Patents

Literature

64results about How to "Full of power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

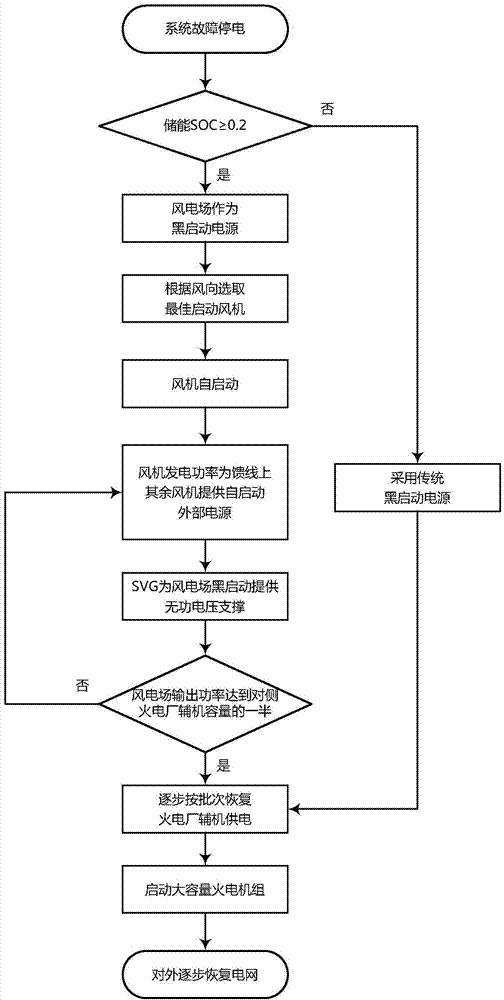

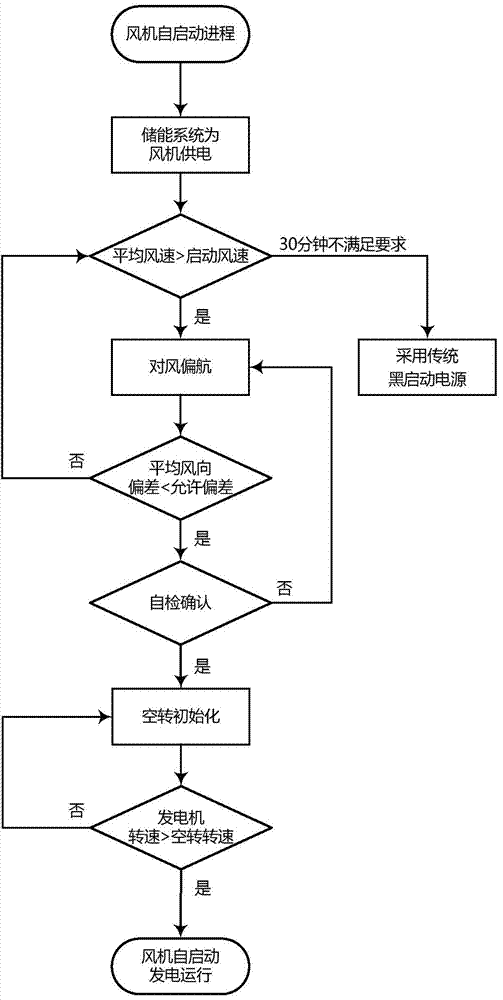

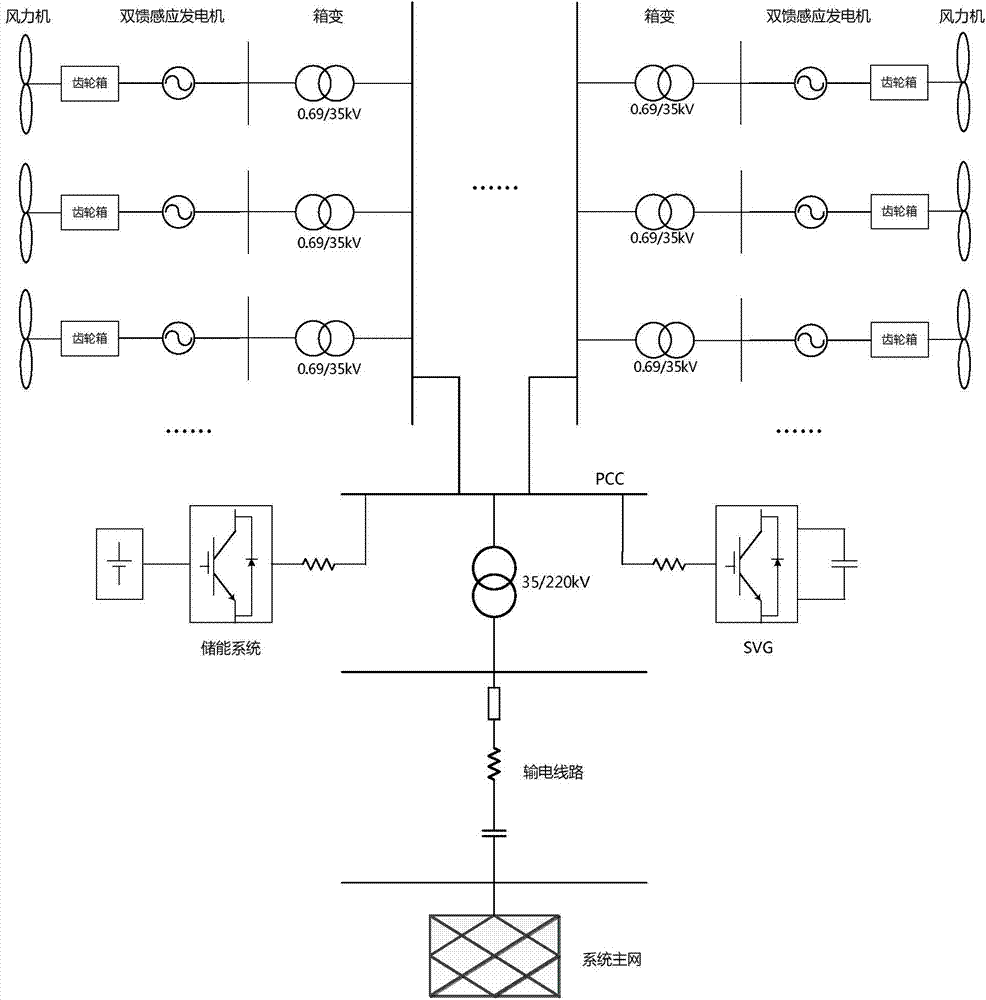

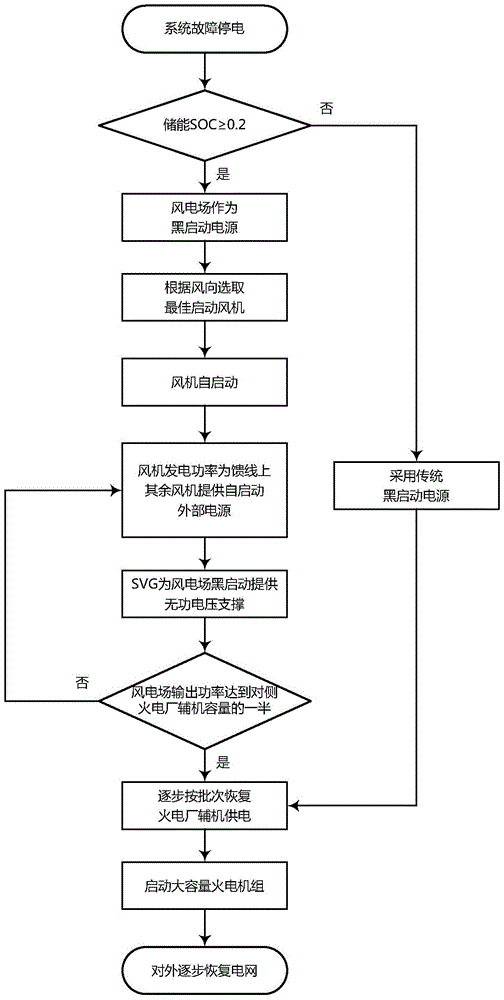

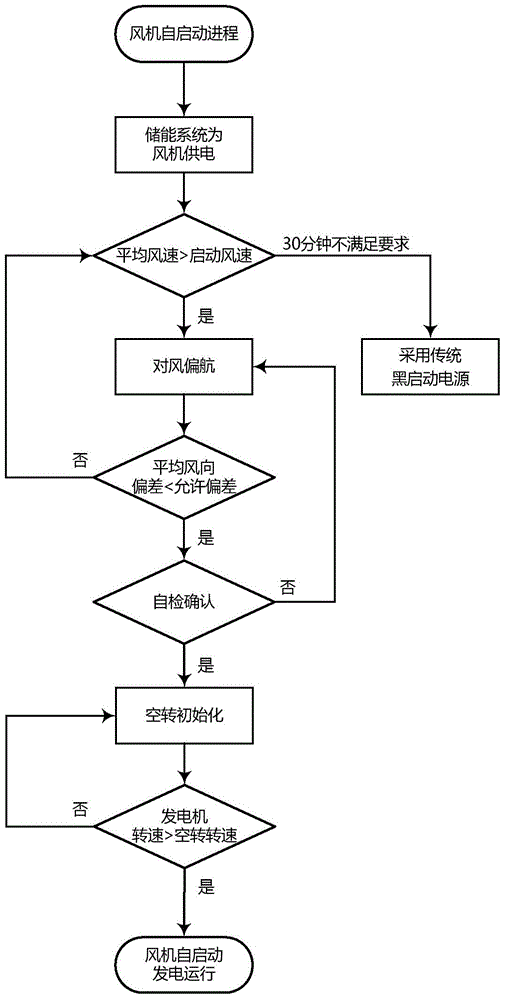

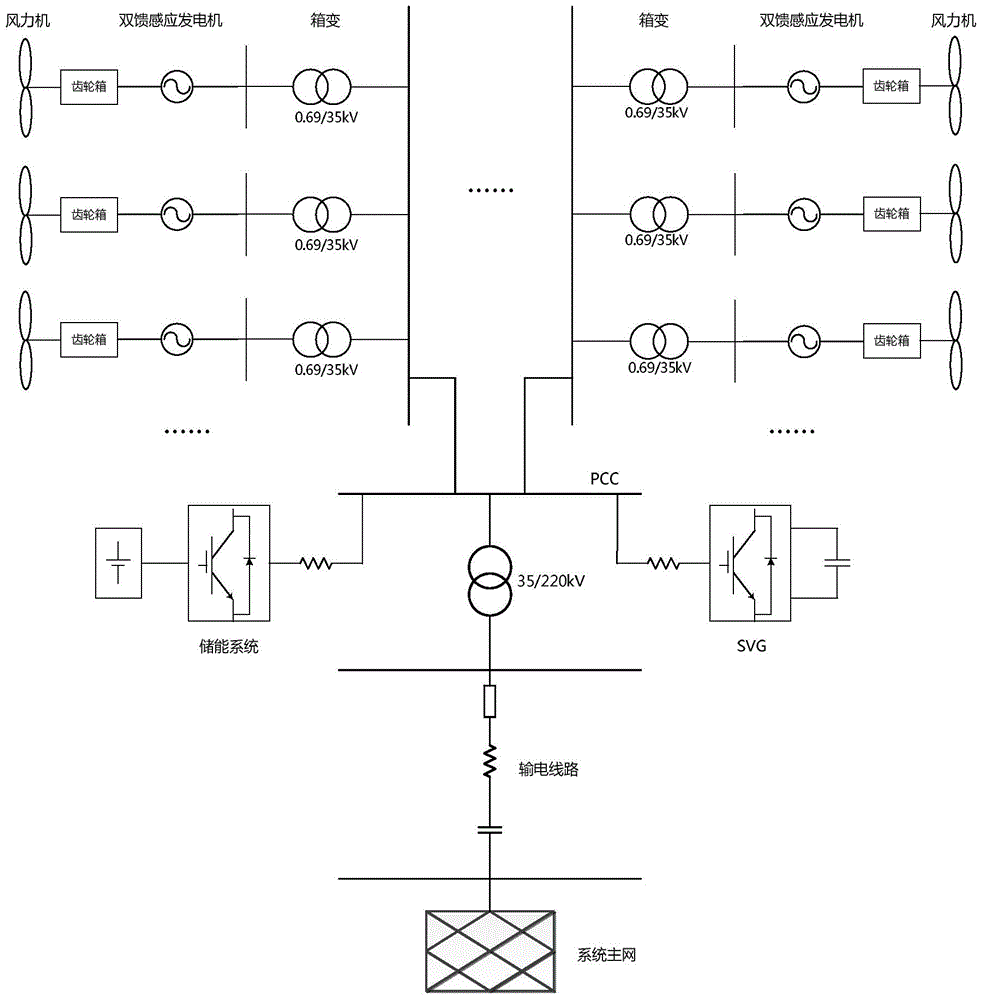

Black-start method for power grid

InactiveCN104716671AReliable recoveryRestoration of power is reliableSingle network parallel feeding arrangementsWind energy generationElectric power systemPower grid

The invention discloses a black-start method for a power grid. The start method comprises the following steps: when an electric power system is powered off due to a fault, judging whether a wind power plant is used as a black-start power supply or not according to the charge state of an energy storage system configured in the wind power plant, if the charge state of the energy storage system is less than 0.2, starting a high-capacity thermal power unit by using the traditional black-start power supply, and externally recovering the power grid step by step. According to the black-start method, wind resources can be adequately utilized and the wind power plant is taken as the black-start power supply for carrying out black-start for the power grid.

