Patents

Literature

48results about How to "Play a role in maintaining pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

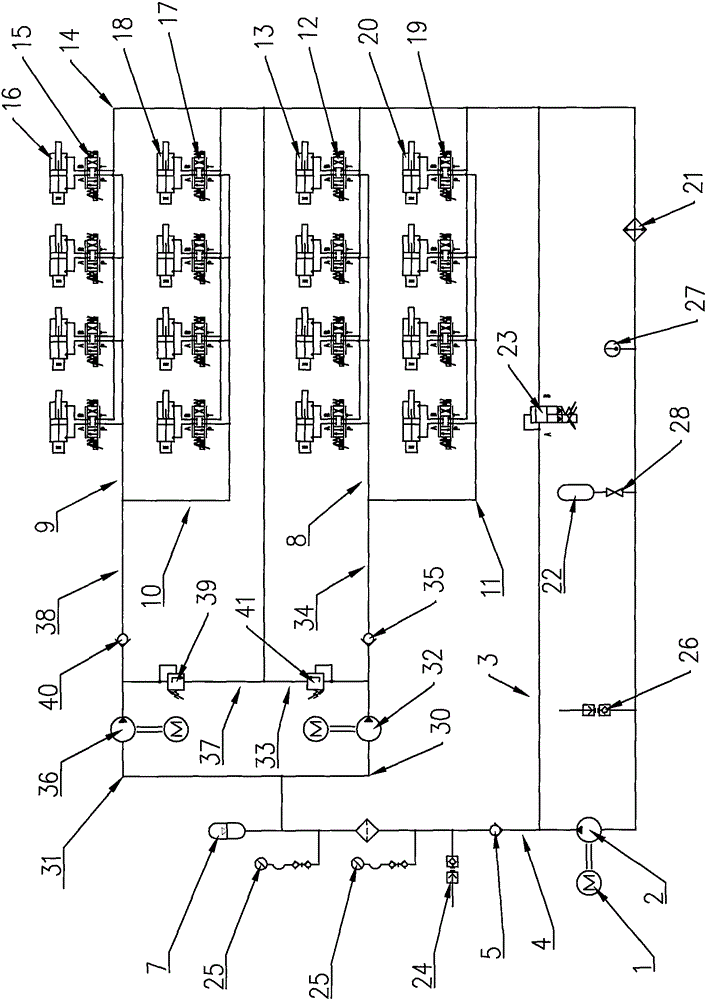

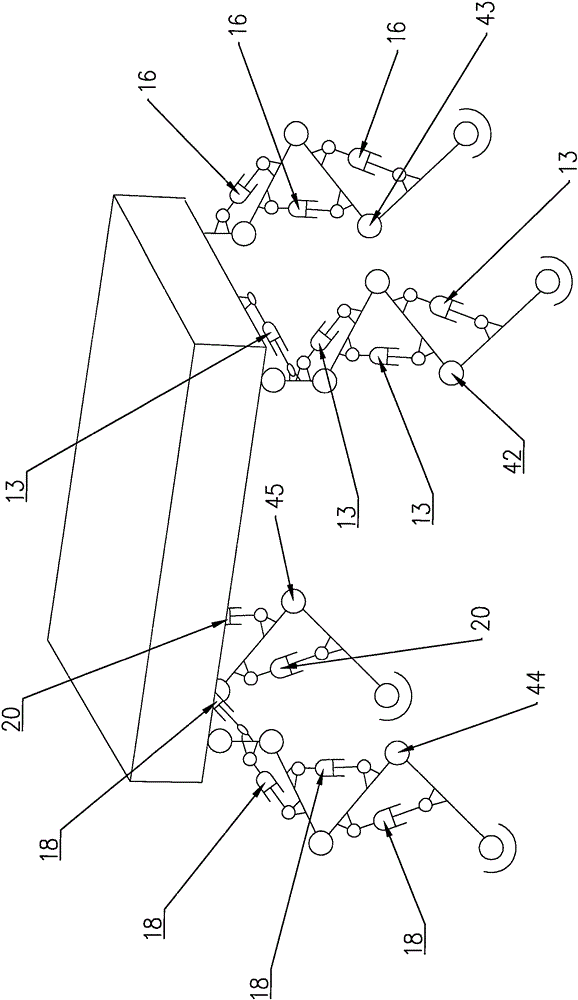

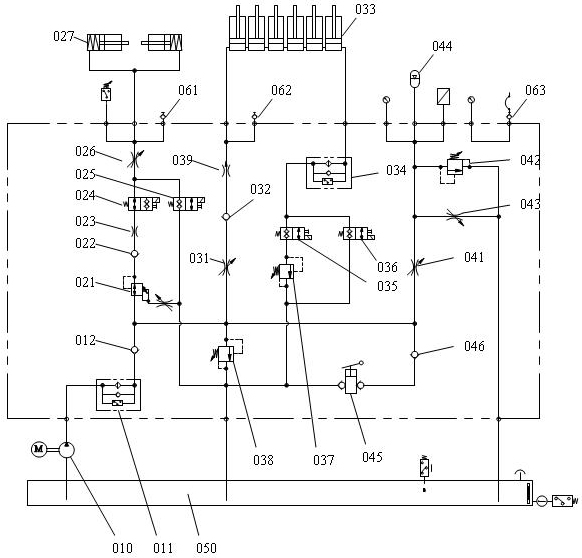

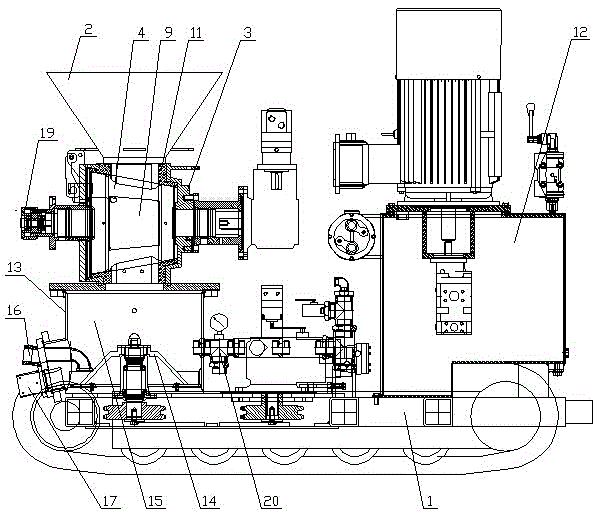

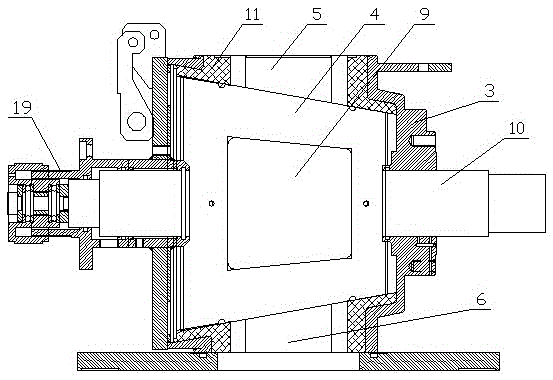

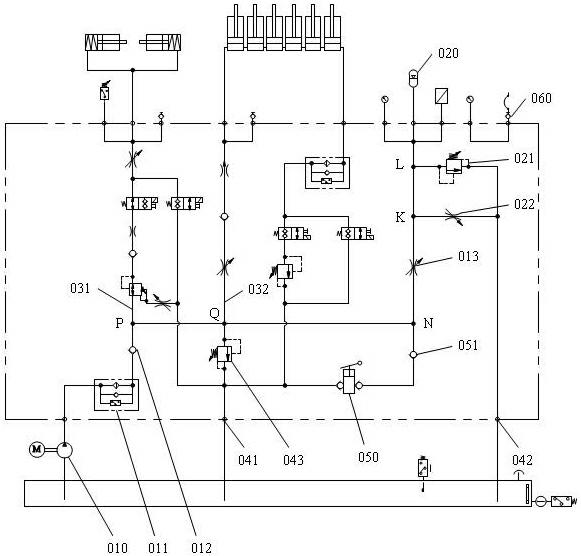

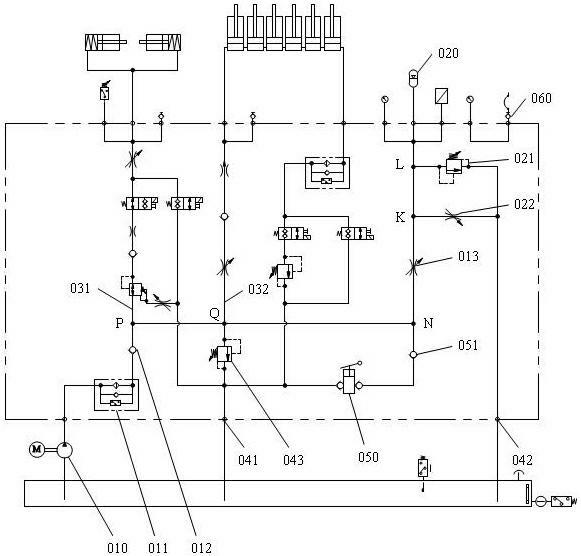

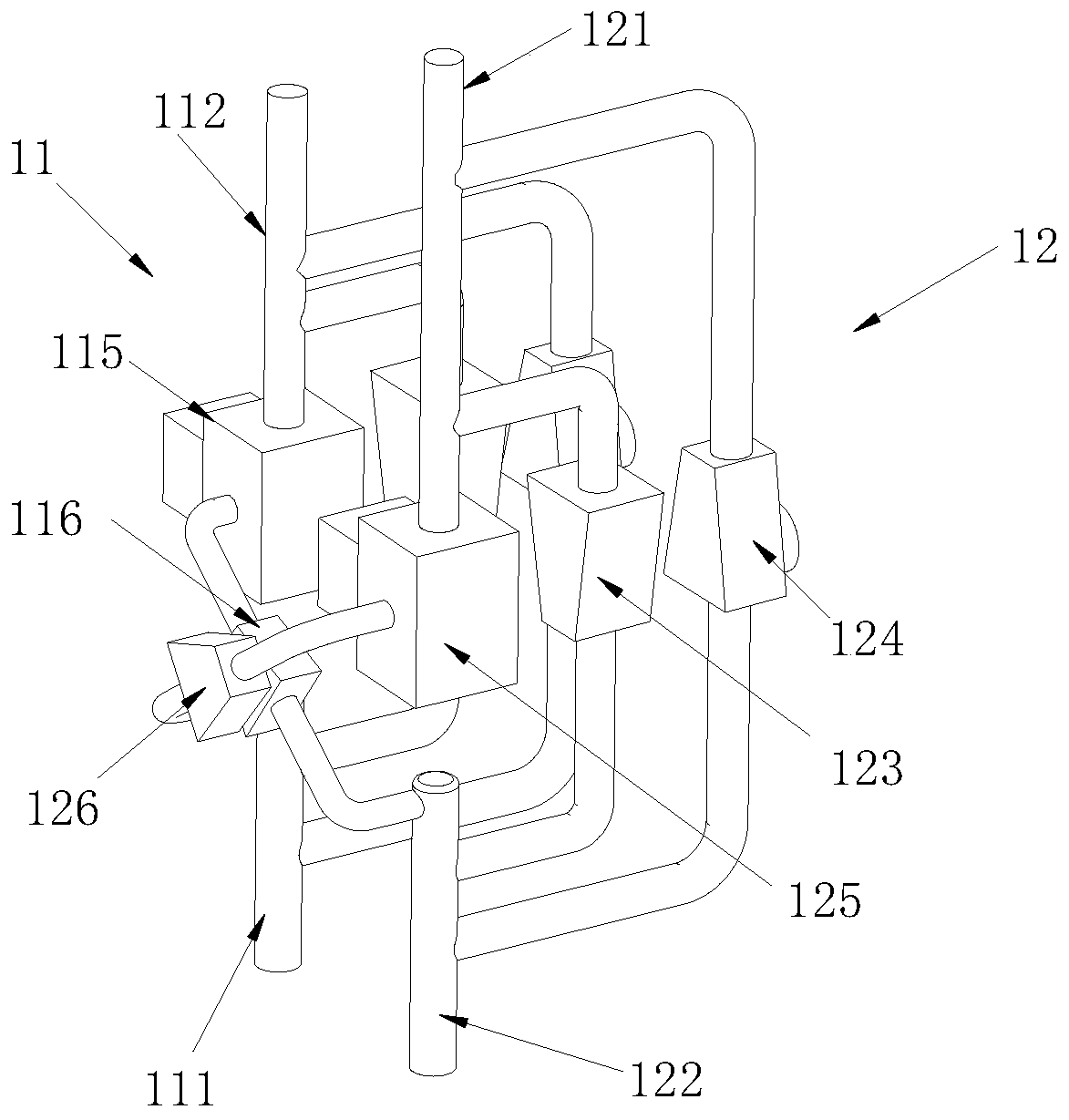

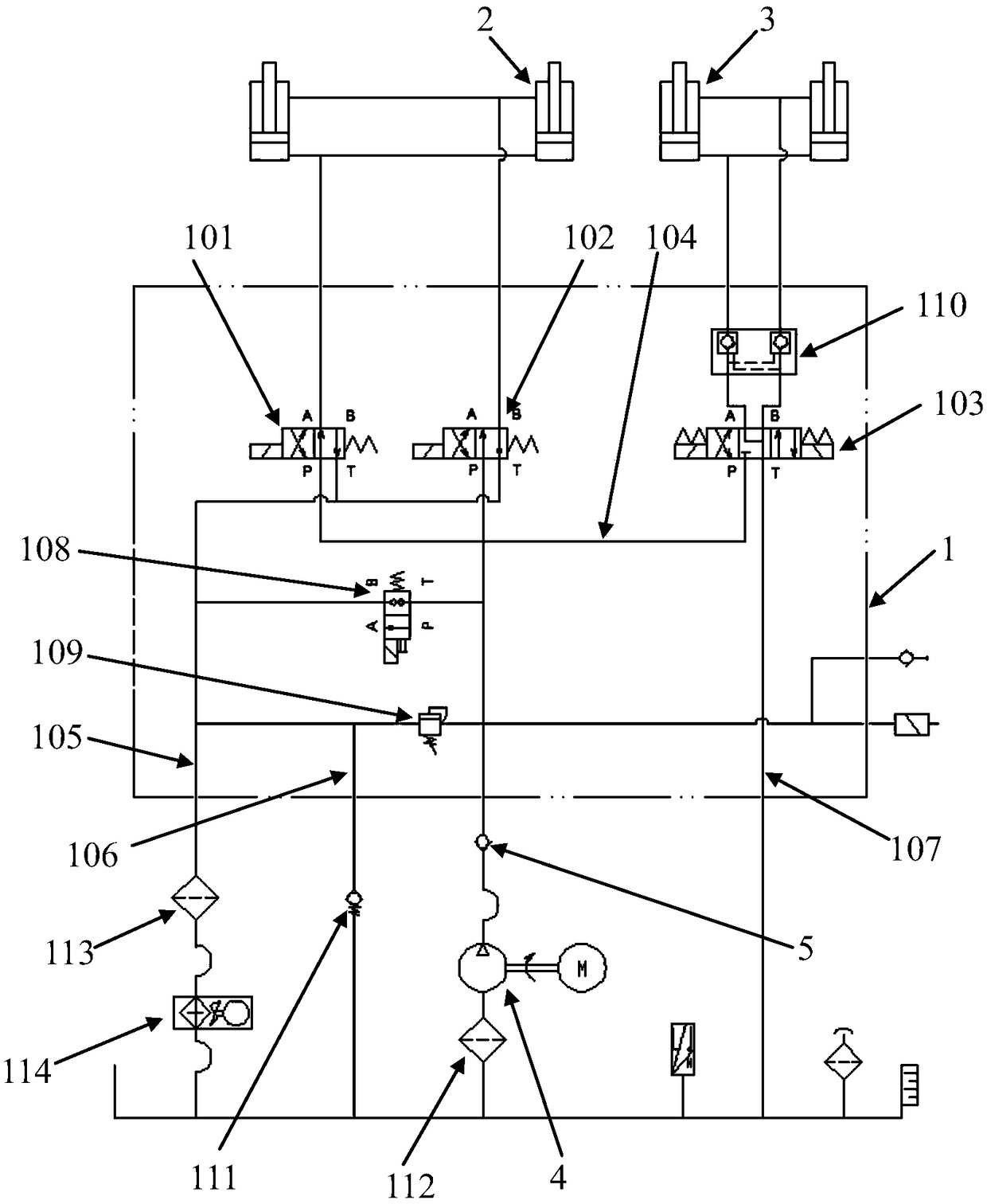

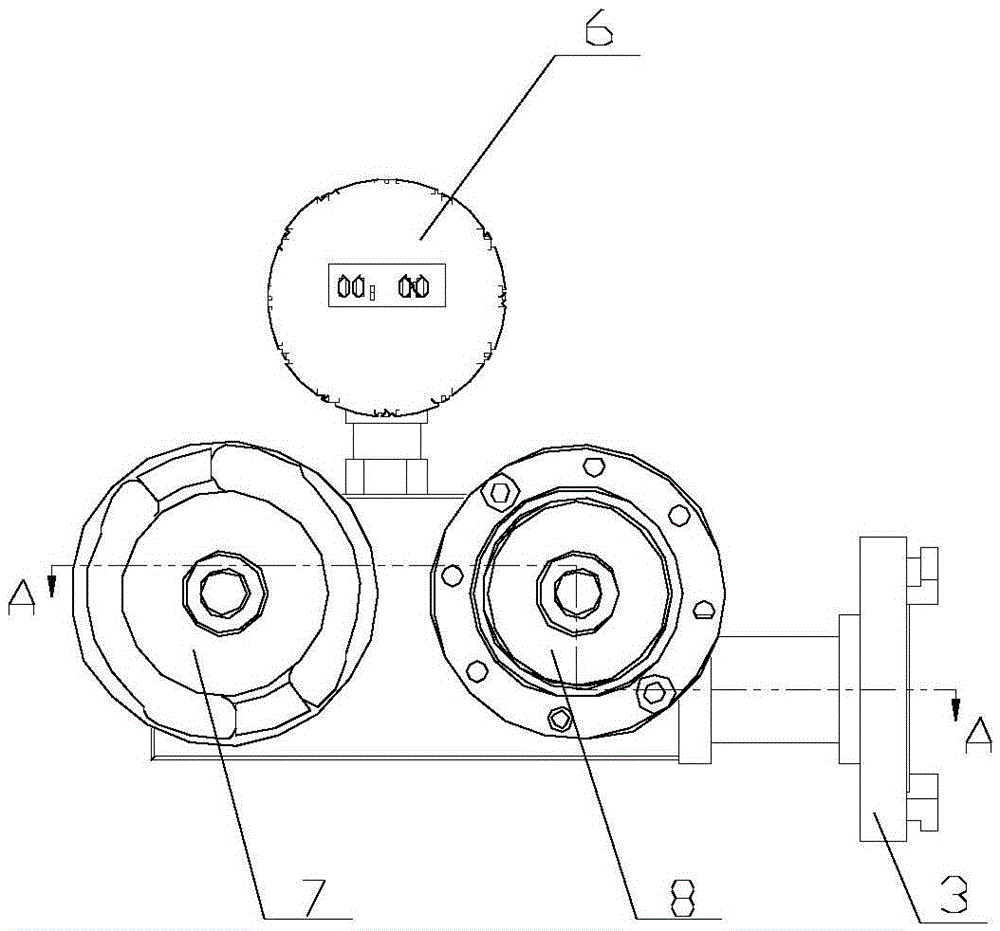

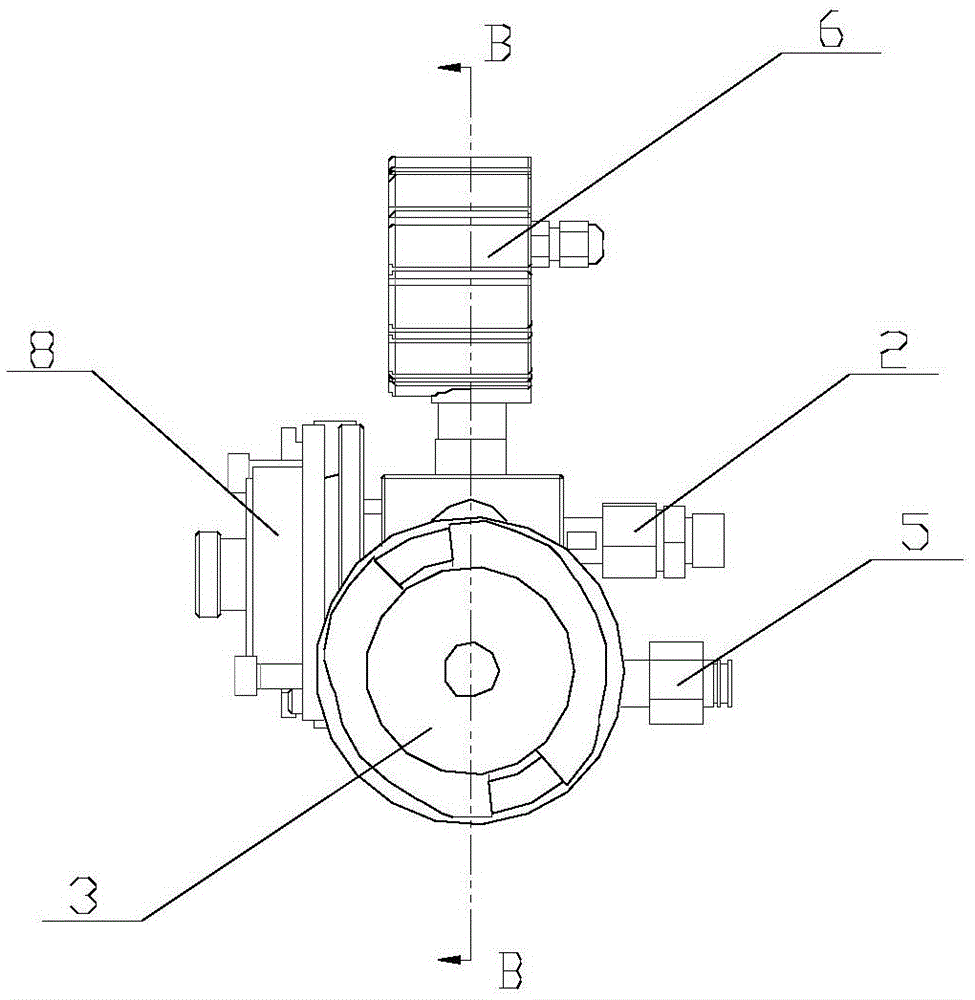

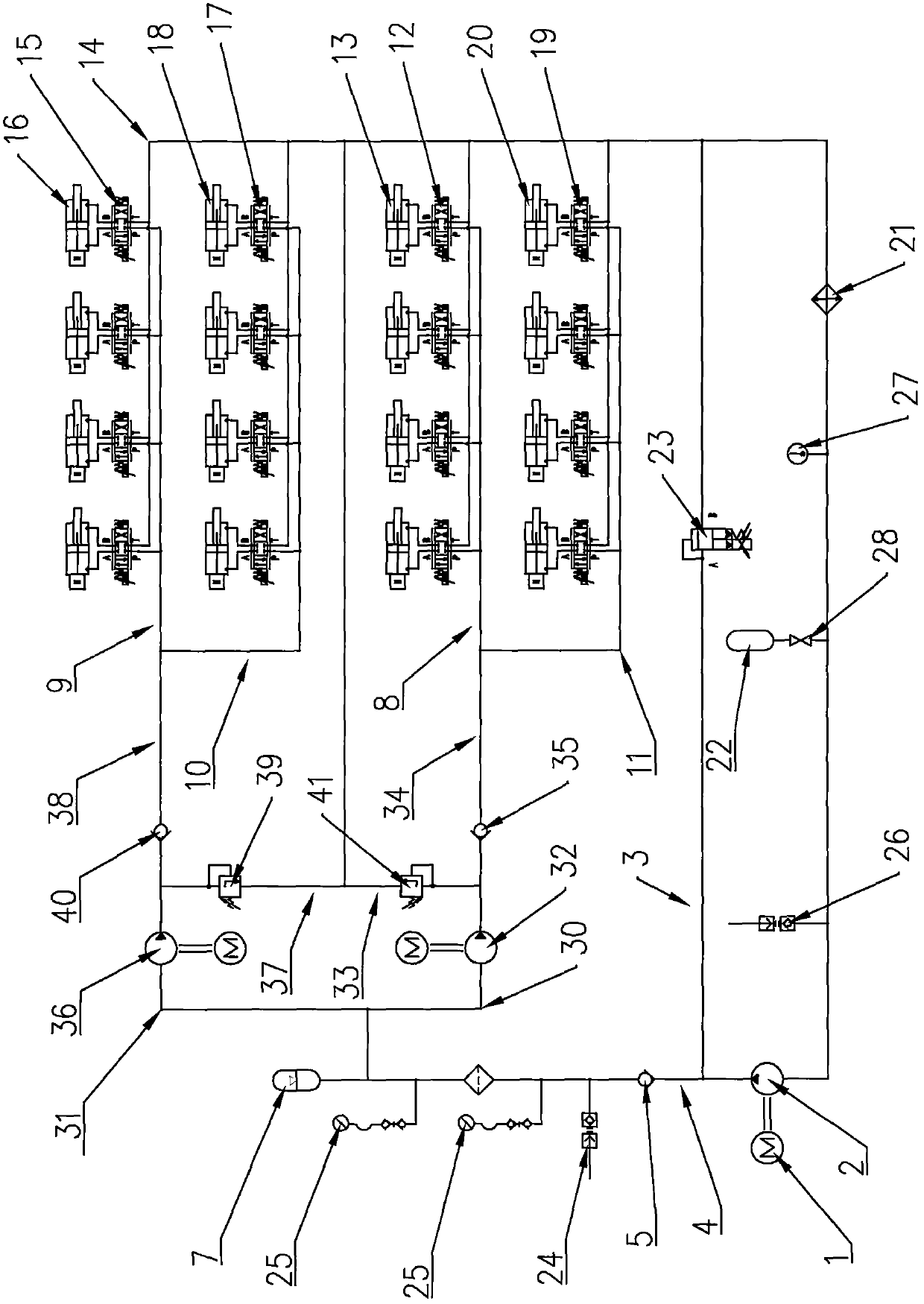

Electric servo hydraulic power source drive system of four-foot robot

ActiveCN105156382APlay a role in maintaining pressureEasy to check for faultsProgramme-controlled manipulatorServomotor componentsHydraulic pumpHigh pressure

