Beam strengthening method

A beam and anchoring technology, used in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of difficult material strength, low strength of shotcrete, poor anchoring performance, etc., to overcome high maintenance costs, strong effectiveness and Economical, stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

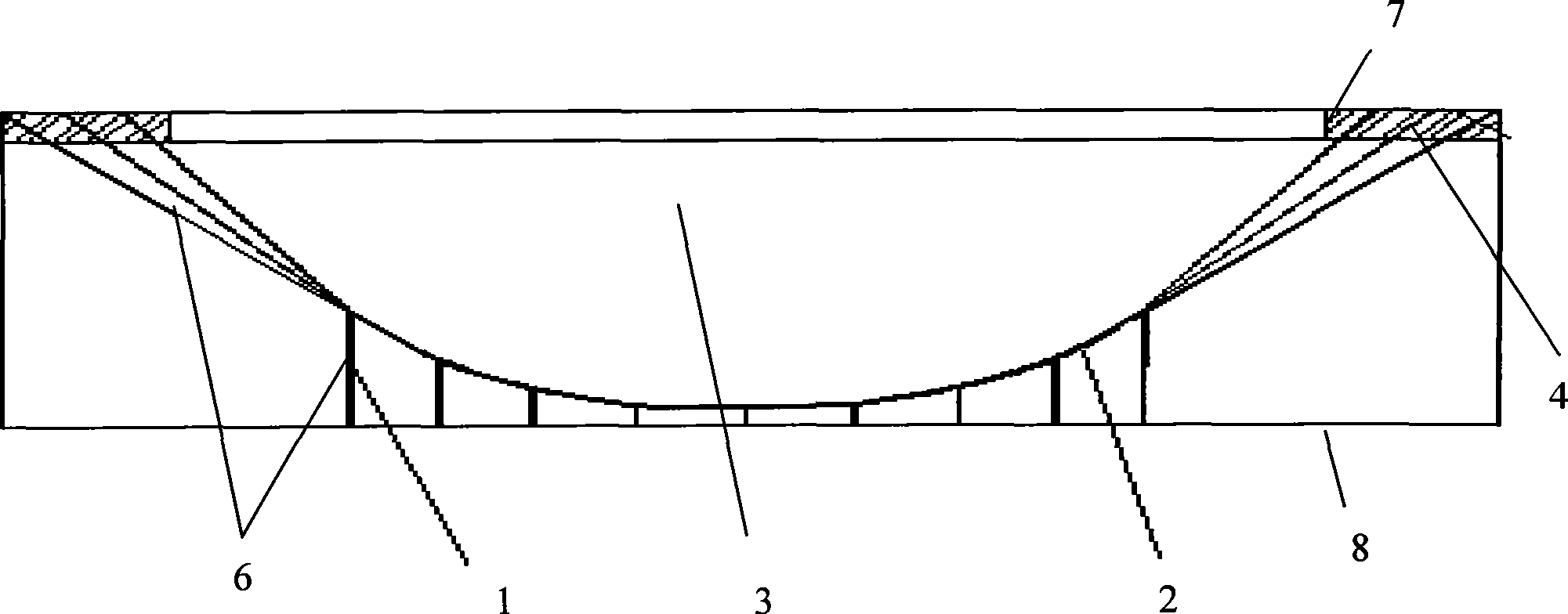

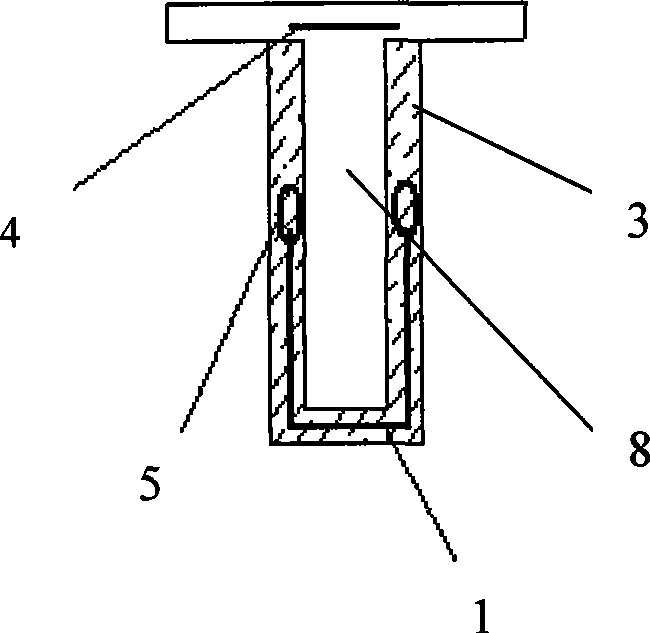

[0025] A T-shaped simply supported girder bridge has a total length of 470m and 33 holes. Due to the development of transportation, the load standard needs to be increased from steam-13 and tow-60 to steam-20 and hang-100. After testing, it was found that some T-beams of the whole bridge had a small amount of cracks due to years of operation, but the health status was acceptable. The following beam reinforcement methods were used to strengthen the bridge to achieve the purpose of improving its bearing capacity. After reinforcement, the beam structure is as figure 1 so and figure 2 shown.

[0026] A beam reinforcement method comprises the following steps:

[0027] Step (1) Drilling and slotting: chisel the anchor groove 7 on the top surface of the beam body 8 first, drill holes along the sides of the beam rib according to the designed inclination, and chisel out the fixed side along the web according to the design according to the parabolic shape Set the positioning groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com