Owner:SOUTHEAST UNIV

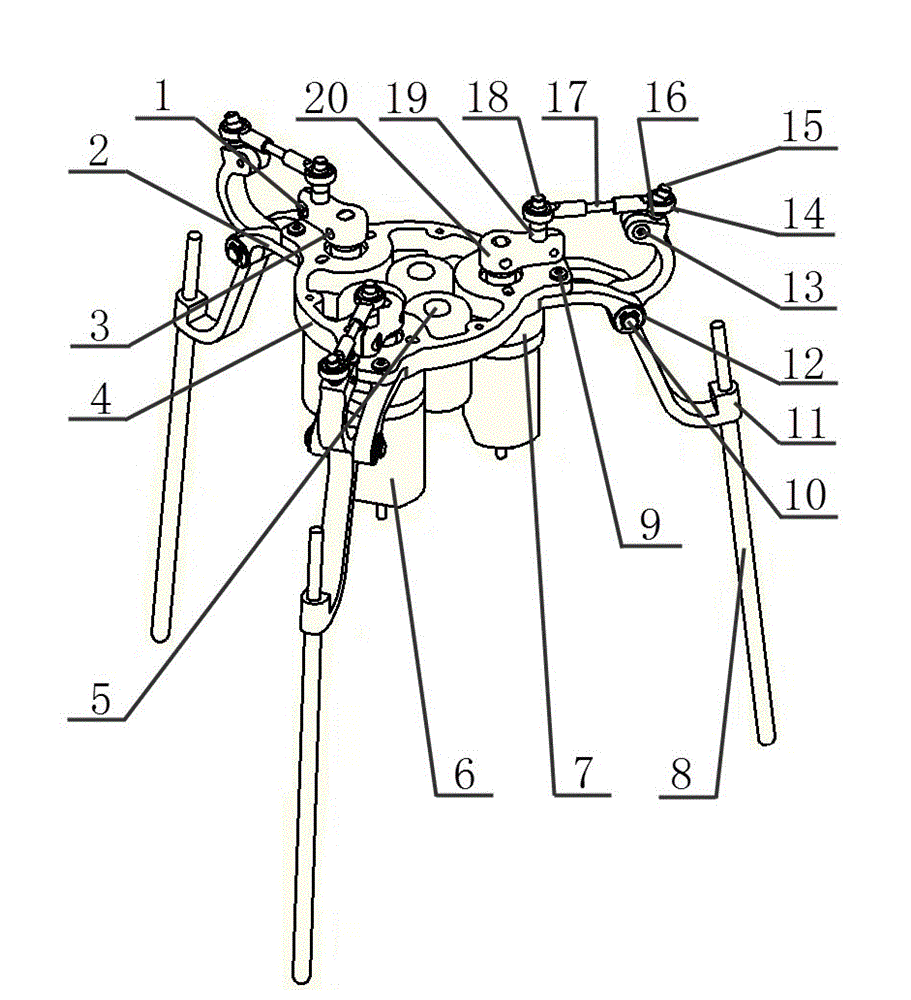

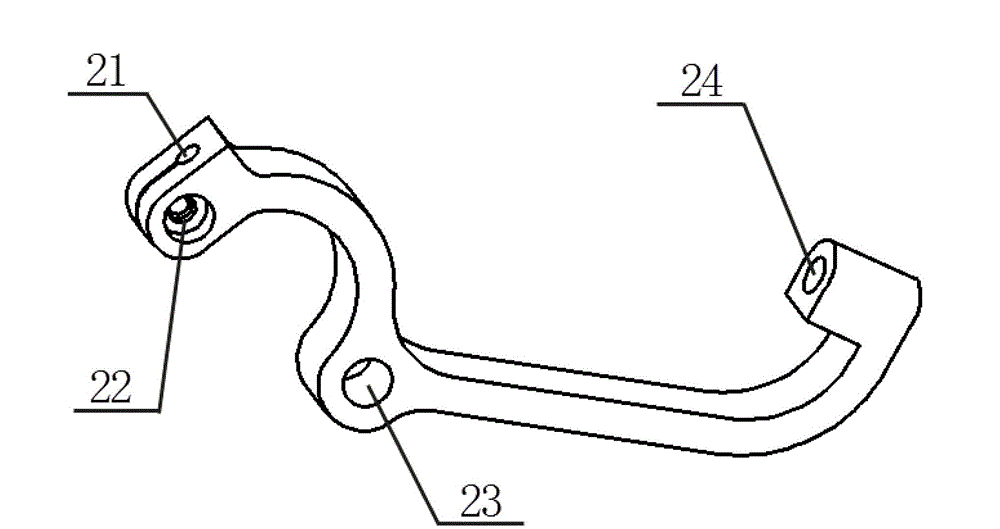

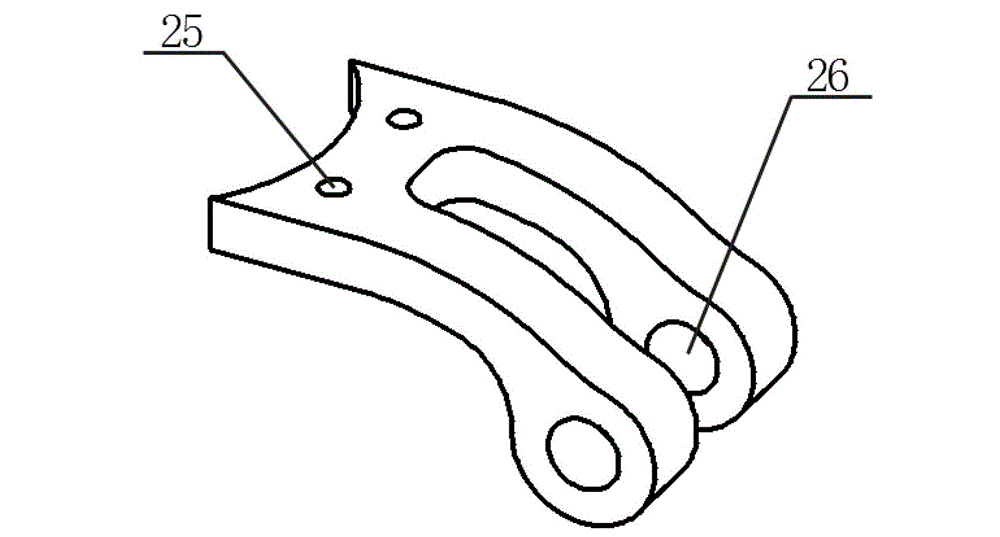

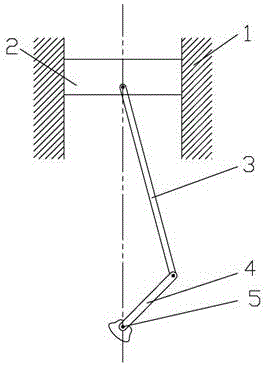

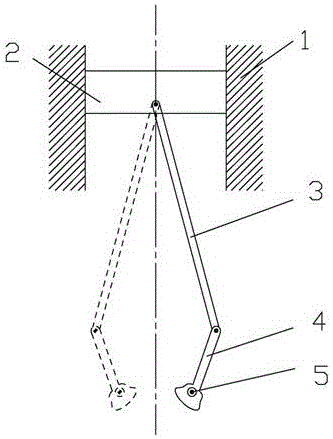

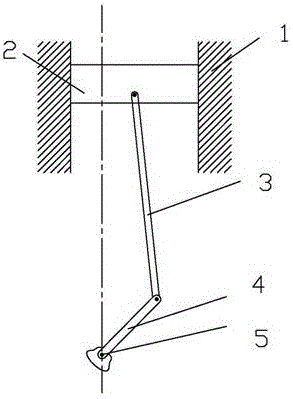

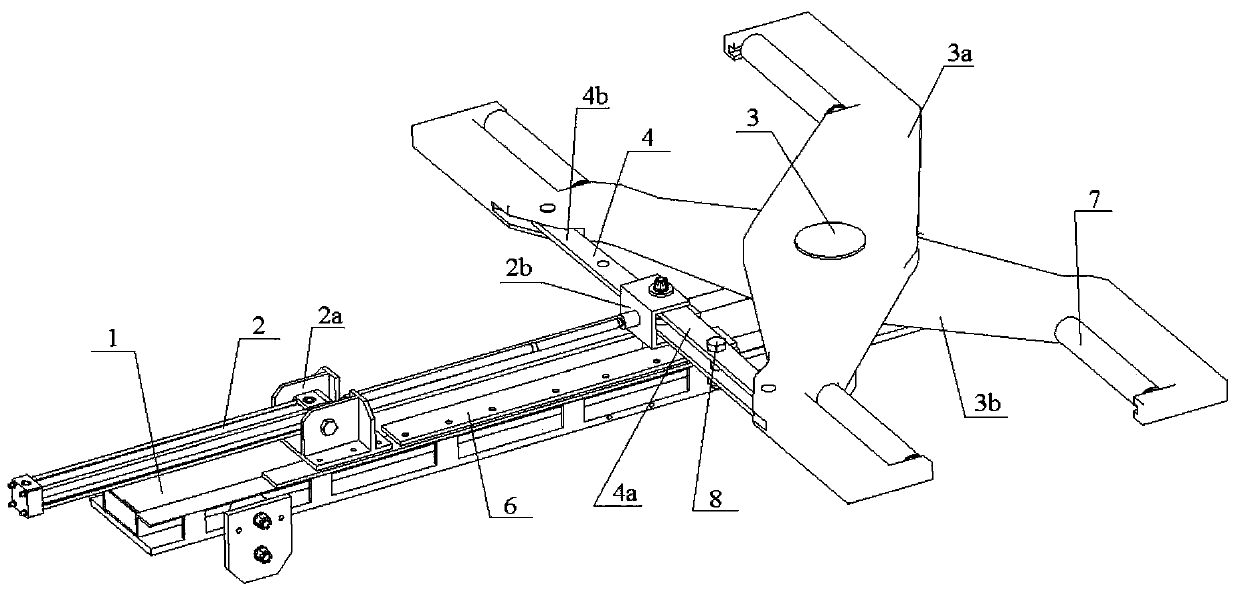

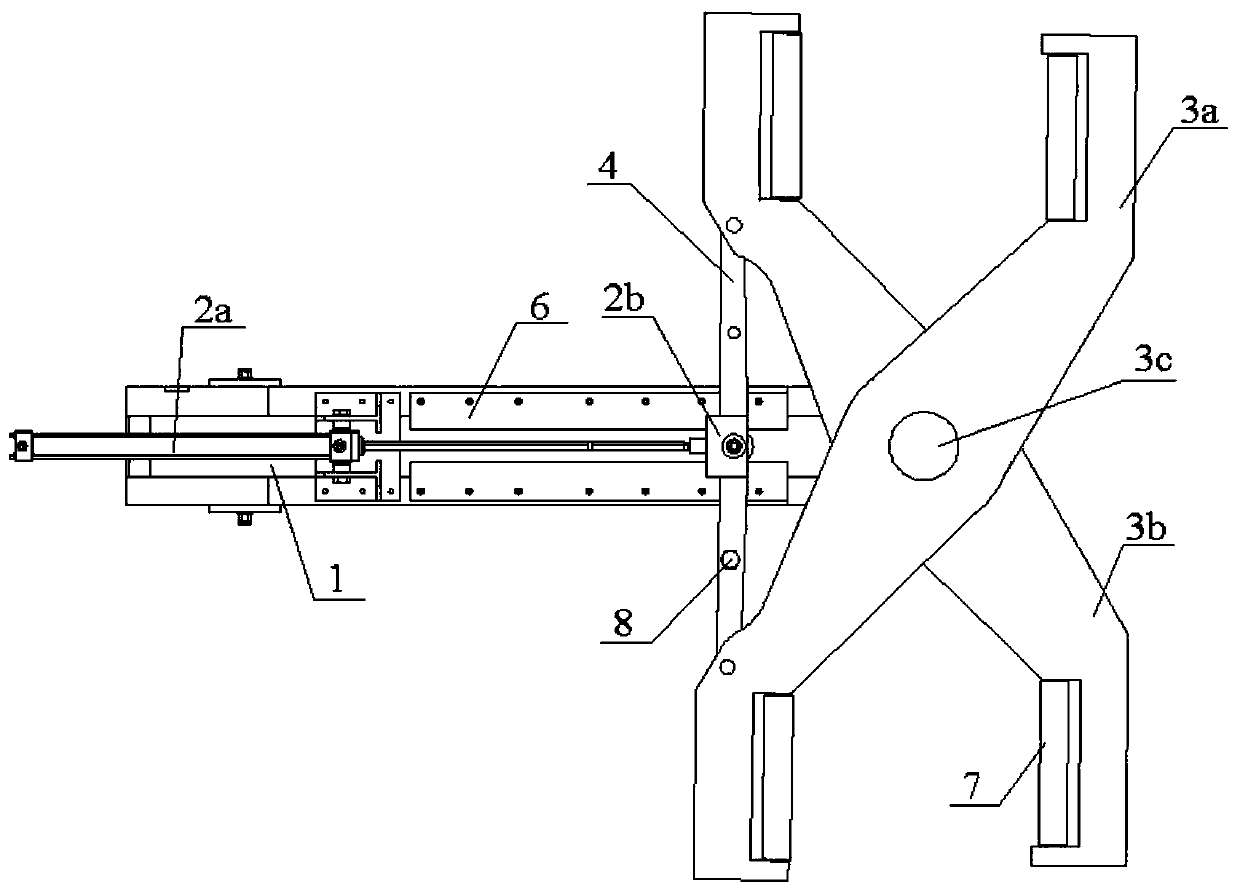

Tripod robot

InactiveCN102975785AAchieve omnidirectional movementFull of powerVehiclesElectric machineryRelative motion

The invention relates to a tripod robot which belongs to the field of mechanical control. Three rocker brackets are fixedly arranged on a body uniformly at a horizontal interval of 120 degrees. Rockers are fixedly arranged on the rocker brackets through rocker rotary shafts and rotate around the rocker rotary shafts. Legs are fixedly arranged on the rockers and are free from relative movement with the rockers. An One aluminum alloy spherical connector is connected to the each rockers through a small sleeve. An The other aluminum alloy spherical connector is connected to a each crankshaft through a large sleeve. The aluminum alloy spherical connectors connected to the rockers is are connected with the aluminum alloy spherical connectors connected to the crankshafts through an aluminum alloy spherical connector connecting rods. The crankshafts is are connected with an output shafts of a motors. A cCoders is are connected with a control ends of the motors. A pPower supply supplies and a control circuits are connected with a power inputs of the motors to supply power to the motors. The tripod robot provided by the invention is stable in operation, has a practical application value, and lays a foundation for subsequent researches.

