Steel tube truss grouting reinforcing and supporting structure for high-stress weak broken surrounding rocks

A technology for crushing surrounding rock and steel pipe trusses, applied in shaft lining, tunnel lining, underground chambers, etc., can solve problems such as limited bearing capacity, poor overall performance, and small application range, and achieve improved bearing performance, good integrity, and The overall performance of the structure is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] All components of the present invention are high-strength, high-rigidity steel materials, and the shape and size of the components are made according to the profile of the roadway. In this example, only the rectangular roadway is used for introduction:

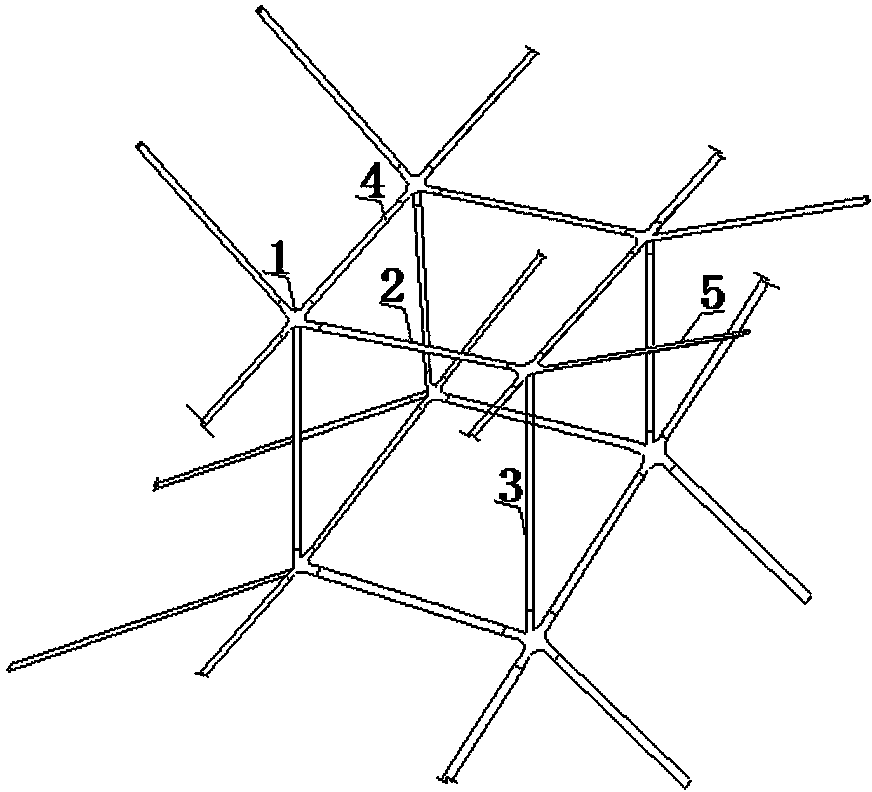

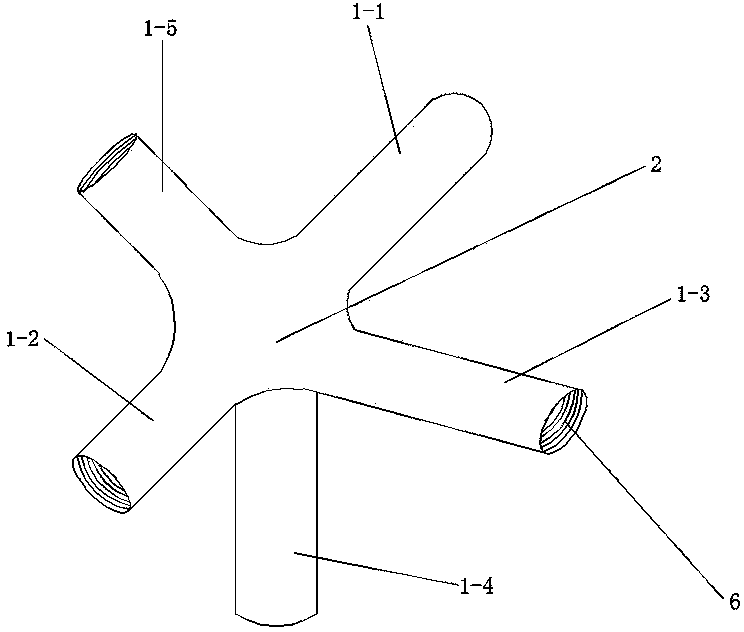

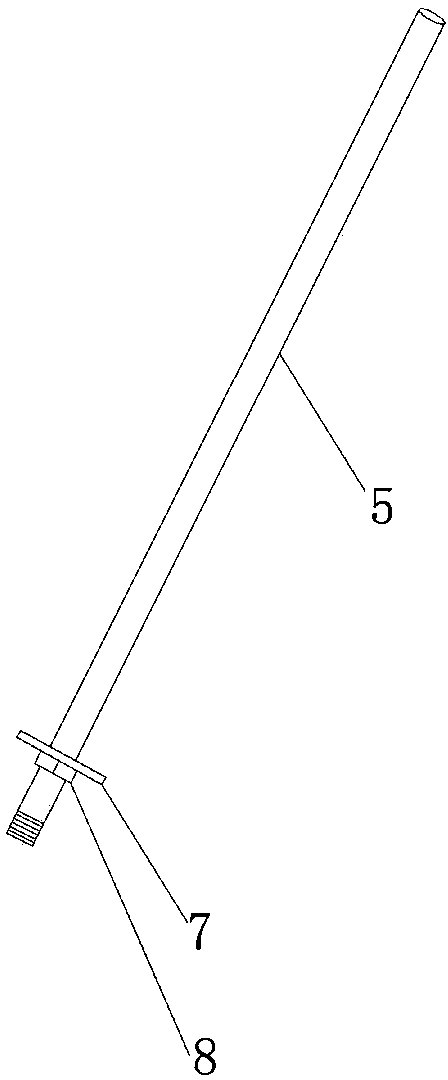

[0021] Such as figure 1 , figure 2 As shown, the present invention includes a five-way joint 1, a push rod 2, a side bar 3, a shoulder bar 4 and a grouting anchor 5, and the five-way joint 1 includes a first interface 1-1, a second interface 1-2, The third interface 1-3, the fourth interface 1-4 and the fifth interface 1-5, and the five interfaces communicate with each other, wherein the first interface 1-1 and the second interface 1-2 are located on the same axis, and the fifth interface The five interfaces 1-5, the third interface 1-3, and the fourth interface 1-4 are located in the same pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com