Fireproof emergency turn-off hydraulic control system

A technology of controlling the system and shutting off electricity, applied in the direction of servo meter circuit, valve details, multi-way valve, etc., can solve the problems of hidden dangers of personnel, safety accidents, difficult operation, etc., and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

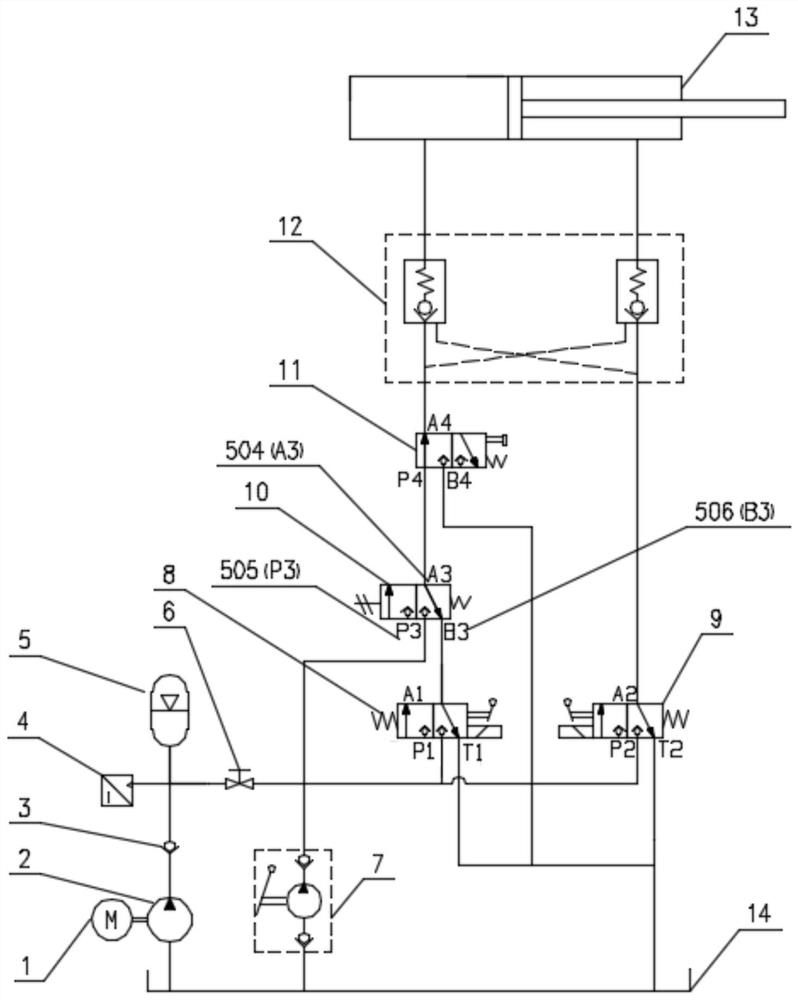

[0037] see figure 1 As shown, the control system of the present invention includes an accumulator, a first control valve, a second control valve, a third control valve, a fourth control valve, a multi-way fire prevention and pressure relief valve, an oil circuit connected to the upper chamber of the executive oil cylinder, a connection Execute the oil circuit in the lower chamber of the cylinder and the oil return circuit connected to the oil tank;

[0038] Among them, the accumulator is connected to the oil circuit connected to the upper chamber of the executive cylinder through the multi-way fire prevention pressure relief valve to form a fire prevention oil circuit;