Owner:BEIJING UNIV OF TECH

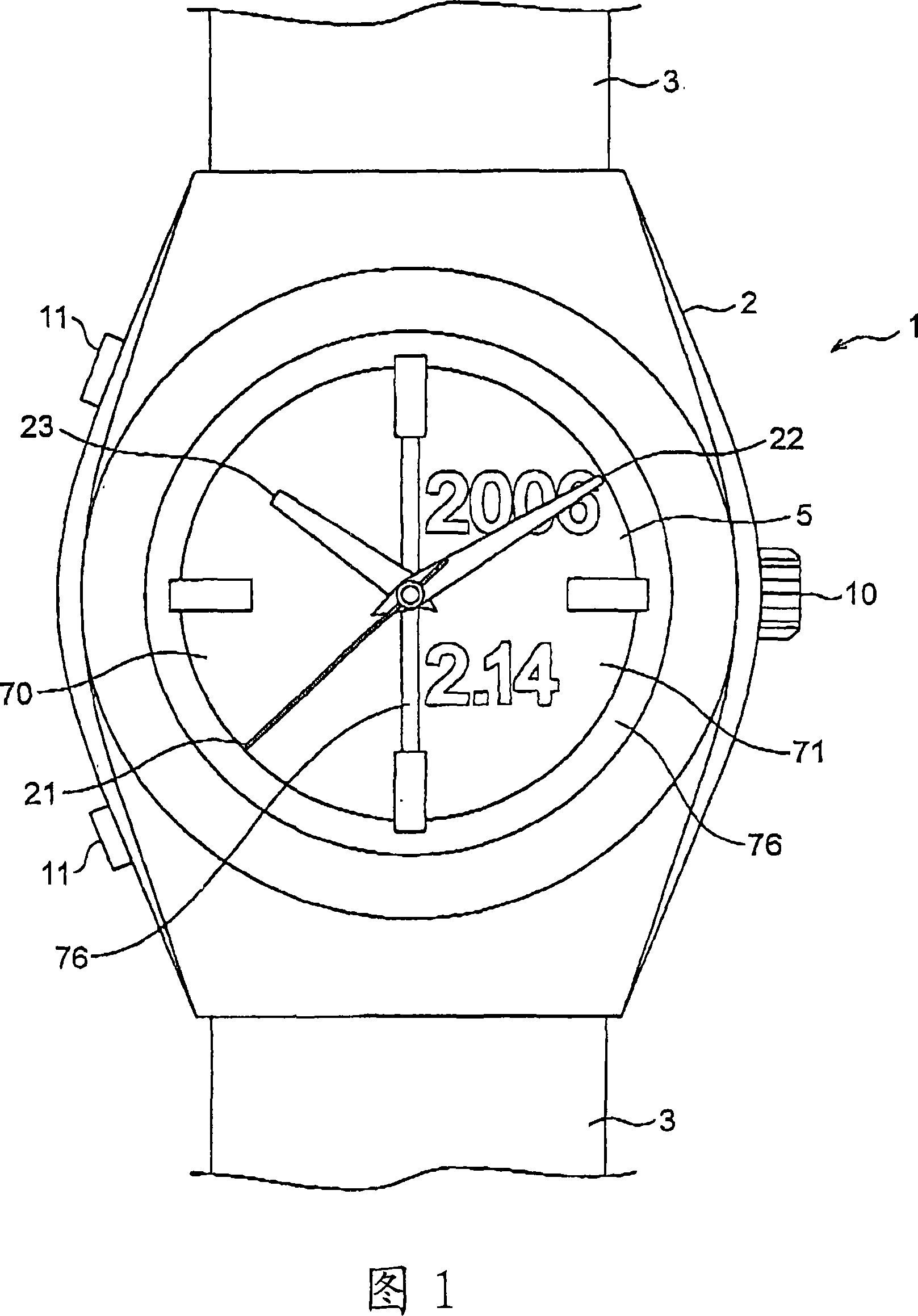

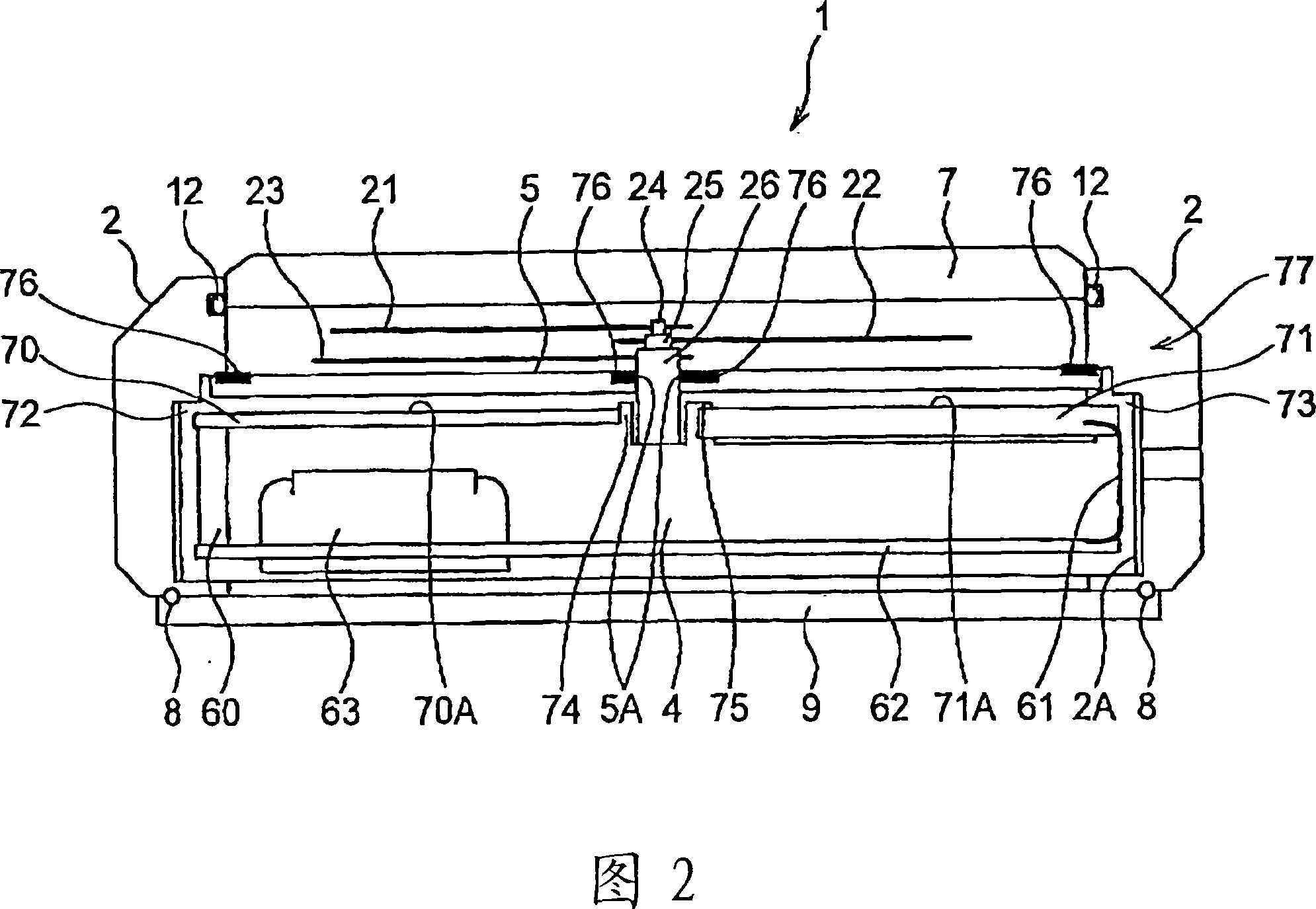

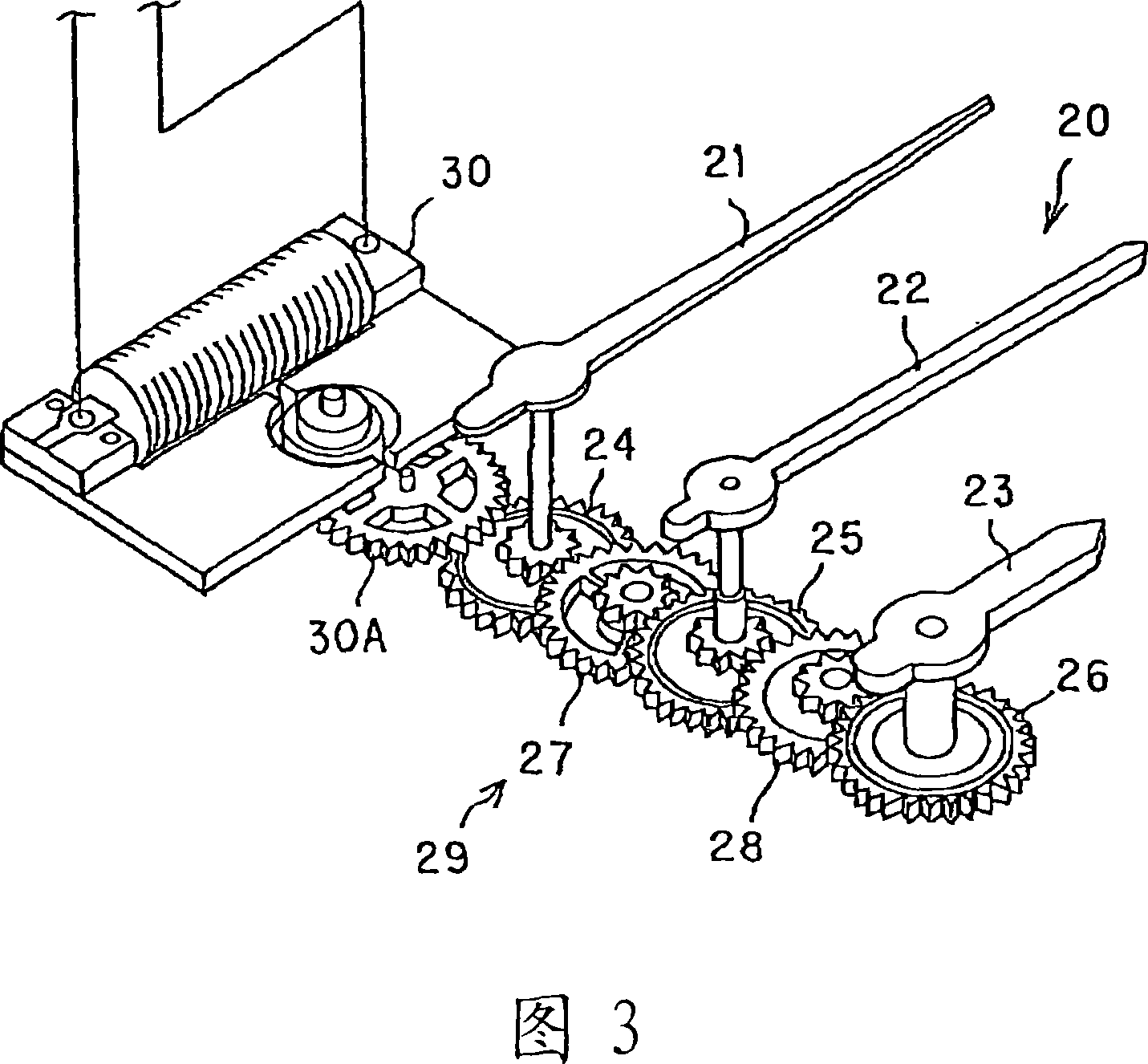

Wristwatch

InactiveCN101055464ALimit setting areaFull of powerVisual indicationsElectric power supply circuitsElectrical batterySolar cell

A wristwatch having a display unit with memory that retains the display state of a last preceding display update operation, and a solar cell for displaying operating power at least to the display unit with memory during the display update operation. The display unit with memory and the solar cell render a dial or a display panel.