An electric servo hydraulic power source drive system of a four-foot robot comprises a quantitative gear pump. The oil outlet of the quantitative gear pump is connected with the inlet of a high-pressure oil pipe. The outlet of the high-pressure oil pipe is connected with the inlet of a left oil supply pipe and the inlet of a right oil supply pipe. The left oil supply pipe is connected with a left hydraulic pump in series. The outlet of the left oil supply pipe is connected with the inlet of a left overflow pipe and the inlet of a left supercharging oil pipe. The middle of the left overflow pipe is connected with a left overflow valve in series. The outlet of the left supercharging oil pipe is connected with the oil inlet of a left front leg oil supply pipe and the oil inlet of a right rear leg oil supply pipe. The right oil supply pipe is connected with a right hydraulic pump in series, and the outlet of the right oil supply pipe is connected with the inlet of a right overflow pipe and the inlet of a right supercharging oil pipe. The middle of the right overflow pipe is connected with a right overflow valve in series. The outlet of the right supercharging oil pipe is connected with the oil inlet of a right front leg oil supply pipe and the oil inlet of a left rear leg oil supply pipe. According to the purpose, the electric servo hydraulic power source drive system of the four-foot robot is light, large in effective volume, constant in oil supplementing pressure, long in driving mileage, low in noise, long in service life, and stable and reliable in performance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

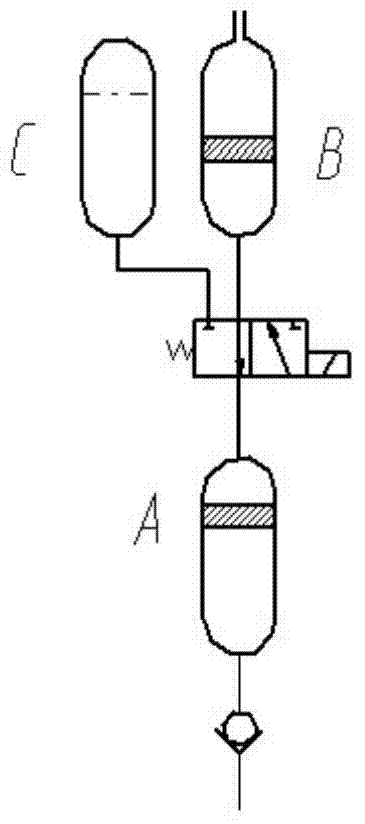

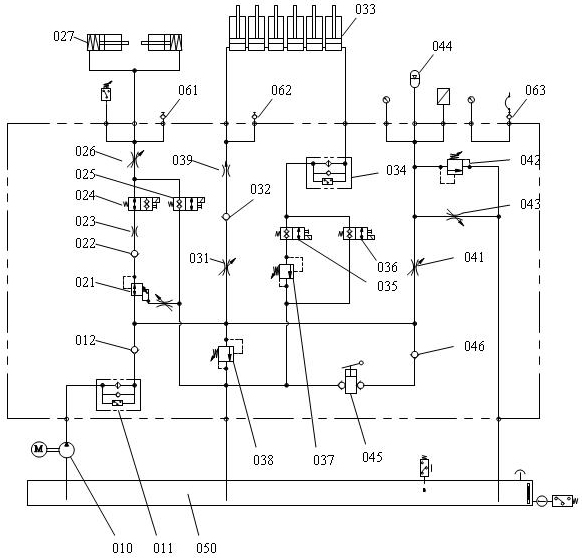

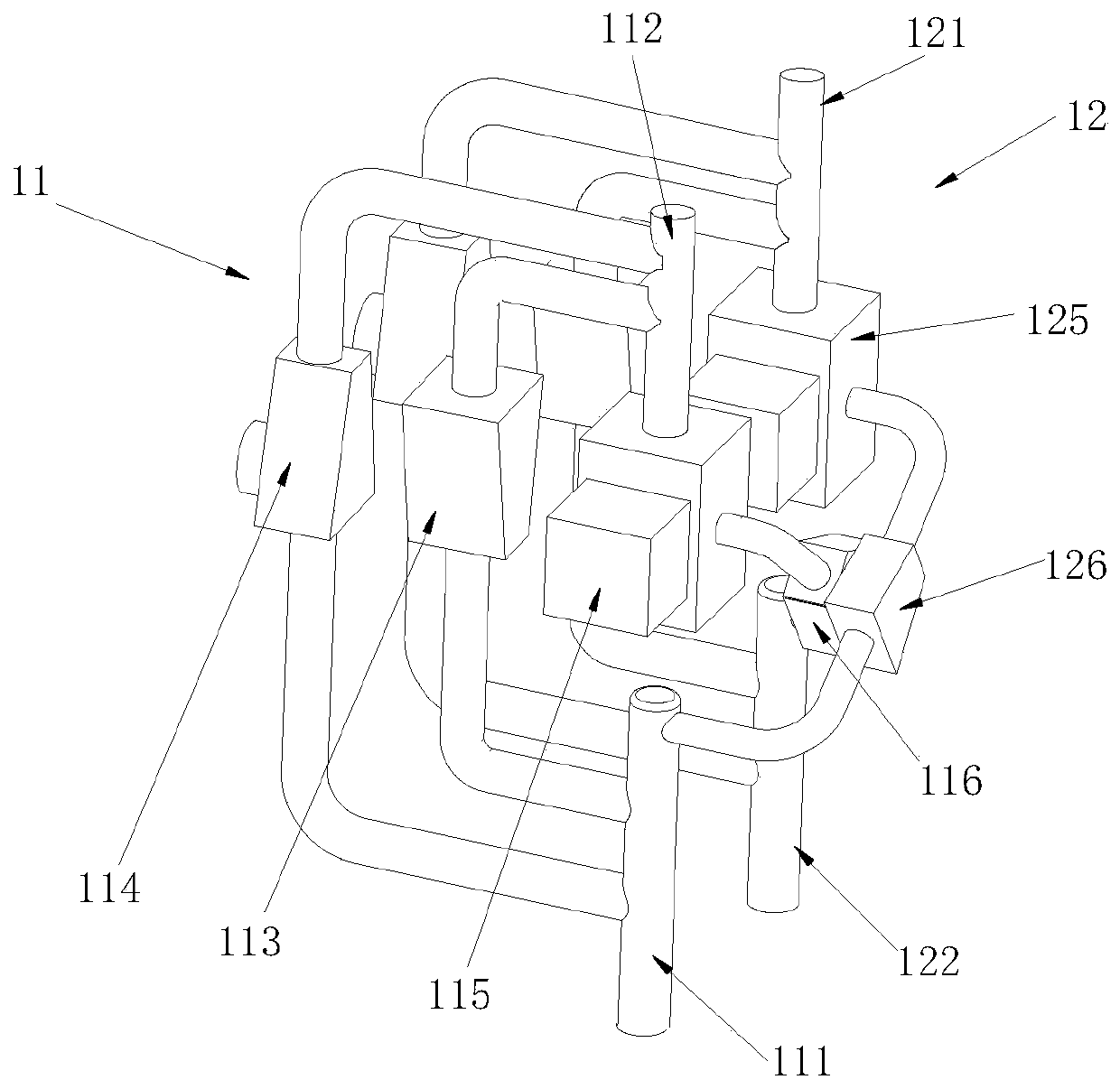

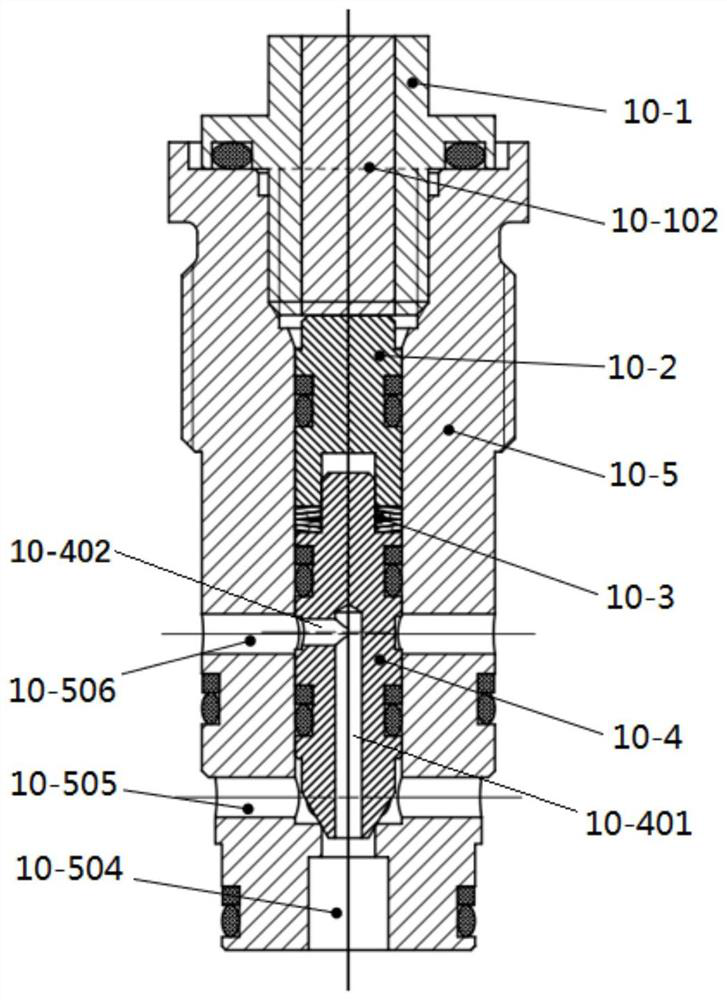

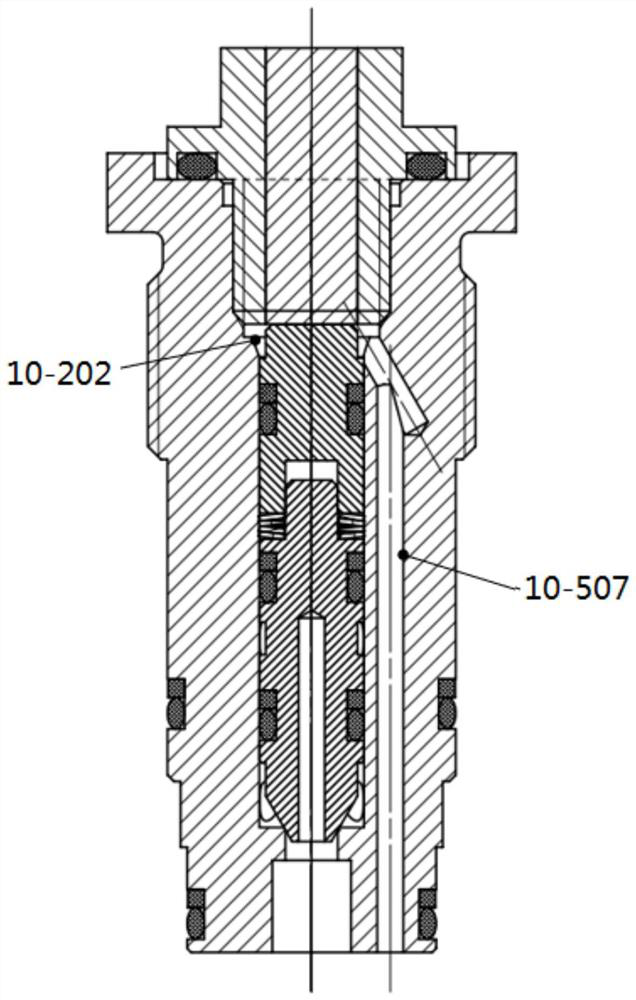

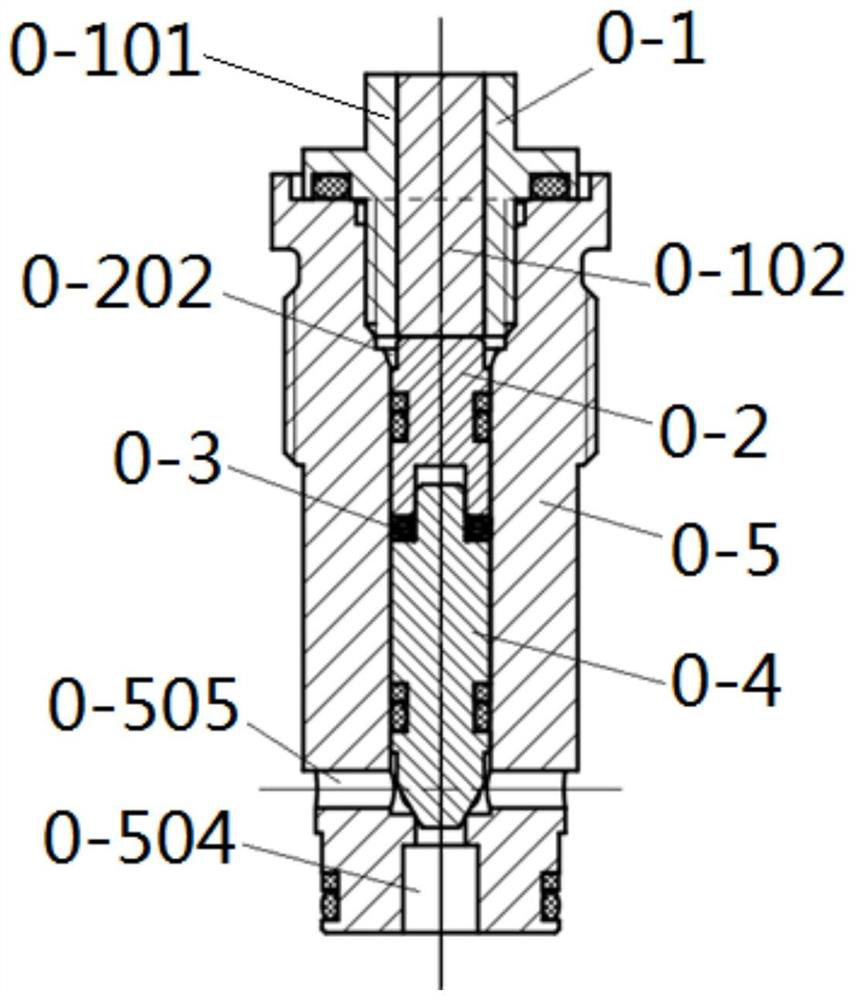

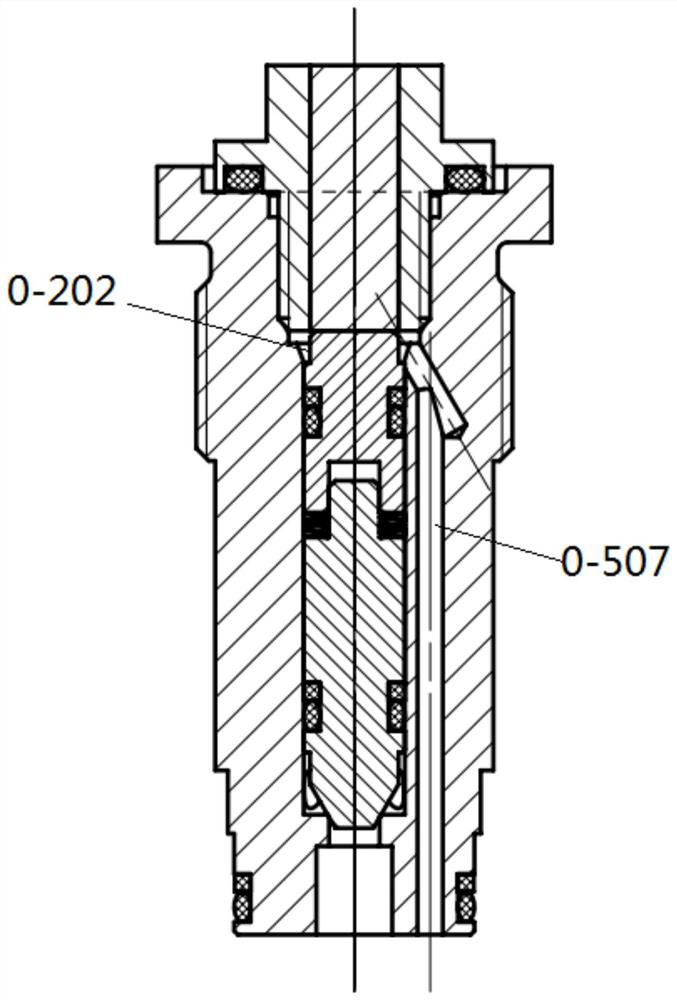

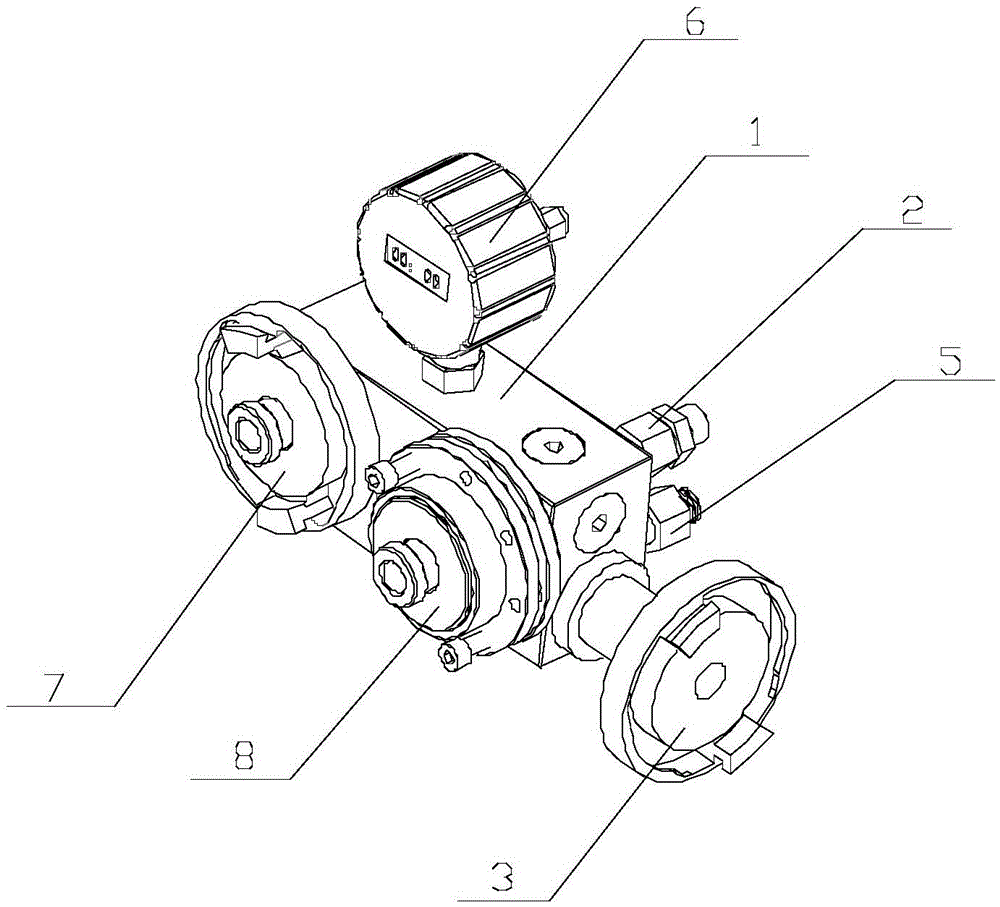

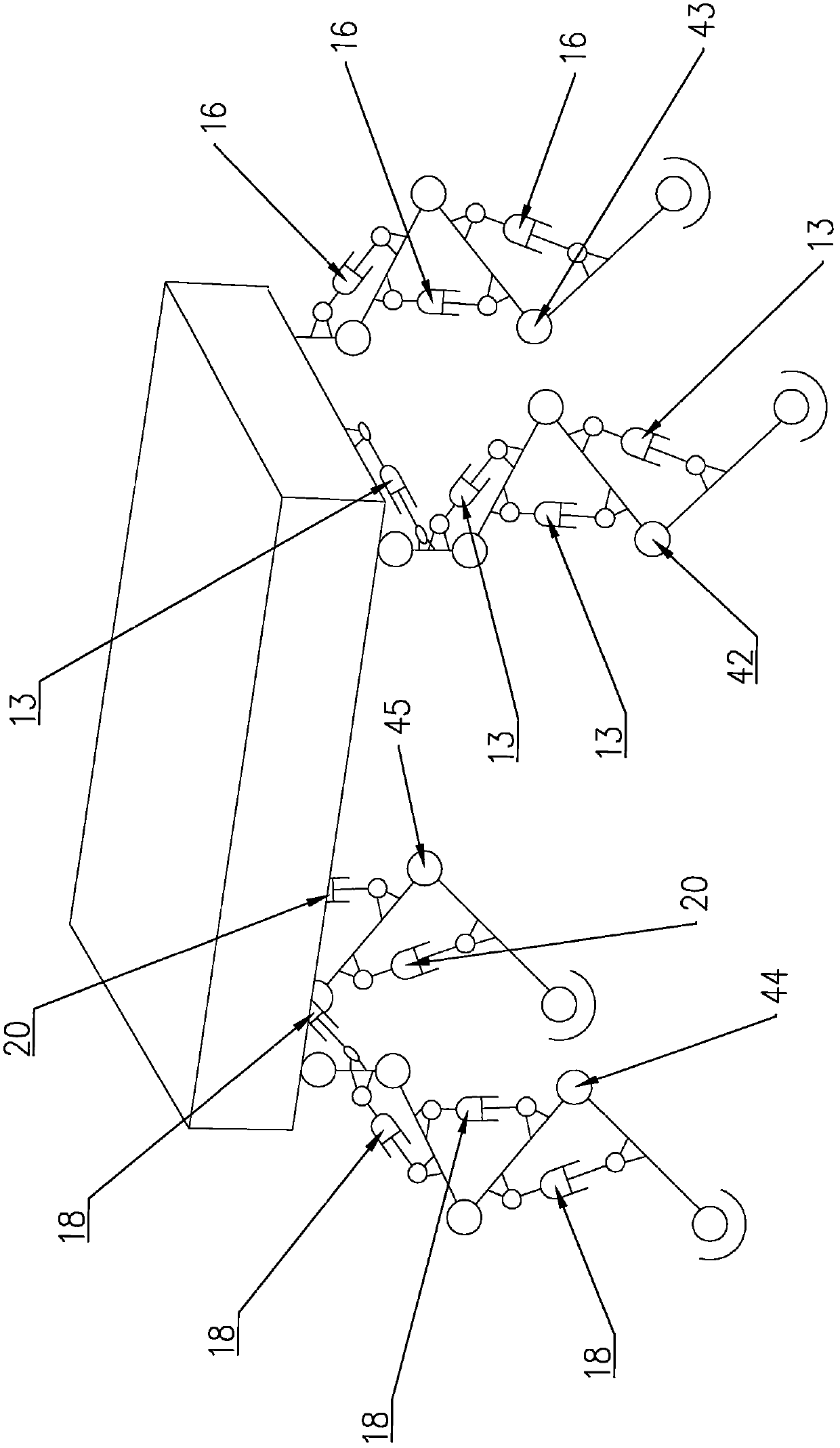

Two-position three-way electromagnetic reversing valve for deep-sea collection

ActiveCN103615570ANot affected by depthRelieve pressureOperating means/releasing devices for valvesMultiple way valvesEngineeringHigh pressure

A two-position three-way electromagnetic reversing valve for deep-sea collection comprises an end cap, a valve body, a left valve seat, a double-end conical valve core, a right valve seat, an electromagnet and the like. Openings A, B and C are formed in the valve body, the end cap, the valve body and the electromagnet are sequentially connected, the left valve seat, the double-end conical valve core and the right valve seat are sequentially disposed inside the valve body from left to right, a conical valve hole is arranged in each of the left valve seat and the right valve seat, an annular groove is formed in each lateral cylindrical face, multiple uniformly-distributed connecting holes are formed in each annular groove and communicated with the conical valve holes inside the respective valve seats, a connecting groove on the double-end conical valve core communicates a left-side inner cavity between the left valve seat and the double-end conical valve core with a right-side inner cavity between the double-end conical valve core and the right valve seat, the double-end conical valve core is connected with an armature pushing rod penetrating the right valve seat, horizontal moving of the double-end conical valve core is realized by controlling a coil to be powered on and off, the opening A and the opening B are externally connected with deep-sea high pressure, the opening A is externally connected with a water incoming one-way valve, and the opening C is communicated with low pressure.

