Sterility test process isolator for double-sided laminar flow operation

A technology of isolator and process, applied in the direction of manufacturing tools, manipulators, gasified substances, etc., to achieve the effect of increasing controllability, reducing pollution, and ensuring sterility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

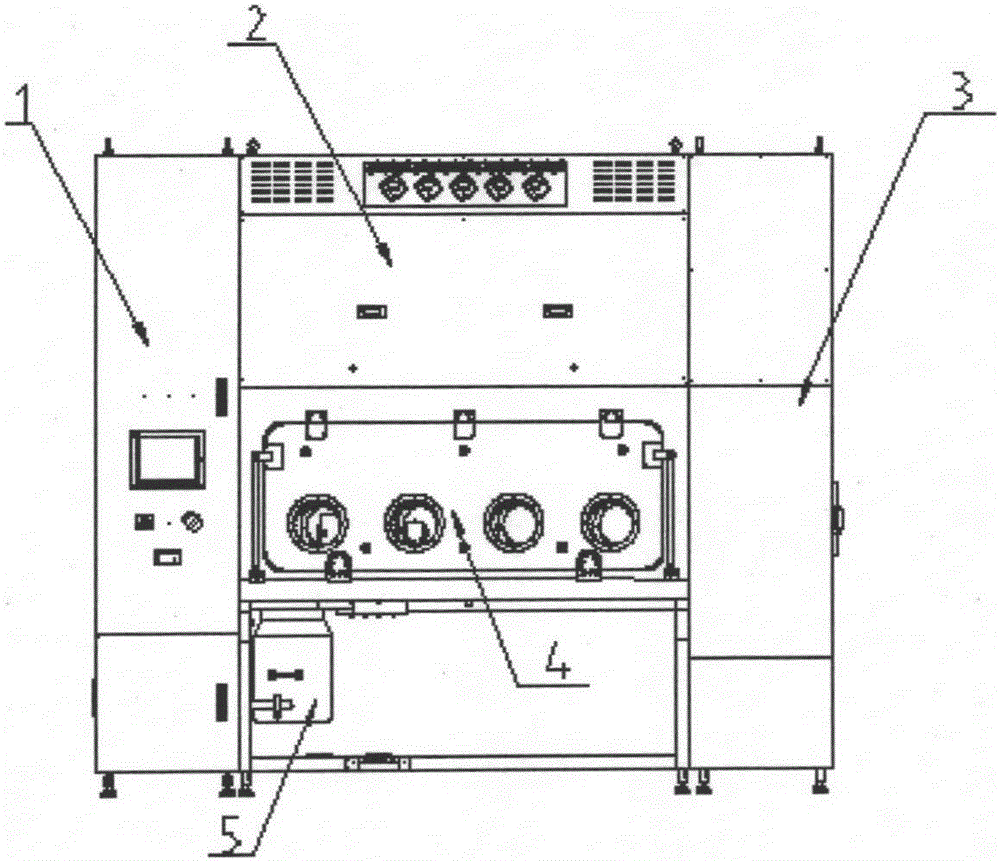

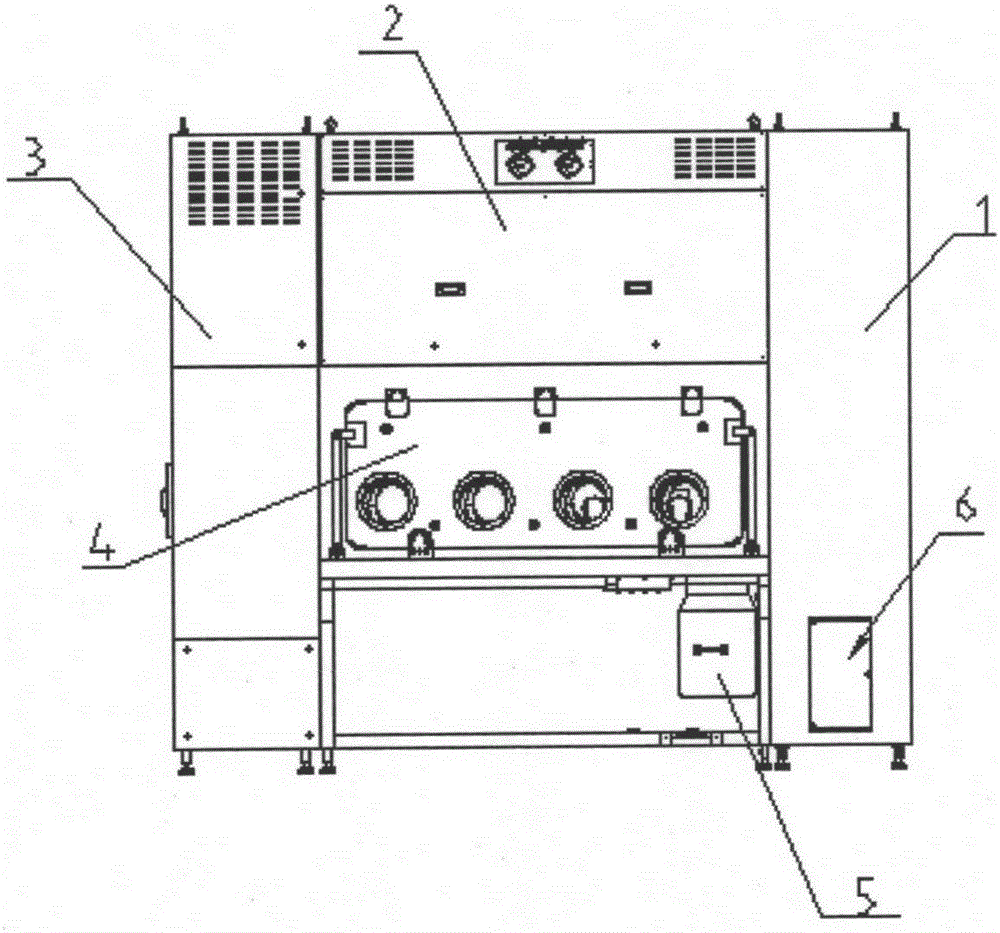

[0045] Such as Figure 1-2 Shown here is a general assembly drawing of a double-sided operation sterile inspection process isolator provided by the present invention, including a glove compartment system with an air handling system 2 on the top and an electrical cabinet system 1 on both sides of the glove compartment system. , Transfer warehouse components.

