Pre-separating seedling plate

A seedling tray and tray bottom technology, applied in the application, cultivation, agriculture and other directions, can solve the problems such as difficulty in meeting the accuracy requirements for the accuracy of the seedlings, loss of fertilizer and water, and rotten roots of the seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

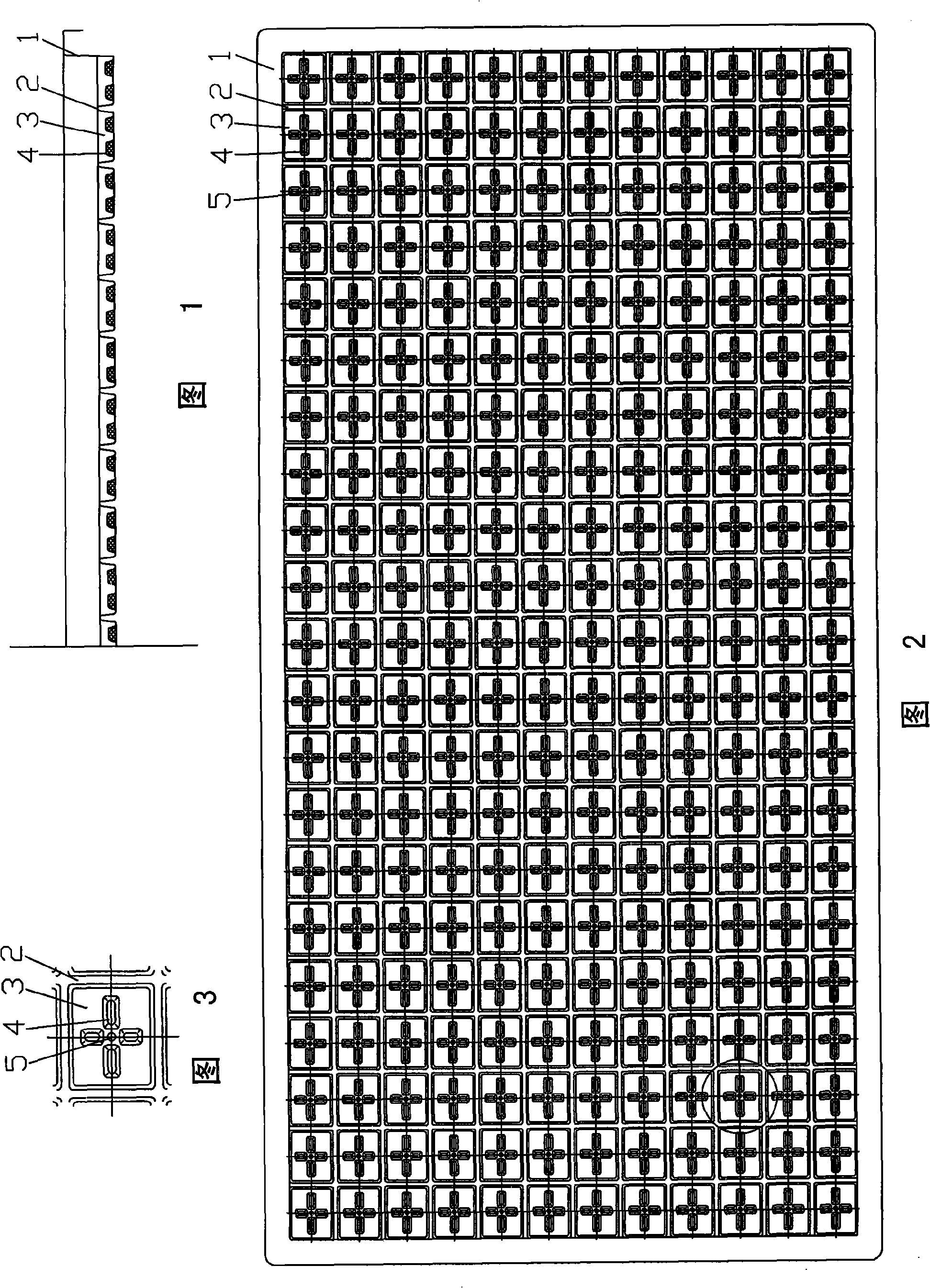

[0013] The pre-divided seedling tray of this embodiment is shown in Figures 1, 2, and 3. The bottom of the tray body 1 is divided into an array of several rectangular trays 3 formed by criss-crossing upwardly protruding long ribs 2. In the dish lattice 3, be divided into matts by four short ribs 4 that are distributed in a cross shape. The area of each quadrant of the matts is set according to the requirements of planting 1-2 plants / hole, which is equal to the area of the required seedling block, which is about 1.4×1.17cm 2 . Both long ribs and short ribs have a draft angle. The four short ribs 4 are in the shape of a rectangular truncated cone, and are not connected to each other and the long ribs 2 around the pan grid, so they can form a uniform water channel structure inside the grid area.

[0014] In order to make the seedling tray have sufficient rigidity and save material, the long ribs are hollow ribs whose wall thickness is equal to the thickness of the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com