Centrifugal fan

A centrifugal fan and volute technology, applied in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve problems such as difficulty in suppressing single-unit noise and increasing single-unit noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

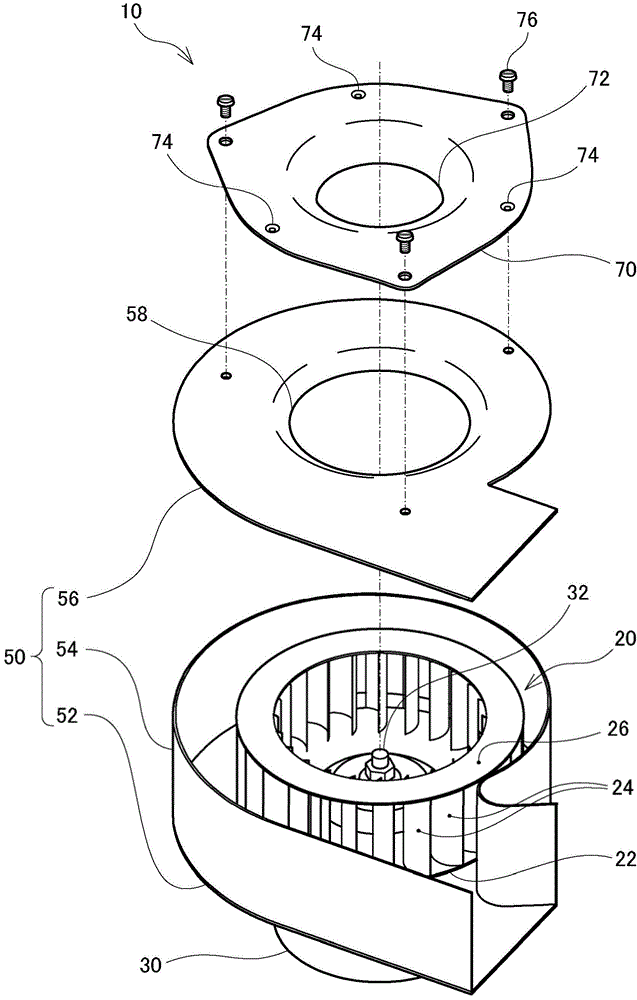

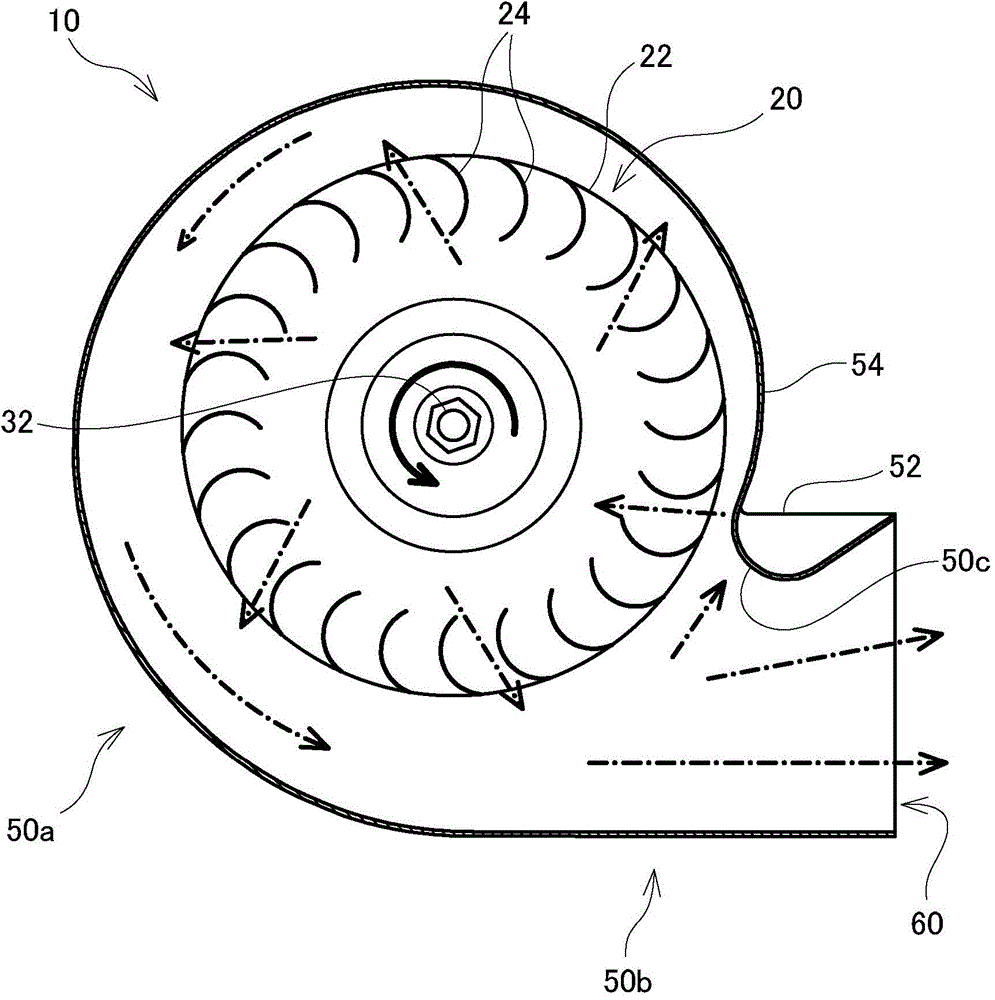

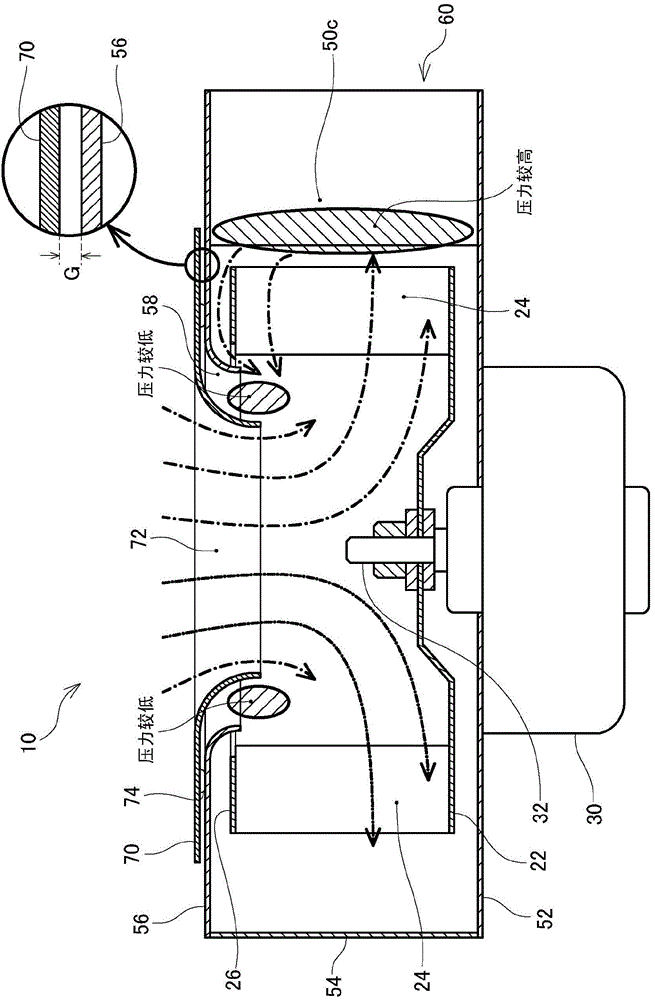

[0021] figure 1 It is a perspective view showing the disassembled state of the centrifugal fan 10 of this embodiment. The centrifugal fan 10 is connected to, for example, a combustion device (not shown) having a built-in burner, and is used to send combustion air to the burner. As shown, the centrifugal fan 10 includes an impeller 20 that generates wind by rotation, a driving motor 30 for rotating the impeller 20 , a fan housing 50 for accommodating the impeller 20 , and the like.

[0022] The impeller 20 of the present embodiment is a so-called multi-blade blower in which a plurality of blades 24 formed elongately in the axial direction of the rotating shaft 32 of the driving motor 30 are radially arranged with respect to the rotating shaft 32 at predetermined intervals. cylindrical shape. One end (lower end in the drawing) of the blade 24 is attached to the outer edge portion of the substantially circular rotating disc 22 , and the other end (upper end in the drawing) of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com