A high-altitude bare cable insulation installation device

A cable insulation and cable technology, which is applied in the direction of overhead line/cable equipment, insulation/armored cable repair equipment, etc., can solve problems such as hidden dangers, cable safety, and difficult manual operation, so as to achieve high installation efficiency and stable power transmission , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

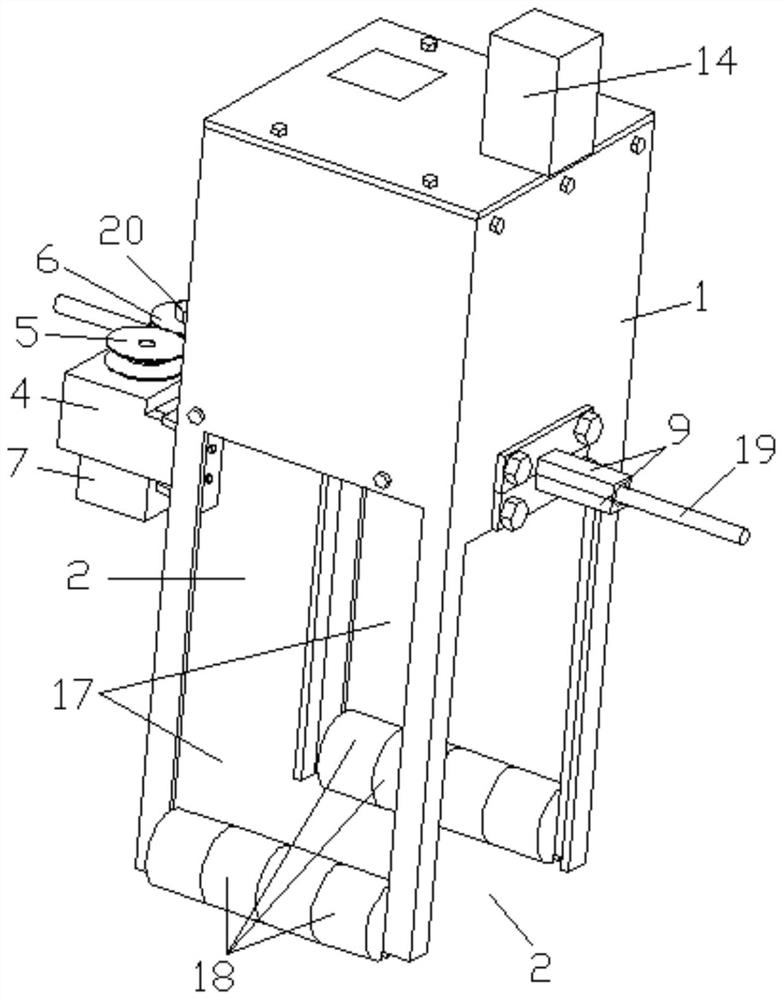

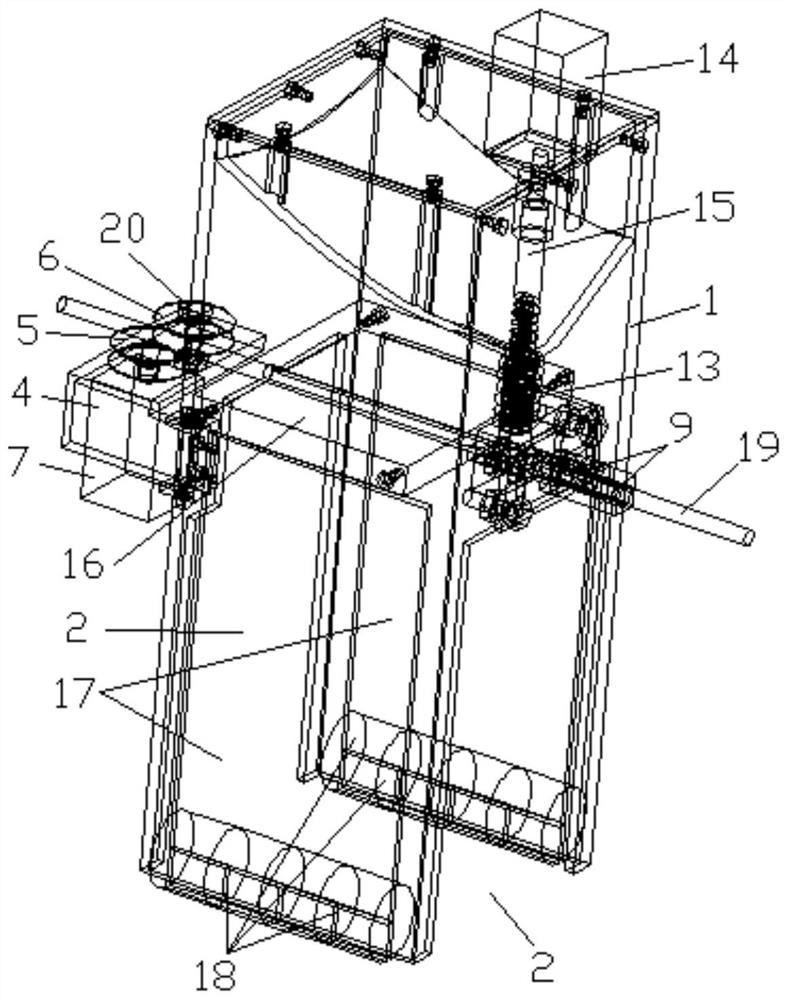

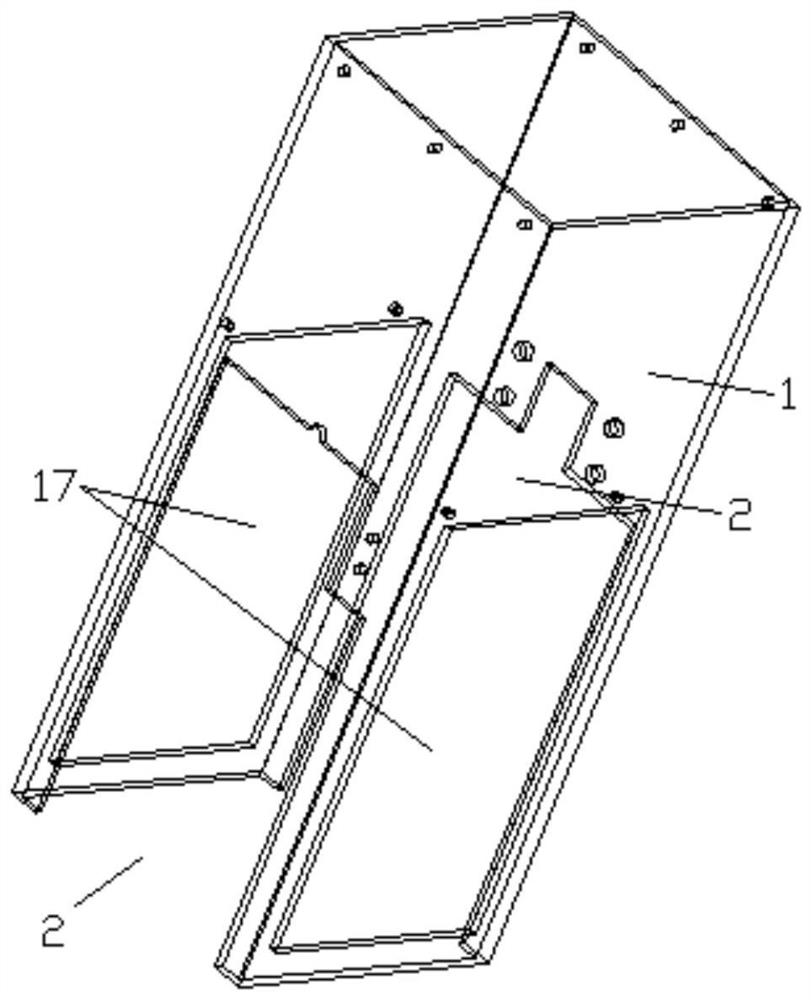

[0041] On the basis of the above structure, in this embodiment, openings 17 are provided on the opposite side walls of the box body 1. The openings 17 are in the shape of a "mouth", and each opening 17 is respectively provided with a plurality of counterweights. Block 18, each counterweight 18 is provided with a bayonet socket, directly counterweight 18 is stuck on the bottom of opening two 17 by bayonet. The weights of the parts of the box body 1 positioned at both sides of the cable 19 are adjusted by the counterweight 18 to make them equal, so as to ensure that the box body 1 is erected on the cable 19 stably and ensure the stability of the insulation layer installation.

[0042] It should be noted that the number of counterweights 18 at the two openings 17 may be inconsistent, and the weight of each counterweight 18 may also be inconsistent, as long as the box body 1 is erected on the cable 19 stably.

Embodiment 2

[0044] On the basis of Embodiment 1, in this embodiment, a support positioning plate 16 is installed horizontally and fixedly in the box body 1, and the support positioning plate 16 is integrally formed with the box body 1, or is detachably connected with the box body 1 by