Starch-free ham

A ham and starch technology, applied in the field of food science, can solve the problems of flavor, taste, color change, ham cannot meet consumer demand, and lose the original characteristics of fresh meat, so as to improve the fresh and tender taste, improve the elasticity, and the texture of shredded meat clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

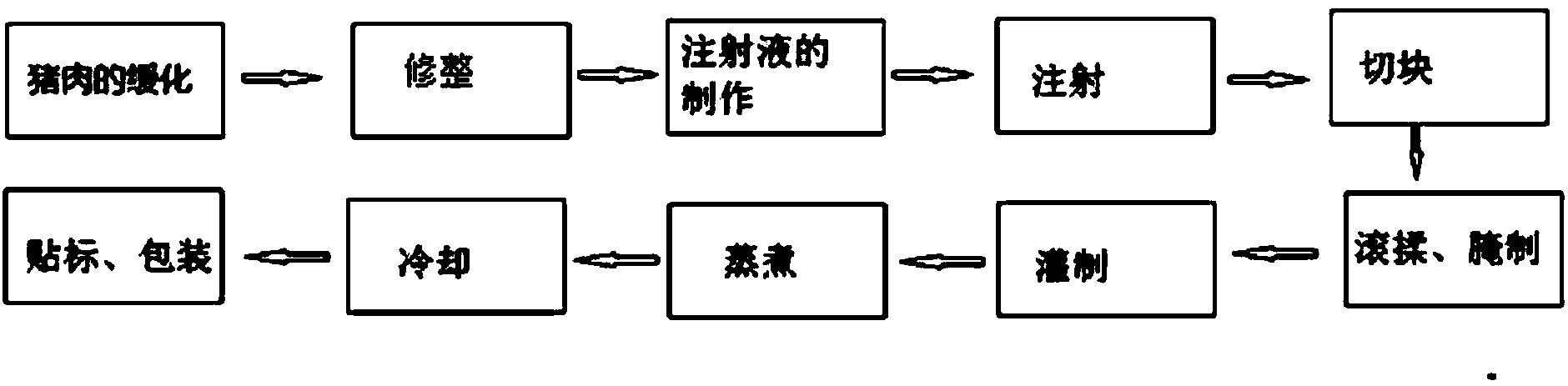

Image

Examples

Embodiment 1

[0027] A kind of starch-free ham, its raw material composition and weight parts are: 100 parts of pork hind legs, 60 parts of ice water, 3.1 parts of salt, 1.5 parts of white sugar, 1.5 parts of glucose, 0.4 parts of monosodium glutamate, 0.7 parts of sodium tripolyphosphate , 0.7 parts of sodium hexametaphosphate, 0.8 parts of sodium pyrophosphate, 0.6 parts of injection carrageenan, 0.06 parts of sodium erythorbate, 0.016 parts of sodium nitrite, 0.024 parts of monascus red pigment, 0.06 parts of pepper powder, 0.06 parts of nutmeg powder, 4 servings of soy protein.

[0028] The preparation method of described starch-free ham is as follows:

[0029] (1) Mitigation of pork: The pork is thawed at 14-16°C and the wind speed is 2m / s for 8 hours, and the meat temperature reaches the temperature standard of 0-4°C chilled fresh meat.

[0030] (2) Trimming: remove the fascia and fat blocks in the meat.

[0031] (3) Production of injection: mix ice water with salt, white sugar, glu...

Embodiment 2

[0040] A starch-free ham, the raw material composition and parts by weight are: 100 parts of pork hind leg, 60 parts of ice water, 3.1 parts of salt, 1.5 parts of white sugar, 1.5 parts of glucose, 0.4 parts of monosodium glutamate, 1.0 parts of sodium tripolyphosphate , 0.5 parts of sodium hexametaphosphate, 0.7 parts of sodium pyrophosphate, 0.6 parts of injection carrageenan, 0.06 parts of sodium erythorbate, 0.016 parts of sodium nitrite, 0.024 parts of monascus red pigment, 0.07 parts of pepper powder, 0.05 parts of nutmeg powder, 4 servings of soy protein.

[0041] The preparation method of described starch-free ham is as follows:

[0042] (1) Mitigation of pork: The pork is thawed at 14-16°C and the wind speed is 2m / s for 8 hours, and the meat temperature reaches the temperature standard of 0-4°C chilled fresh meat.

[0043] (2) Trimming: remove the fascia and fat blocks in the meat.

[0044] (3) Production of injection: mix ice water with salt, white sugar, glucose, ...

Embodiment 3

[0053] A kind of starch-free ham, its raw material composition and weight parts are: 100 parts of pork hind legs, 60 parts of ice water, 3.1 parts of salt, 1.5 parts of white sugar, 1.5 parts of glucose, 0.4 parts of monosodium glutamate, 0.5 parts of sodium tripolyphosphate , 1.0 parts of sodium hexametaphosphate, 0.7 parts of sodium pyrophosphate, 0.6 parts of injection carrageenan, 0.06 parts of sodium erythorbate, 0.016 parts of sodium nitrite, 0.024 parts of monascus red pigment, 0.08 parts of pepper powder, 0.04 parts of nutmeg powder, 4 servings of soy protein.

[0054] The preparation method of described starch-free ham is as follows:

[0055] (1) Mitigation of pork: The pork is thawed at 14-16°C and the wind speed is 2m / s for 8 hours, and the meat temperature reaches the temperature standard of 0-4°C chilled fresh meat.

[0056] (2) Trimming: remove the fascia and fat blocks in the meat.

[0057] (3) Production of injection: mix ice water with salt, white sugar, glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com