Onsite fire hose detection device quick in water filling and pressure stabilizing

A fire hose, on-site detection technology, applied in the direction of using stable tension/pressure to test the strength of materials, etc., can solve the problems of small flow, cannot be maintained, and cannot meet the detection standards, and achieve accurate detection results, easy transportation, Detect quick effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

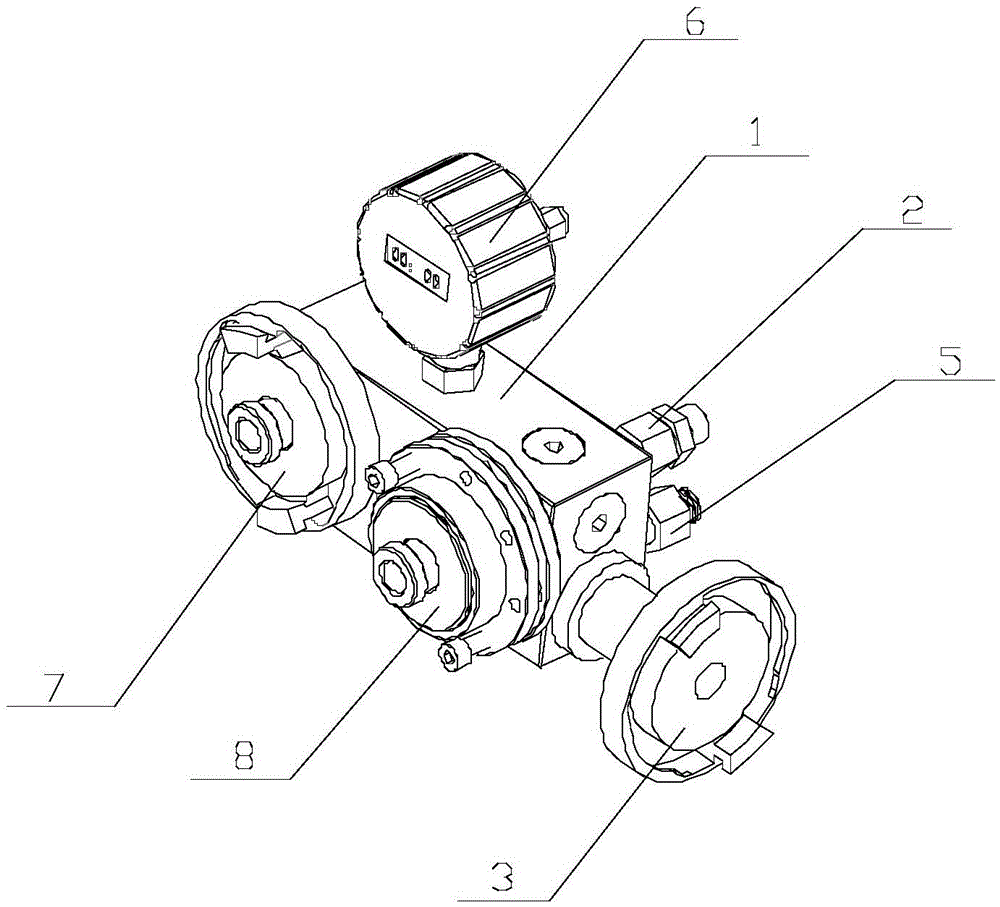

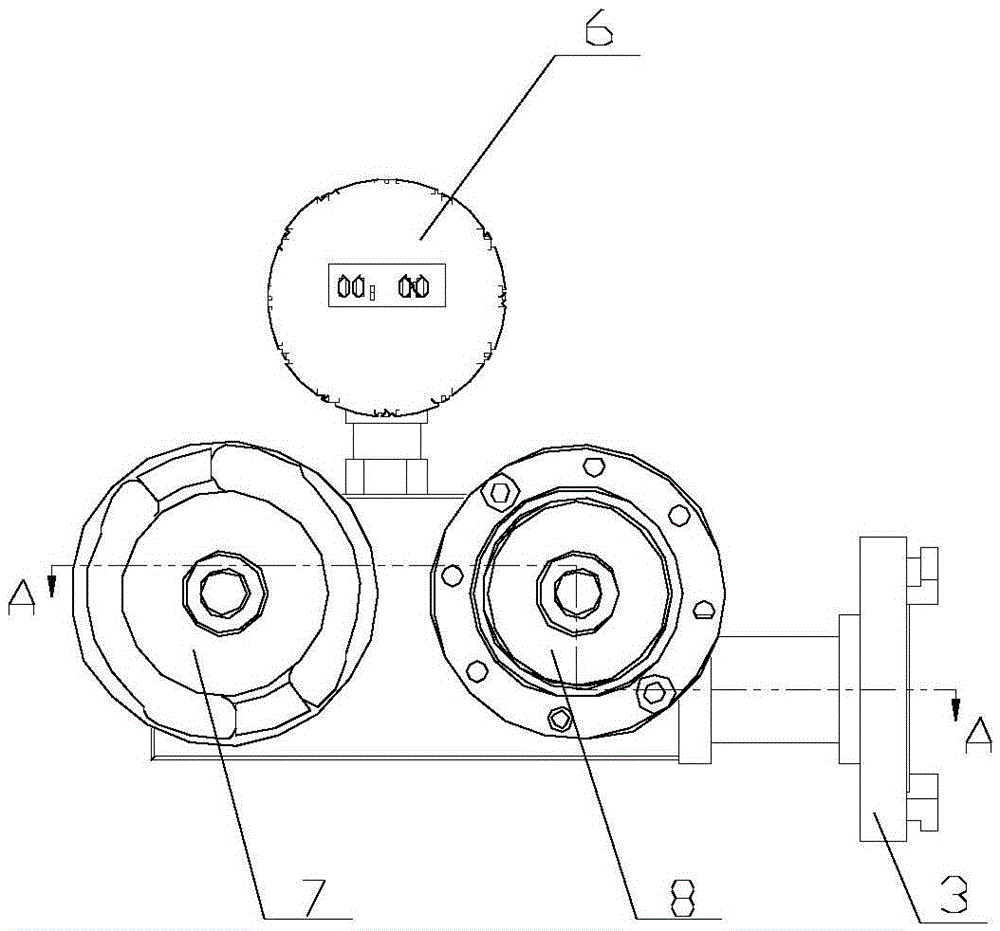

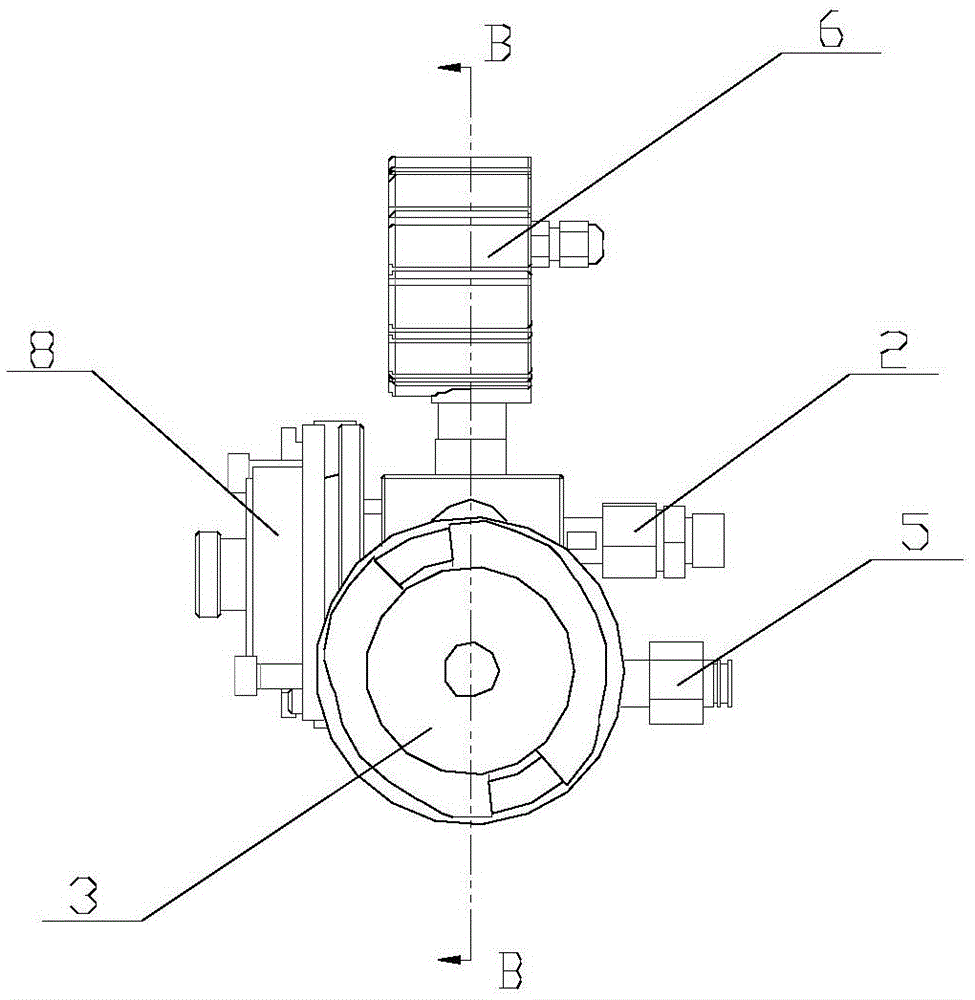

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a motor, a booster pump and a detection device, the motor is connected to the booster pump, and the detection device includes a housing 1 and water inlet A2, water inlet B3, Water outlet 5, digital display pressure controller 6, detection port A7 and detection port B8, wherein water inlet A2 is connected to the outlet of the booster pump, water inlet B3 is connected to the fire hydrant through a fire hose, and water outlet 5 is connected to the booster pump. The water inlet of the pressure pump is connected. There are two detection terminals, among which the detection terminal A7 is used to detect the burst pressure of the hose (the main detection indicators are: working pressure, test pressure, and burst pressure), and the detection terminal B8 is used to detect the overall performance of the fire hose and the interface (in Whether the fire-fighting hose leaks under the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com