Head for automatic blasting, loosening and feeding

An automatic, spray tube technology, applied in the direction of shovels, plows, agricultural machinery and implements, can solve the problem of small flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

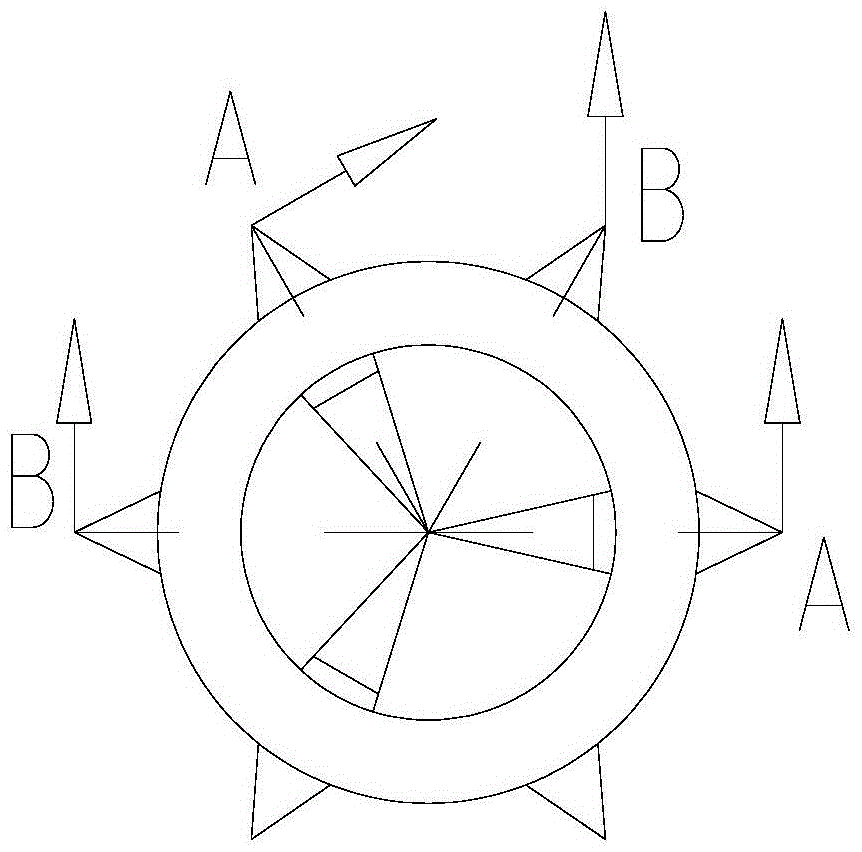

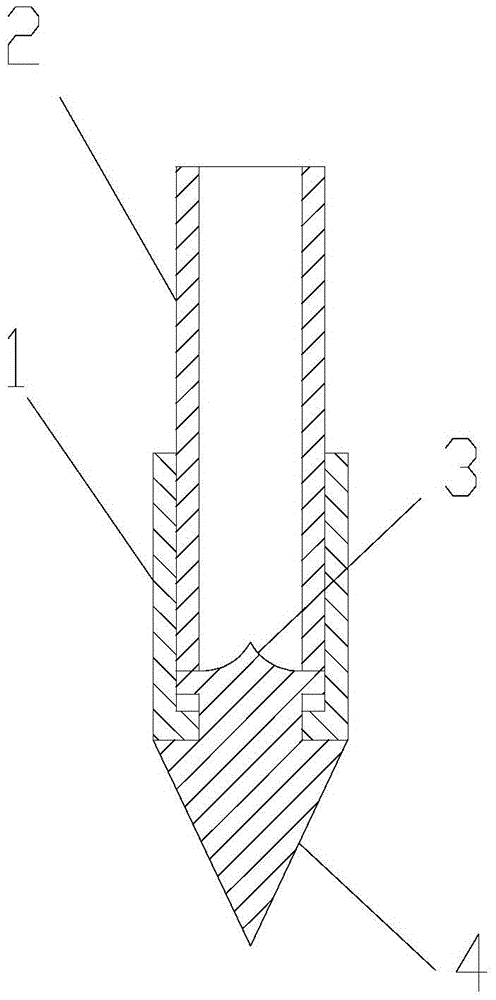

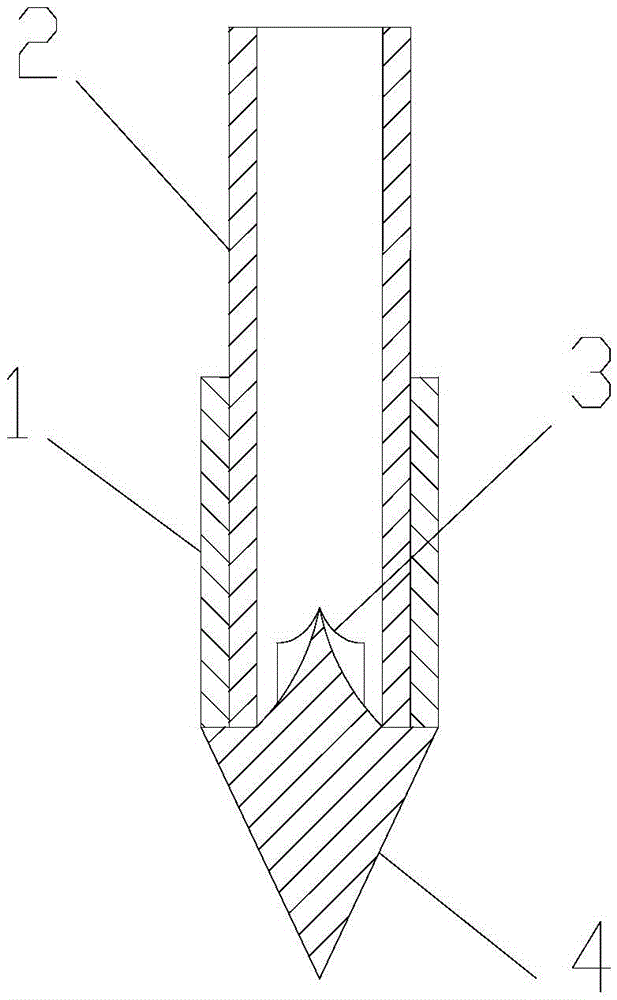

[0017] figure 1 It is a top view of the present invention; figure 2 for figure 1 Middle A-A sectional view; image 3 for figure 1 Middle B-B sectional view; Figure 4 It is a structural schematic diagram of the tapered flow divider of the present invention. As shown in the figure, the automatic blasting loosening head of this embodiment includes a spray pipe 2 and a conical diverter that is slidingly fitted with the outlet end of the spray pipe 2; the conical diverter includes an integrally formed upper cone 3 and the lower cone 4; the upper cone 3 is inserted into the injection pipe 2 for splitting the gas flowing out of the injection pipe 2, the lower cone 4 is used for inserting into the working soil and the top of the lower cone 4 is provided with a The sealing platform 6 that seals the outlet of the injection pipe 2; the automatic blasting loosening head of the present invention, before implementing the soil loosening operation, insert the injection pipe 2 together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com