Owner:SEIKO EPSON CORP

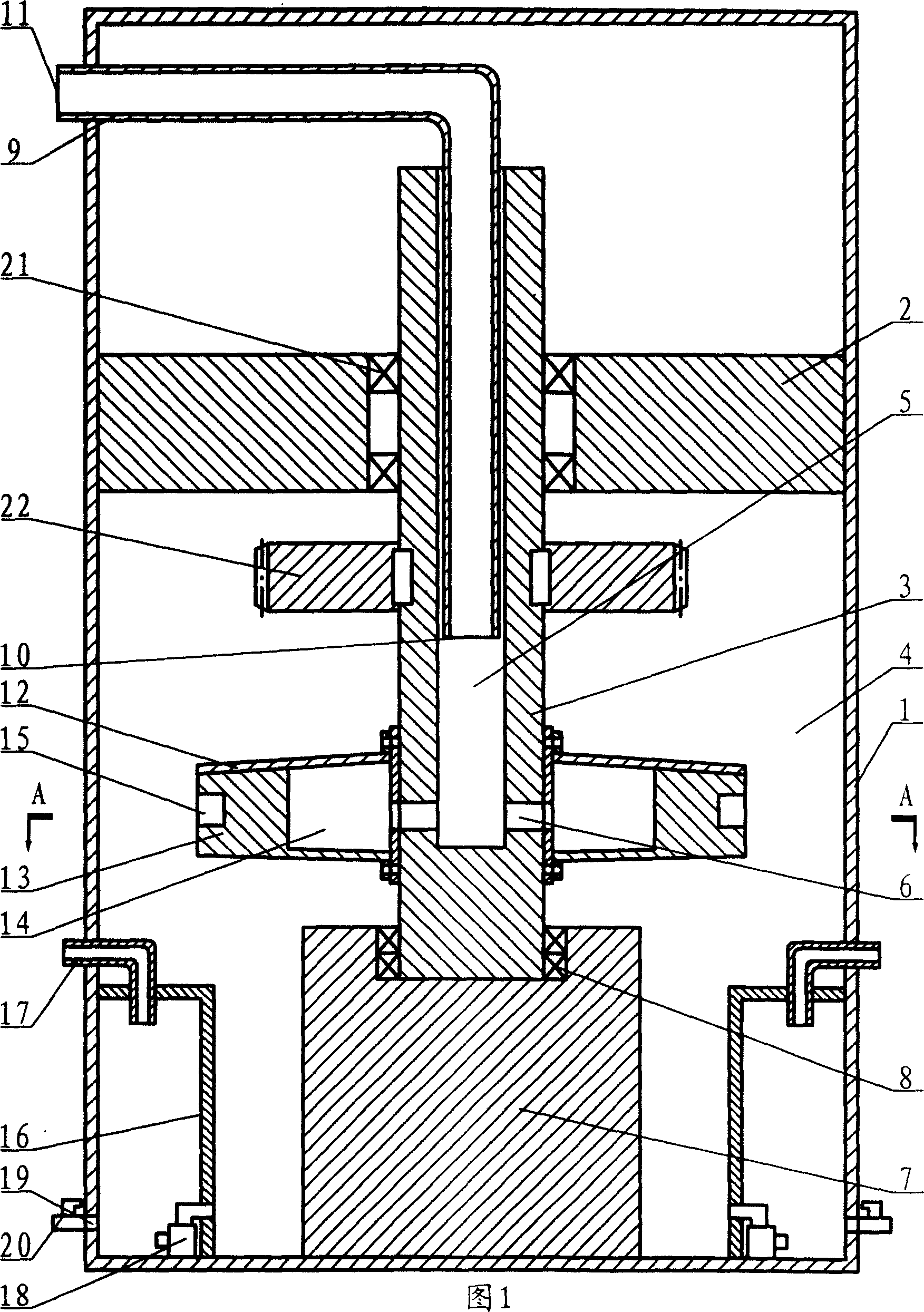

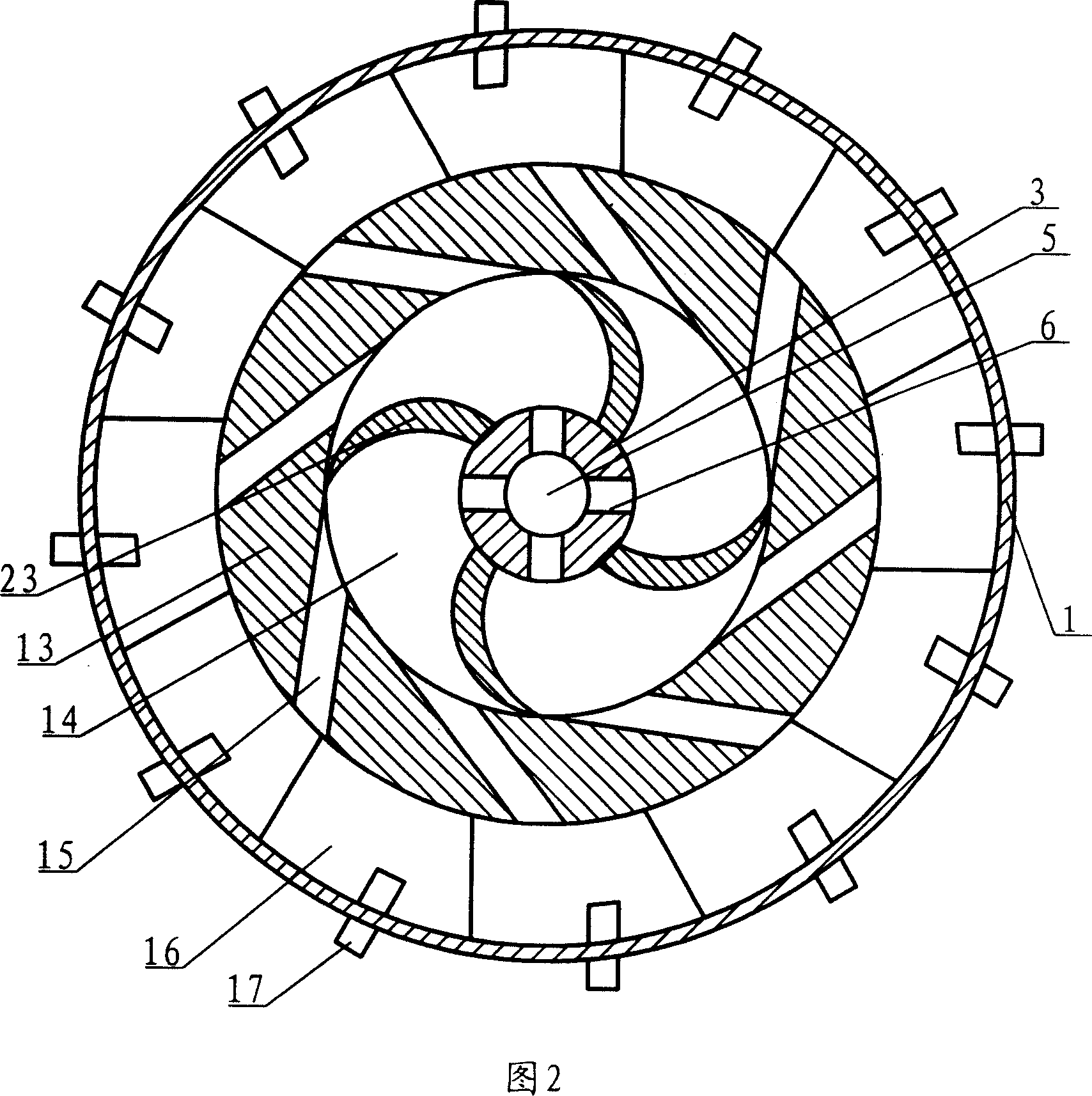

Rotary-shaft water-feeding type water turbine

InactiveCN1952385AReduce frictionHigh energyHydro energy generationReaction enginesRotational axisWater storage

The invention relates to a hydraulic turbine with water supply by revolving spindle, comprising shell, upper cover, rotary spindle and power output gear on the rotary spindle. A closed water cavity is formed between shell and upper cover. It is characterized in that upper flow and lower passages arranged in certain angle are set in the rotary spindle, the diameter of lower flow passage is less than one of upper flow passage; the end of rotary spindle is supported by bearing of rotor load-bearing platform, injecting mechanism is fixed on the rotary spindle and inlet pipe less than flow passage and connected with it is set in the shell; drainage device is set on the bottom of shell; injecting mechanism is rotor water storage room formed by upper and lower plates of rotor wheel and injecting port is set on the lower plate of rotor wheel. It is provided with energy saving and low cost, conquers a mass of water flows out of the vane circumference and among vane, avoids water-hinder phenomenon and makes full use of water resource. It is no-pollution drainage and has an influence for human protection absolutely.

