High-pressure injection pump

A high-pressure injection, No. 1 technology, applied in the direction of jet pumps, pumps, pump devices, etc., can solve the problems of not being able to increase the water pressure and flow rate in the outlet pipe of the high-pressure jet pump, and unable to stabilize the water flow pressure in the outlet pipe, so as to reduce energy consumption , Increase water speed and water pressure, increase the effect of water speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

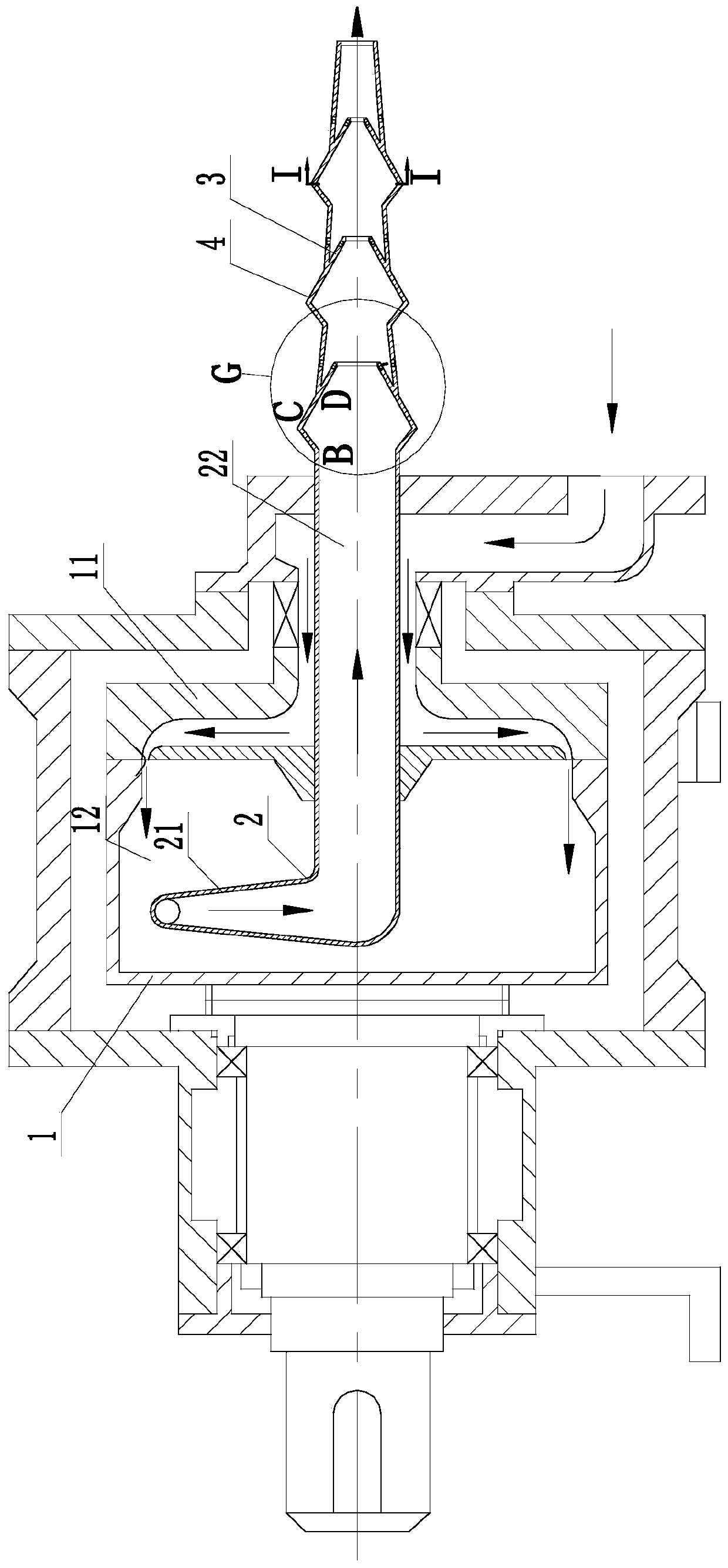

