Construction method of cast-in-place drainage ditch

A construction method and drainage ditch technology, applied in the field of drainage engineering, can solve the problems of narrow construction site, complex construction technology, and large impact on current traffic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

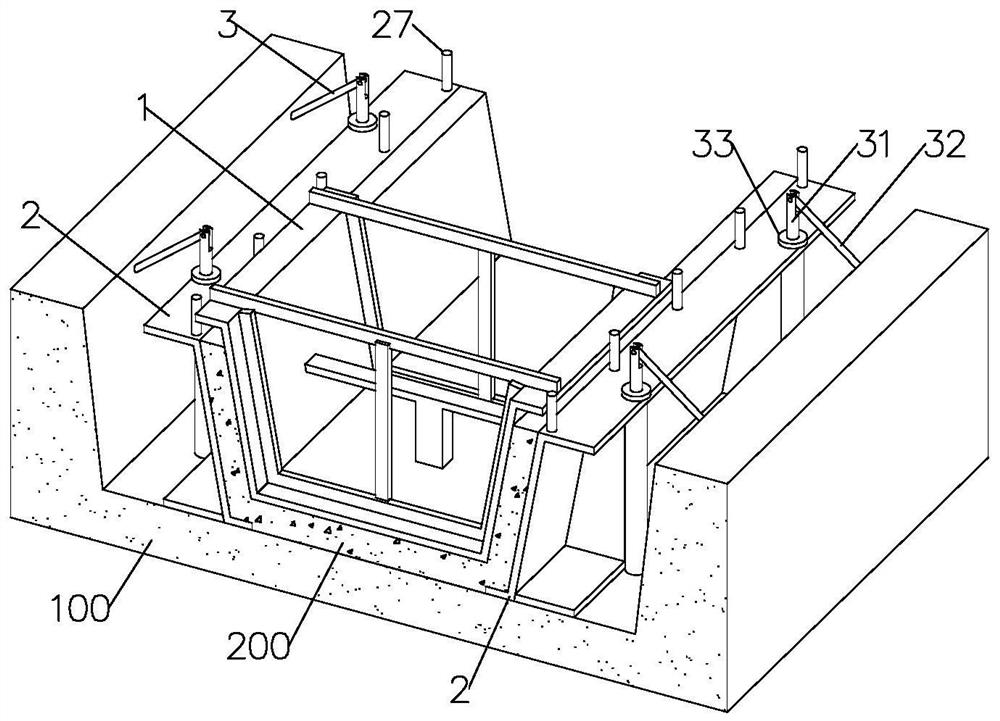

[0044] The following is attached Figure 1-4 The application is described in further detail.

