High-speed stubble cleaning harrow

A high-speed technology for stubble removal, applied in the field of stubble removal rakes, can solve problems such as the deviation of the tractor’s travel direction, and achieve the effects of improving operation quality, facilitating transportation, and preventing missing stubble removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

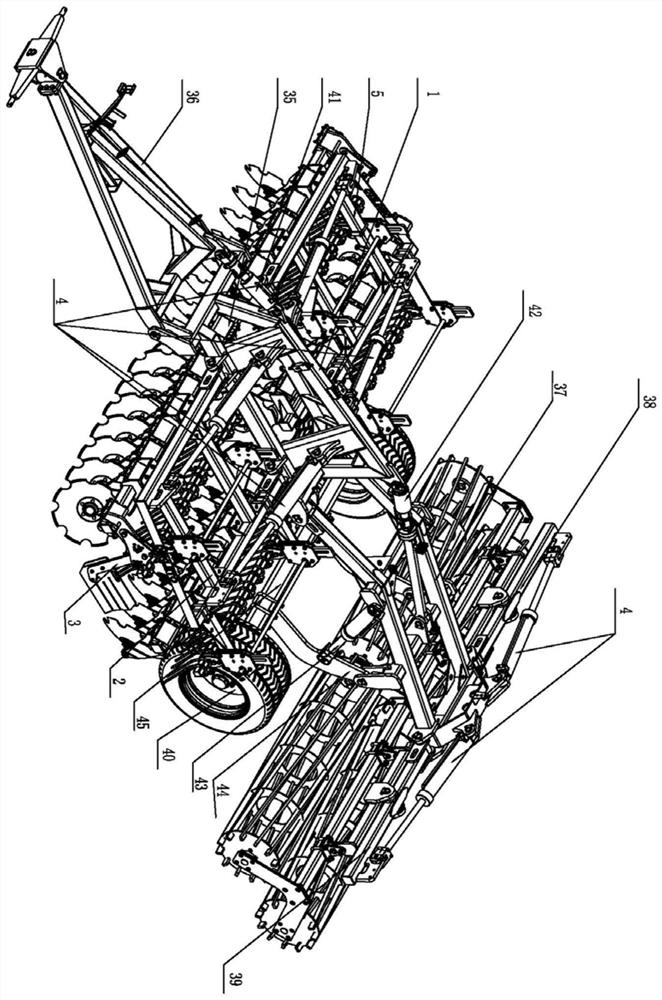

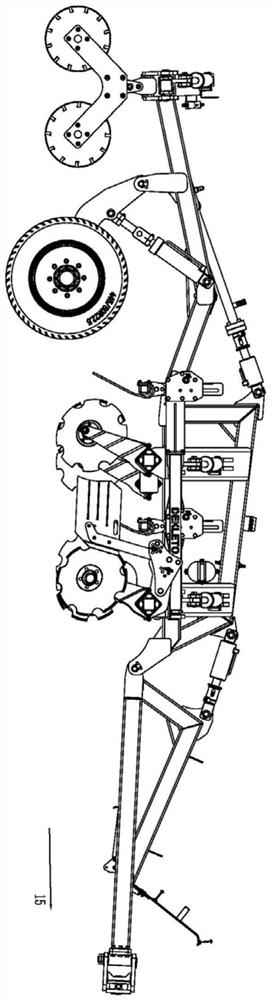

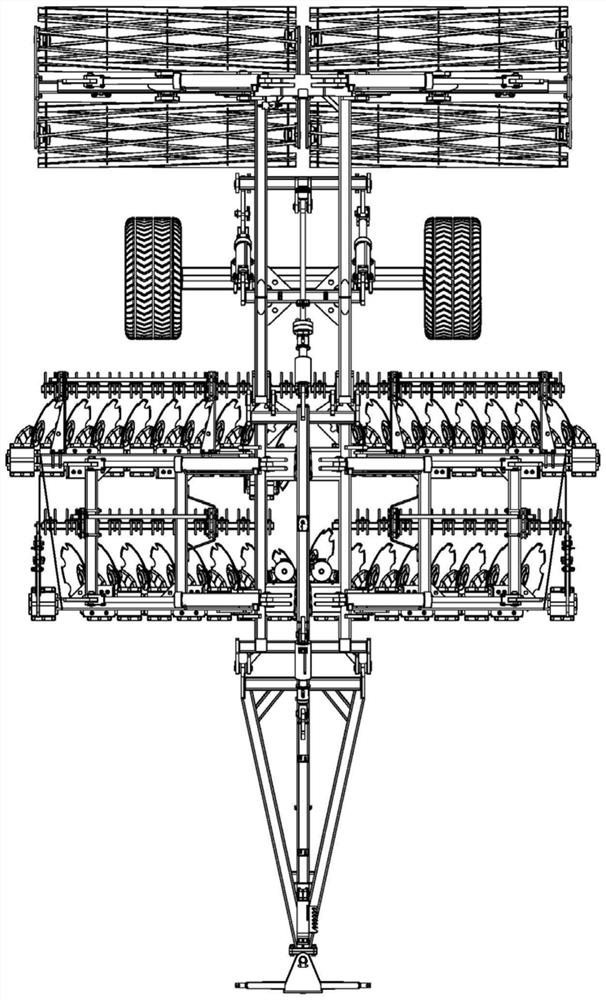

[0063] The high-speed stubble harrow includes the main rake assembly 1, the middle rake assembly 35, the left folding rake assembly 2, and the right folding rake assembly 5. The left folding rake assembly 2 and the right folding rake assembly 5 can be It is connected to the left and right sides of the main rake assembly 1 in a folded manner, the middle rake assembly 35 is fixedly connected under the main rake assembly 1, and the front end of the main rake assembly 1 is movably connected with The traction frame assembly 36, the rear end of the main rake assembly 1 is movably connected with a rear adjusting tailstock assembly 37, and the rear left and right sides of the rear adjusting tailstock assembly 37 are respectively connected with a left folding pressing roller assembly 39 and a right folding roller assembly 39. The pressure roller assembly 38, the lower end of the rear adjusting tailstock 37 is connected with two road wheels 40, the two road wheels 40 are connected by an ...

Embodiment 2

[0068] On the basis of Example 1, the front row of the middle rake frame is also symmetrically provided with a third rake 9, and the third rake 9 is located outside the first rake 8 and the second rake 7, The concave side surface of the third rake piece 9 faces outward and forward obliquely.

Embodiment 3

[0070] The difference from Example 2 is that the fourth rake blade and the fifth rake blade are located in the rear row of the middle rake frame, the fourth rake blade and the fifth rake blade are arranged face to face, and the The fourth rake is shifted forward in the direction of traction relative to the fifth rake, and the concave sides of the fourth rake and the fifth rake are obliquely facing inward and forward; the middle rake The rear position of the rear row is also symmetrically provided with a sixth rake, the sixth rake is located on the outside of the fourth rake and the fifth rake, and the concave side of the sixth rake is inclined towards the inside and toward the ahead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com