High-stress impact burst roadway anchor rod, design method and work method

A technology of rock burst and high stress, which is applied in the installation of bolts, calculations, mining equipment, etc., can solve the problems of high pre-tightening force, reduced bearing capacity, low anchoring force, etc., and achieve high anchoring force and high pre-tightening force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

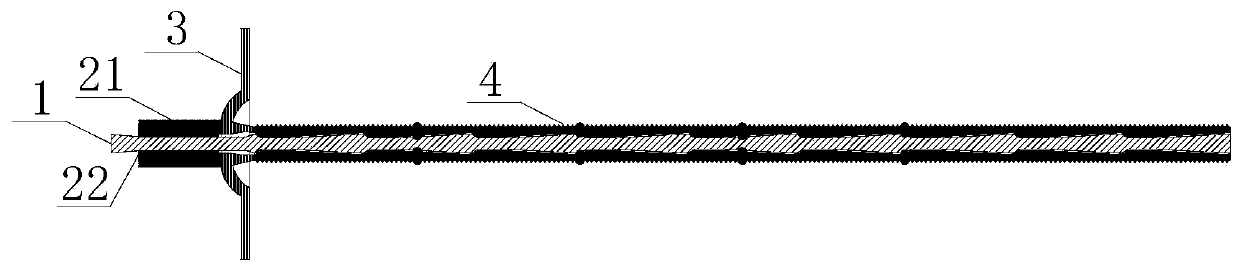

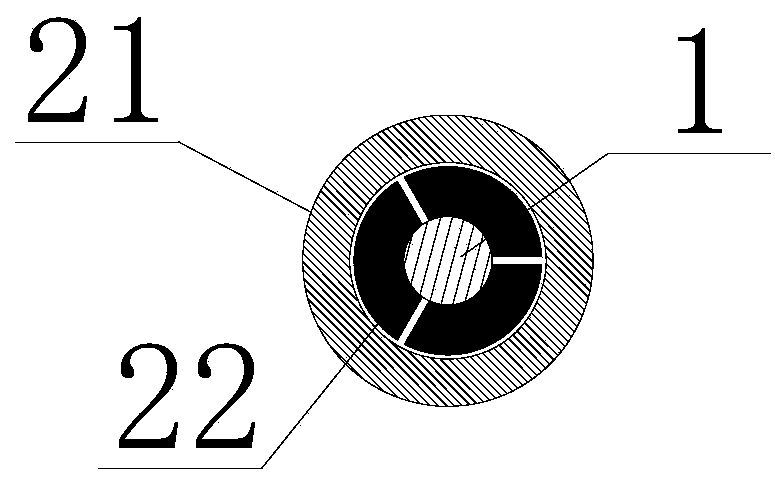

[0047] Such as figure 1 As shown, the high-stress impact ground pressure roadway bolt of the present invention includes a nodular bolt body 1, a bolt tail lock, a force transmission tray 3 and a sleeve 4;

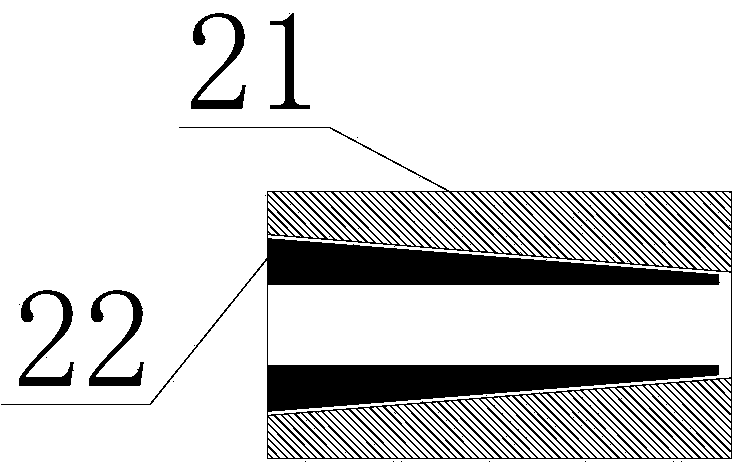

[0048] The nodular anchor rod body 1 is provided with protrusions at intervals, and the protrusions are spherical protrusions or spindle-shaped protrusions; the tail end of the nodular anchor rod body 1 is provided with threads, and the threads are sequentially provided with a force transmission tray 3 and A bolt tail lock, the nodular anchor rod body 1 is provided with a sleeve 4, the sleeve 4 is a metal tube with a through-slit in the axial direction, the outside of the metal tube is provided with fine threads, and the inside of the metal tube is provided with a nodular The protrusion on the anchor rod body 1 is a concave structure that matches the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com