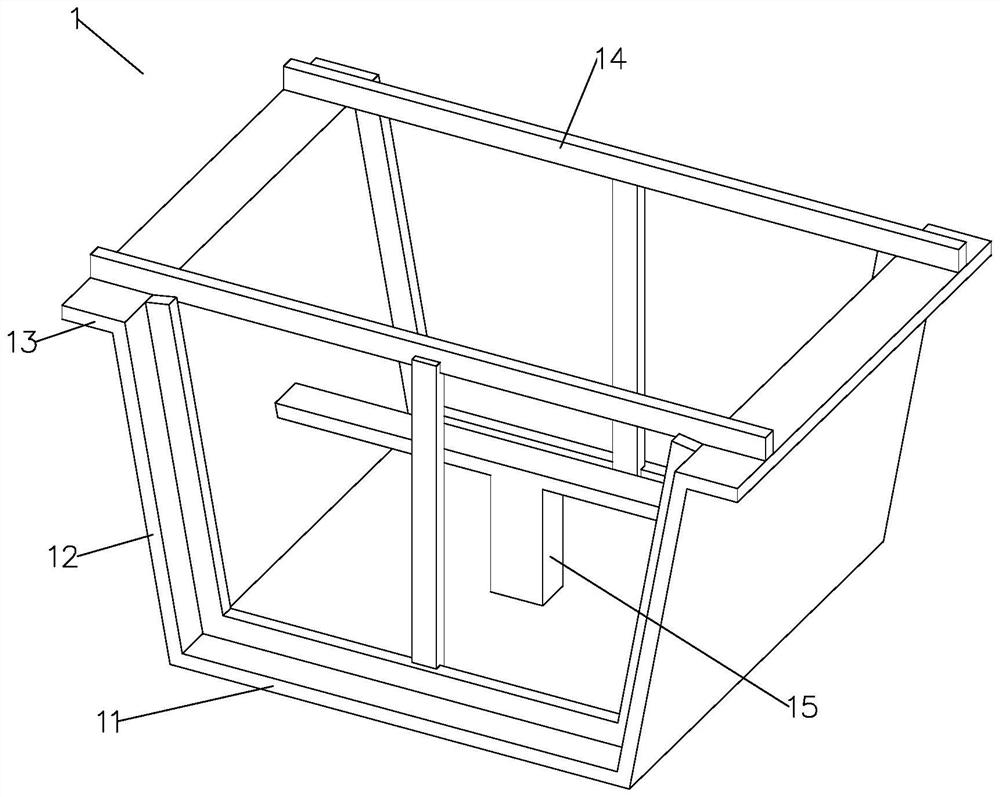

[0045] The embodiment of the application discloses a construction method of a cast-in-place drainage ditch. refer to figure 1 In this construction method, the structure of the shaped drainage ditch 200 is poured by using the pouring mold to pour the construction in the trench. The shaped drainage ditch 200 is the main body of the drainage ditch. The type is selected according to the design requirements, and the opening width at the bottom can be selected to be different. The variable U-shaped groove can also choose a trapezoidal groove whose opening width gradually increases upwards. In this embodiment, a trapezoidal groove is selected as an example, and a groove with a trapezoidal cross-section is also excavated on the groove foundation 100 .

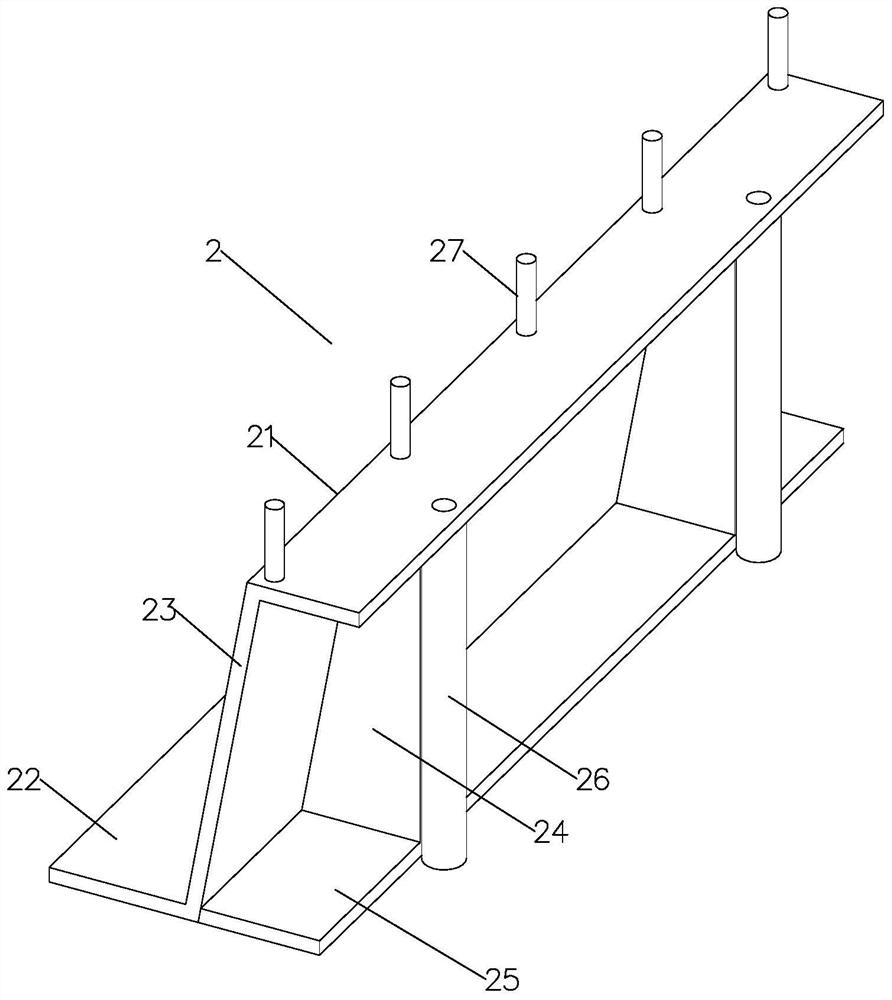

[0046] refer to figure 1 , the pouring mold includes a bottom mold and a pressure mold 1, wherein the bottom mold is placed in the trench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com