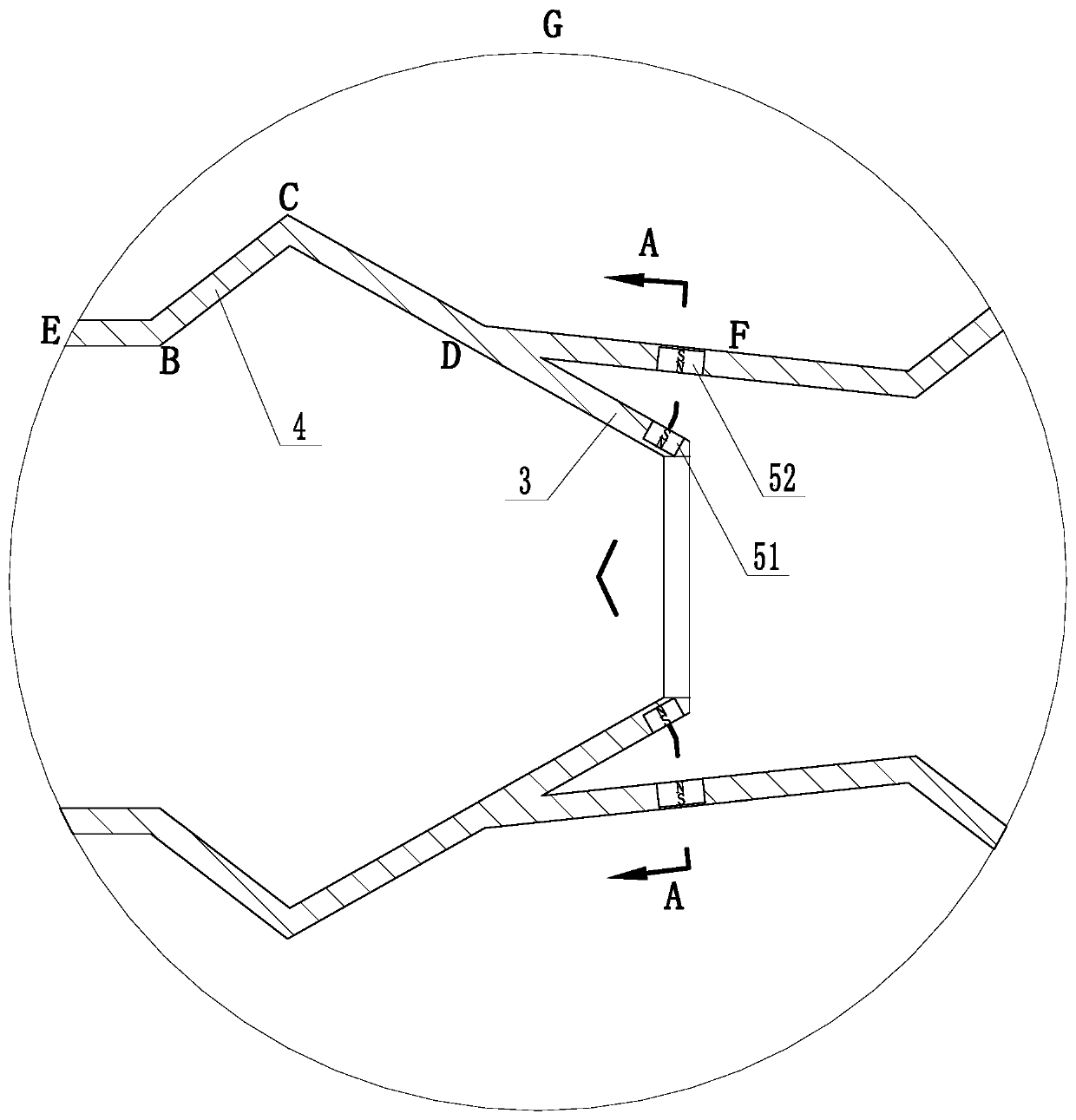

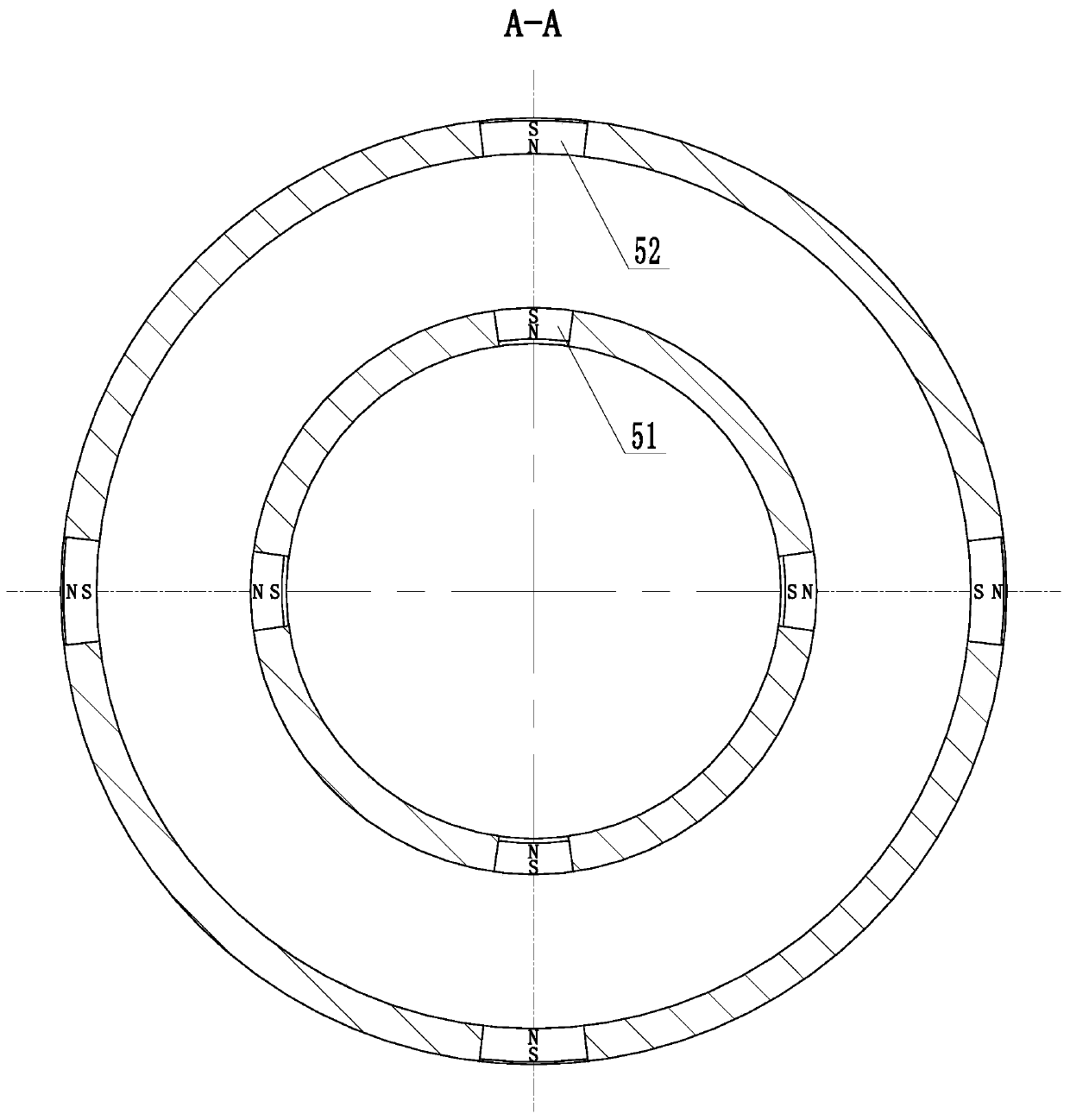

[0022] use Figure 1 to Figure 5 A high-pressure injection pump of the present invention will be described as follows.

[0023] Such as Figure 1 to Figure 5 As shown, a high-pressure jet pump according to the present invention includes a rotor body 1 and a manifold 2. The rotor body 1 includes an impeller 11 and a rotor chamber 12. The manifold 2 includes a diffuser section 21 and an outlet pipe. 22; the impeller 11 and the outlet of the impeller are arranged in the rotor chamber 12; the diffuser section 21 of the collector 2 is also arranged in the rotor chamber 12, and the outlet pipe 22 of the collector 2 is connected to the outside; its characteristics In that: the shape of the outer surface of the diffuser section 21 of the collector 2 is streamlined; the diffuser section 21 of the collector 2 is evenly distributed in an array along the circumference of the outlet pipe 22 of the collector 2, and the collector The number of diffusion sections 21 in 2 is at least three; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com