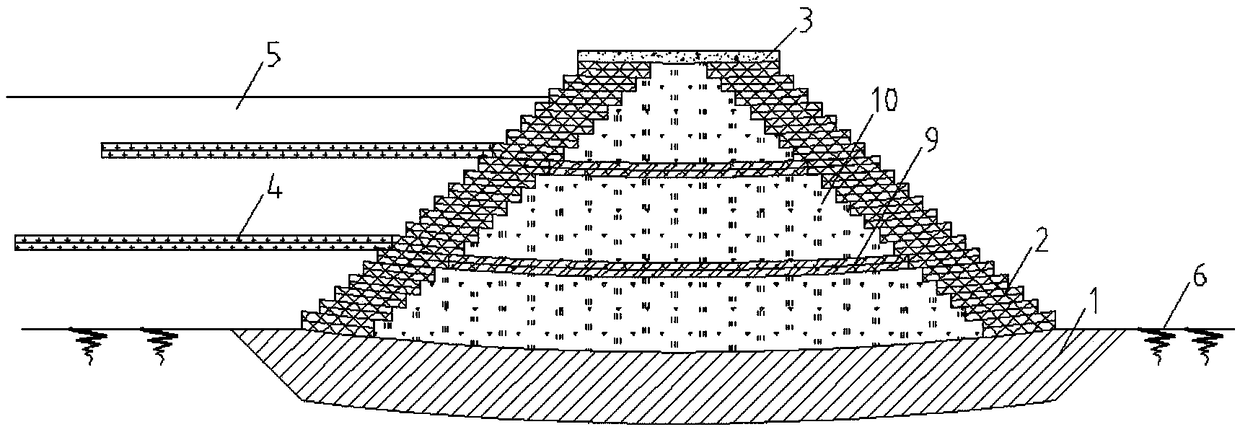

[0053] Embodiment 3 (as image 3 ):

[0054] The utility model relates to a geocell enclosure, in which side slopes on both sides are formed by multi-layer geogrids, and embankment core soil is filled between the side slopes. In the core soil of the embankment, an inner tie bar is set to connect the geogrid slopes on both sides. Set the inland side tie bars on the inner side slope.

[0055] The construction method is:

[0056]1. On the completed foundation (according to the actual situation, adopt corresponding foundation treatment measures), lay the geocell filling layer upward in sequence;

[0057] 2. Each layer of geocell retracts back a certain distance to form a certain slope;

[0058] 3. Fill the embankment core soil between the two side slopes formed by the geocell until the top of the enclosure;

[0059] 4. Set the internal tension belt at the appropriate position in the filling layer;

[0060] 5. According to the needs, choose whether to set the inland side tie ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com