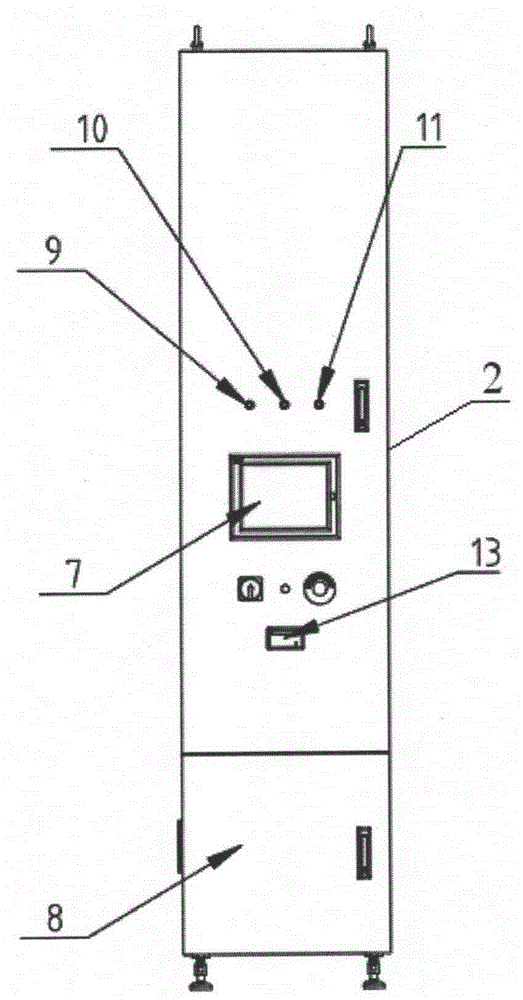

[0046] Electrical cabinet system components 1 such as Figure 3-4 As shown, the bottom of the electrical cabinet system 1 is provided with a vacuum pump and valve body installation box 8 and an integrated hydrogen peroxide vapor sterilization system 6, and the pump body connected to the integrated hydrogen peroxide vapor sterilization system 6 is located in the vacuum pump and valve body In the installation box 8, the integrated hydrogen peroxide vapor sterilization system 6 communicates with the air processing system 2 and the transfer bin assembly 3 through a pipeline. The electrical cabinet system 1 is provided with a glo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com