Owner:BEIJING UNIV OF TECH

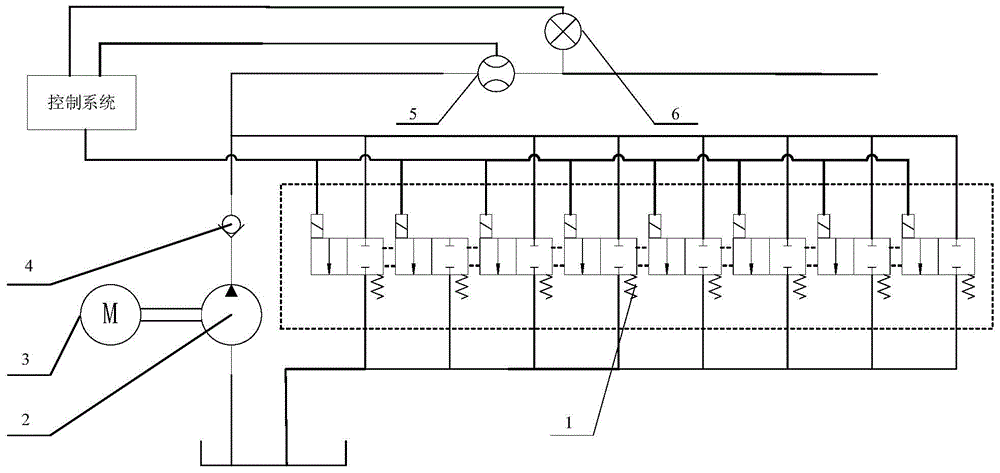

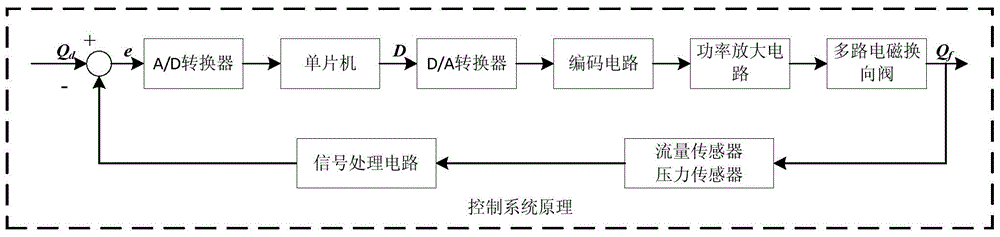

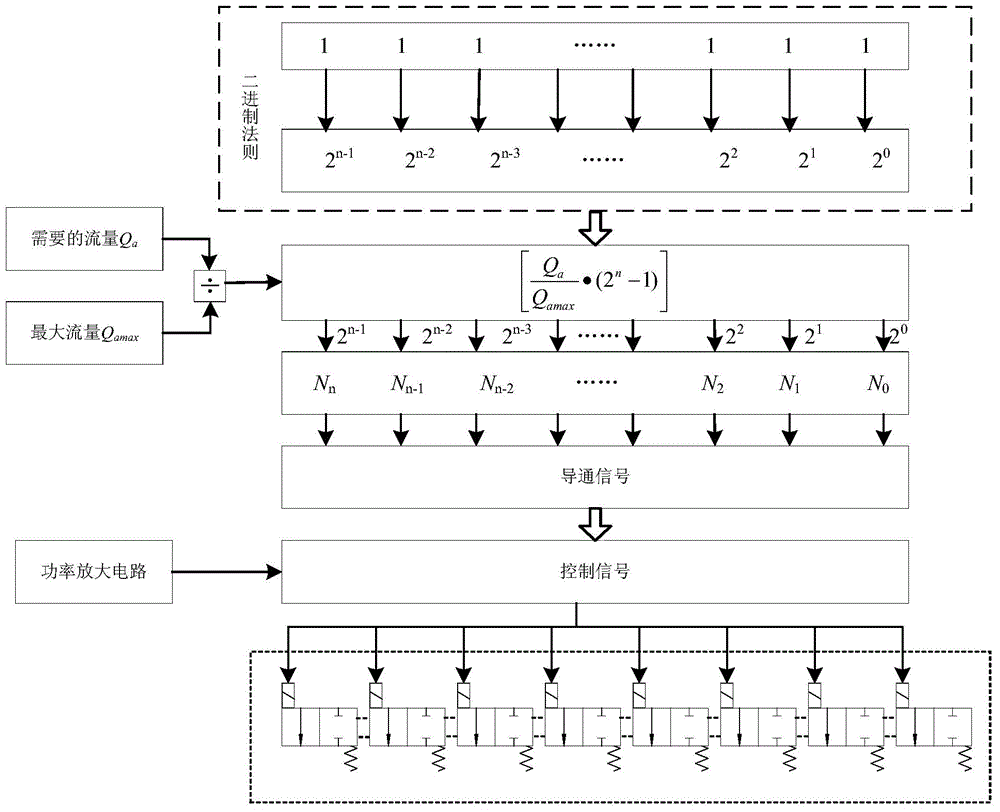

Numerical variable pump based on multichannel solenoid directional valve binary system flow regulation and control

InactiveCN105041782ALow cleanliness requirementsAvoid traffic fluctuationsServomotor componentsFluid-pressure actuator componentsMicrocontrollerMicrocomputer

The invention discloses a numerical variable pump based on multichannel solenoid directional valve binary system flow regulation and control. The main body of the pump is a metering pump; the flow regulation of surplus flow overflow is realized by the on-off of n submodules of a designed multichannel solenoid directional valve; a flow sensor and a pressure sensor are mounted in a main oil circuit; output ends of the flow sensor and the pressure sensor are connected with a signal processing circuit; processed signals are transmitted to a single chip microcomputer by an A / D converter; a bypass overflow quantity is obtained through computation, and is compared with a maximum overflow quantity; a specific value is subjected to conversion into an integer between 0 and 2n-1 by the single chip microcomputer; the integer is transmitted into a code circuit to be converted into n-bit binary coding and used as a control signal of the multichannel solenoid directional valve; and a power amplification circuit enables the corresponding submodules to act, and the pressure or flow of the main oil circuit is regulated. According to the numerical variable pump based on multichannel solenoid directional valve binary system flow regulation and control, the pressure and flow of the main oil circuit are regulated by regulating the bypass overflow quantity through the on-off of different modules; and the numerical variable pump based on multichannel solenoid directional valve binary system flow regulation and control has the advantages that the pressure and flow fluctuation is low; the environment adaptability is strong; the dynamic property is good and the like.

Owner:XI AN JIAOTONG UNIV

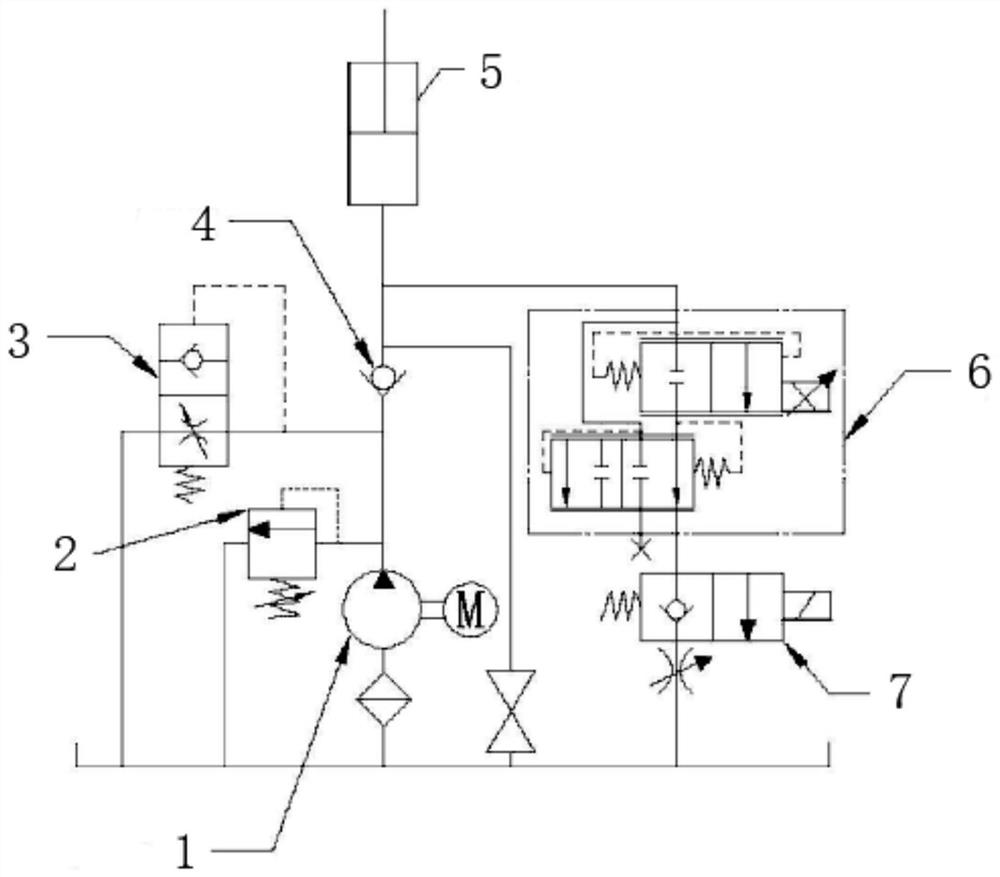

Wind power generation hydraulic system

InactiveCN101979870AUniform flow velocitySmooth brakingWind motor controlServomotorsSystem pressureFuel tank

The invention discloses a wind power generation hydraulic system, which comprises an oil pump, an external oil tank, a spindle brake unit, yawing brake unit and a safe pressure maintaining unit, wherein the oil pump is connected with a spindle brake oil cylinder group through a reducing valve and a first electromagnetic valve, connected with a yawing brake oil cylinder group through a first adjustable throttle, and connected with an energy accumulator through a second adjustable throttle by the same pipeline; the spindle brake oil cylinder group is connected with the external oil tank through a pipeline; the yawing brake oil cylinder group is connected with the external oil tank through a third electromagnetic valve and a first overflow valve by a pipeline; the energy accumulator is connected with the external oil tank through a third overflow valve by a pipeline; and the external oil tank is connected with the yawing brake oil cylinder group through a second overflow valve and the first adjustable throttle by a pipeline. The wind power generation hydraulic system can perform spindle brake and yawing brake, and is provided with the system pressure maintaining device.

Owner:SHANGHAI ELECTRICAL HYDRAULICS & PNEUMATICS

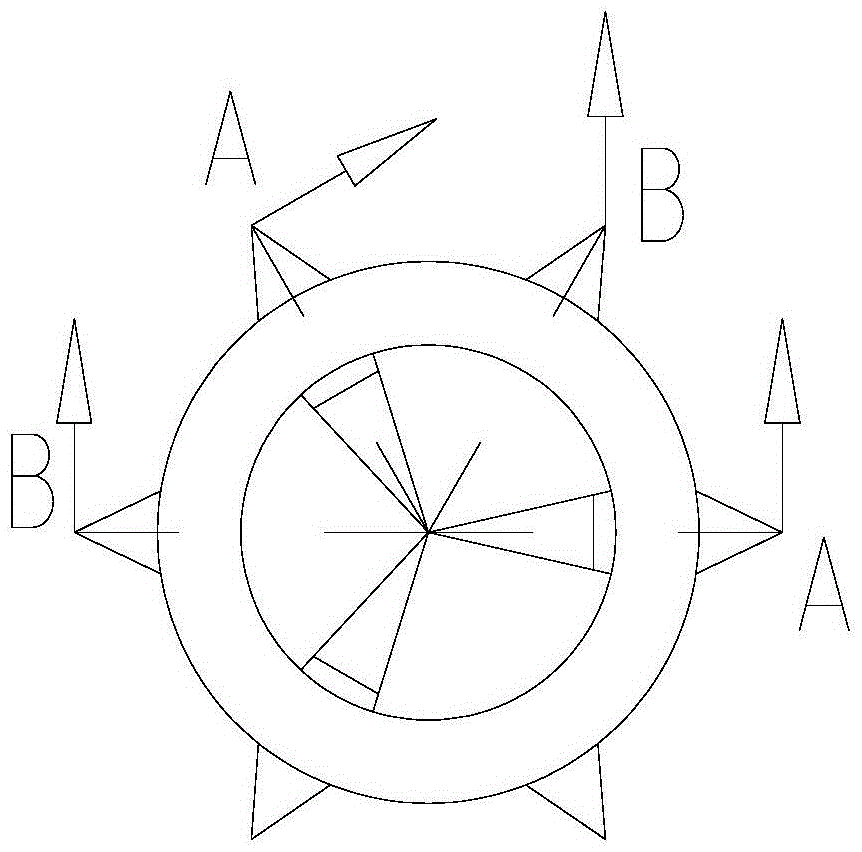

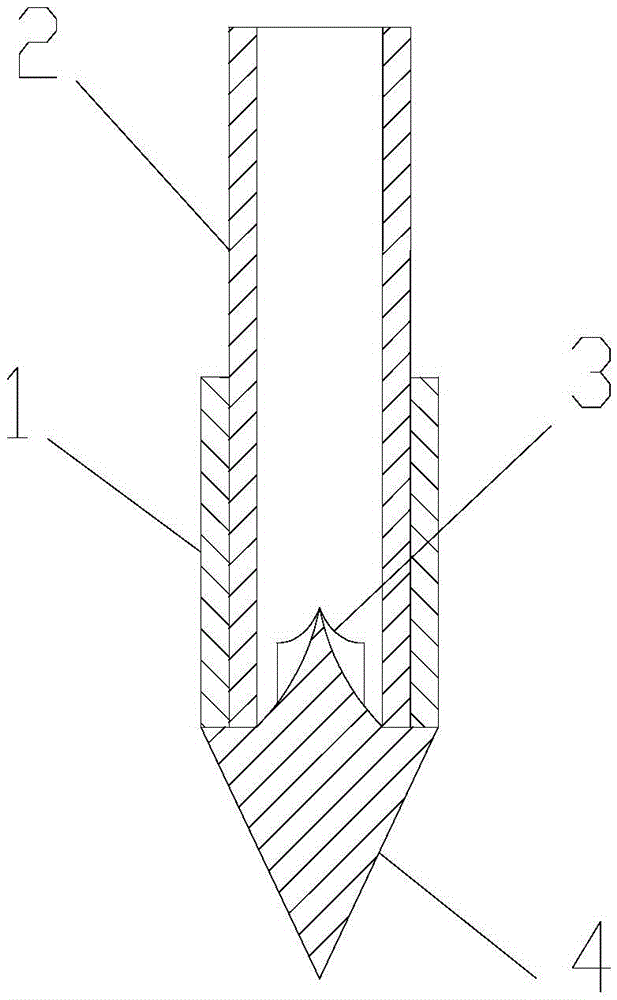

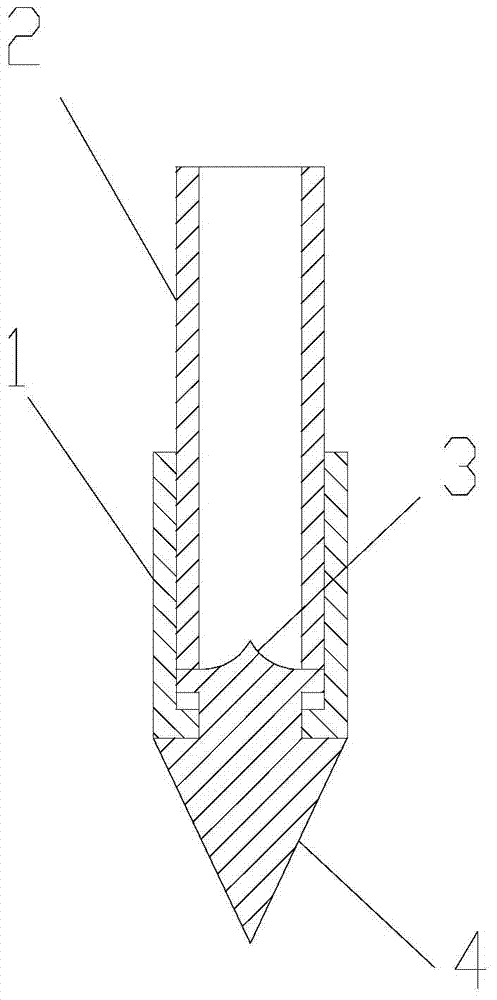

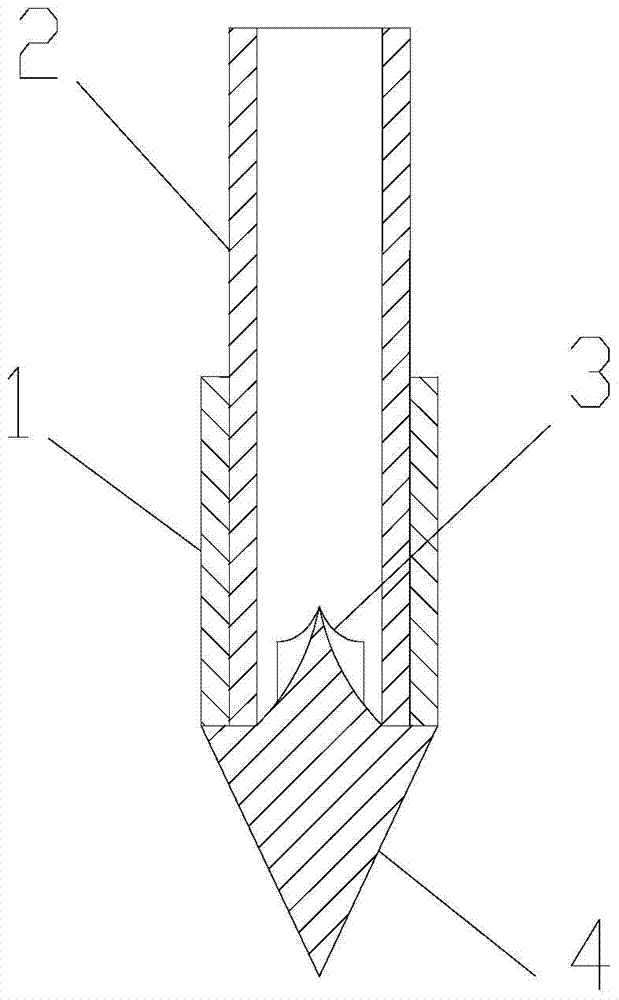

Head for automatic blasting, loosening and feeding

ActiveCN105409369APlay a role in maintaining pressureImprove sealingSpadesPloughsEngineeringFlow diverter

The present invention discloses a head for automatic blasting, loosening and feeding. The head comprises an injection tube and a conical splitter that is slide-fitted with an outlet end of the injection tube. The conical splitter comprises an upper cone and a lower cone which are integrally formed. The upper cone is inserted into the injection tube to split a gas that flows out of the injection tube. The lower cone is used for being inserted into the soil, and a seal platform for sealing the outlet of the injection tube is arranged on the top of the lower cone. According to the head for automatic blasting, loosening and feeding, the machining difficulty of the injection hole is simplified, the problem that the injection hole causes the flow to be small is solved, and on the basis of automatically starting and ending operations, a powerful blast wave is formed to blast and loosen the soil and inject a large quantity of a material.

Owner:CHENGDU TOBEST DIYUAN TECH CO LTD

Remote dust-free concrete sprayer

InactiveCN105484771AReasonable designSimple structureUnderground chambersTunnel liningCoalEngineering

The invention provides a remote dust-free concrete sprayer and belongs to the technical field of concrete spraying devices used in underground coal mines. The remote dust-free concrete sprayer aims at solving the problems of short spraying distances and high springback rate of an existing sprayer. A feeding portion of the existing sprayer is improved, a conical feeder is adopted, at least two rotor material cups are annularly arranged on the surface of a feeding rotor of a cylindrical structure or a circular truncated cone shaped structure at intervals, the feeding rotor is in sealed connection with a feeding shell, the rotor material cups sequentially pass through a feeding port, a discharging port and a residual air port of the feeding shell along with the feeding rotor, when the rotor material cups gradually rotate to the discharging port of the feeding shell, an air supplementing port is communicated with the rotor material cups to enable materials in the rotor material cups to quickly enter a spraying portion, the rotor material cups continue to rotate along with the rotor and later pass through the residual air port of the feeding shell to discharge out residual air and materials in the rotor material cups so as to facilitate that the rotor material cups receive materials from a hopper portion again when continuing to rotate to the position of the feeding port.

Owner:ZOUCHENG TIANHE SCI & TECH

Automatic spray blast loosening head

ActiveCN105409369BPlay a role in maintaining pressureImprove sealingSpadesPloughsEngineeringFlow diverter

Owner:重庆天本地源科技有限公司

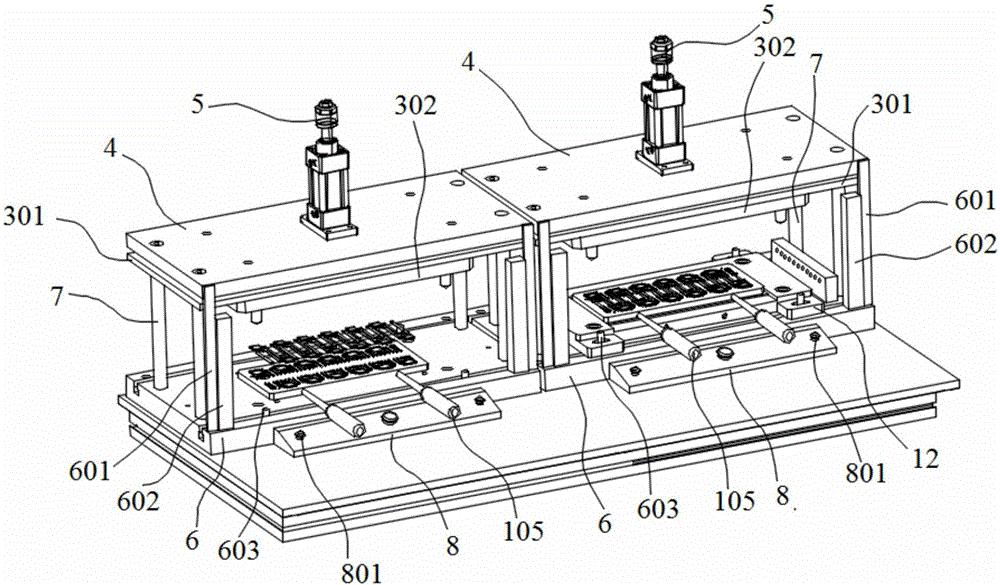

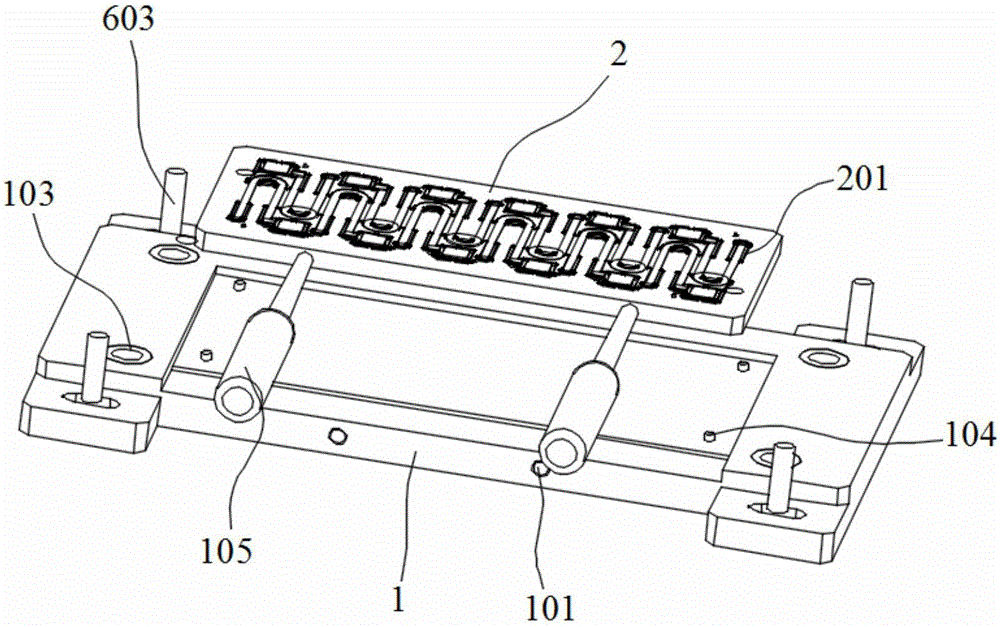

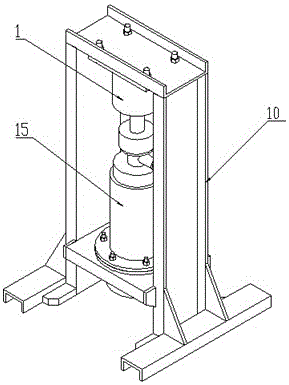

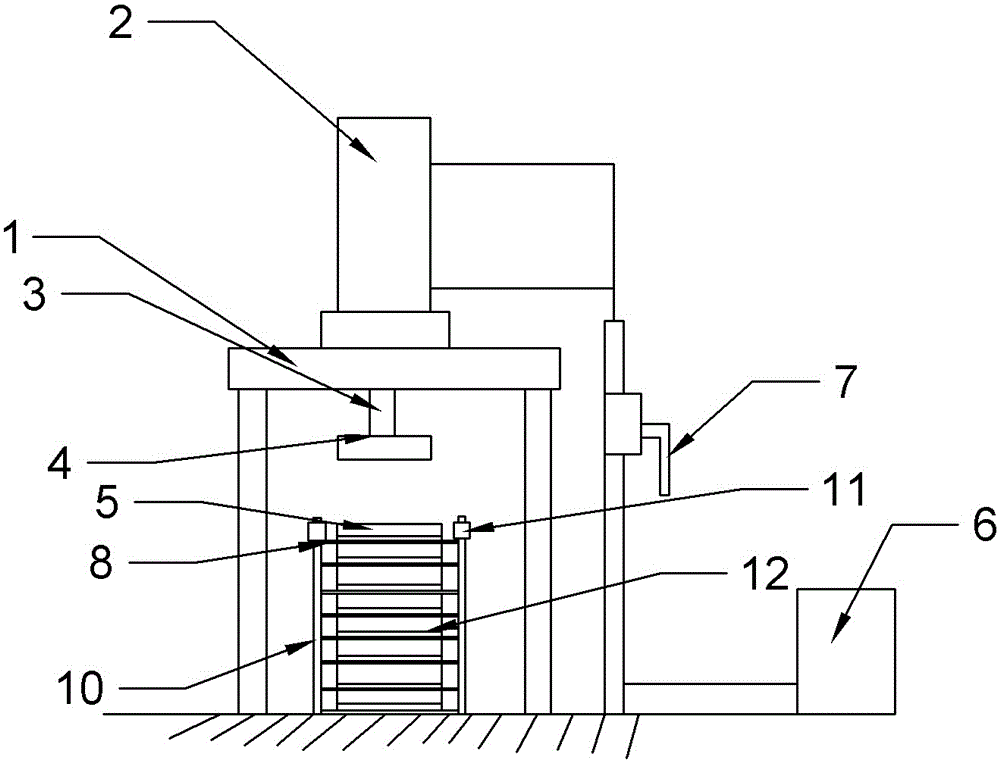

Fingerprint module applied hot and cold pressure integrated processing apparatus

PendingCN106604562AEasy to debugAccurate pressurePrinted circuit assemblingPCB positioning during processingPistonFingerprint

