Forming device of powder forming machine

A technology of powder molding machine and molding device, applied in the direction of material molding presses, punching machines, presses, etc., can solve the problems of unstable working state, instability, machine loss, etc., to improve quality and performance, improve stability the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

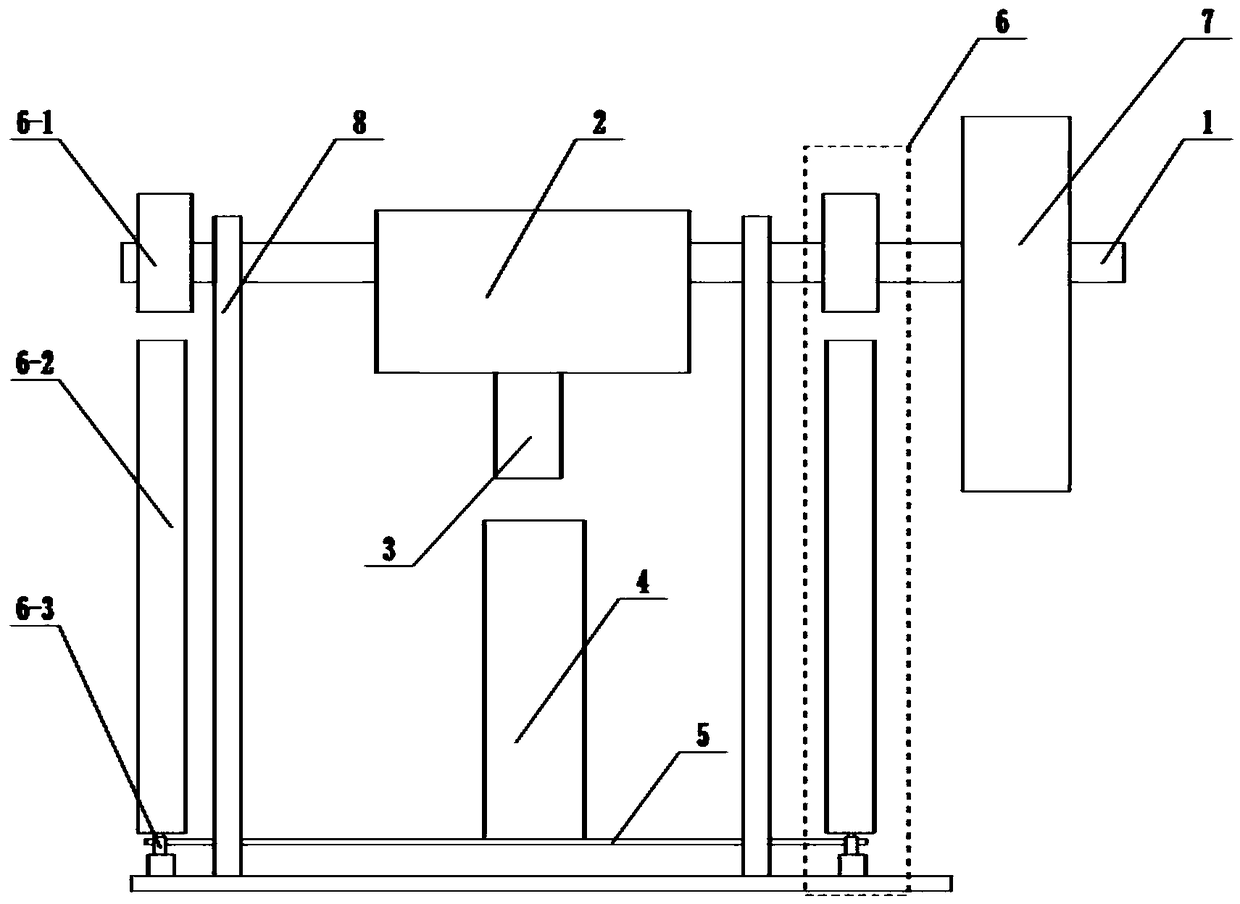

[0010] like figure 1 As shown, a molding device of a powder molding machine includes a main shaft 1, an eccentric wheel 2, a lower die shaft 3, a demoulding shaft 4, a stripping plate 5, a pressing mechanism 6, a pulley 7 and a frame 8; the eccentric wheel 2 is fixed Set on the main shaft 1, the lower die shaft 3 is fixedly installed on the far end of the eccentric wheel 2, the stripping shaft 4 is fixedly mounted on the stripping plate 5, and is located directly below the lower die shaft 3; the pressing mechanism 6 includes a cam 6- 1. The push rod 6-2, the cylinder 6-3, and the cam 6-1 are fixedly set on the main shaft 1. One end of the push rod 6-2 is connected with the plunger of the cylinder 6-3, and the other end is located on the positive side of the cam 6-1. bottom, and is in movable crimping with the cam 6-1; the number of the pressing mechanism 6 is two groups, and is symmetrically distributed on both sides of the eccentric wheel 2, and the stripping plate 5 is set h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com