Nitrogen-doped titanium dioxide supported palladium catalyst for TADBIW hydrogenolysis debenzylation and preparation and application of catalyst

A titanium dioxide and palladium catalyst technology, applied in the directions of physical/chemical process catalysts, organic chemistry, chemical instruments and methods, etc., can solve the problem of difficulty in ensuring high atomic utilization and high catalytic activity of noble metals, limiting large-scale mass production, and difficult preparation processes. Large and other problems, to achieve the effect of reducing synthesis cost, high yield and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of nitrogen-doped titania supported palladium catalyst as described above, described preparation method specifically comprises the following steps:

[0033] (a) Take the titanium precursor and add it to the solvent and stir it, then add a nitrogen source to form a mixture, stir until it is completely hydrolyzed, then age and post-treat to obtain a nitrogen-doped titanium dioxide carrier. The titanium precursor is selected from isopropyl titanate, One or more mixtures of tetrabutyl titanate, titanium acetate or titanium tetrachloride, the solvent is selected from one or more mixtures of water, methanol, ethanol, isopropanol or ethylene glycol, and the nitrogen source is selected from Since one or more of ammonium chloride, ammonia water, ammonium carbonate, ammonium bicarbonate or ethylenediamine are mixed, the temperature of hydrolysis is room temperature, the temperature of aging is room temperature, and the aging time is 15h. The post-treat...