The invention discloses a fingerprint module applied hot and cold pressure integrated processing apparatus which comprises a substrate, an object carrying plate, a vertical buffer pressure mechanism, a fixed plate and a vertical cylinder wherein the vertical buffer pressure mechanism is further provided with an active plate, a pressing plate, a plurality of springs and a plurality of pressing heads. The springs are located in the upper through holes and arranged between the upper through holes and the active plate; the piston of the vertical cylinder is connected with the active plate; the substrate further comprises a hot pressure substrate and a cold pressure substrate; the front end of the bottom plate is provided with a connection column; the connection column is fixedly provided with an alarm device. The operation console is provided with a starting button and an emergency halting button. According to the invention, through hot pressure, the metal fingerprint can be fixed onto a flexible circuit board and at the same time, due to the pressure protection in the hot pressure processing, the product is not deformed in the hot pressure process; then in the pressure protection, the product is cooled down so that the product is not deformed or broken in the cooling process.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

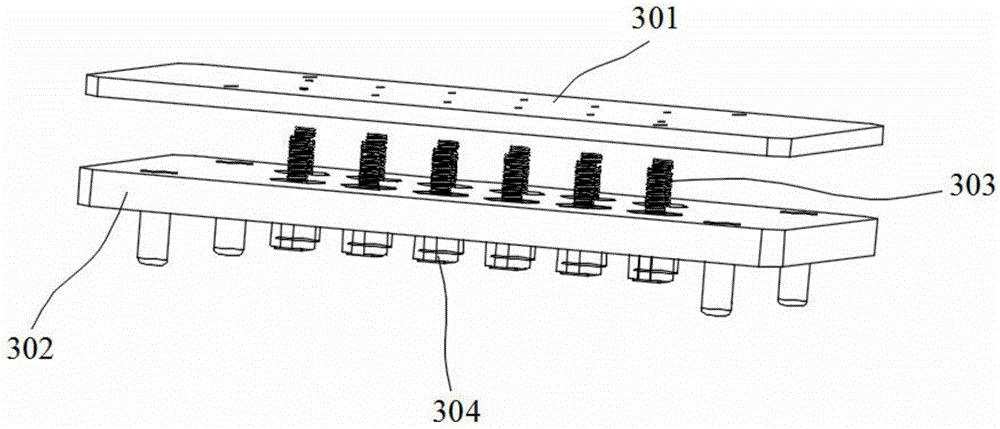

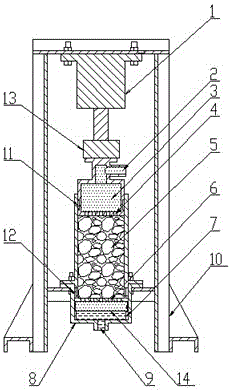

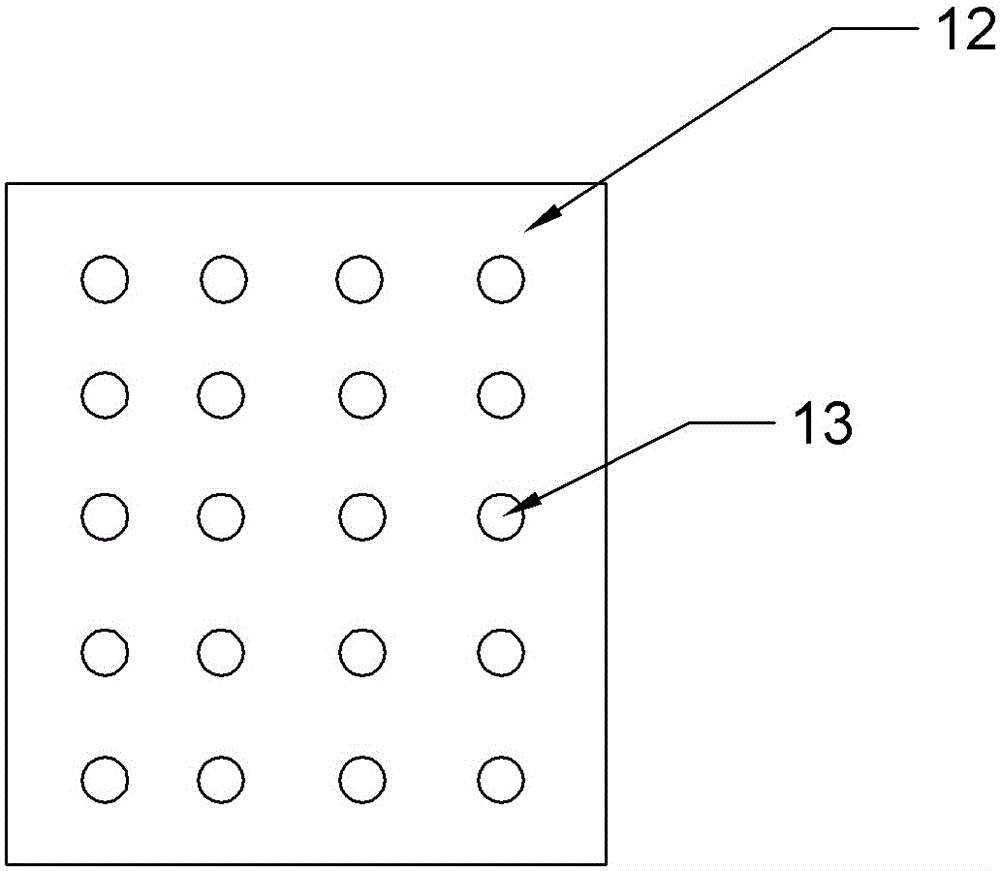

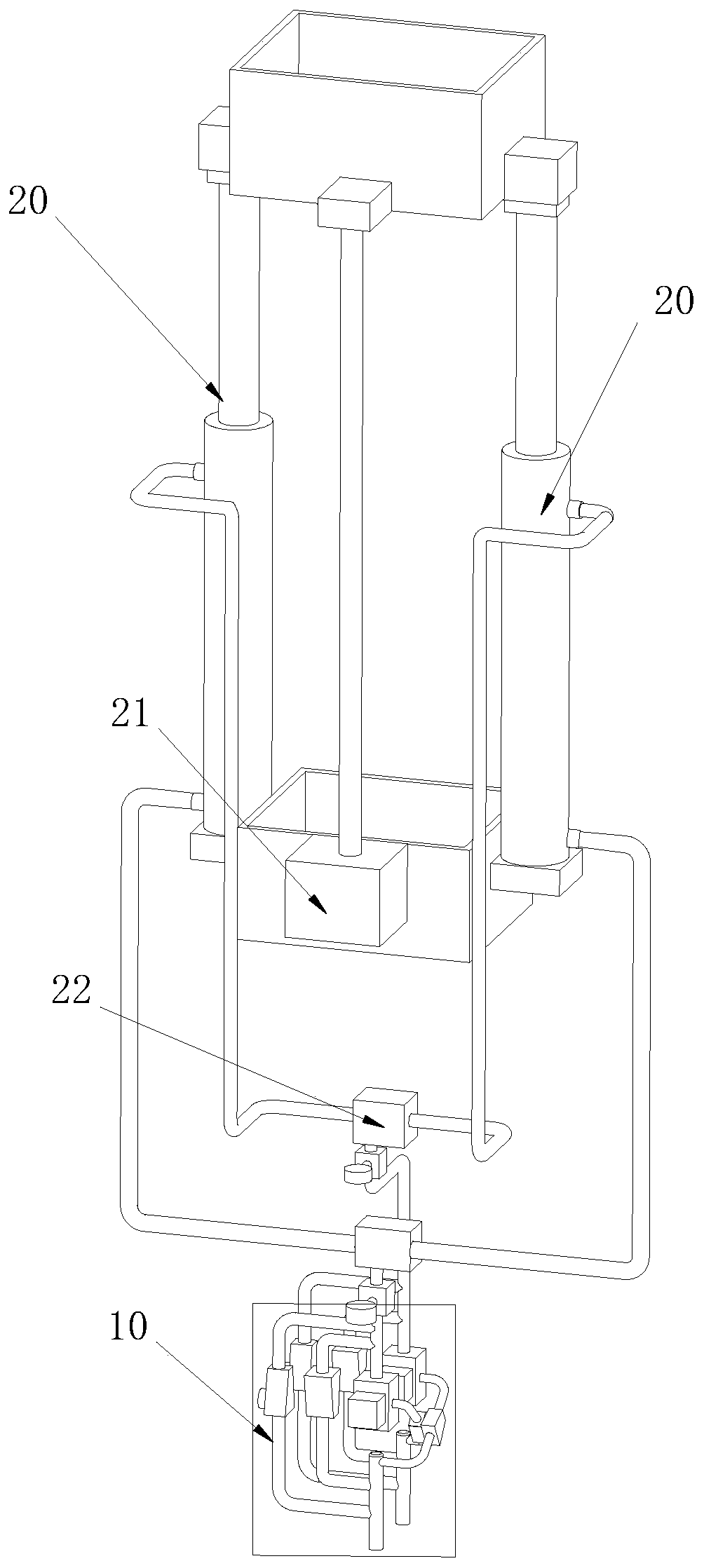

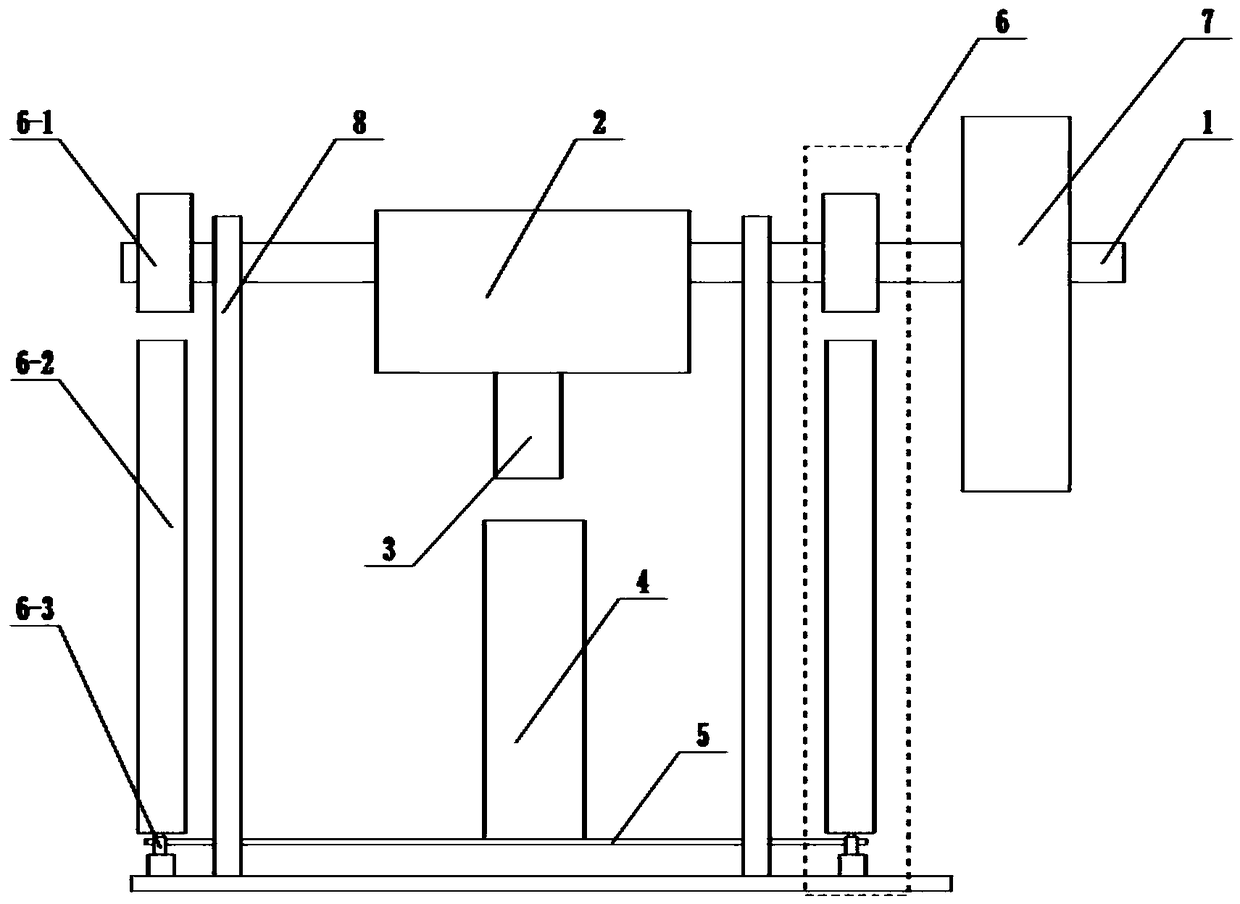

Permeation device for water and sand two-phase seepage of fractured rock mass

PendingCN106226219AEvenly distributedMake sure to collectPermeability/surface area analysisWater sourcePerformance index

The invention provides a permeation device for water and sand two-phase seepage of a fractured rock mass. The permeation device comprises a longitudinal loading mechanism, a supporting frame, a permeation device body and a pressure control device, wherein the permeation device body comprises the supporting frame, and a permeameter and a longitudinal loading mechanism which are mounted on a pedestal of the supporting frame; the longitudinal loading mechanism is mounted at the upper end in the supporting frame through a bolt; the permeameter is arranged at the lower end in the supporting frame; the permeameter comprises a cylinder base, a filter device, a gravel cavity and a water and sand cavity. The permeation device for water and sand two-phase seepage of the fractured rock mass has the advantages of stable and continuous supplying of a dynamic pressure water source, openness of sand grain loss, sand grain collection and the like; all performance indexes of a permeation system are matched, and the stability is high; an experiment can be repeatedly tested, and real and accurate test data can be guaranteed; the permeation device has certain reference significance.

Owner:HENAN POLYTECHNIC UNIV

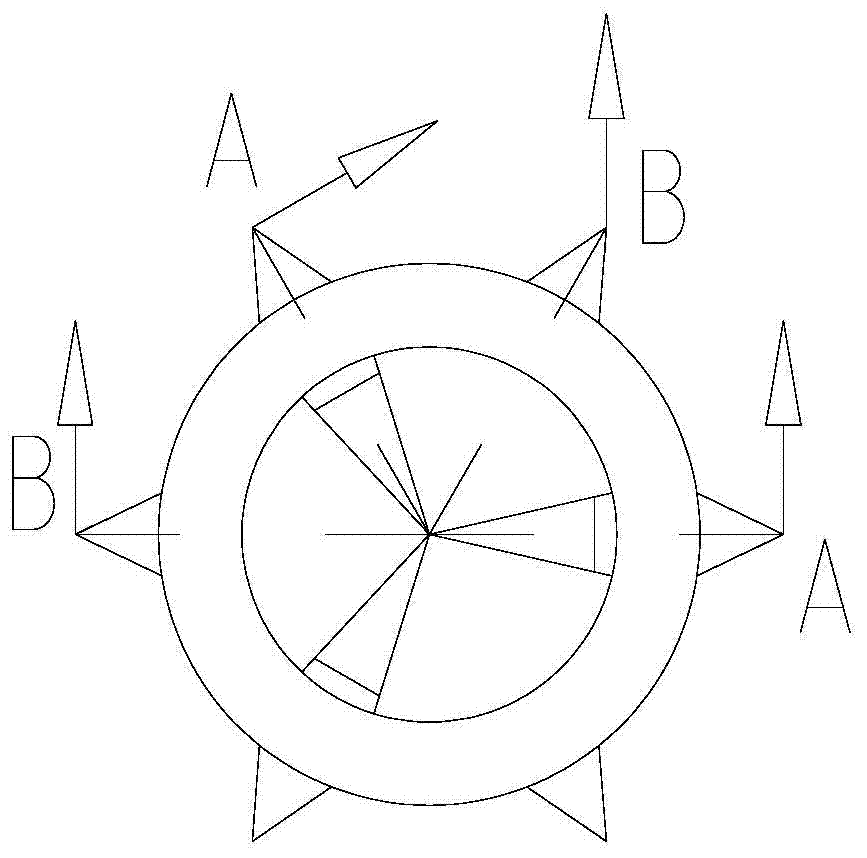

High-pressure injection pump

The invention belongs to the technical field of water pumps, and particularly relates to a high-pressure injection pump. The high-pressure injection pump includes a rotor body, a collecting main, wherein the rotor body includes impellers and a rotor cavity, and the collecting main includes diffusion sections and an outlet pipe; the outer surfaces of the diffusion sections of the collecting main are in streamline shapes; and the diffusion sections of the collecting main are evenly distributed in an array mode in the circumferential direction of the outlet pipe, the number of the diffusion sections of the collecting main is at least 3, the outlet pipe of the collecting main is made of elastic materials, and the inner diameters of the cross sections of the outlet pipe are gradually decreasedfrom the left to the right. According to the high-pressure injection pump, the number of the diffusion sections of the collecting main is at least 3, thus water amount flowing into inner cavities of the diffusion sections is increased, rate of flow of water flowing into the outlet pipe and pressure of the water flowing into the outlet pipe are increased, the pressure and the rate of flow of the water flowing out of the outlet pipe are increased, the inner diameters of the cross sections of the outlet pipe are gradually decreased from the left to the right, thus when water flow passes the outlet pipe from the left to the right, water pressure is gradually increased, and thus the pressure of the water flowing out of the outlet pipe is increased.

Owner:TONGLING ZHAOLIN IND & TRADE CO LTD

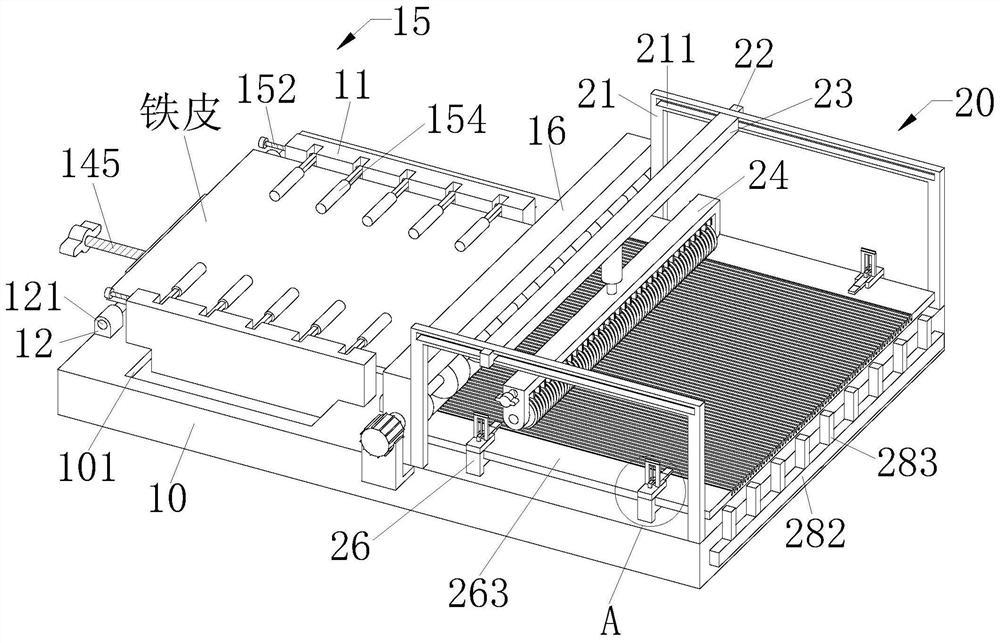

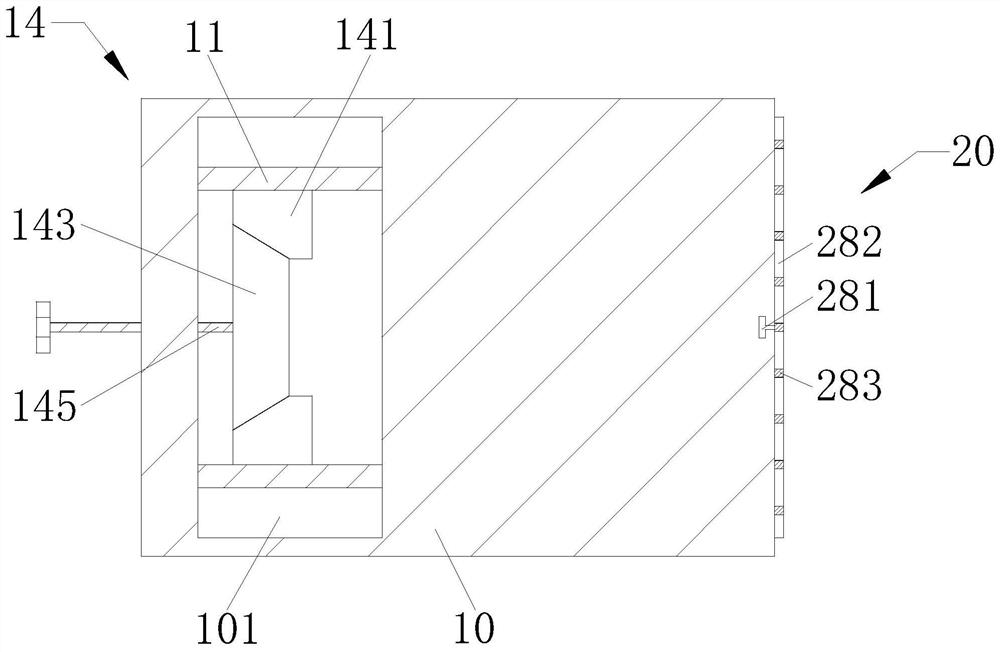

Packaging tin raw material tinplate machining treatment system and machining method

InactiveCN113560393APlay a guiding roleHigh precisionShaping toolsMetal-working feeding devicesStampingMachining

The invention relates to a packaging tin raw material tinplate machining treatment system and machining method. The system comprises a workbench and a rolling device arranged on the workbench. According to the packaging tin raw material tinplate machining treatment system and machining method, two T-shaped clamping plates are driven by the two wedge-shaped blocks to move oppositely or reversely, the front end and the rear end of a to-be-machined iron sheet can be properly extruded, the to-be-machined iron sheet can be adjusted in the center position of the top of the workbench, iron sheets of different specifications and sizes can be further adjusted, the iron sheets are prevented from moving in the conveying process, the left-right reciprocating rectilinear motion of a T-shaped electric sliding block can drive a left square bracket-shaped lug base and a stamping plate to move synchronously, so that the iron sheet subjected to primary stamping can be rolled in a reciprocating mode, the pressure maintaining effect on the iron sheet subjected to the primary stamping is achieved, the corrugated shape of the iron sheet subjected to the primary stamping is stabler, and the phenomenon that the surface of the iron sheet rebounds after the one-time stamping is prevented, so that the corrugated stamping shape is guaranteed.

