Measurement device for tail spatial position of robot

A technology of spatial position and measuring devices, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of high cost of vision and laser measurement technology, inapplicability of multi-degree-of-freedom robots, and high requirements for the cleanliness of the measurement environment, which is conducive to promotion and structure Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings.

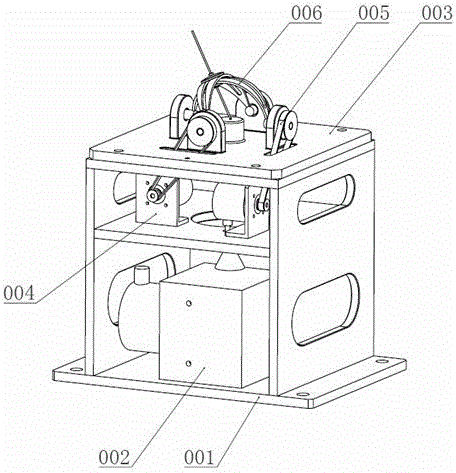

[0016] Such as figure 1 As shown, a device for measuring the spatial position of the end of a robot includes a base 001, a wire-pulling encoder 002, a transition mounting plate 003, an encoder assembly 004, a timing belt 005, and a follow-up pointing mechanism 006. The wire-pulling encoder 002 is screwed Installed at the bottom of the base 001, the transition mounting plate 003 is installed on the top of the base 001 by screws, the two encoder components 004 are installed in the middle of the base 001 by screws, and the follow-up pointing mechanism 006 is through deep groove ball bearings 011 It is installed in the four circular holes of the transitional mounting plate 003, and the follow-up pointing mechanism 006 is connected to the encoder assembly 004 through a timing belt 005.

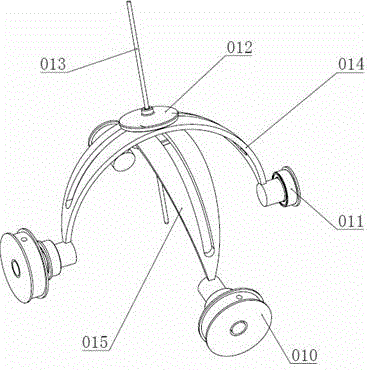

[0017] Such as image 3 As shown, the follower pointing mechanism 006 includes an outer arc follower 014...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com