Processing method of beef short ribs

A processing method, cowboy bone technology, which is applied in the field of food processing, can solve problems such as dry taste, difficulty in chewing, and insufficient tenderness of steak, and achieve the effects of reducing oxidation, preventing infection, and avoiding the astringency of meat texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

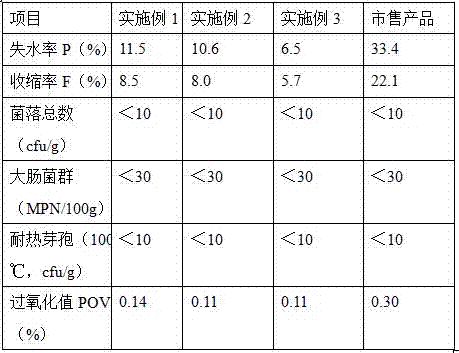

Embodiment 1

[0028] A kind of processing method of cowboy bone, concrete steps are:

[0029] (1) Specification cut into pieces:

[0030] Clean and disinfect the bone sawing machine according to the requirements of the "Sanitary Standard Operating Procedure SSOP", slice the trimmed cowboy bone raw materials according to the thickness of 9 mm and the width of 40-45 mm, and each piece weighs 50-60 grams; slice it well The denim bones are put into the sterilized stainless steel bucket and weighed;

[0031] (2) Natural thawing:

[0032] Put the weighed cowboy bone into the designated thawing area and let it thaw naturally until it is completely thawed;

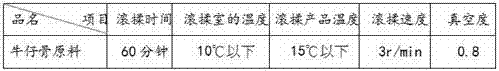

[0033] (3) Tumbling and standing still:

[0034] According to the seasoning required for 100 kg of cowboy bones: A ingredients: sodium tripolyphosphate 150g, black pepper 80g, margarine 500g, black pepper marinade 1200g, white sugar 1300g; B ingredients contain: soybean protein 1kg, 1kg soy sauce, 4kg modified starch;

[0035] Add ingredie...

Embodiment 2

[0041] A kind of processing method of cowboy bone, concrete steps are:

[0042] (1) Specification cut into pieces:

[0043] Clean and disinfect the bone sawing machine according to the requirements of the "Sanitary Standard Operating Procedure SSOP", slice the trimmed cowboy bone raw materials according to the thickness of 9 mm and the width of 40-45 mm, and each piece weighs 50-60 grams; slice it well The denim bones are put into the sterilized stainless steel bucket and weighed;

[0044] (2) Natural thawing:

[0045] Put the weighed cowboy bone into the designated thawing area and let it thaw naturally until it is completely thawed;

[0046] (3) Tumbling and standing still:

[0047] Seasonings required according to the ratio of 100 kg of cowboy bones: A ingredients: 160g of Balmiphos, 100g of black pepper, 600g of margarine, 1500g of black pepper marinade, 1500g of white sugar; B ingredients include: 2kg of soybean protein, soy sauce 2kg, modified starch 5kg;

[0048] P...

Embodiment 3

[0055] A kind of processing method of cowboy bone, concrete steps are:

[0056] (1) Specification cut into pieces:

[0057] Clean and disinfect the bone sawing machine according to the requirements of the "Sanitary Standard Operating Procedure SSOP", slice the trimmed cowboy bone raw materials according to the thickness of 9 mm and the width of 40-45 mm, and each piece weighs 50-60 grams; slice it well The denim bones are put into the sterilized stainless steel bucket and weighed;

[0058] (2) Natural thawing:

[0059] Put the weighed cowboy bone into the designated thawing area and let it thaw naturally until it is completely thawed;

[0060] (3) Tumbling and standing still:

[0061] According to the ratio of 100 kg of cowboy bones, the seasoning required: A ingredients: 180g of balmephos, 110g of black pepper powder, 700g of margarine, 1900g of black pepper marinade, 2000g of white sugar, 500g of white fungus polysaccharide; B ingredients: soybean protein 3kg, soy sauce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com