Owner:尹立志

Dried tofu squeezing machine

InactiveCN105028676APlay limitPlay a role in maintaining pressureCheese manufactureFood sciencePulp and paper industryPiston rod

The invention relates to the field of dried tofu processing equipment, and particularly relates to a dried tofu squeezing machine which comprises a rack, a cylinder and a power mechanism, wherein the rack comprises a rack column and a rack top plate, the cylinder is positioned on the rack top plate, the piston rod of the cylinder penetrates through the rack top plate and is vertically downward, a squeezing head is arranged at the lower end of the piston rod, a plurality of layers of overlapped dried tofu containing boxes are arranged below the squeezing head, an extension block is arranged at the side wall of each of two ends of the dried tofu containing box, a limiting hole is formed in the extension block, and a connecting rod penetrating through the limiting hole is arranged at the bottom of the rack. According to the invention, due to the arrangement of the connecting rod, the dried tofu containing boxes are limited, so that pressure maintaining can be achieved without using the cylinder, resources can be saved, and the cost is reduced.

Owner:重庆乐嚼食品有限公司

Safe pressurizer of wind power generation hydraulic system

InactiveCN102116256AGuaranteed to workPlay a role in maintaining pressureFluid-pressure actuator safetyWind motor controlFuel tankWind force

The invention discloses a safe pressurizer of a wind power generation hydraulic system, which is applied to the technical field of wind power generation, and comprises an oil pump, and an accumulator connected with an oil pump pipeline; an oil inlet of a spindle brake unit and an oil inlet of a yawing brake unit are arranged on the oil pump and an accumulator pipeline in sequence; a manual pump branch connected with a first interface of an external oil tank through a manual pump pipeline, a first adjustable throttle valve, a throttle valve branch connected with a second interface of the external oil tank through a throttle valve pipeline, and a first spillover valve branch connected with the second interface of the external oil tank through a first spillover valve pipeline are arranged between the oil inlet of the yawing brake unit and the accumulator pipeline in sequence. When oil supply of the pipeline of the accumulator adopted by the safe pressurizer of the wind power generation hydraulic system is cut off, the hydraulic oil stored in the pipeline is released and flows into a spindle brake device and a yawing brake device so as to guarantee the normal work of the two devices; and when a fan is stopped for overhauling, the pressure of the accumulator can supplement the pressure loss in the system to play the role of pressurizing.

Owner:SHANGHAI ELECTRICAL HYDRAULICS & PNEUMATICS

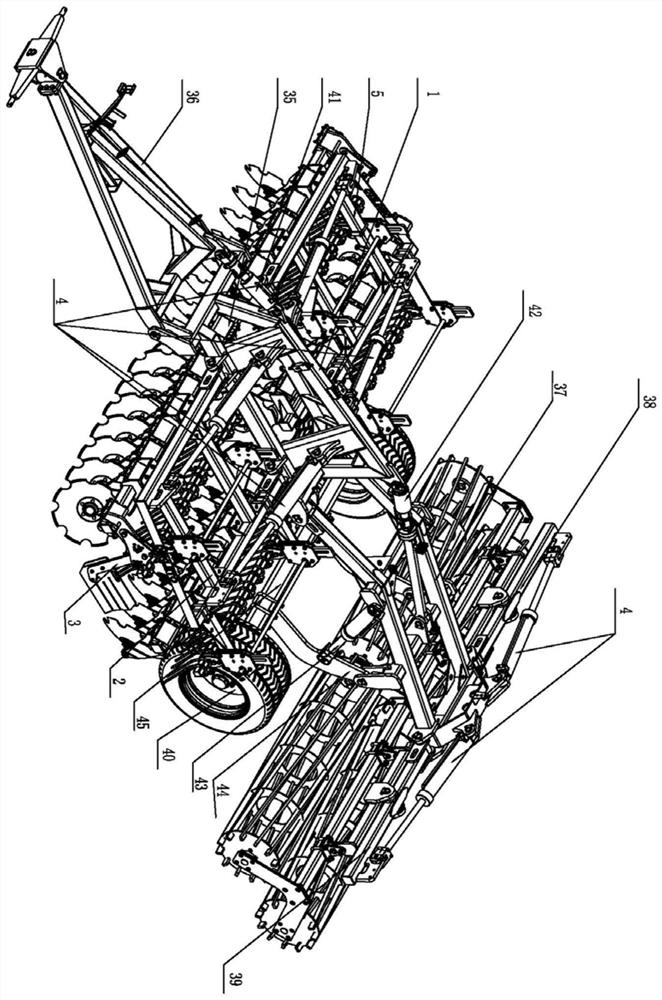

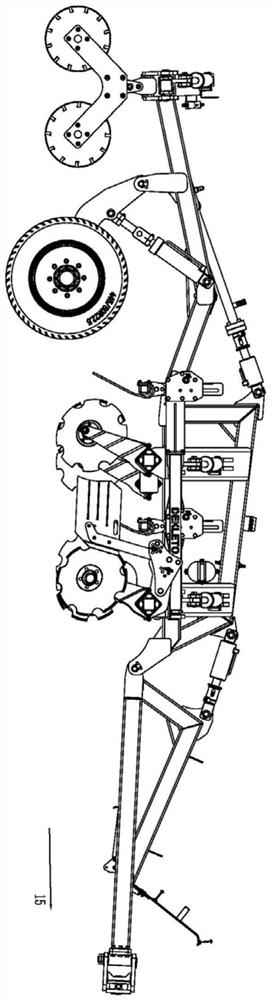

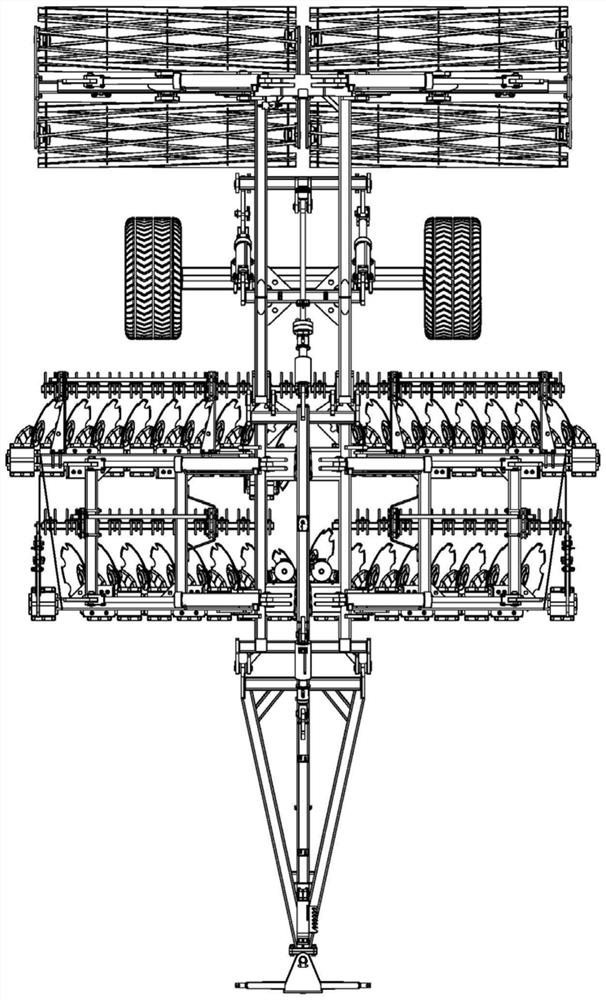

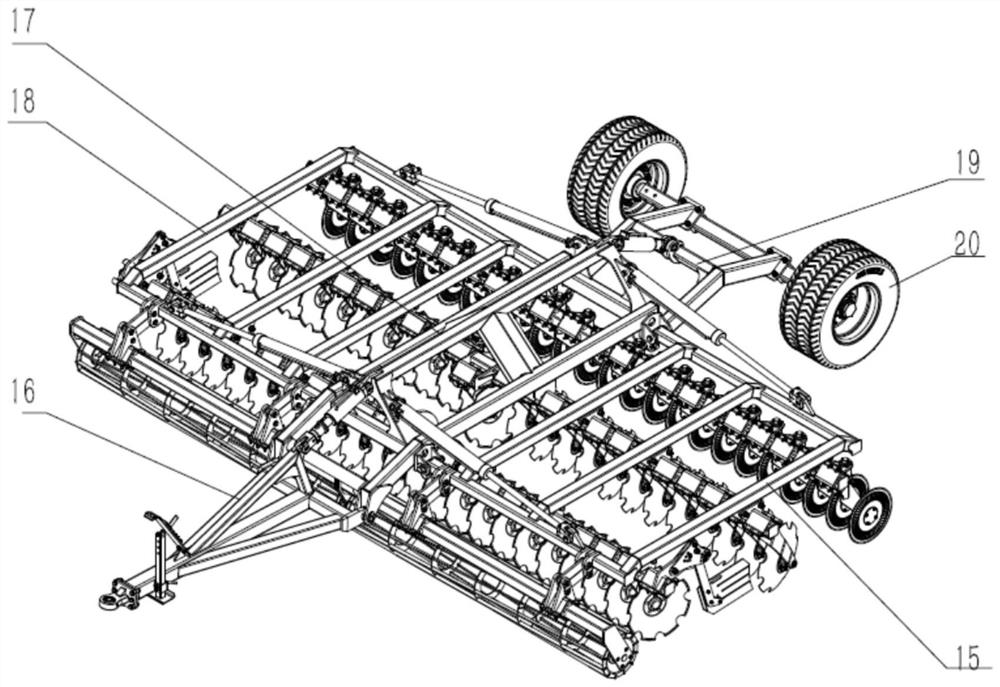

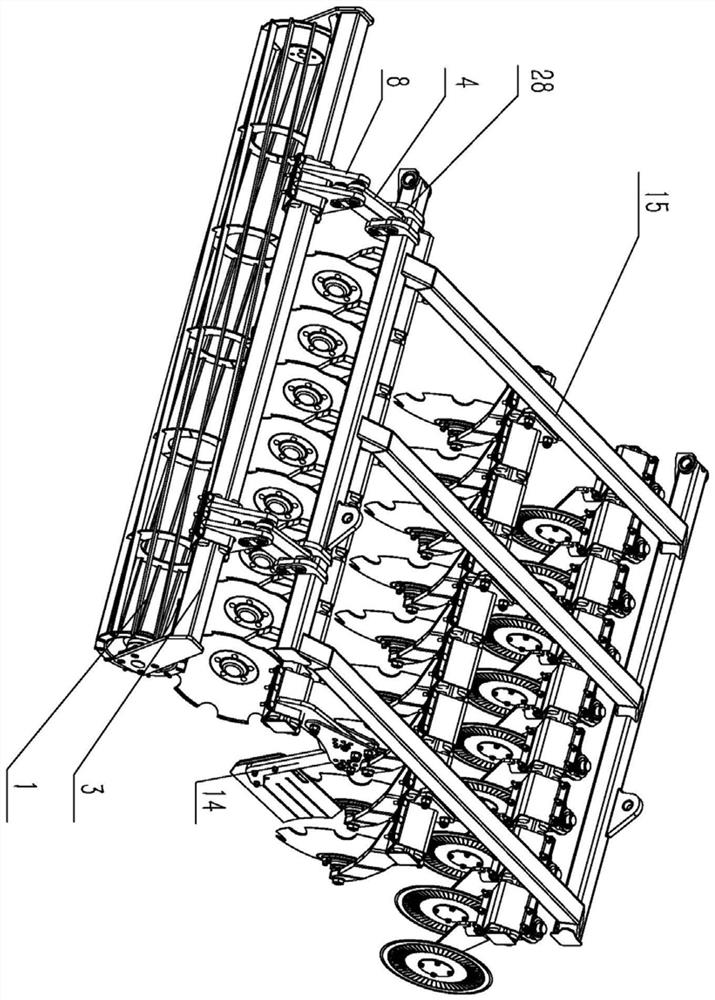

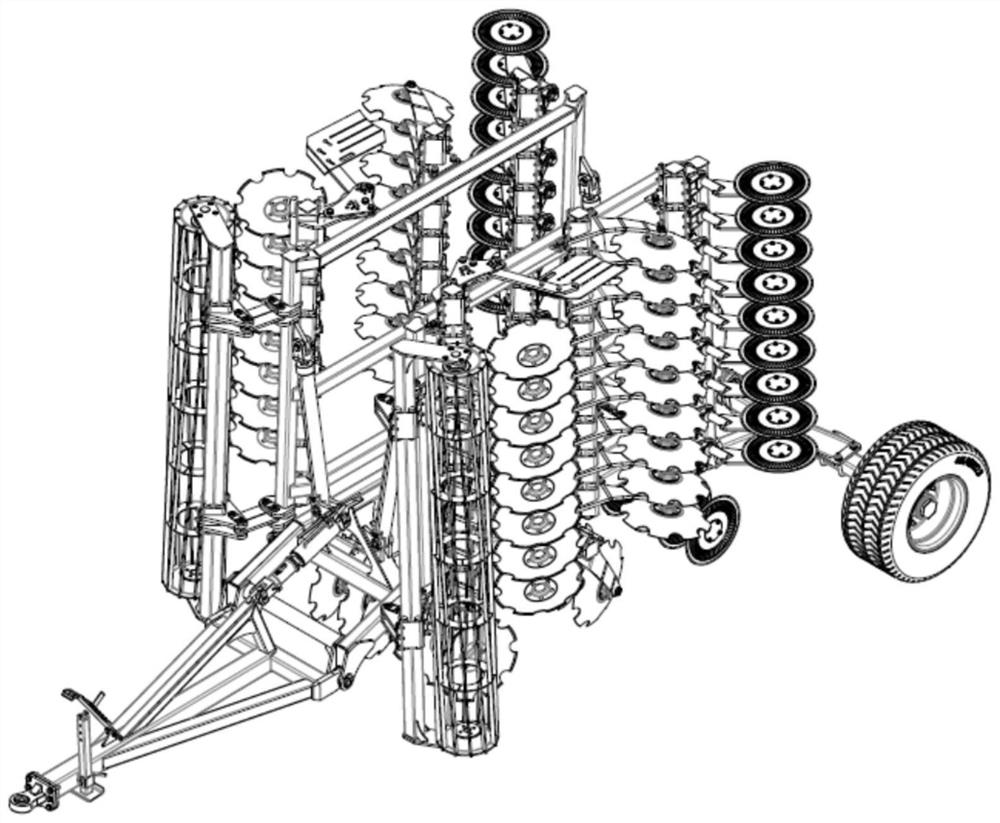

High-speed stubble cleaning harrow

The invention discloses a high-speed stubble cleaning harrow. The high-speed stubble cleaning harrow comprises a main harrow frame assembly, a middle harrow frame assembly, a left folding harrow frameassembly and a right folding harrow frame assembly, wherein the left folding harrow frame assembly and the right folding harrow frame assembly are connected to the left side and the right side of themain harrow frame assembly in a foldable mode, and the rear end of the main harrow frame assembly is movably connected with a rear adjusting tailstock assembly; a left folding press roller assembly and a right folding press roller assembly are connected to the left side and the right side of the rear portion of the rear adjusting tailstock assembly respectively, two walking wheels are connected to the lower end of the rear adjusting tailstock, the two walking wheels are connected through an axle, and the axle is connected with the rear adjusting tailstock through a connecting arm; and the harrow blades on the left-right harrow frame and the front-back harrow frame are symmetrically designed, lateral traction force is avoided, power is exerted more sufficiently, and oil consumption is reduced.

Owner:宜兴博登泰科工业装备有限公司

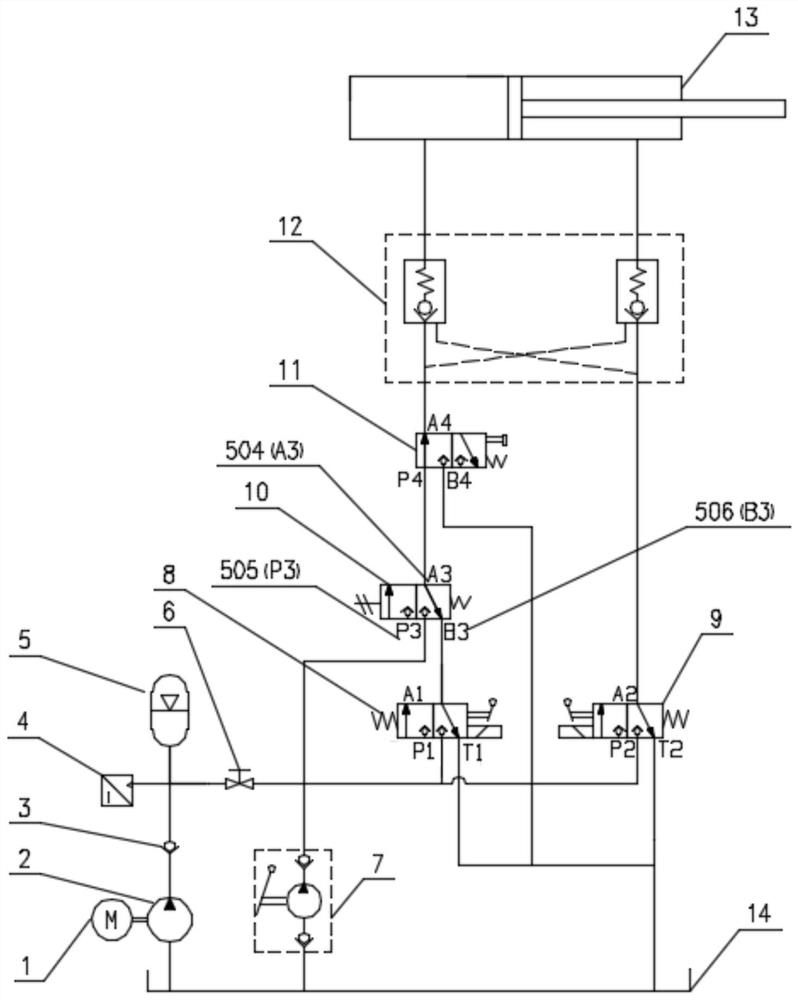

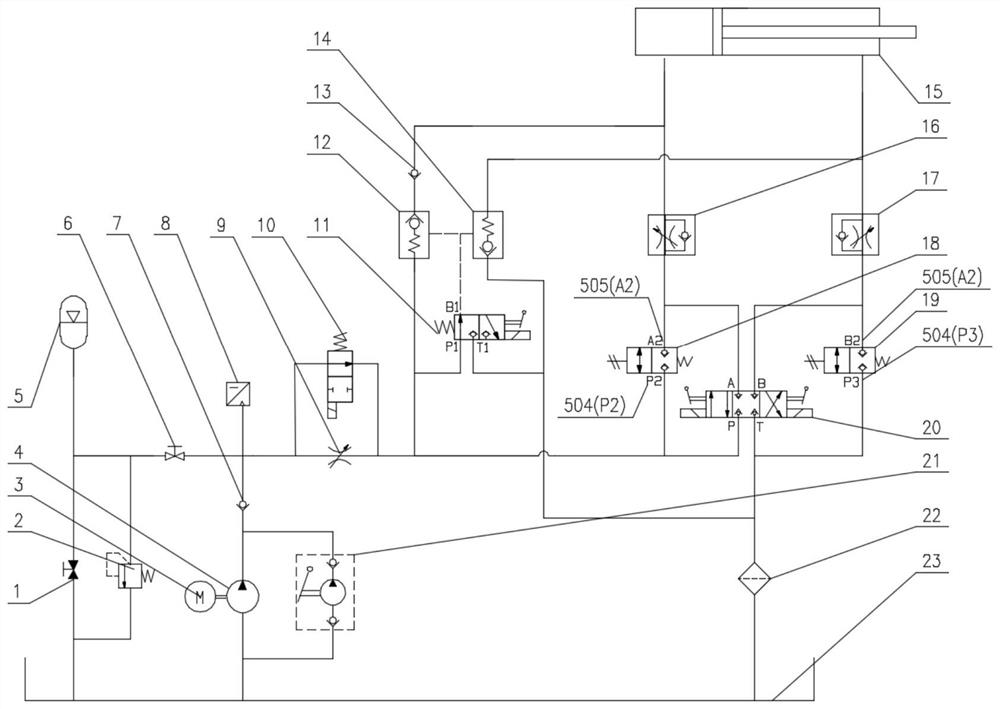

Integral steel platform jacking oil cylinder oil circuit controlling system

InactiveCN111577712AGuarantee safe operationGuaranteed safe operationServomotor componentsFluid-pressure actuator componentsHydraulic pumpDirectional Valve

The invention discloses an integral steel platform jacking oil cylinder oil circuit controlling system. The system comprises a hydraulic pump station, a one-way valve, a plurality of jacking oil cylinder controlling units, and a PLC. An oil outlet hydraulic pipeline of the hydraulic pump station communicates with an oil inlet of the one-way valve, and a multi-oil-outlet pipeline is arranged at thean oil outlet of the one-way valve via a hydraulic hose. Each of the jacking oil cylinder controlling units comprises a three-position four-way proportional directional valve, a locking valve group and a jacking oil cylinder; and the three-position four-way proportional directional valve is used for realizing change of the hydraulic oil flow direction in the jacking oil cylinder in different working situations of the jacking oil cylinder including cylinder extending and cylinder retracting. The locking valve group is arranged on an oil circuit pipeline between the three-position four-way proportional directional valve and the jacking oil cylinder. The PLC is used for controlling the three-position four-way proportional directional valves and the locking valve groups to work. The integralsteel platform jacking oil cylinder oil circuit controlling system can be adapted to change of flow direction of hydraulic oil in an oil pipe, and has dual effects of locking and unloading in both flow directions of the hydraulic oil, so safe operation of the hydraulic oil cylinder is ensured.