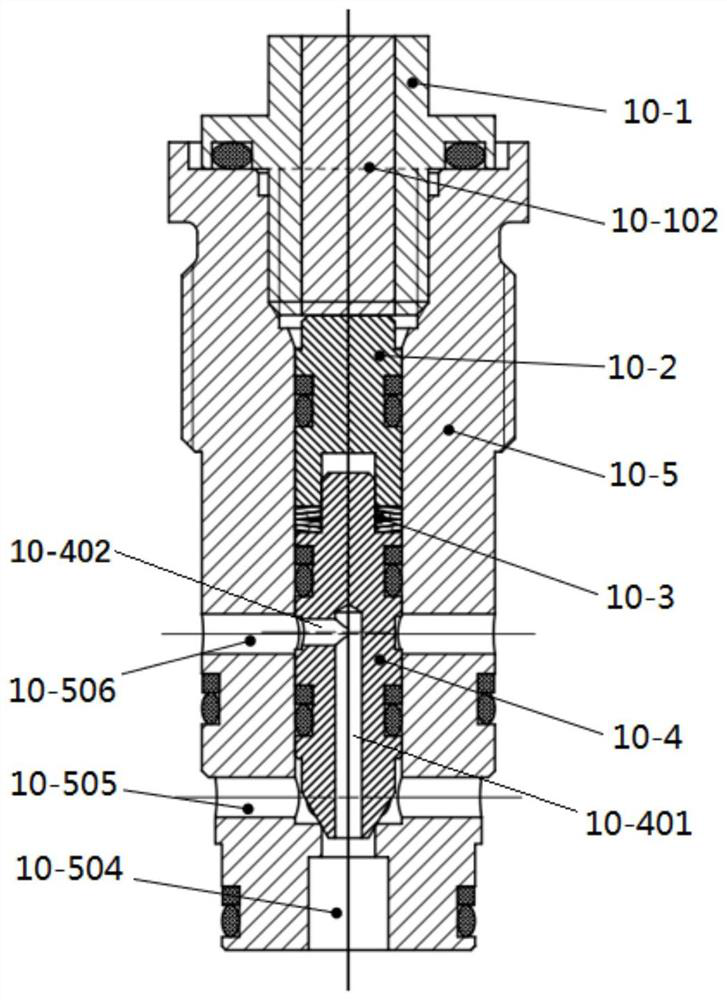

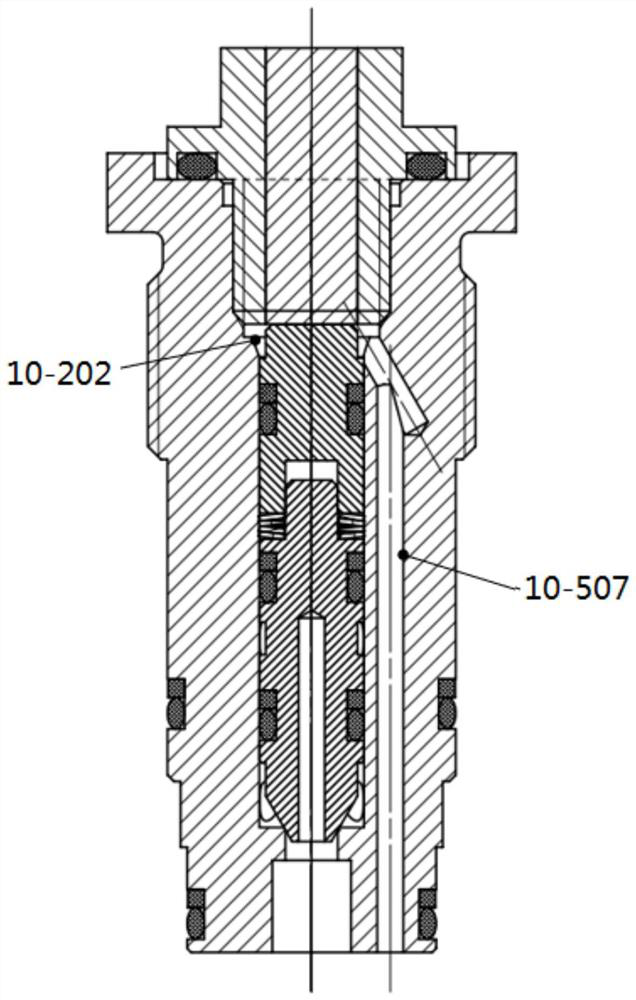

[0039] The accumulator is connected to the oil circuit connected to the upper chamber of the actuator cylinder through the first control valve to form a first oil circuit, and the oil circuit connected to the upper chamber of the actuator cylinder passes through the first hydraulic control check valve, multi-w...

Embodiment 2

[0046] On the basis of the scheme of Embodiment 1, the first control valve and the second control valve in the control system of this embodiment are electromagnetic control valves, and the first control valve is closed when it is powered on, and it is opened when it is powered off, and the second control valve is closed when it is powered on. In this state, the first control valve and the second control valve are always energized. In case of a circuit failure, the first control valve is opened and the second control valve is closed, that is, the first oil circuit is opened. , Turn off the second oil circuit, the high-pressure oil in the accumulator enters the upper chamber of the actuator cylinder through the first oil circuit, the high-pressure oil in the first oil circuit opens the second one-way hydraulic control valve to open the fourth oil circuit, and the actuator cylinder The hydraulic oil in the lower chamber returns to the oil tank through the fourth oil circuit. Unde...

Embodiment 3

[0049] On the basis of the above-mentioned embodiments, the control system of this embodiment is provided with a reversing valve, such as a manual reversing valve, which is set in the fire prevention oil circuit or / and the first oil circuit, and the reversing valve It is connected to the oil return line connected to the oil tank. The reversing valve is a multi-way two-position valve. In one state, the passage in the valve located on the fire prevention oil passage or / and the first oil passage is opened, and the passage in the valve connected to the oil tank is closed. , does not affect the above-mentioned working process of the overall control system. After a fire or emergency shutdown of the controlled valve, the reversing valve can be switched to another state, that is, the passage in the valve located on the fire prevention oil circuit or / and the first oil circuit is closed. , the passage in the valve connected to the oil tank is opened, so that the controlled valve can be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com