Method for making low clast bullet and bullet made by the method

A production method and technology of perforating bullets, which are applied in the direction of cartridge ammunition, ammunition, weapon accessories, etc., can solve problems affecting production safety, hazards, and damage to wellhead facilities, so as to improve perforating effects, reduce costs, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

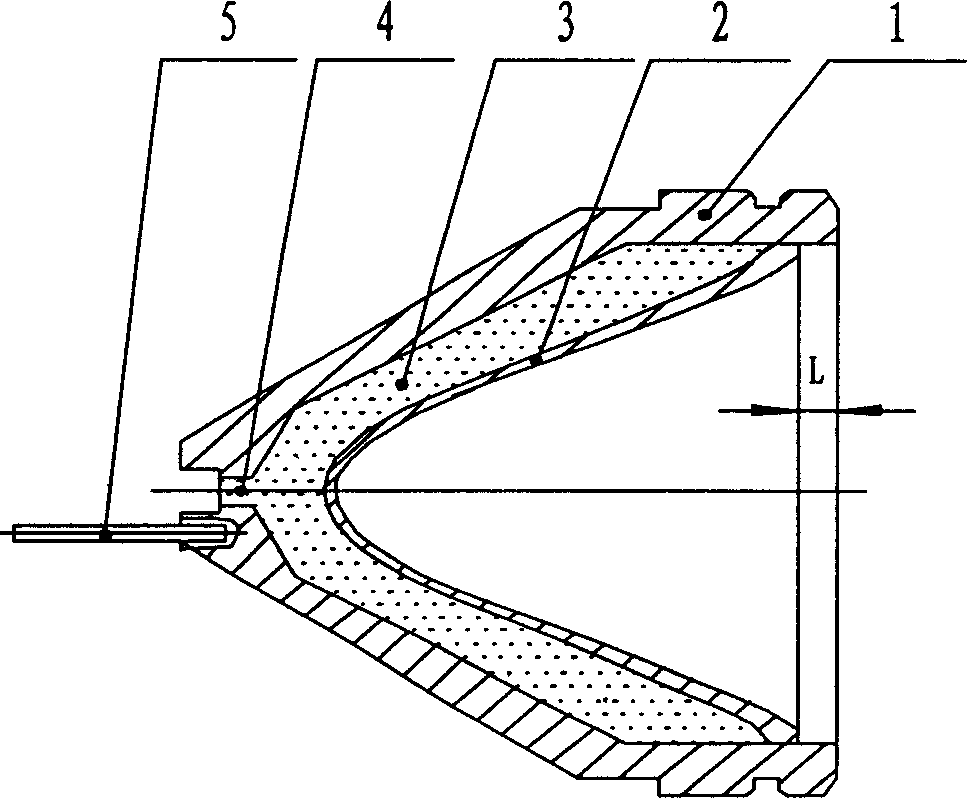

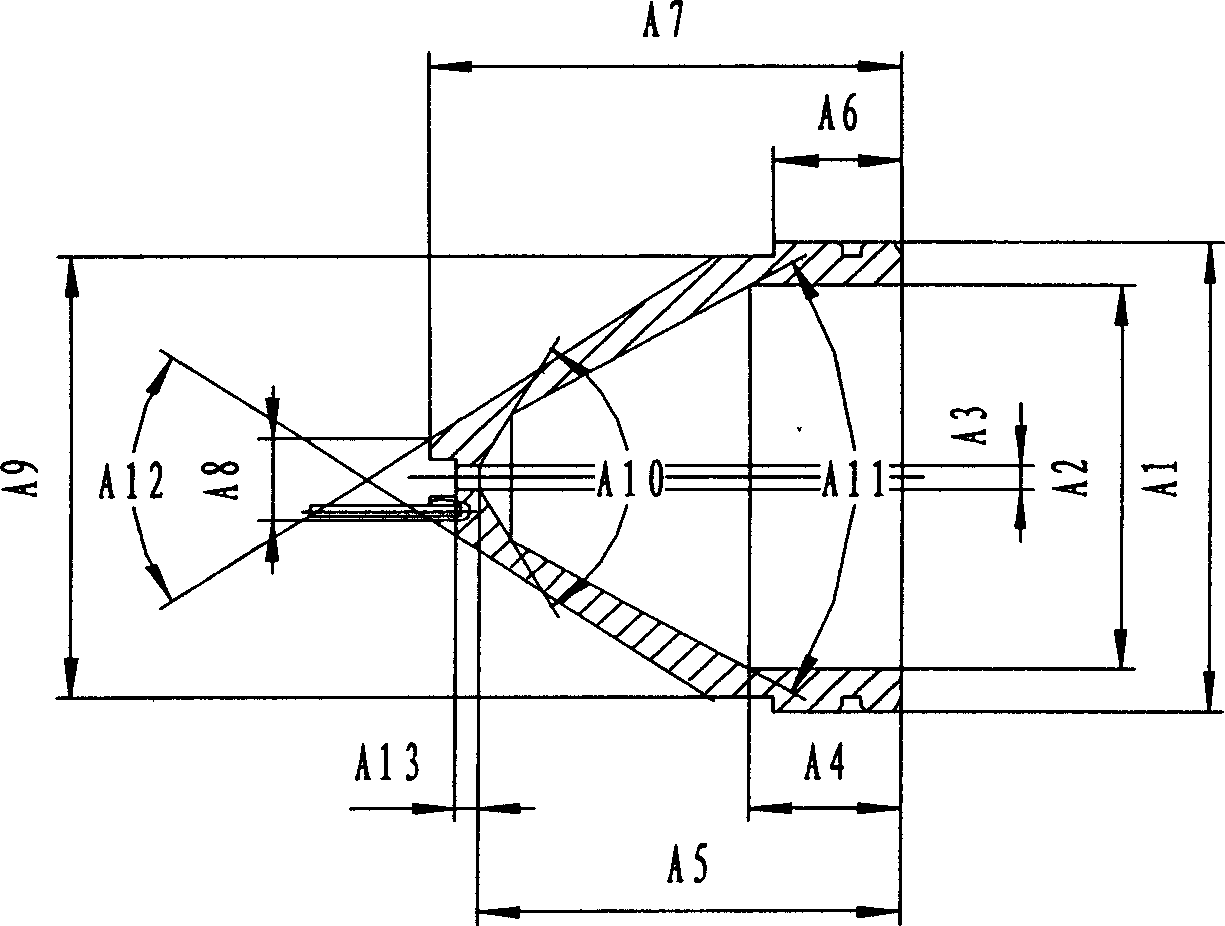

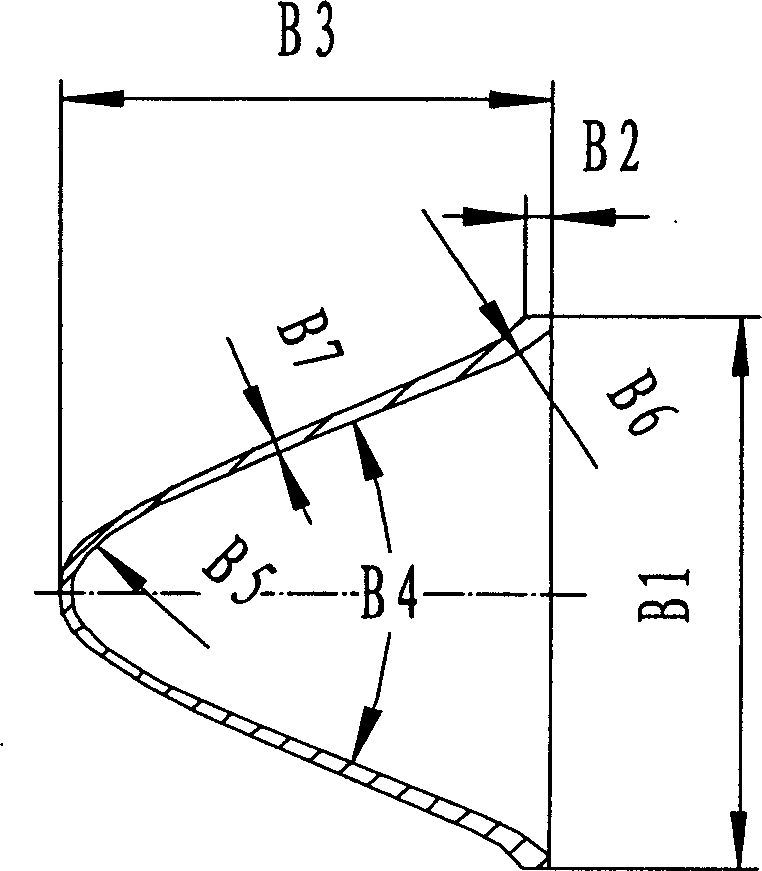

[0018] refer to Figure 1-Figure 3 , the low debris perforating charge is composed of a shell case 1, a booster charge 4, a main charge 3, and a drug-shaped cover 2. The front part of the shell case 1 is flat-headed and conical. The rear part is cylindrical, the front outer surface of the cartridge case 1 and the front part of the inner cavity are conical, the conical drug-shaped cover 2 is arranged in the cartridge case 1, and a booster charge 4 is arranged between the drug-shaped cover 2 and the inner wall of the cartridge case 1 And the main charge 3, the cartridge case 1 is made of zinc-aluminum alloy die-casting or ductile iron. For the zinc-aluminum alloy, the weight parts of zinc and aluminum in the total weight are 75-98 zinc and 25-2 aluminum, specific examples are: 75 zinc, 25 aluminum; 98 zinc, 2 aluminum; 85 zinc, 15 aluminum. For the ductile iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com