Owner:SHANGHAI CONSTRUCTION GROUP

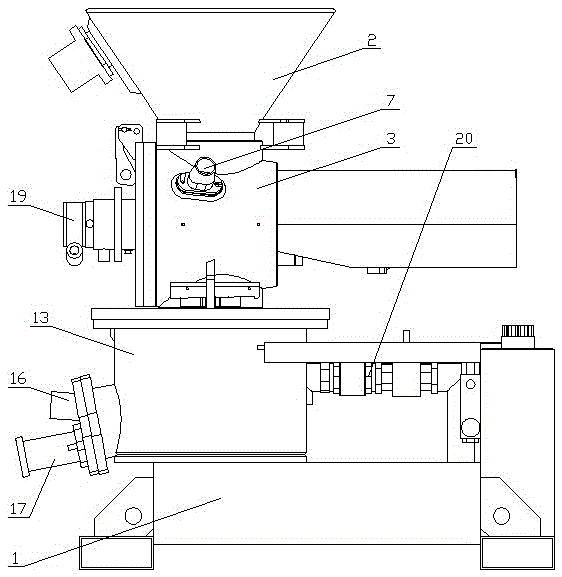

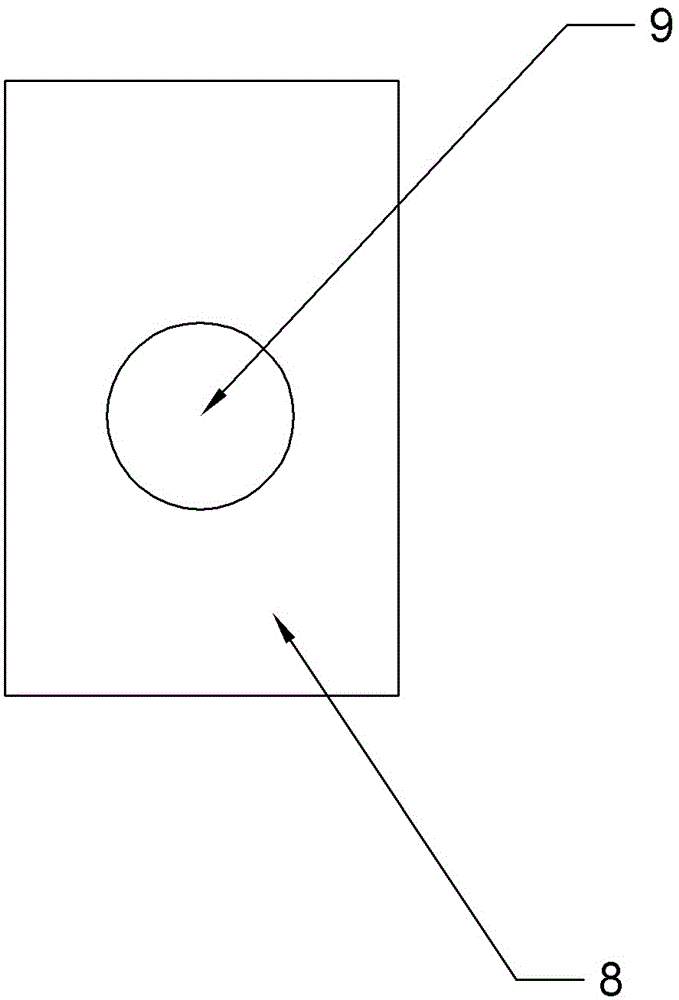

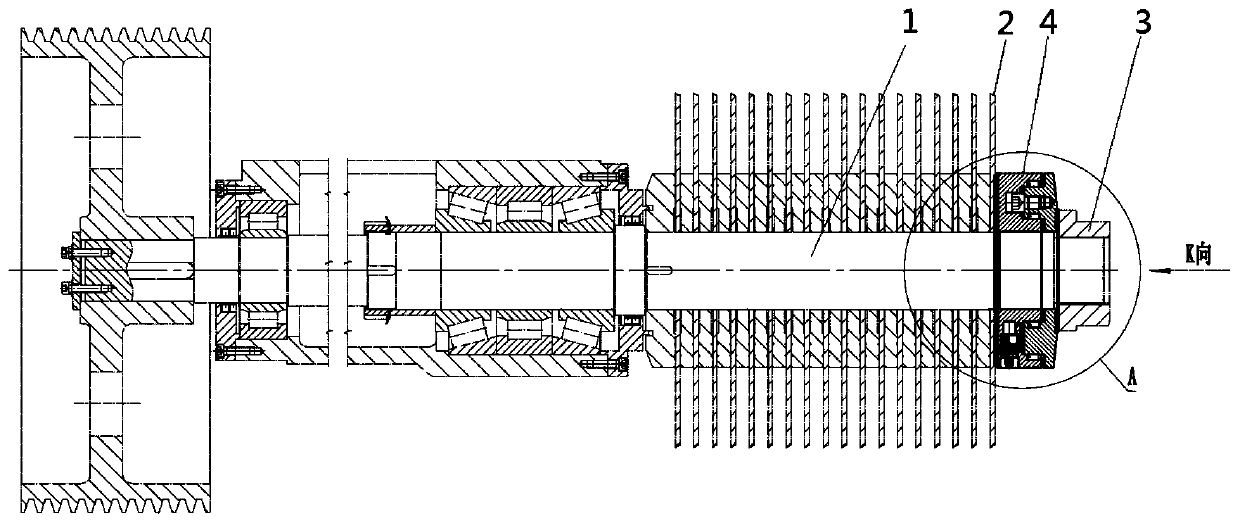

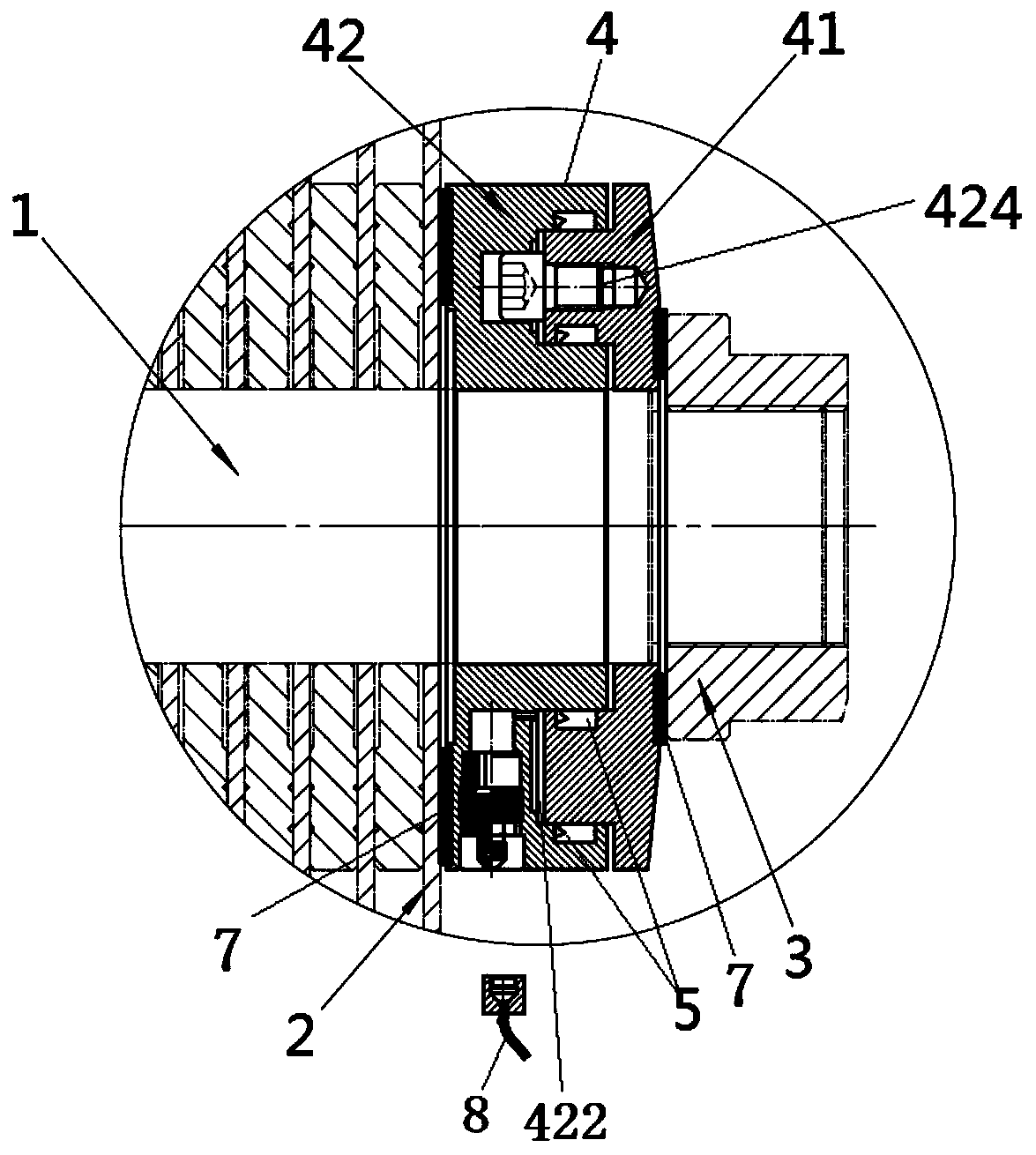

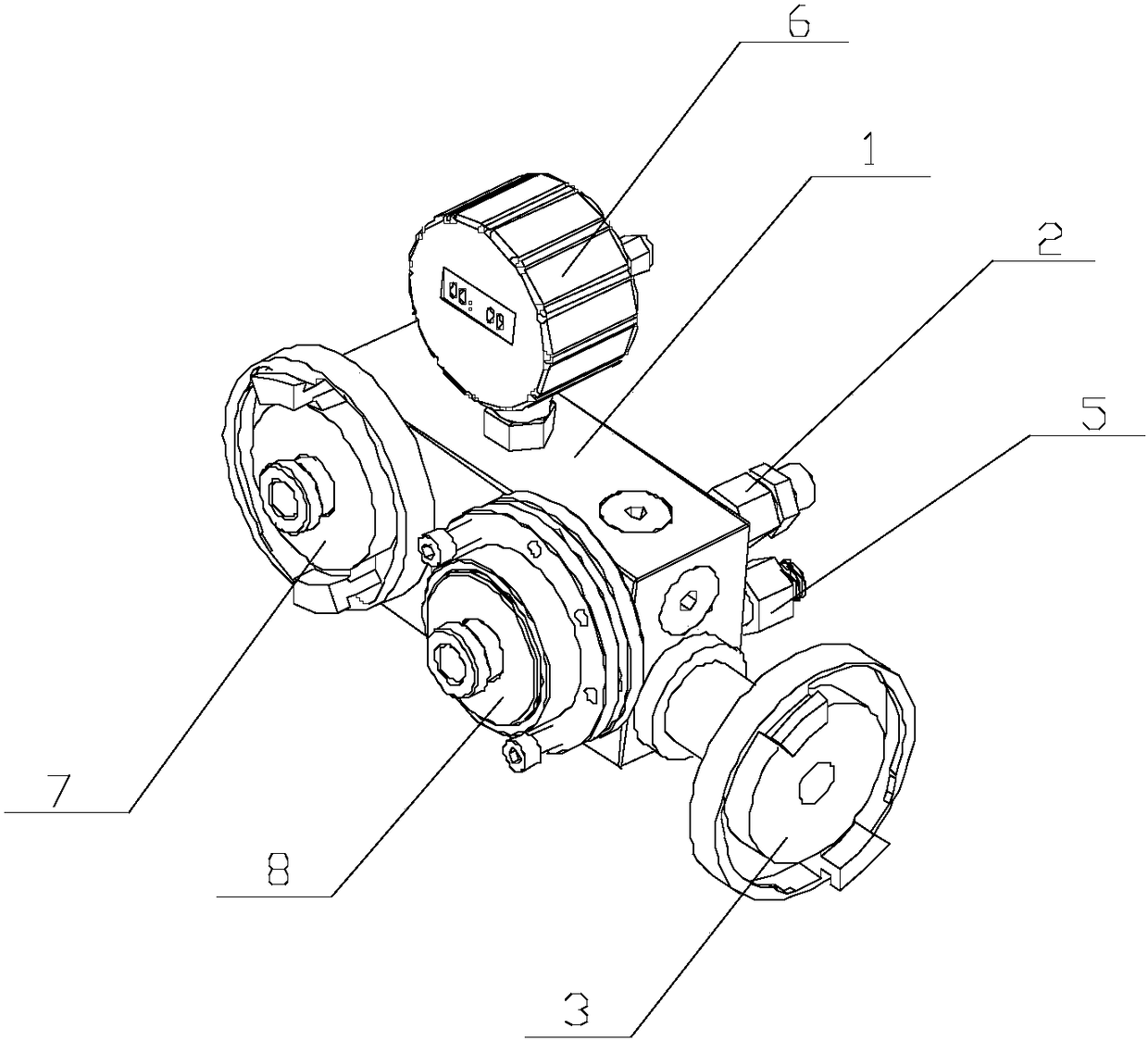

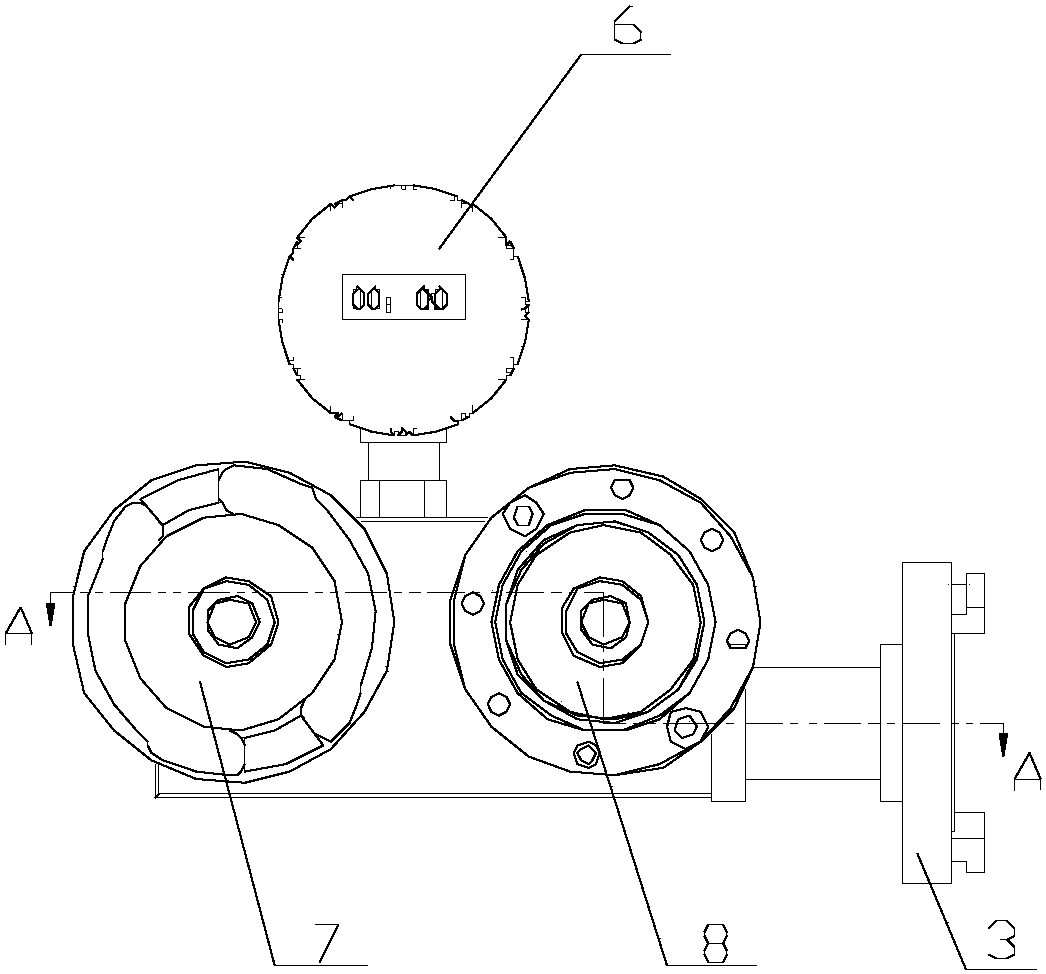

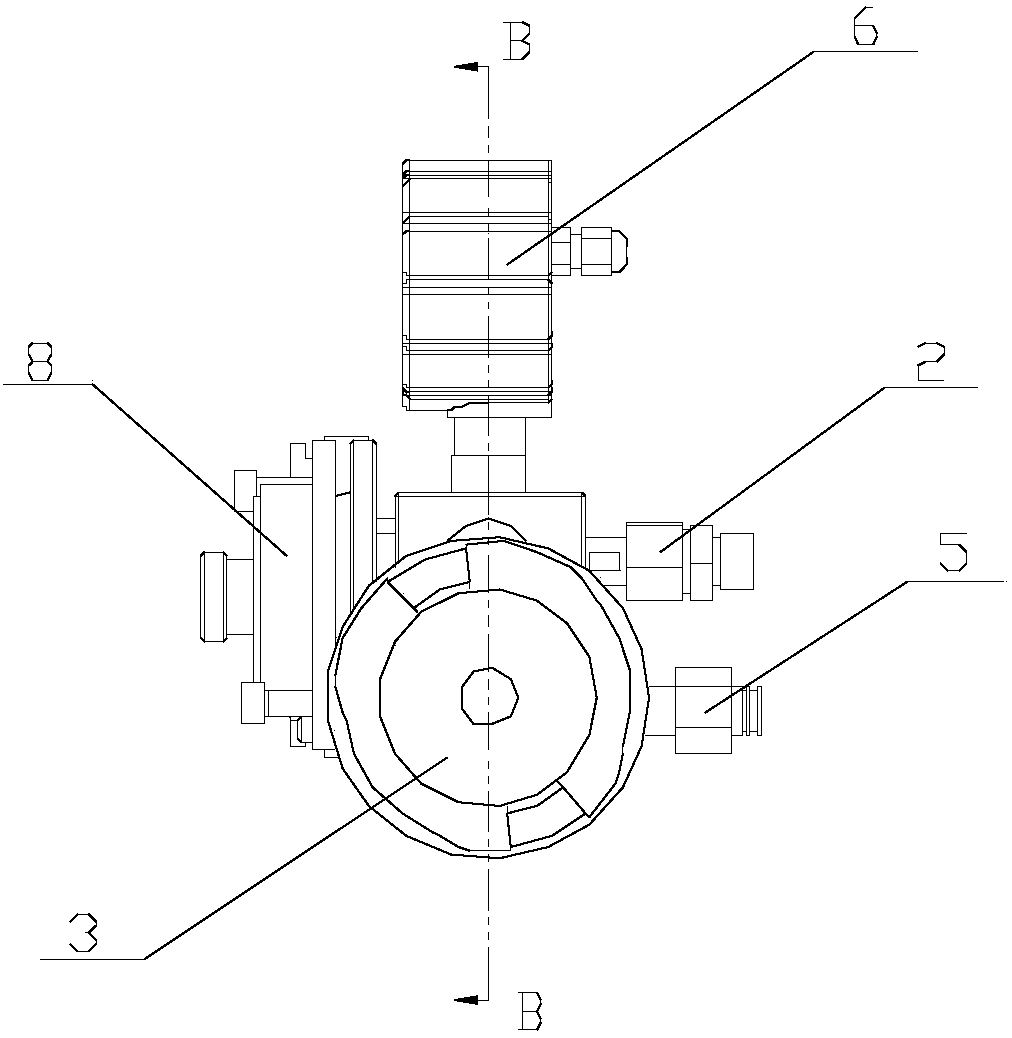

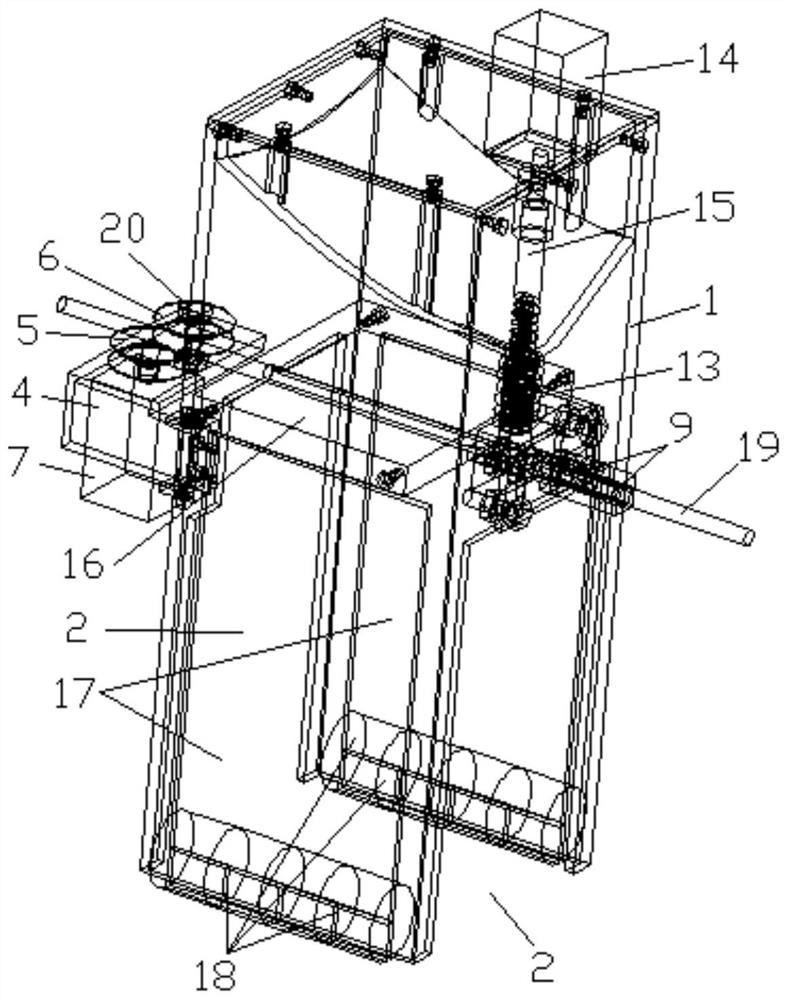

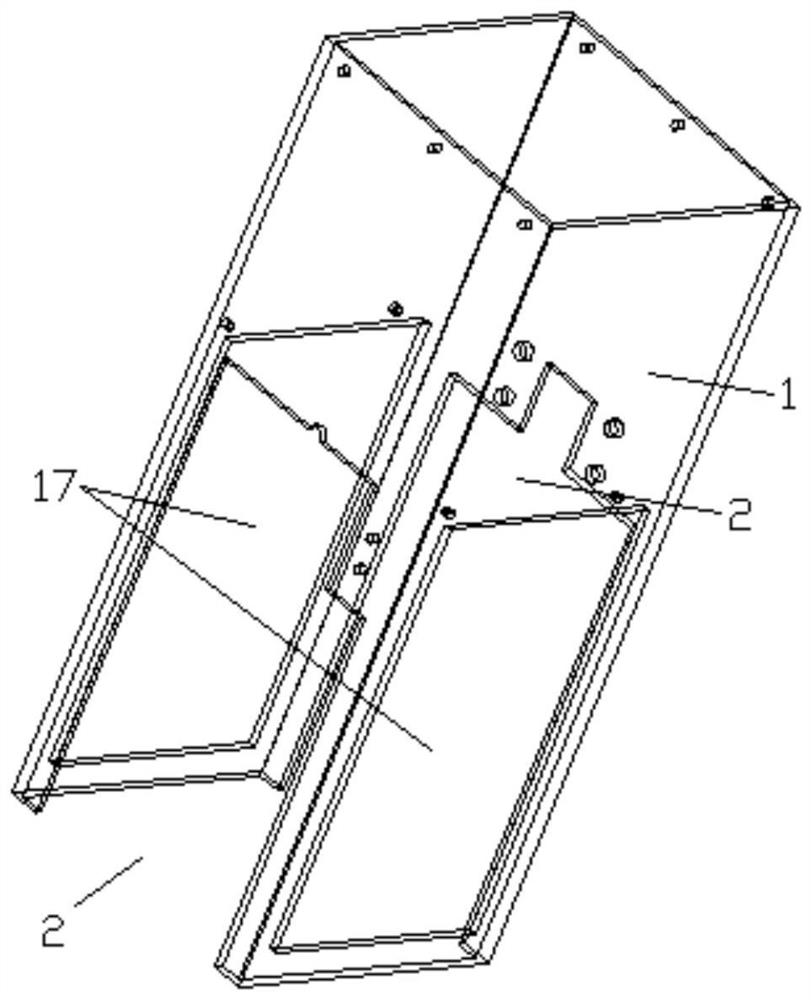

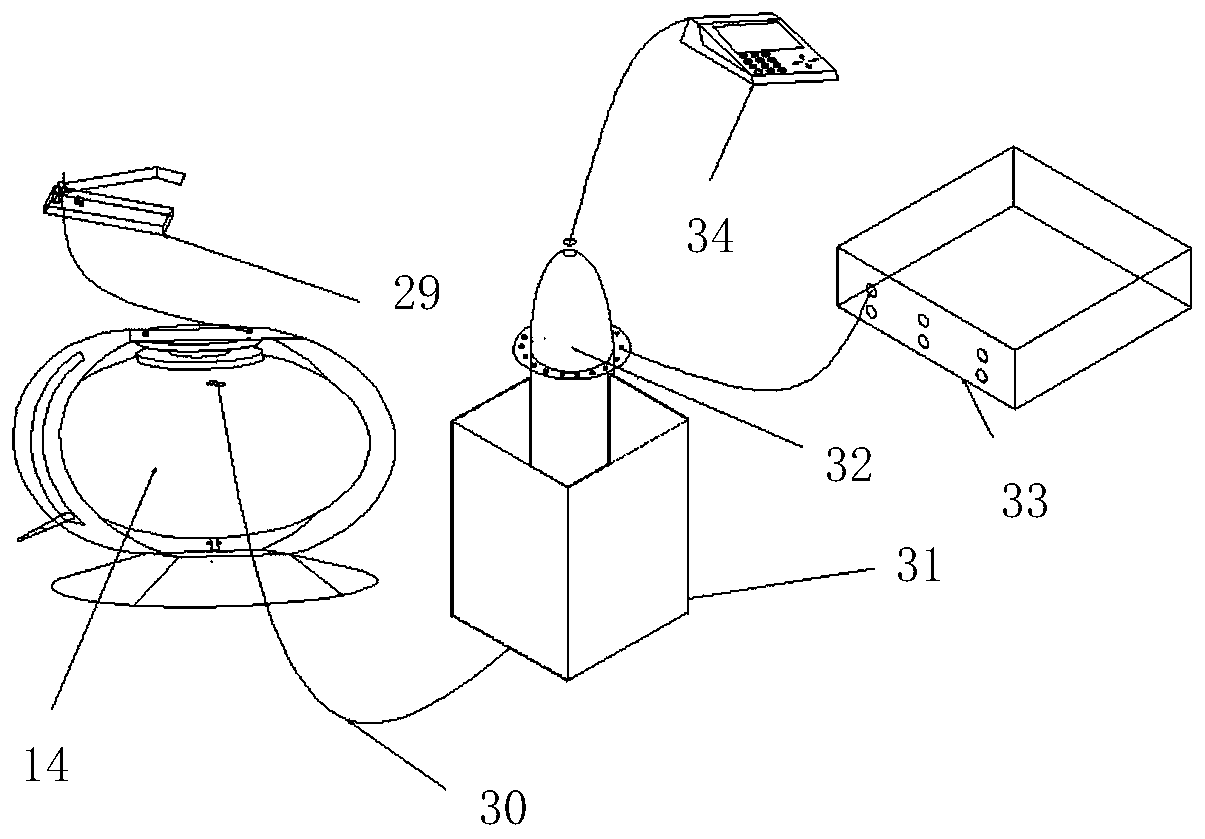

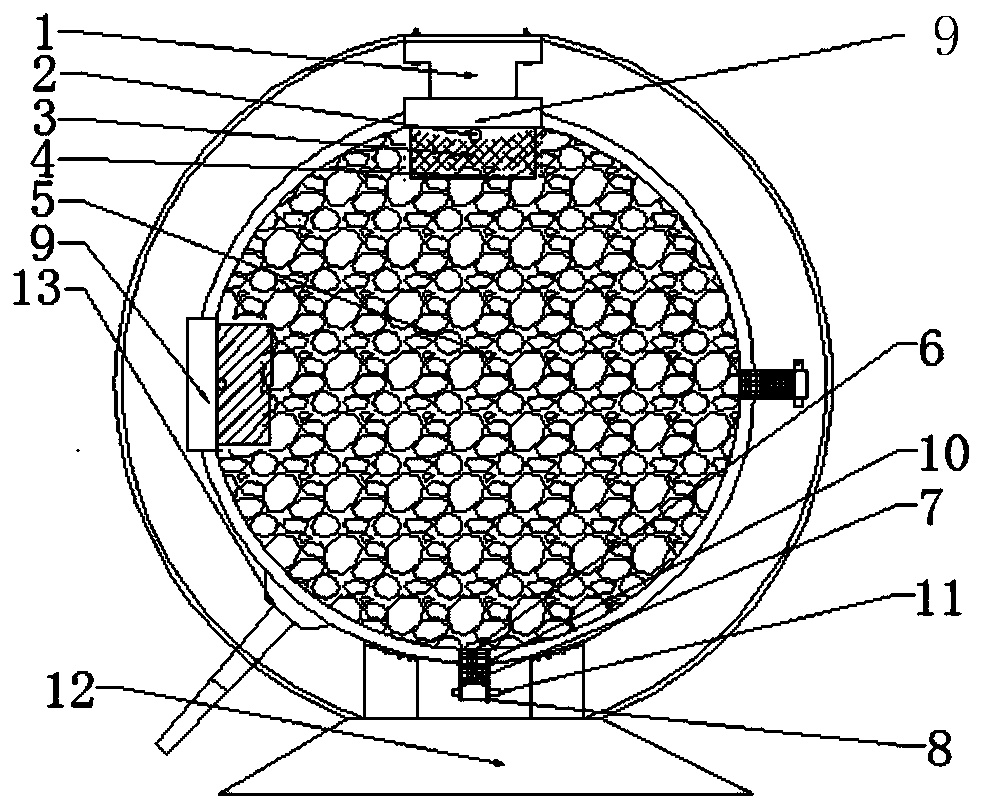

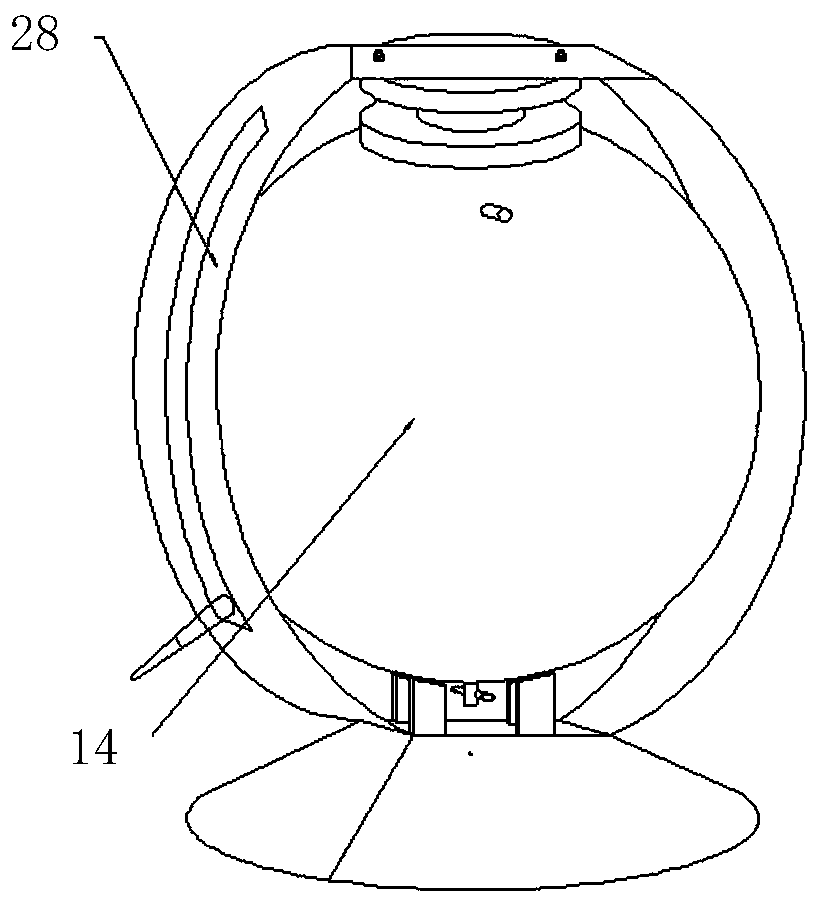

Electric servo hydraulic source of four-leg robot

InactiveCN108105185ALight in massIncrease effective volumeFluid-pressure actuator safetyProgramme-controlled manipulatorElectric machineryQuadrupedal robot

The invention provides an electric servo hydraulic source of a four-leg robot. The electric servo hydraulic source comprises a quantitative gear pump (2) driven by a servo motor (1), and an oil outletof the quantitative gear pump (2) is connected with an inlet of an oil drainage pipe (4); an oil drainage pipe one-way valve (5), a filter (6) and an energy accumulator (7) are sequentially arrangedin the middle of the oil drainage pipe (4) from front to back; and the oil drainage pipe (4) is connected with oil inlets of a left front leg oil supply pipe (8), a right front leg oil supply pipe (9), a left back leg oil supply pipe (10) and a right back leg oil supply pipe (11). According to the electric servo hydraulic source of the four-leg robot provided by the invention, the weight is light,the effective volume is large, oil supplementation pressure is constant, the endurance mileage is long, noise is low, the service life is long, and performance is stable and reliable.

Owner:CHANGSHA ZHIWEI ELECTRONICS TECH CO LTD

Fireproof emergency turn-off hydraulic control system

PendingCN114370524AImprove securityPlay a role in maintaining pressureOperating means/releasing devices for valvesServomotor componentsControl systemFire - disasters

The invention discloses a fireproof emergency turn-off hydraulic control system. According to the disclosed scheme, the system comprises an energy accumulator, a first control valve, a second control valve, a third control valve, a fourth control valve, a multi-way fireproof pressure release valve, an oil way connected with an upper cavity of an execution oil cylinder, an oil way connected with a lower cavity of the execution oil cylinder and an oil return way connected with an oil tank. All the valves are connected to form a fireproof oil way and a plurality of control oil ways. The fireproof release valve is arranged in an oil way of the hydraulic system, and when a fire disaster occurs, the valve element is opened after unbalanced stress, and the oil way is automatically communicated to achieve valve closing; the fireproof release valve can automatically sense the environment temperature when a fire occurs, the valve can be automatically closed no matter an accident site is powered on or powered off, and once the environment reaches the dangerous temperature, the safety is very high.

Owner:XIAN AEROSPACE PROPULSION INST +1

Hydraulic oil cylinder piston design capable of preventing cylinder tube from being damaged

The invention provides hydraulic oil cylinder piston design capable of preventing a cylinder tube from being damaged. According to the design, the cylinder tube and a piston sleeved with the cylindertube are included, the piston comprises a piston head and a piston rod, and the piston head is in a guiding ring shape and is adjacent to a rod cavity of an oil cylinder. The right end of the piston head is adjacent to a rodless cavity of the oil cylinder and provided with a boss, a copper sleeve is arranged between the cylinder tube and the boss, the outer diameter of the copper sleeve is seamlessly attached to the cylinder tube through an O-shaped sealing ring, and the inner diameter of the copper sleeve is seamlessly attached to the boss through an O-shaped sealing ring. A thread flange isarranged at the right end of the copper sleeve, the inner diameter of the thread flange and the piston rod are fixed through a thread, and the right end of the thread flange reversely jacks the rightend face of the boss of the piston through a tightening bolt to enable the copper sleeve to be fixed to the boss. The problem that due to the self-weight of a piston, the piston rubs a cylinder tube to damage an oil cylinder is solved, meanwhile the sealing effect of the piston is ensured, and the pressure maintaining effect is achieved.