bolts. When the box body 1 and the edge of the supporting positioning plate 16 are respectively provided with screw holes that cooperate with the bolts; The locating groove 21 that cooperates with the cable 19 is provided with, and the stability of the box body 1 sliding on the cable 19 is increased by supporting the locating plate 16 and the locating groove 21, so as to ensure the quality of the insulating layer installation.

[0045] It should be noted that the positioning groove 21 can be arranged on the lower surface of the supporting positioning plate 16, or can be arranged on the upper surface of the supporting positioning plate 16. When the positioning groove 21 is arranged on the upper surface of the ...

Embodiment 3

[0048] On the basis of Embodiment 2, in this embodiment, the traveling mechanism includes a mounting plate 4, a driving wheel 5, a driven wheel 6 and a driving member, and the mounting plate 4 is detachably mounted on the corresponding opening 12, and the mounting plate 4 is installed The specific method is as follows: the position on the side of the opening 2 on the box body 1 is vertically fixed with a U-shaped fixing block by bolts, and the bottom of the U-shaped fixing block and the box body 1 are respectively provided with screw holes that cooperate with the bolts; A pair of screw holes are oppositely arranged on both sides of the U-shaped fixed block, and the mounting plate 4 is L-shaped. One end of the mounting plate 4 is provided with a through hole cooperating with the above-mentioned screw holes, and the positioning bolts 8 pass through one of the screw holes successively. hole and another screw hole to connect the mounting plate 4 and the U-shaped fixed block togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com