Numerical variable pump based on multichannel solenoid directional valve binary system flow regulation and control

An electromagnetic directional valve, digital variable technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, servo motor components, etc., can solve problems such as poor control accuracy, large valve flow pulsation, and zero dead zone. , to achieve the effect of improving reliability, avoiding flow fluctuations and eliminating dead zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

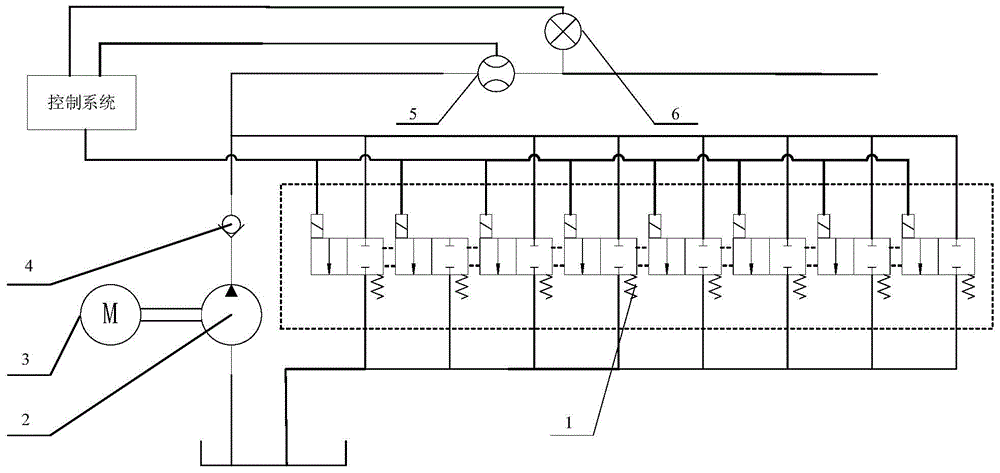

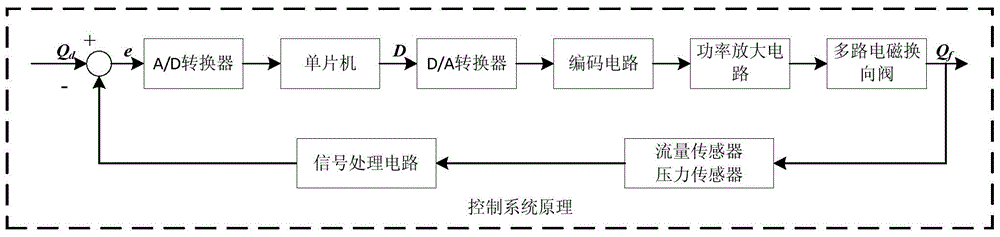

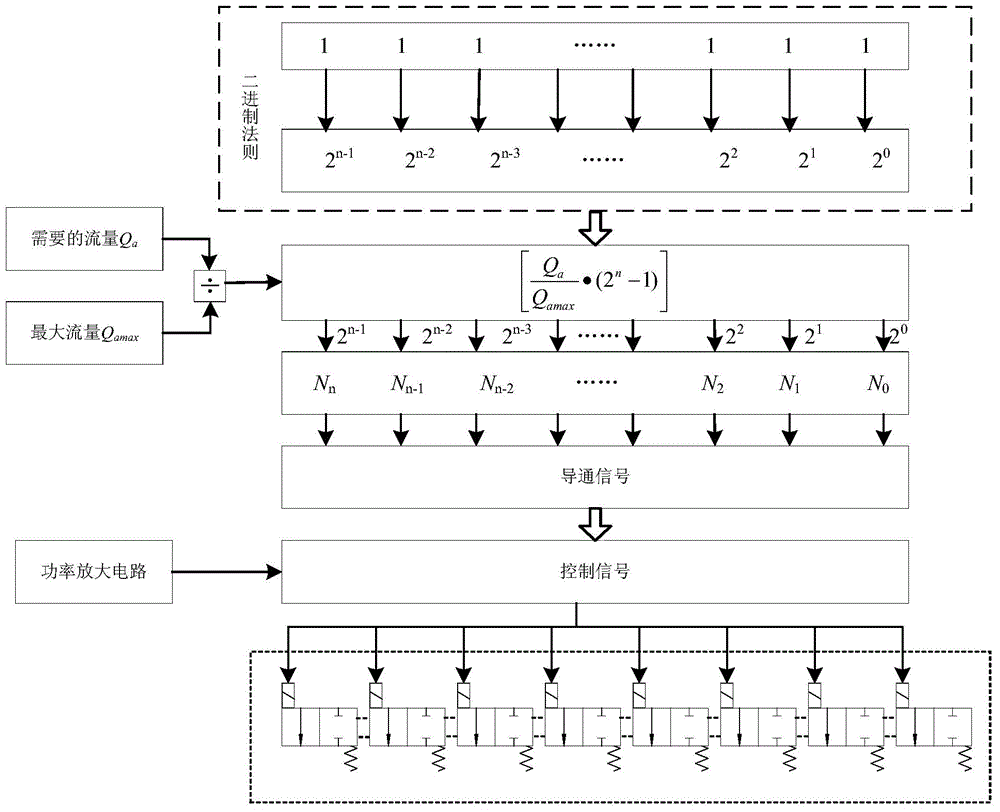

[0021] The present invention is a digital variable pump based on the binary flow control of multi-channel electromagnetic reversing valves. The structure of the pump body is as follows: figure 1 As shown, it includes multi-channel electromagnetic reversing valve 1, quantitative pump 2, motor 3, check valve 4, flow sensor 5, pressure sensor 6, power supply, power amplifier circuit, encoding circuit, single-chip microcomputer, A / D converter, D / A converter and signal processing circuit. Wherein, the flow sensor 5, the pressure sensor 6, the power supply, the power amplifier circuit, the encoding circuit, the single-chip microcomputer system, the A / D converter, the D / A converter, and the signal processing circuit constitute the control part. The main body of the digital variable pump is a quantitative pump 2, and the variable mechanism of the variable pump incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com