Owner:广东精铟海洋工程创新研究有限公司 +1

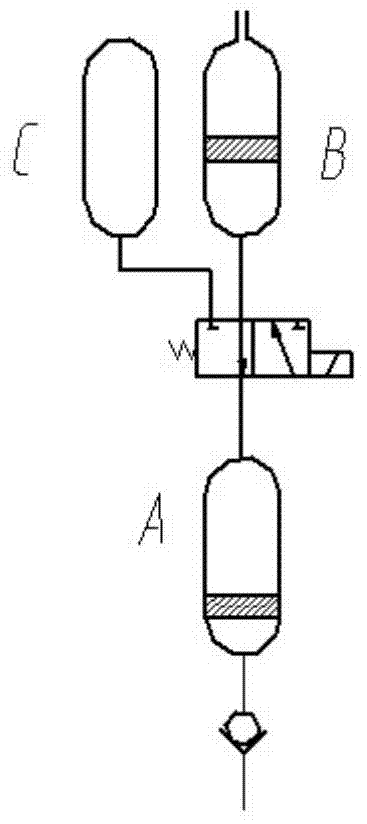

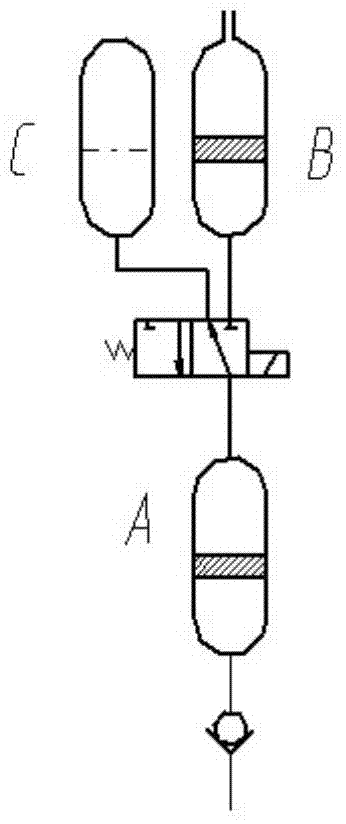

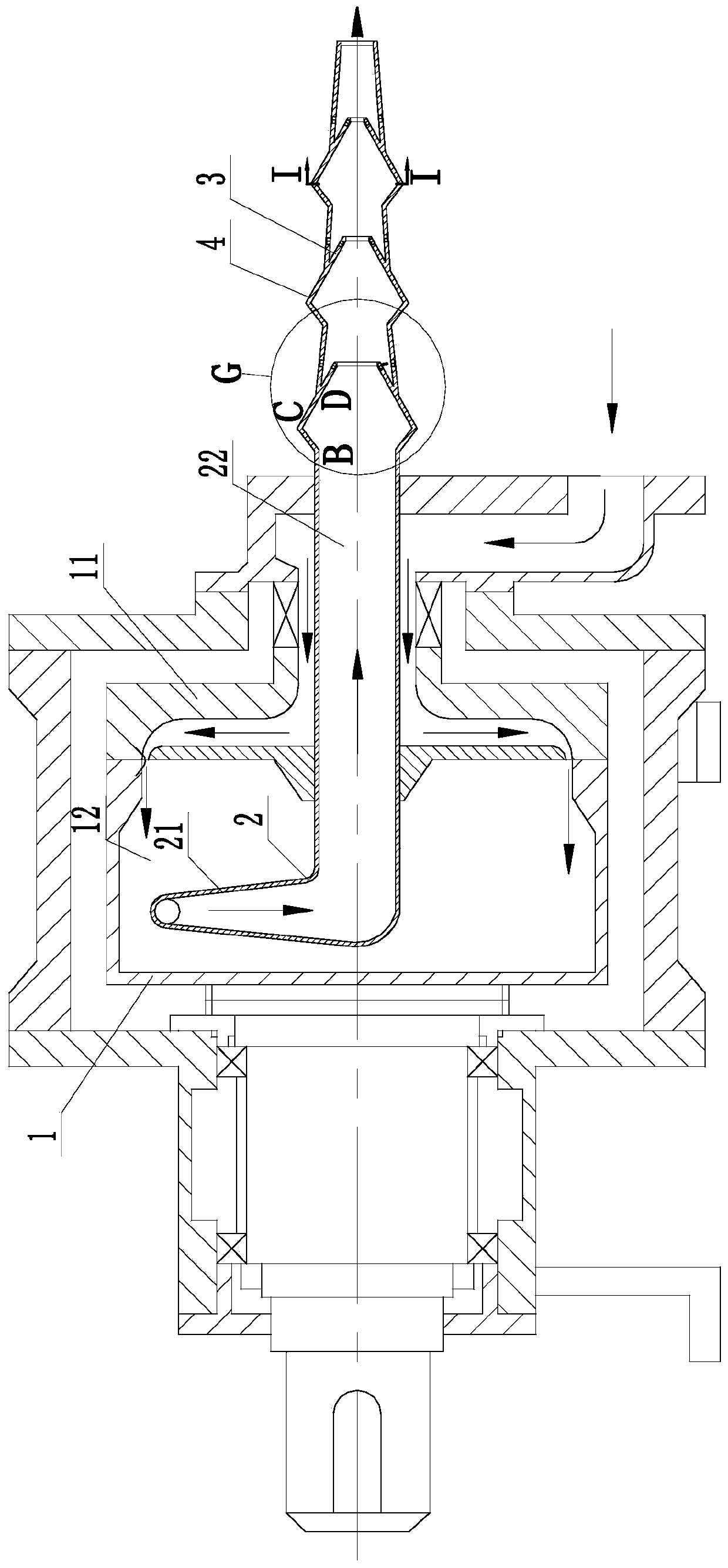

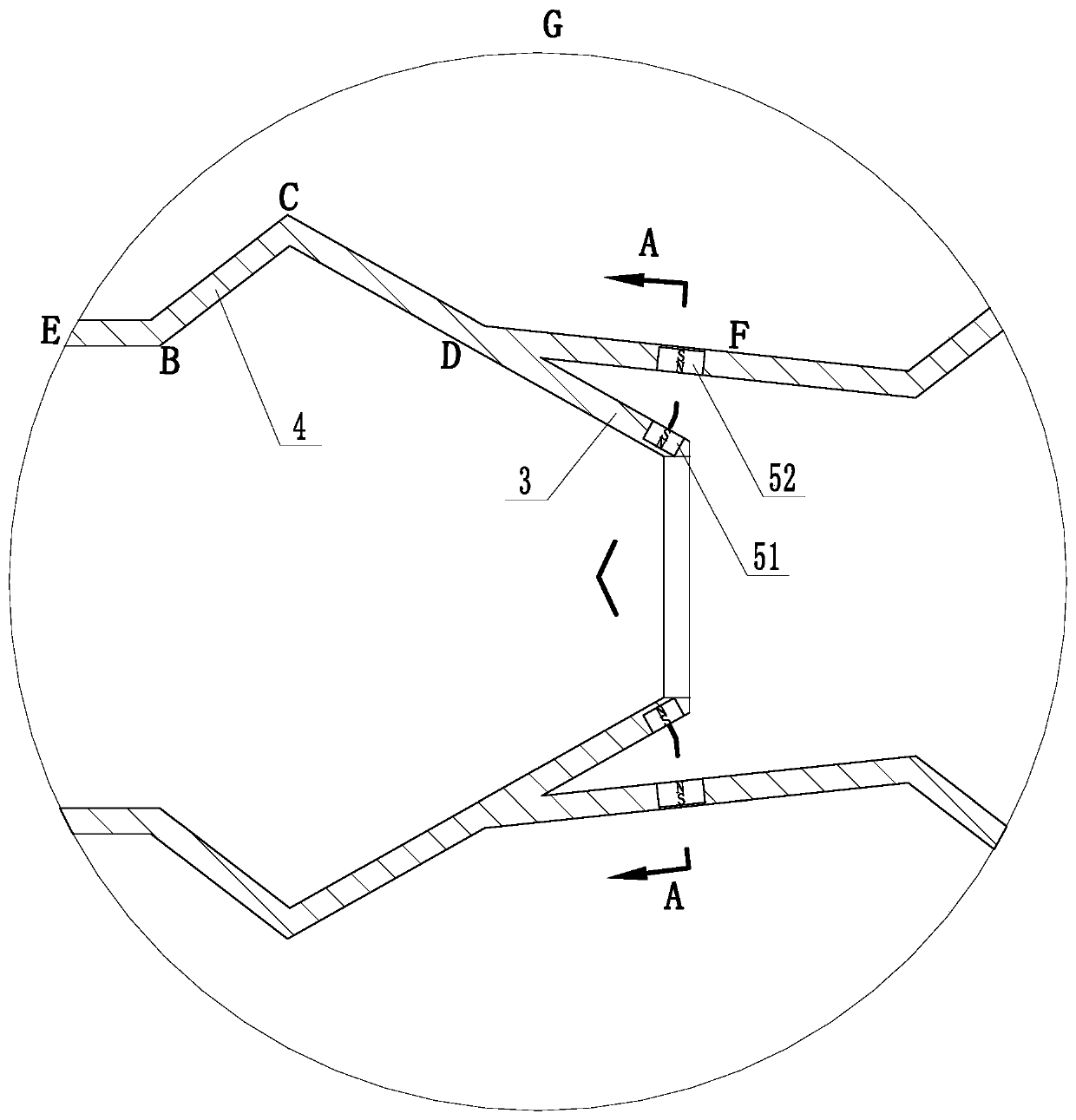

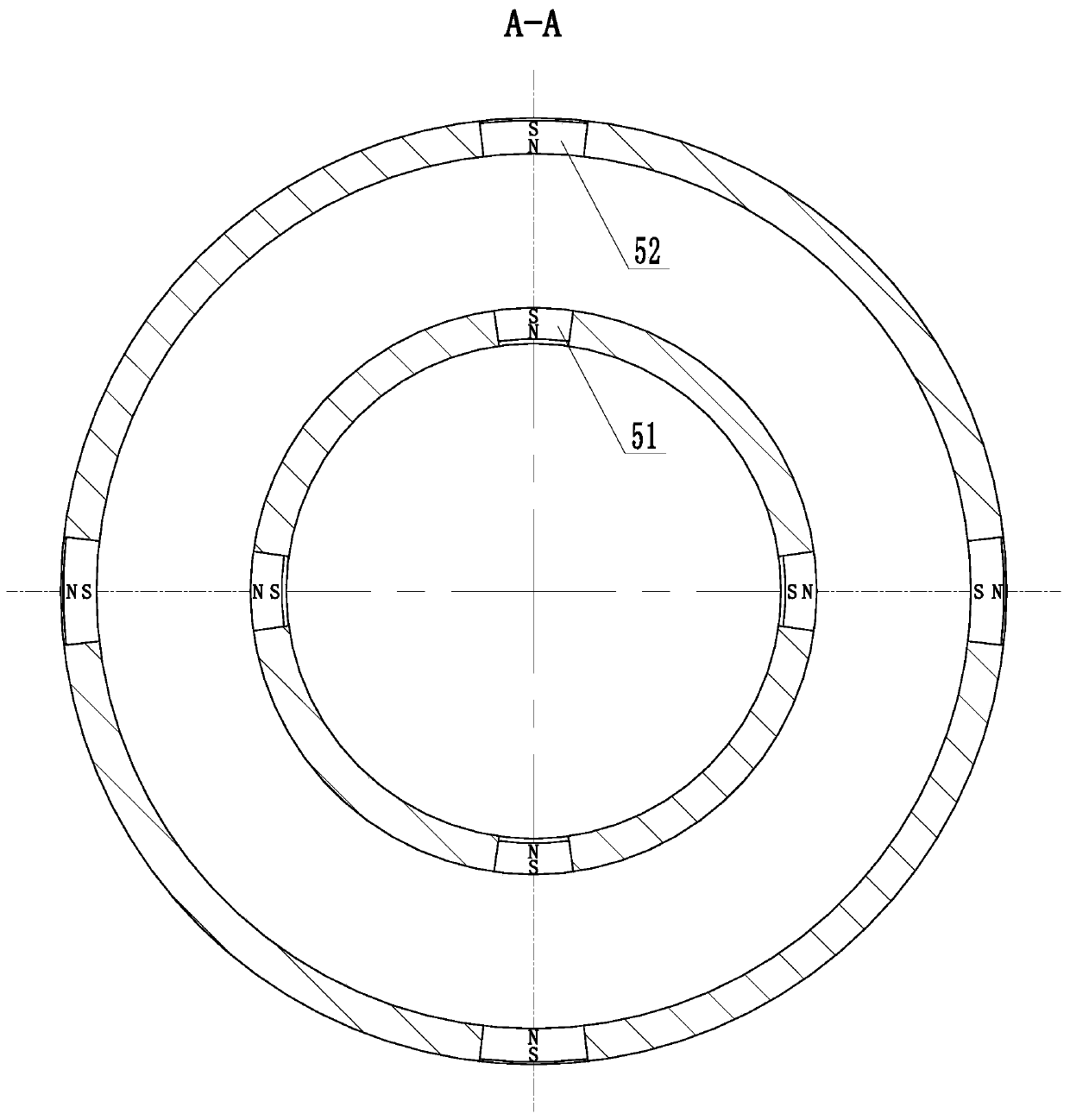

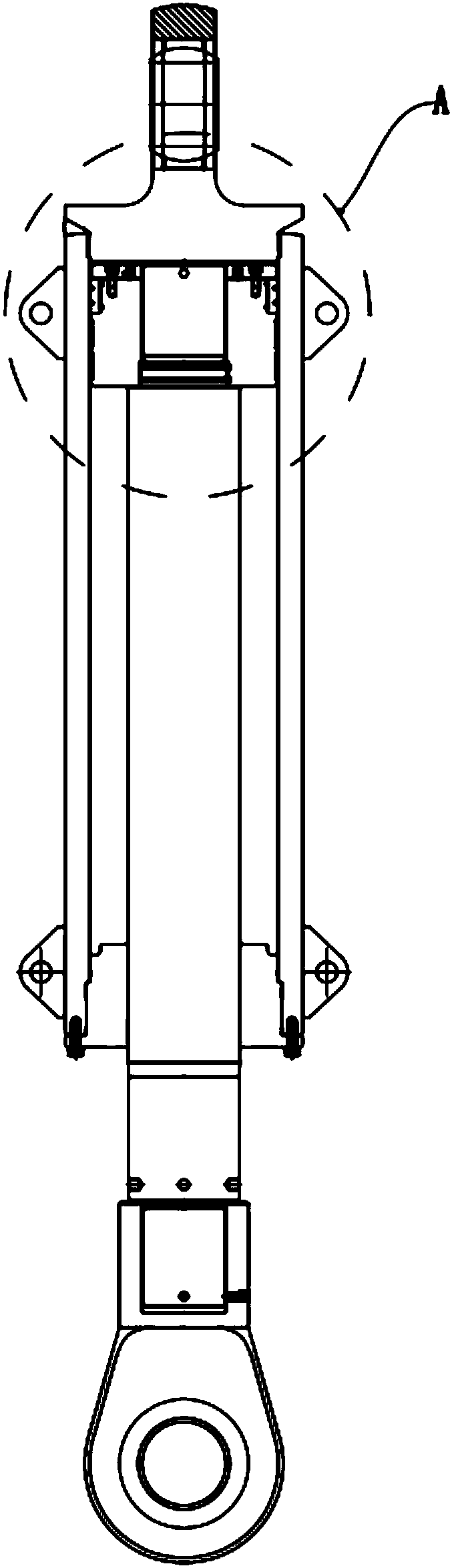

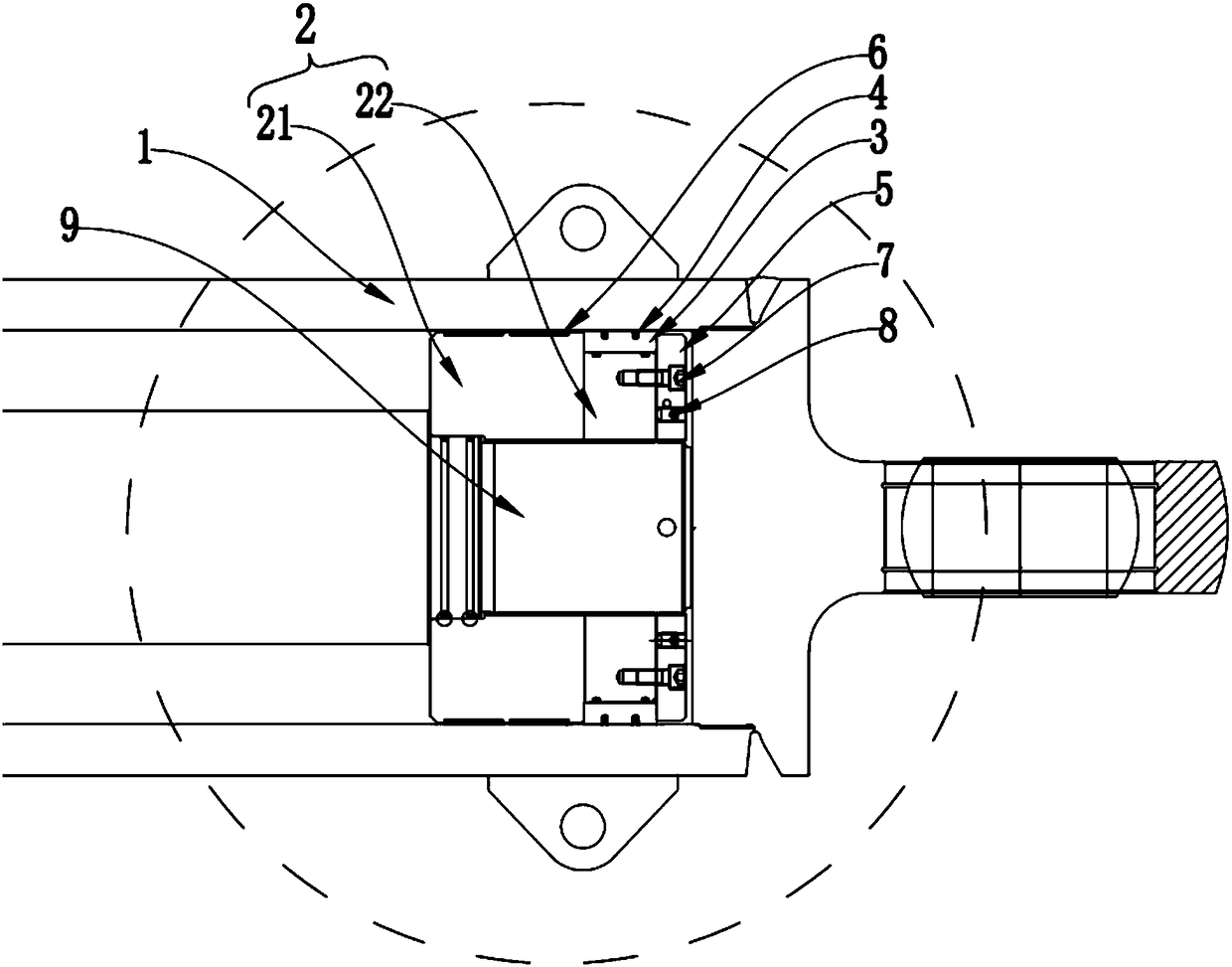

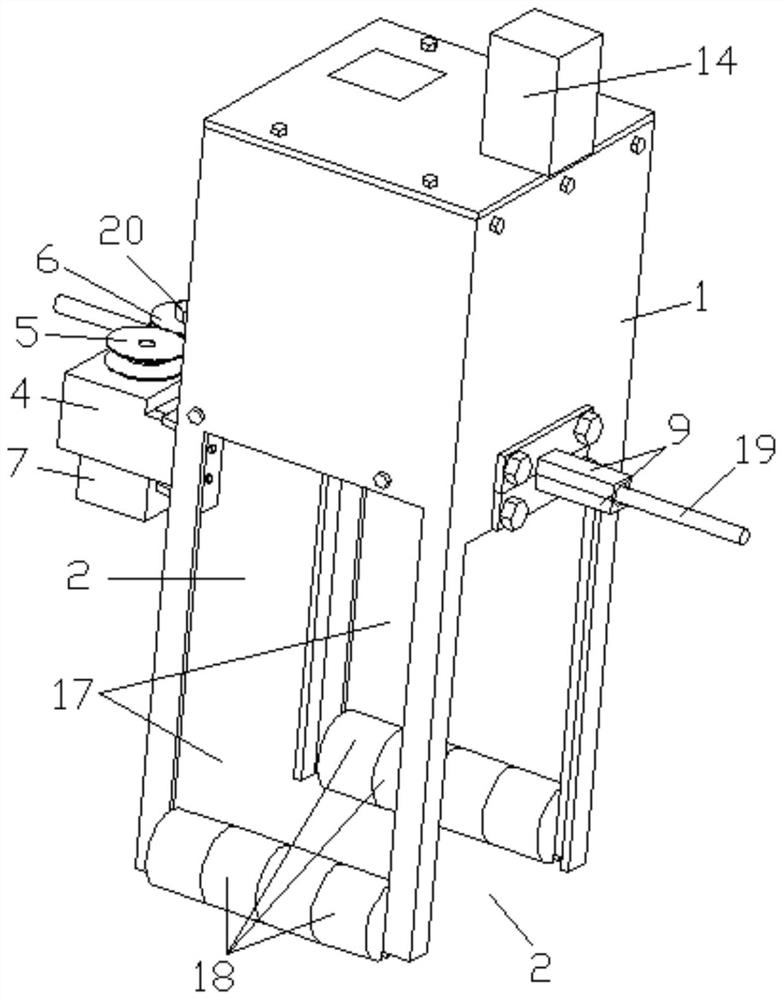

Stone machine spindle box saw blade clamping power assisting device

ActiveCN109747053AGood loosening effectPlay a role in maintaining pressureWorking accessoriesStone-like material working toolsTurbochargerEngineering

The invention discloses a stone machine spindle box saw blade clamping power assisting device. The stone machine spindle box saw blade clamping power assisting device comprises a stone machine spindle, a saw blade on the spindle, a clamping nut, a hydraulic clamping power booster is arranged on a stone machine spindle between the saw blade and the clamping nut, the hydraulic clamping power boostercomprises an oil cylinder front cover A, an oil cylinder back cover B, a reverse thrust turbocharger assembly, a pressure regulator assembly, and an oil inlet and outlet assembly; and the oil cylinder front cover A and the oil cylinder back cover B are rotating bodies thatarranged in an axial direction andpenetrate through a center hole, annular convex desk type pistons arranged along the circumference of the end face of the oil cylinder front cover A are embedded into annular groove-type piston chambers arranged along the circumference of the end face of the oil cylinder back cover B to axially slidably cooperate with the tensioning saw blade and the clamping nut, the reverse thrust turbocharger assembly and the pressure regulator assembly adjust tension, and the direction of the spindlerotation is opposite to the direction of a clamping nut screw thread. The stone machine spindle box saw blade clamping power assisting device has the effects of double safety of saw blade clamping, saw blade loosening preventing, and labor saving.

Owner:蔡崇友 +1

Heavy stubble cleaning harrow and stubble cleaning operation method of high-stubble straw

PendingCN111972056AImprove job performanceImprove stubble removal effectMowersHarrowsAgricultural engineeringStructural engineering

The invention discloses a heavy stubble cleaning harrow. The heavy stubble cleaning harrow is characterized by comprising a main harrow frame assembly, a middle harrow frame assembly, a left folding harrow frame assembly and a right folding harrow frame assembly, wherein the left folding harrow frame assembly and the right folding harrow frame assembly are connected to the left side and the rightside of the main harrow frame assembly in a foldable mode; the middle harrow frame assembly is fixedly connected to the lower portion of the main harrow frame assembly; the front end of the main harrow frame assembly is movably connected with a traction frame assembly; the rear end of the main harrow frame assembly is movably connected with a rear adjusting tail frame assembly; walking wheels areconnected to the rear portion of the rear adjusting tail frame assembly; the front end of the left folding harrow frame assembly is connected with a left pressing roller assembly; and the front end ofthe right folding harrow frame assembly is connected with a right pressing roller assembly. According to the heavy stubble cleaning harrow, high-stubble straw is pressed down, the straw is crushed and mixed through the front row of harrow pieces and the rear row of harrow pieces, and straw rhizomes are subjected to secondary cutting through disc slices, so that the straw can be fully crushed, repeated operation of the stubble cleaning harrow on an operated residual stubble field is not needed, and the operation efficiency is improved.

Owner:宜兴博登泰科工业装备有限公司

Hydraulic control system of safety stop valve

PendingCN114198347AEasy to operateRestore fire protectionFluid-pressure actuator safetyServomotor componentsControl systemControl valves

The invention discloses a hydraulic control system of a safety stop valve. According to the disclosed scheme, an energy accumulator, a first fireproof valve, a second fireproof valve, a valve closing control valve, a valve opening control valve, an oil way connected with an upper cavity of an execution oil cylinder, an oil way connected with a lower cavity of the execution oil cylinder and an oil return way connected with an oil tank are included; all the valves are connected to form a valve opening oil way and a valve closing oil way. The two fireproof release valves are arranged in the oil way of the hydraulic system, the fireproof valves are opened in the case of fire, and the oil way is automatically communicated to achieve valve closing; the fireproof release valve can automatically sense the environment temperature when a fire occurs, the valve can be automatically closed no matter an accident site is powered on or powered off, and once the environment reaches the dangerous temperature, the safety is very high. And the system has an emergency turn-off function, the valve opening and closing functions can be recovered by switching oil ways after emergency turn-off, and meanwhile, the fireproof function can be conveniently and quickly recovered.

Owner:CHINA PETROLEUM & CHEM CORP +1

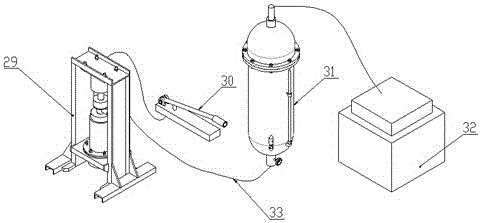

An on-site detection device for fire hoses capable of rapid water filling and pressure stabilization

ActiveCN105606457BWill not flow backPlay a role in maintaining pressureMaterial strength using tensile/compressive forcesEngineeringCheck valve

The invention discloses an onsite fire hose detection device quick in water filling and pressure stabilizing. The onsite fire hose detection device comprises a motor, a booster pump and a detector, the detector comprises a shell, a detection end A, a detection end B, a digital display pressure controller, a water inlet end A, a water inlet end B and a water outlet end, the detection end A positioned on the shell is used for detecting a burst pressure of a fire hose, and the detection end B is used for detecting integral performances of the fire hose and connectors. The shell internally comprises a chamber A and a chamber B, the water inlet end B and the water outlet end connected with a water inlet of the booster pump are communicated with the chamber A, the detection end A and the water inlet end A connected with a water outlet of the booster pump are communicated with the chamber B, and a check valve is arranged between the chamber A and the chamber B. When the water pressure in the chamber B is larger than that in the chamber A, the check valve is turned off, and the digital display pressure controller is connected to the chamber B to control starting of the motor through a contactor. The onsite fire hose detection device is convenient and quick in detection and accurate in detection result and capable of quickly filling the fire hose with water within 1min and has a function of pressure maintaining.

Owner:应急管理部四川消防研究所

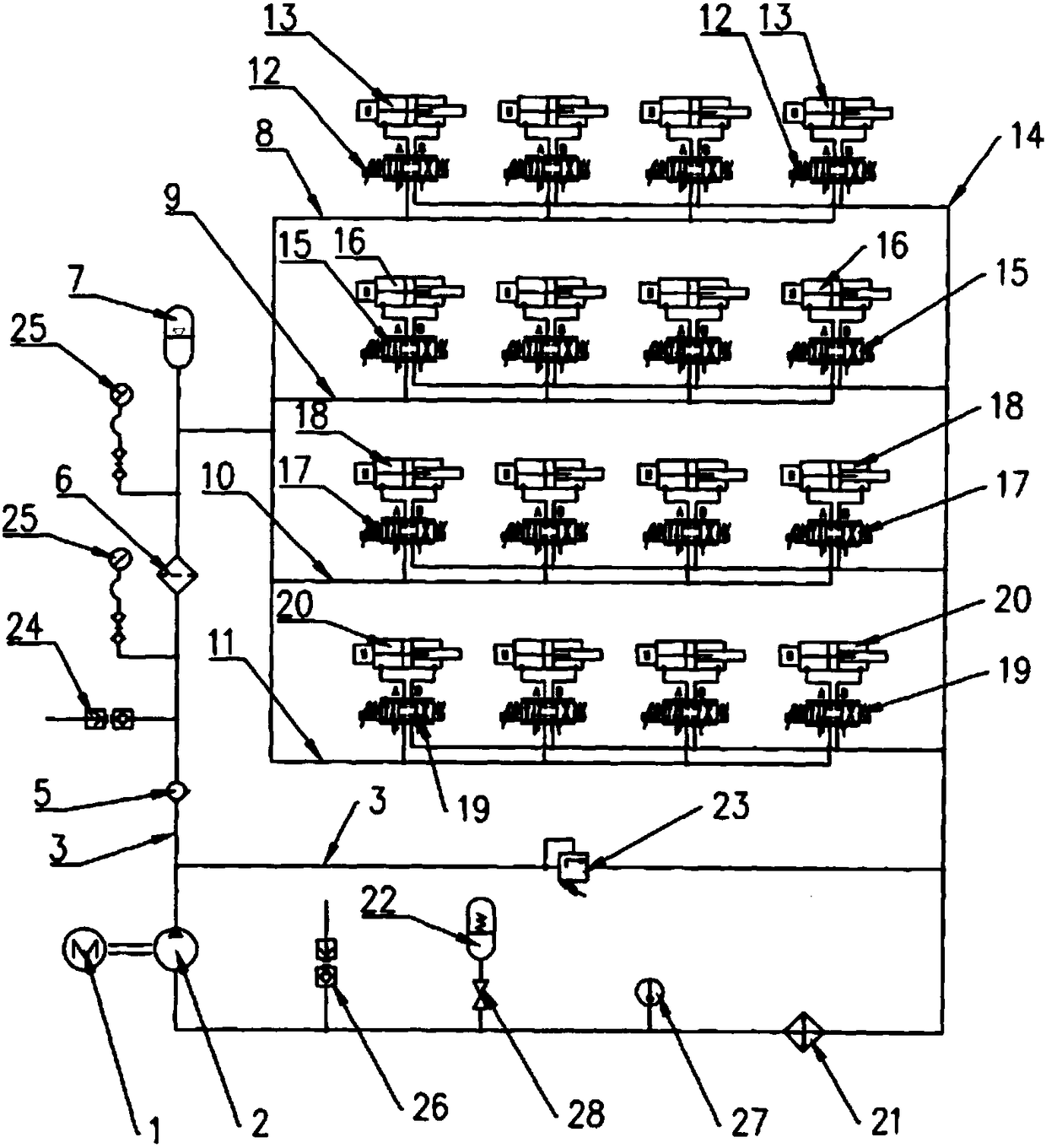

Hydraulic valve set for garbage compression

InactiveCN109356891AAvoid damageExtended service lifeServomotor componentsServomotorsEngineeringMechanical engineering

The invention provides a hydraulic valve set for garbage compression. The hydraulic valve set for garbage compression comprises a first two-position four-way electromagnetic valve, a second two-position four-way electromagnetic valve, a three-position four-way electromagnetic valve, an oil inlet, a first oil outlet and a second oil outlet; a P oil port of the first two-position four-way electromagnetic valve, a P oil port of the second two-position four-way electromagnetic valve and a P oil port of the three-position four-way electromagnetic valve communicate to the oil inlet; a T oil port ofthe first two-position four-way electromagnetic valve and a T oil port of the second two-position four-way electromagnetic valve communicate to the first oil outlet; a T oil port of the three-positionfour-way electromagnetic valve communicates to the second oil outlet; and a two-position two-way electromagnetic valve and an overflow valve are arranged between the oil inlet and the oil outlet in parallel. The hydraulic valve set can realize idling startup, uses the two-position two-way electromagnetic valve for unloading, reduces the impact force during reversing of hydraulic oil, and meanwhile, achieves longer service life.

Owner:扬州海纳尔液压设备有限公司

Forming device of powder forming machine

The invention belongs to the technical field of forming processing equipment, and relates to a forming device of a powder forming machine. The forming device comprises a main shaft, an eccentric wheel, a lower punching mold shaft, a demolding shaft, a demolding plate, jacking mechanisms, a belt wheel and racks; each jacking mechanism comprises a cam, a push rod and an air cylinder; the cams are fixedly arranged on the main shaft in a sleeve mode, one ends of the push rods are connected to plungers of the air cylinders, the other ends of the push rods are located under the cams and are movablyconnected to the cams in a press mode; the eccentric wheel, the cams and the belt wheel are fixedly arranged on the main shaft in a sleeve mode, and the lower punching mold shaft is fixedly installedat a far end of the eccentric wheel; and two jacking mechanisms are symmetrically distributed on the two sides of the eccentric wheel. According to the device, the jacking mechanisms and the cams andthe eccentric wheel are arranged coaxially, so that when a product is pressed, the air cylinders play a pressure maintaining role, the pressing stability is improved, the loss in the pressing processis reduced, the quality and the performance of the powder forming machine are improved, and the cost of the powder forming machine is reduced.

