Solid light microchannel array panel and preparation method thereof

An array panel and optical channel technology, applied in the field of optical components, can solve problems such as difficult to achieve optical effects, unfavorable packaging and use, and harsh environmental requirements, and achieve the effects of favorable packaging and use, low cost, and low cleanliness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] refer to Figure 7 , a method for preparing a solid optical microchannel array panel, comprising the following steps:

[0071] drawing the first light-transmitting medium material rod and the opaque base material rod into thin rods of the first light-transmitting medium material and the thin rods of the opaque base material;

[0072] Arranging and combining the thin rods of the first light-transmitting medium material and the thin rods of the opaque base material to form a composite rod, the first rods of the light-transmitting medium material being wrapped by the adjacent rods of the opaque base material;

[0073] Draw a primary composite rod to make a primary composite channel filament;

[0074] According to the size requirements of the optical channel to be prepared, the primary composite channel wire is made into a rough composite wire rod of the size required by the solid optical microchannel array panel;

[0075] Fusing the blank composite wire rod into a blank ...

no. 1 example

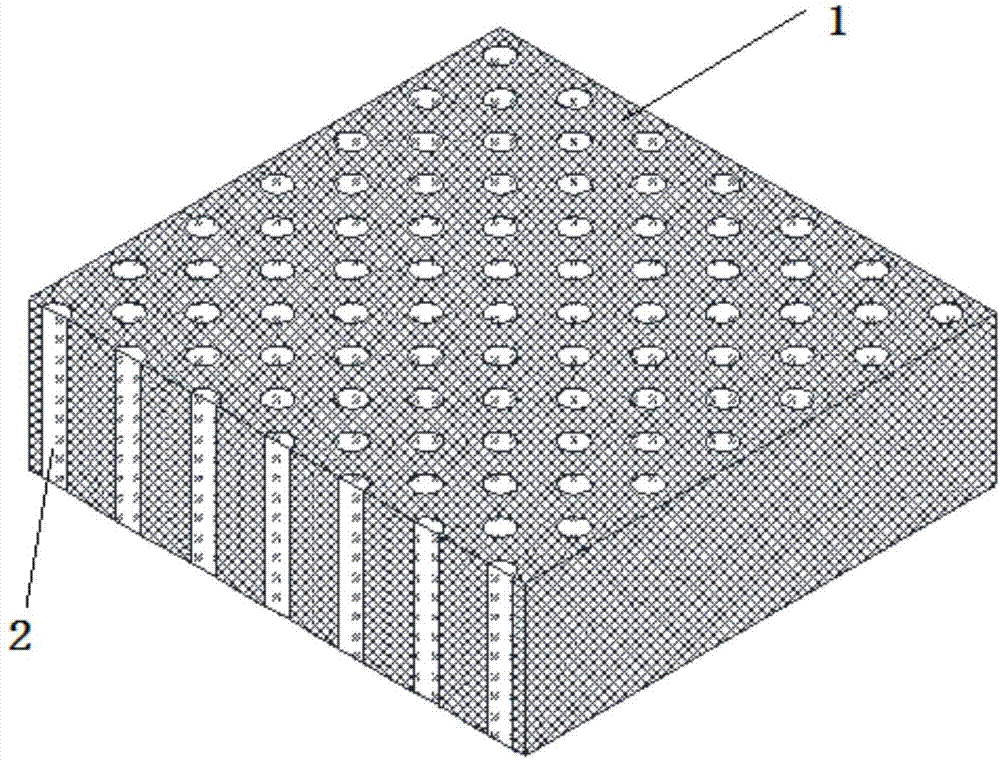

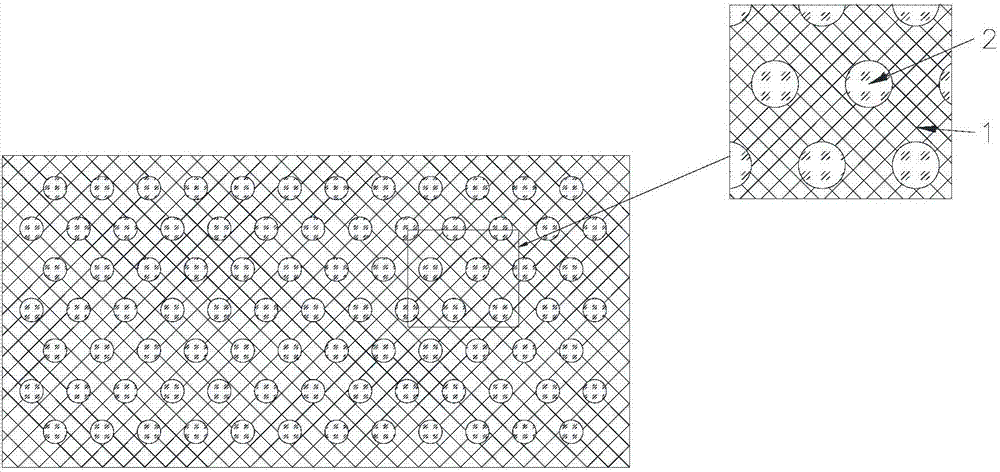

[0113] Aiming at the problems caused by the non-solid structure of through holes in the existing microhole array structure, the present invention proposes a new solid optical microchannel array panel. Such as figure 1 and 2 As shown, the array panel mainly includes a light-tight base 1 and a plurality of light-transmitting channels 2 .

[0114] Wherein, the light-transmitting channel 2 uses a transparent optical medium (such as transparent glass, transparent plastic, etc.) as the light channel to allow light to pass through. In addition, the light-transmitting channel 2 is a solid light channel.

[0115] The opaque substrate 1 uses opaque or light-absorbing materials (such as opaque glass, opaque plastic, etc.) as spacers to isolate the light between the light-transmitting channels 2 .

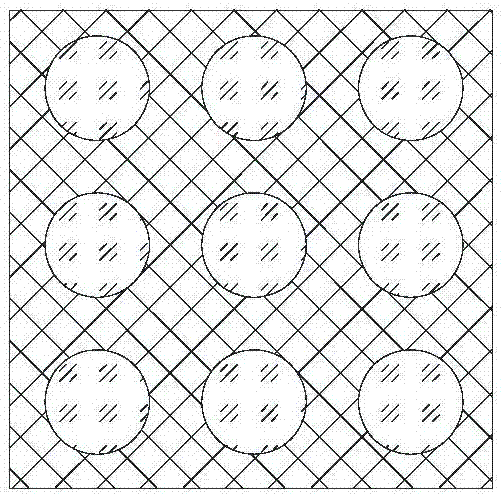

[0116] Such as figure 1 and figure 2 As shown, each light-transmitting channel 2 is arranged in parallel, and the light-impermeable matrix 1 is filled between each light-transmitting cha...

no. 2 example

[0120] Such as Figure 9-12 As shown, the transparent glass rod 202 made of transparent glass with the second light-transmitting medium rod, the black glass tube 201 made of black glass as the opaque base material tube, and the first thin filler wire made of black glass The black filament 203 and the second thin filler filament are black filament 204 made of black glass as an example, assuming that the optical channel size of the primary composite channel filament does not meet the optical channel size requirements to be prepared, the method of fusing the blank rod is vacuum drawing Manufacturing method, then adopt the tube-and-rod method of the present invention to prepare the technological process of solid optical microchannel array panel as follows:

[0121] The first step: use the rod tube to pull the single-channel thin rod.

[0122] The specific realization process of adopting rod-tube farad single-channel thin rods is as follows: according to the designed process param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com