Embodiment 1

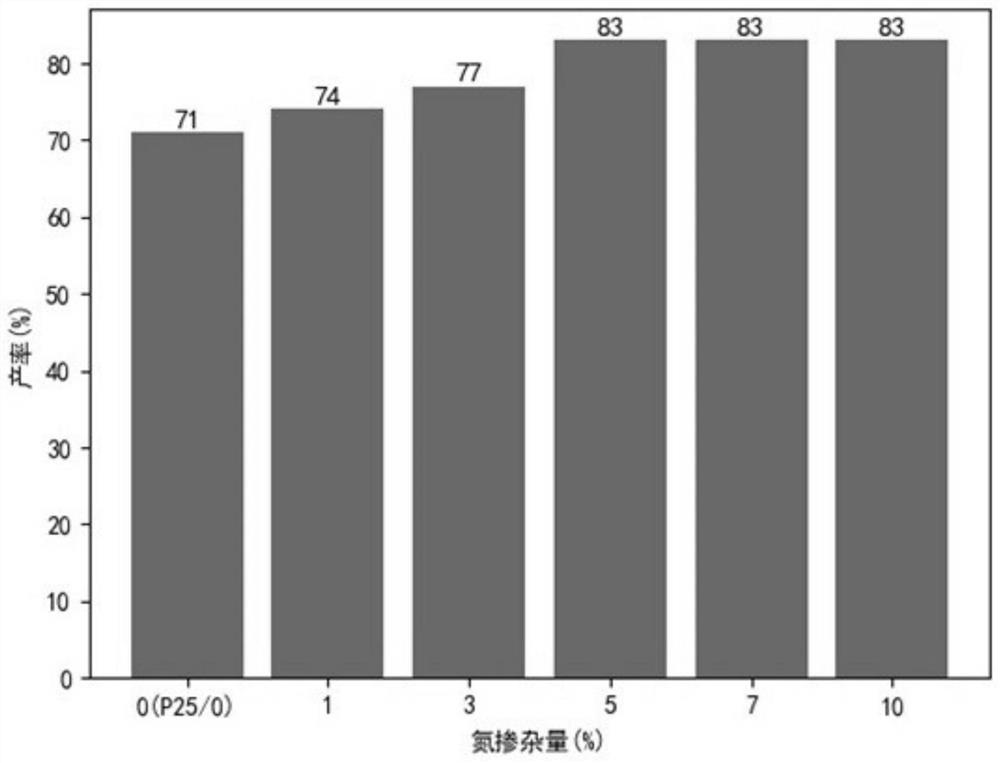

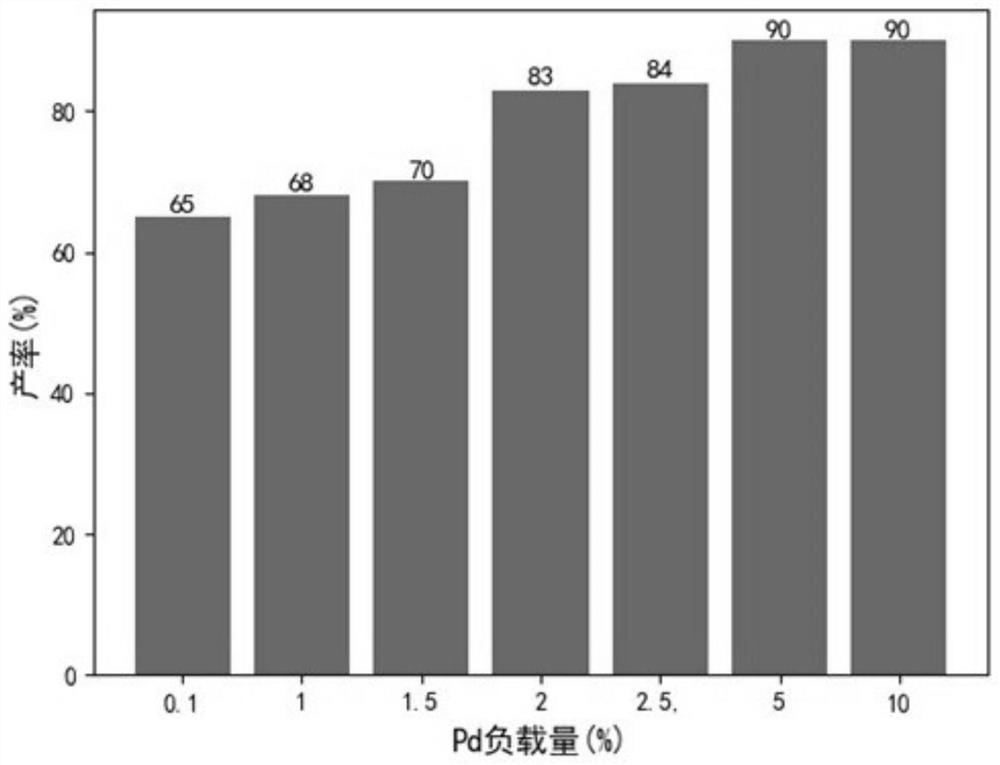

[0037] A nitrogen-doped titanium dioxide-supported palladium catalyst for TADBIW hydrogenolysis and debenzylation, with nitrogen-doped titanium dioxide as a carrier, palladium as an active component, palladium loaded on the carrier, and the doping amount of nitrogen is 5wt.% of the total amount of the carrier , through XRD characterization analysis, see Figure 4 , No diffraction peak of any palladium was found, indicating that the particle size of palladium was no more than 3nm, palladium was in granular form, and the loading of palladium was 2wt.% of the total amount of the catalyst. Prepared by the following steps:

[0038] First, a 5wt.% nitrogen-doped titanium oxide support was prepared by the sol-gel method:

[0039] Add 4ml of isopropyl titanate to 10ml of isopropanol, stir, take 0.2252g of ammonium chloride and dissolve it in 0.7ml of deionized water to form an ammonium chloride solution, and add the ammonium chloride solution to the above-mentioned isopropanol , sti...

Embodiment 2

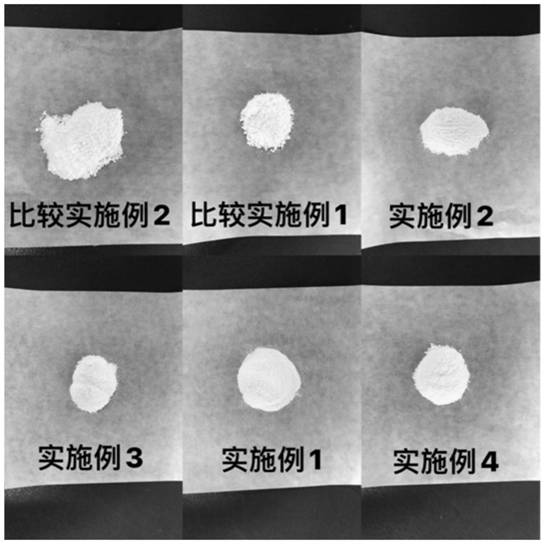

[0046] A nitrogen-doped titanium dioxide-supported palladium catalyst for TADBIW hydrogenolysis and debenzylation, with nitrogen-doped titanium dioxide as a carrier, palladium as an active component, palladium loaded on the carrier, and the doping amount of nitrogen is 1wt.% of the total amount of the carrier , the loading of palladium is 2wt.% of the total amount of catalyst, that is, in the catalyst, except that the nitrogen doping amount is different from that of Example 1, all the others are the same as the materials shown in Example 1, due to the nitrogen doping of the catalyst The impurity is 1wt.%, so the catalyst is recorded as Pd / N 1 TiO 2 -2, the weighing amount of raw materials in the preparation step is weighed as required, and the rest are the same as in Example 1. Among them, the intermediate product 1% nitrogen-doped titanium oxide N 1 TiO 2 The color of the powder sample is yellow, see the photo figure 1 . Pd / N 1 TiO 2 -2 is used for the TADBIW hydrogeno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com