Tunnel assembly type inverted arch precast block structure

A prefabricated and prefabricated block technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problem that the construction quality is easily restricted by external conditions, so as to reduce the workload in the tunnel, reduce the labor intensity in the tunnel, and optimize the tunnel section Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in combination with specific embodiments.

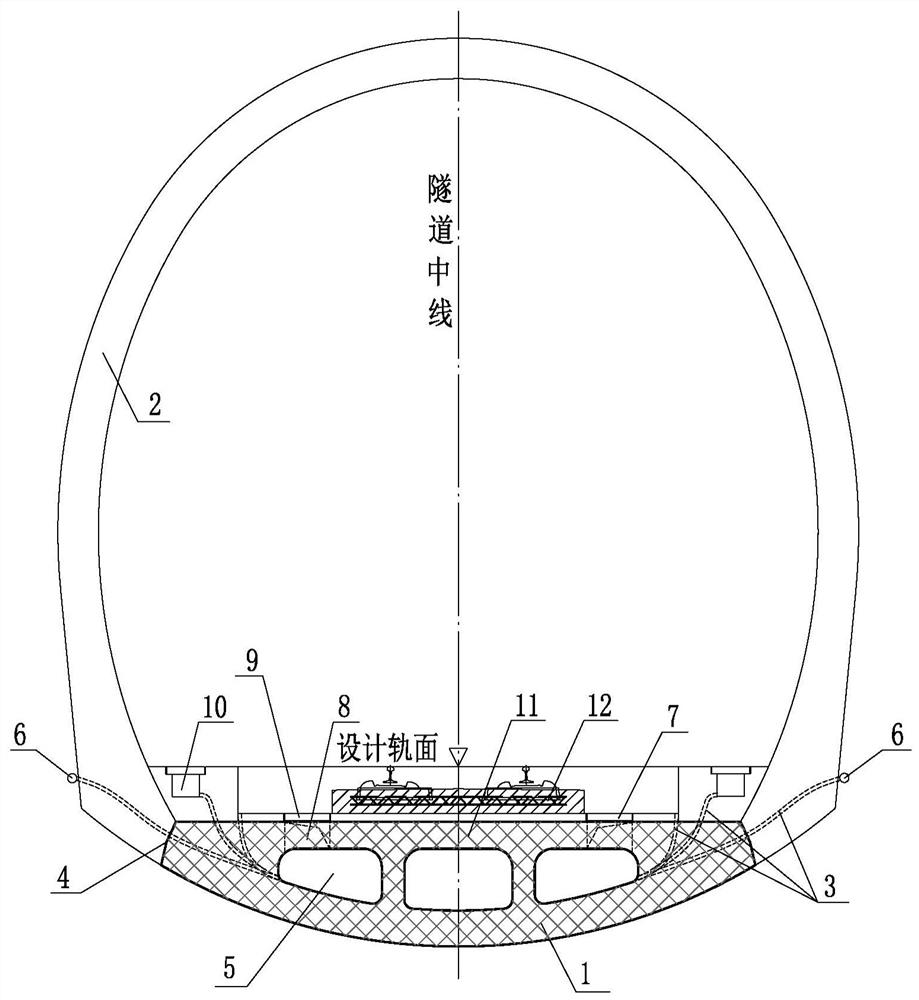

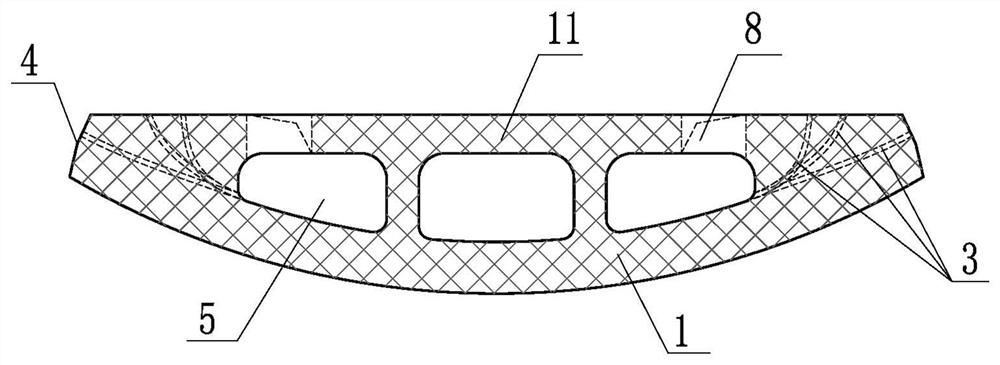

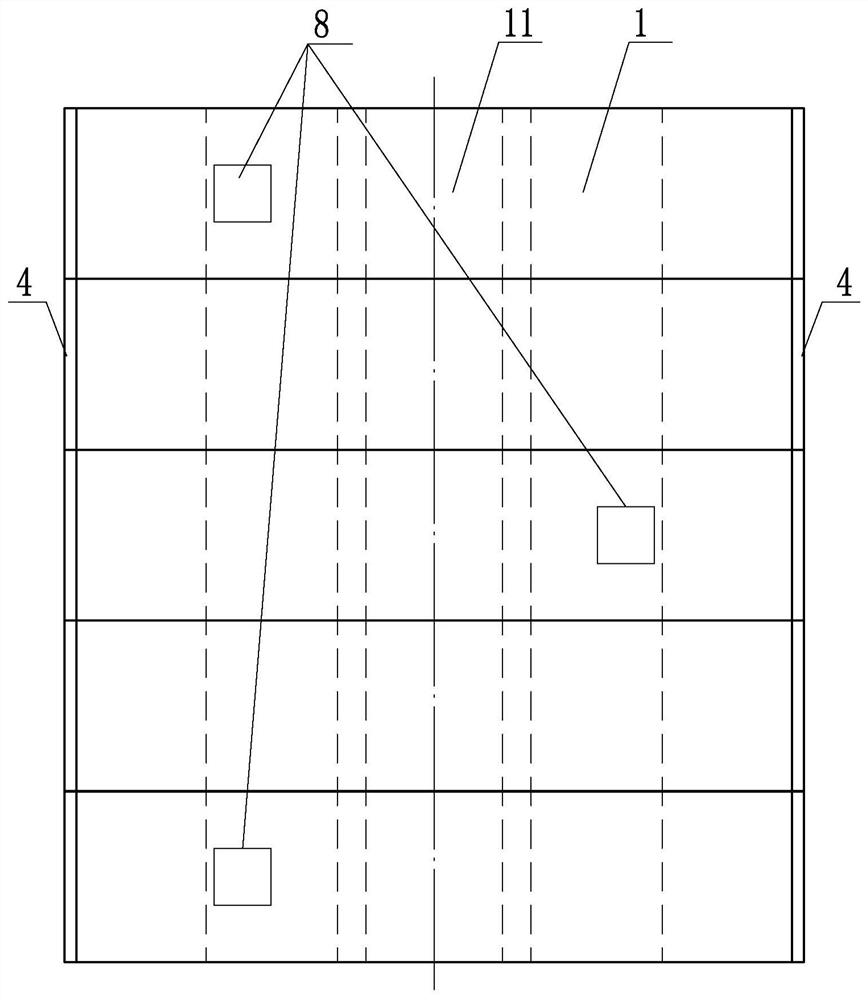

[0027] The invention relates to a prefabricated block structure of an assembled inverted arch of a tunnel. The prefabricated inverted arch block 1 is a prefabricated structure, the bottom surface is an arc surface, the top surface is a plane, and the two sides are the contact surfaces with the secondary lining 2 of the arch wall. 4. A longitudinal through-hole is reserved inside; the assembled inverted arch prefabricated blocks 1 are spliced longitudinally along the line direction to form a tunnel inverted arch structure.

[0028] The contact surfaces 4 on both sides of the assembled inverted arch prefabricated block 1 have tenons or grooves, and corresponding grooves and tenons are provided on the arch wall, and the assembled inverted arch prefabricated block 1 is spliced with the cast-in-place secondary lining 2 into a ring.

[0029] The contact surfaces 4 on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com