Construction method of anchor plate artificial prosthetic roadway

A manual and anchor plate technology, which is applied in the installation of anchor rods, earthwork drilling, shaft equipment, etc., can solve the problems of long construction period, high cost, high labor intensity, etc., and achieve short construction period, low engineering materials, and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

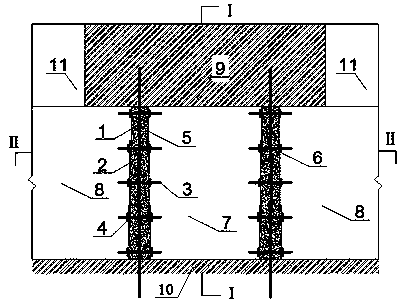

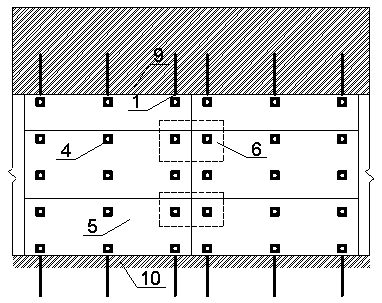

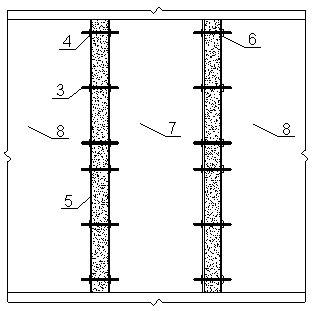

[0027] Below in conjunction with accompanying drawing and embodiment to a kind of anchor plate artificial false alley construction method,

[0028] Step 1: According to the engineering requirements of the upper ore body, select the location and direction of the construction, and formulate the space size according to the service functions required in the later stage;

[0029] Step 2: According to the position, direction and size, mark the roadway line on site, and drill the anchor holes in the roof pillar and floor rock at intervals according to the marking line. The anchor holes are symmetrical up and down and in the same vertical on-line;

[0030] Preferably, the hole depth of the anchor rods in the present invention is 1-1.5m in engineering conditions; the interval between the anchor rod holes is 0.5-1.2m.

[0031] Step 3: After the bolt holes are drilled, the bolts are installed, and the bolts inserted into the roof pillar and the floor rock are connected with suspended st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com