Owner:宁夏鑫博宁精密机械有限公司

Power unit with proportional flow control valve and cartridge flow cushion valve

PendingCN111946682AEliminate vibrationReduce extension speedServomotor componentsServomotorsMarine engineeringControl valves

The invention discloses a power unit with a proportional flow control valve and a cartridge flow cushion valve. The power unit comprises a vane pump and an oil cylinder, wherein an oil outlet port ofthe vane pump communicates with an oil inlet port of the oil cylinder through a first pipeline, an overflow valve, the cartridge flow cushion valve and a one-way valve are sequentially fixed to the first pipeline between the oil outlet port of the vane pump and the oil inlet port of the oil cylinder, an oil outlet port of the oil cylinder communicates with an oil tank communicating with the vane pump through a second pipeline, and the proportional flow control valve and a two-position two-way normally-closed electromagnetic valve are sequentially fixed to the second pipeline between the oil outlet port of the oil cylinder and the oil tank communicating with the vane pump. The power unit has the advantages that the proportional flow control valve and the cartridge flow cushion valve are additionally arranged in the power unit to eliminate vibration generated when the oil cylinder controlled by the power unit stretches out and draws back, and the operation efficiency is improved.

Owner:济南济力机械设备有限公司

A high-altitude bare cable insulation installation device

InactiveCN110416913BStable deliveryPower stabilityApparatus for repairing insulation/armouring cablesApparatus for overhead lines/cablesInsulation layerStructural engineering

The invention relates to a high-altitude bare cable insulating layer adding device, and the device comprises a box body, a walking mechanism, hot melting mechanisms and a forming mechanism. The box body is hollow, and the bottom is open; first openings communicated with the bottom of the box body are formed in the two opposite side walls of the box body respectively, and cavities, located above the first openings, in the box body are divided into storage hoppers used for storing insulating particles through partition plates; feeding ports and discharging ports are formed in the tops and the bottoms of the storage hoppers respectively. The hot melting mechanisms is fixedly arranged in the storage hopper and is used for hot melting of the insulating particles; the walking mechanism is fixedly mounted at one of the first openings and is used for driving the box body to slide along the cable; and the forming mechanism is fixedly arranged at the other first opening, is positioned below thehot melting mechanism, is communicated with the discharge ports through a blanking channel, and is used for adding the hot-melted insulating particles on the cable. The beneficial effects of the invention are that the device can walk on a high-altitude exposed high-voltage cable, enables the insulating layer to be disposed on the high-voltage cable, is simple in operation, is high in installationefficiency, and is safe and reliable.

Owner:WUHAN UNIV OF SCI & TECH

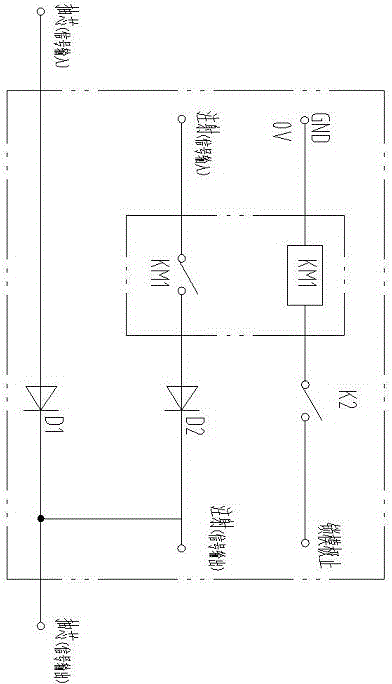

Mold oil cylinder core-pulling sliding block retaining circuit used in injection process of injection molding machine

The invention discloses a mold oil cylinder core-pulling sliding block retaining circuit used in the injection process of an injection molding machine. The mold oil cylinder core-pulling sliding block retaining circuit comprises a core-pulling input end, a core-pulling output end, an injection input end and an injection output end. The core-pulling input end is connected with the core-pulling output end, and the core-pulling input end transmits a signal to control action of a core-pulling valve. A diode D1, a diode D2, a relay KM1 and a mold mode locking pole stop signal circuit are further included. According to the mold oil cylinder core-pulling sliding block retaining circuit, an injection voltage signal is provided for the core-pulling valve at the injection ends, the core-pulling valve is opened, and oil pressure of an original machine can achieve a pressure maintaining function on a core-pulling oil cylinder; and the problems that in the injection process of the original injection molding machine, due to the counter acting force of injection pressure on a mold sliding block, the sliding block retreats slightly, and injection molding defects of trimming, burrs and the like are generated to products are solved.

Owner:YANCHENG BUGAO AUTO PARTS MFG CO LTD

Frequency variable permeation device for broken rock water and sediment two-phase seepage

PendingCN110160938ASimple structureStable and continuous collectionPermeability/surface area analysisPermeameterRock sample

The invention discloses a frequency variable permeation device for broken rock water and sediment two-phase seepage and belongs to the technical field of a penetration test. The frequency variable permeation device for the broken rock water and sediment two-phase seepage comprises a permeameter and a pressure control device. A broken rock storage cavity is set in the permeameter. The broken rock storage cavity is equipped with at least one group of corresponding water and sediment storage cavity and filtering device. The water and sediment storage cavity is equipped with a pressure head and afirst liquid inlet pipe. The filtering device is equipped with a first liquid outlet pipe. The pressure control device comprises an upper cylinder and a lower cylinder. The lower cylinder is equippedwith a second liquid inlet pipe and a second liquid outlet pipe. The second liquid outlet pipe is connected with the first liquid inlet pipe. A stirring device is set in the lower cylinder. A piston is set above the stirring device. A piston rod is connected with a speed controller. According to the frequency variable permeation device for the broken rock water and sediment two-phase seepage, testaccuracy and stability are improved, speed is adjustable, axial loading is finished, and water pressure is uniformly distributed on a broken rock sample.

Owner:LIAONING TECHNICAL UNIVERSITY

Onsite fire hose detection device quick in water filling and pressure stabilizing

ActiveCN105606457AWith the function of keeping pressureQuick checkMaterial strength using tensile/compressive forcesEngineeringCheck valve

The invention discloses an onsite fire hose detection device quick in water filling and pressure stabilizing. The onsite fire hose detection device comprises a motor, a booster pump and a detector, the detector comprises a shell, a detection end A, a detection end B, a digital display pressure controller, a water inlet end A, a water inlet end B and a water outlet end, the detection end A positioned on the shell is used for detecting a burst pressure of a fire hose, and the detection end B is used for detecting integral performances of the fire hose and connectors. The shell internally comprises a chamber A and a chamber B, the water inlet end B and the water outlet end connected with a water inlet of the booster pump are communicated with the chamber A, the detection end A and the water inlet end A connected with a water outlet of the booster pump are communicated with the chamber B, and a check valve is arranged between the chamber A and the chamber B. When the water pressure in the chamber B is larger than that in the chamber A, the check valve is turned off, and the digital display pressure controller is connected to the chamber B to control starting of the motor through a contactor. The onsite fire hose detection device is convenient and quick in detection and accurate in detection result and capable of quickly filling the fire hose with water within 1min and has a function of pressure maintaining.

Owner:应急管理部四川消防研究所

Quadruped robot electroservohydraulic source drive system

ActiveCN105156382BPlay a role in maintaining pressureEasy to check for faultsProgramme-controlled manipulatorServomotor componentsLow noiseGear pump

The quadruped robot electric servo hydraulic source drive system includes a quantitative gear pump, the oil outlet of the quantitative gear pump is connected to the inlet of the high-pressure oil pipe, and the outlet of the high-pressure oil pipe is connected to the inlet of the left oil supply pipe and the inlet of the right oil supply pipe; There is a left hydraulic pump in series on the oil supply pipe, the outlet of the left oil supply pipe is connected with the inlet of the left overflow pipe and the left booster oil pipe, the left overflow valve is connected in series in the middle of the left overflow pipe, and the outlet of the left booster oil pipe is connected with the inlet of the left booster oil pipe. The oil inlet of the left front leg oil supply pipe is connected with the oil inlet of the right rear leg oil supply pipe; the right hydraulic pump is connected in series on the right oil supply pipe, and the outlet of the right oil supply pipe is connected with the outlet of the right overflow pipe and the right booster oil pipe. The inlet is connected, the middle part of the right overflow pipe has a right overflow valve in series, and the outlet of the right booster oil pipe is connected with the oil inlet of the right front leg oil supply pipe and the oil inlet of the left rear leg oil supply pipe. The purpose is to provide a quadruped robot electro-servo hydraulic source drive system with light weight, large effective volume, constant oil supply pressure, long cruising range, low noise, long service life, stable and reliable performance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com