Reinforced concrete culvert settlement joint water seepage treatment method and repair structure

A reinforced concrete and repair structure technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as difficult traffic, affecting roadbed stability, and bad social impact, and achieves obvious anti-seepage effect and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Examples of the present invention:

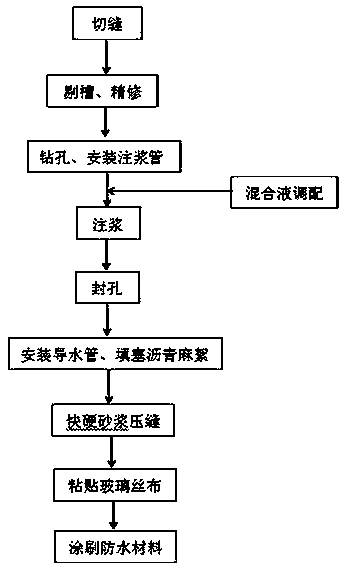

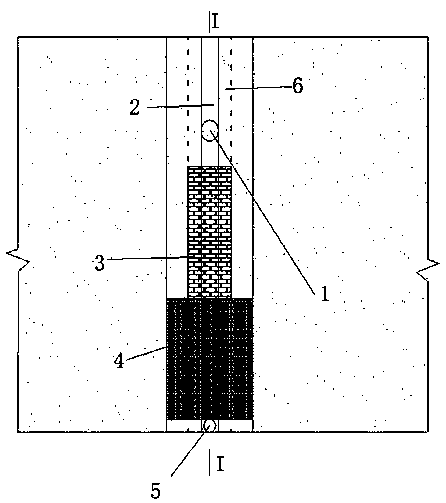

[0028] First, use a cutting machine to cut both sides of the original culvert settlement joint, then use an electric impact drill to pick out the groove, and then artificially refine it into groove 6; groove 6 is 5cm wide and 8cm deep.

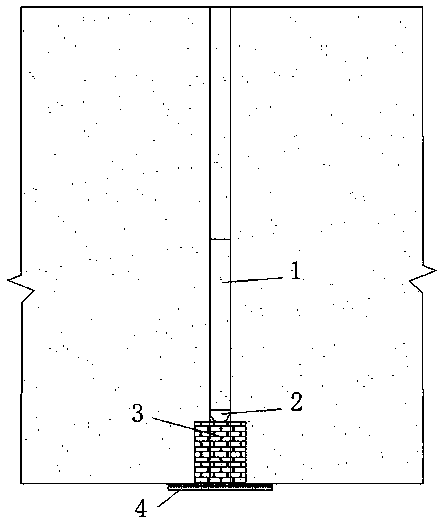

[0029] Second, use an electric drill to drill a hole in the settlement joint of the original culvert, install the grouting pipe 1 and grouting; the interval of the grouting pipe 1 is 25cm, the hole depth is 10cm, and the hole diameter is 15mm; the high-pressure grouting pump is used for grouting water-soluble polyurethane The mixture of plugging agent and acetone is poured from the bottom of the culvert to the top of the culvert at one time. The grouting is stopped after the grouting pressure reaches 0.5MPa. After the grouting solution has solidified for 1 to 2 days, the grouting nails are removed and the leakage is stopped. Wang blocked the grouting hole.

[0030] Third, clean the gaps and grooves 6, inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com