Solid State Lighting

A lighting, solid-state technology, used in fixed lighting devices, lighting devices, lighting and heating equipment, etc., can solve problems such as poor circulation, decreased heat dissipation performance, and no display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

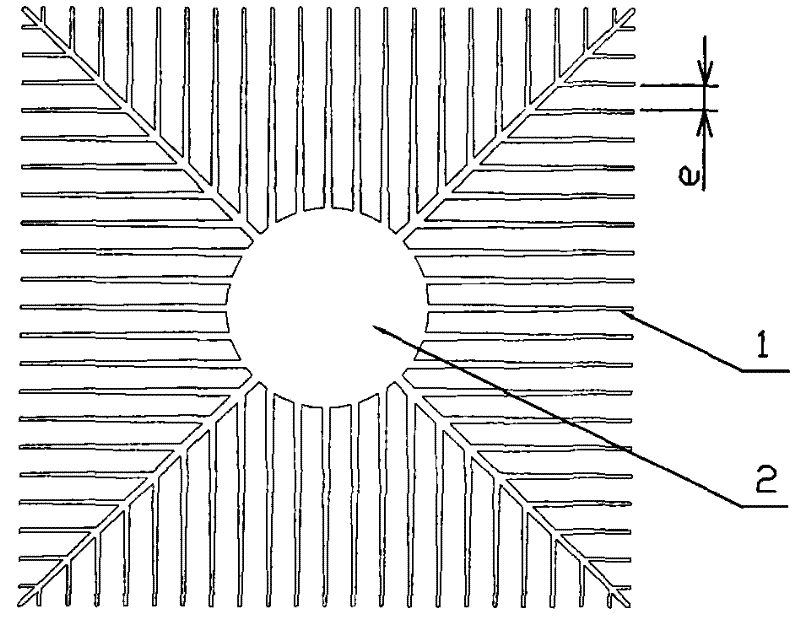

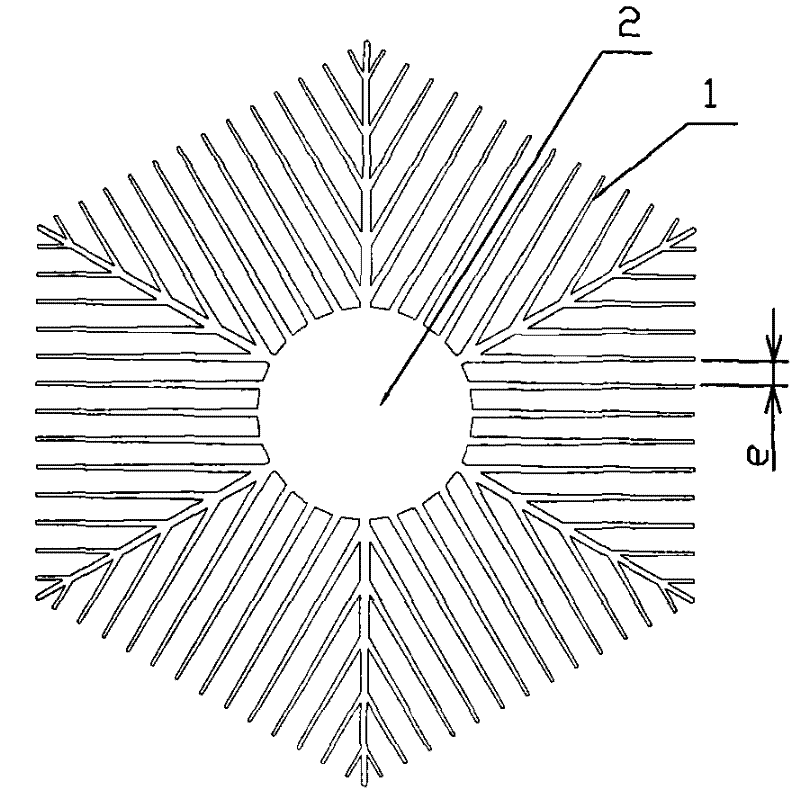

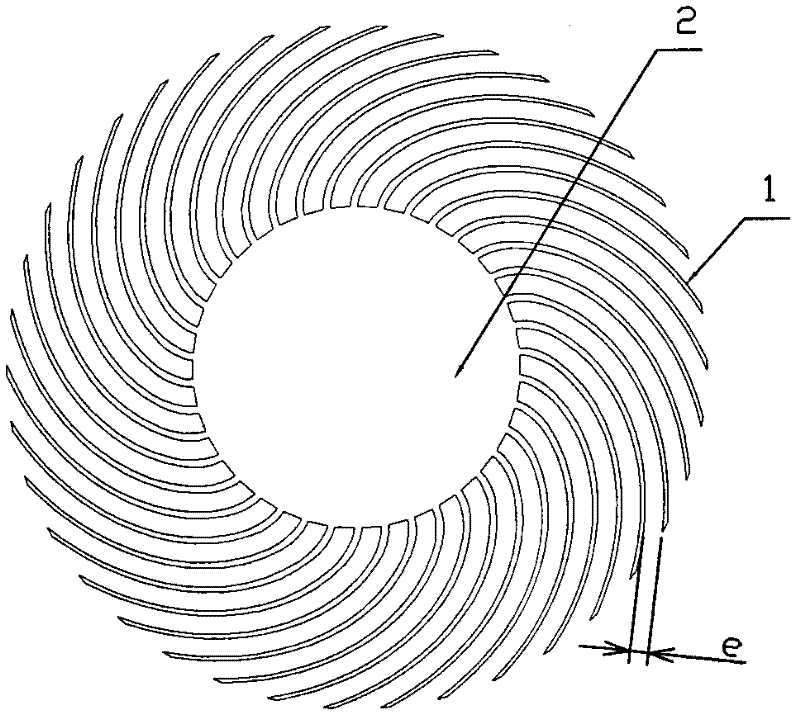

[0022] figure 1 , 2 3 and 3 show three kinds of solar fins with different shapes. The fins 1 protrude from the side of the heat conduction column 2. The heat conduction column 2 shown in the figure is solid or hollow. Using the aluminum extrusion method, the profile can be manufactured, and it can be cut to make a sun fancy heat sink. The manufacturing cost is low, and because of the high ribbing efficiency (material saving) and low internal thermal resistance, it is LED. Cooling first choice.

[0023] Figure 4 In the present invention shown, the heat conduction column 2 is solid, and the LED light source 3 is arranged on the front end surface of the heat conduction column 2. Through the contact heat transfer with the end surface, the heat of the LED light source 3 is transferred to the heat conduction column 2, and then transferred to the heat conduction column 2 by the fins 1. into the air. In the figure, rib 1 is divided into thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com