Owner:李晓东

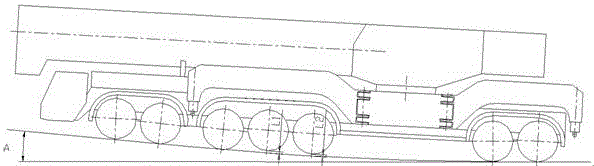

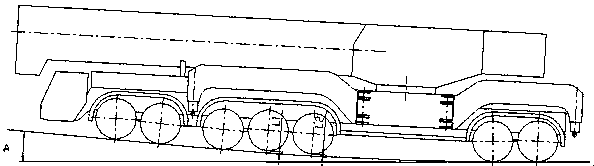

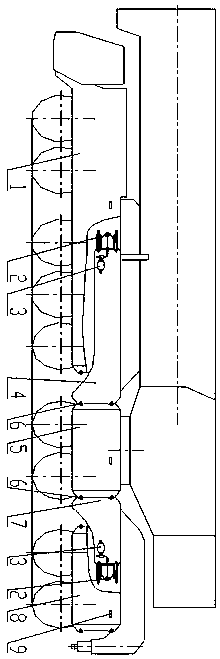

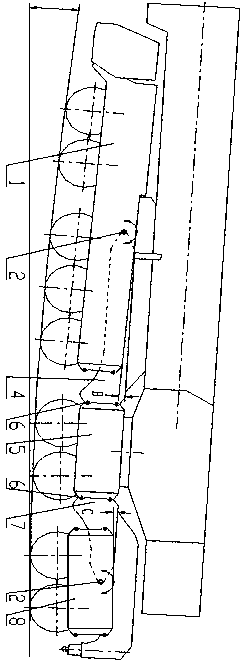

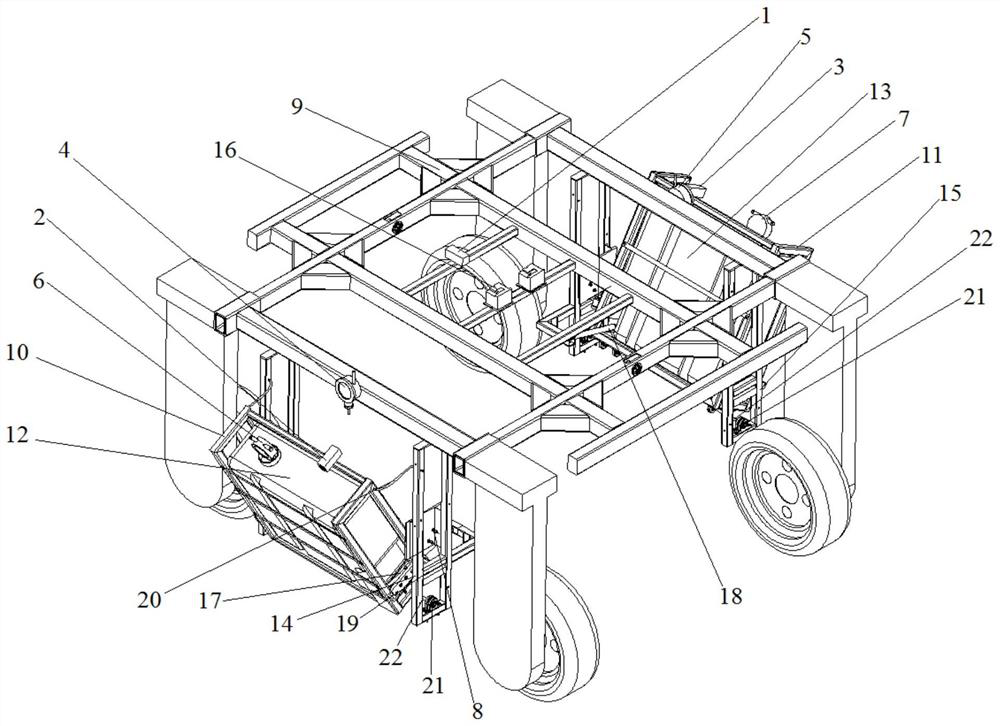

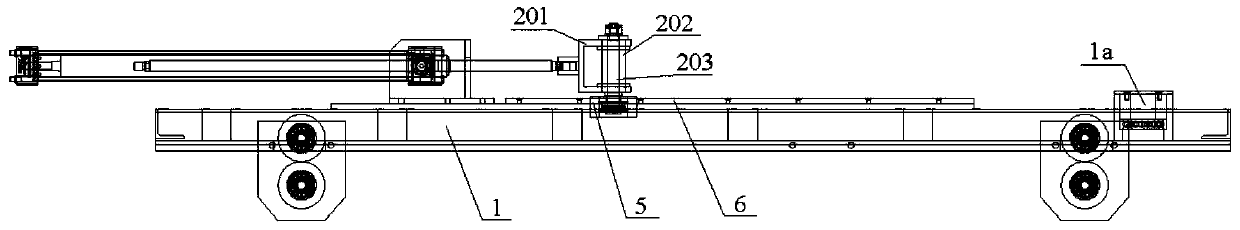

Modular flexible chassis, application thereof and crane thereof

ActiveCN106698210AWide range of usesEasy maintenanceServomotorsServometer circuitsModularityComputer module

The invention discloses a modular flexible chassis, application thereof and a crane thereof, and belongs to the field of crane equipment. The chassis consists of multiple modules with different functions; all the modules adopt different combination and connection modes to realize flexibility and modularization of a vehicle body; the assembled chassis is high in ground self-adaptability; the chassis comprises a driving control driving module positioned at an advancing end, support bearing modules connected with the driving control driving module, a crane operation module arranged between the support bearing modules, and a driven driving module positioned at a tail end; the support bearing modules include a front support bearing module and a back support bearing module; the crane operation module is positioned between the front and back support bearing modules; the driving control driving module is connected with the front support bearing module; and the driven driving module is connected with the back support bearing module. Compared with a traditional structure, the modular flexible chassis has such multiple functions as high ground self-adaptability, multiple purposes, convenience to maintain and high power.

Owner:XUZHOU HEAVY MASCH CO LTD

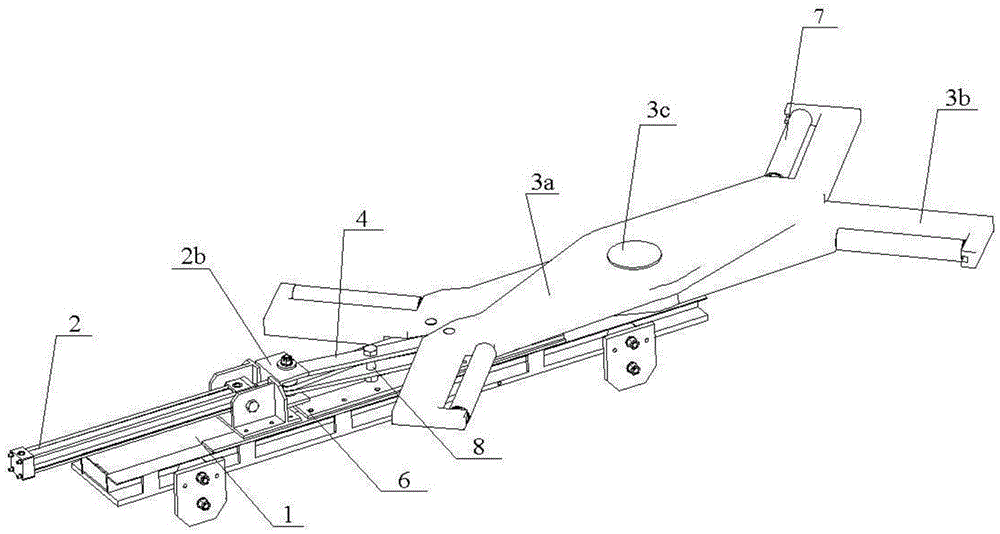

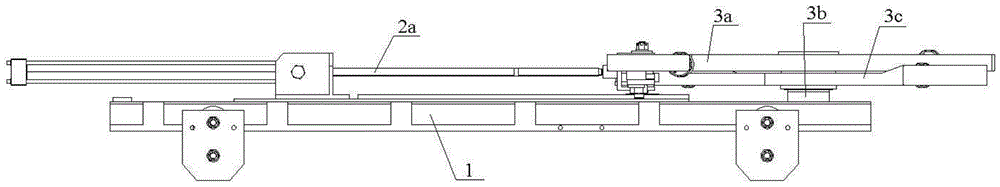

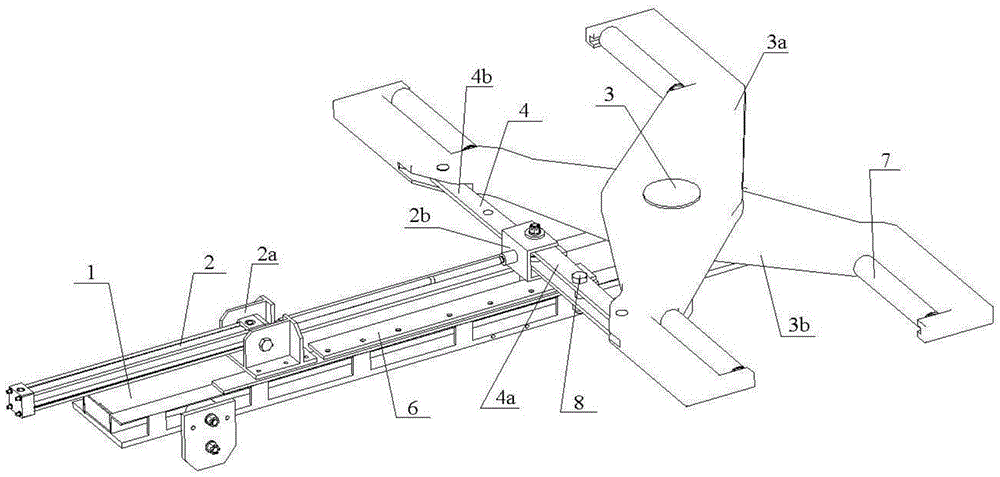

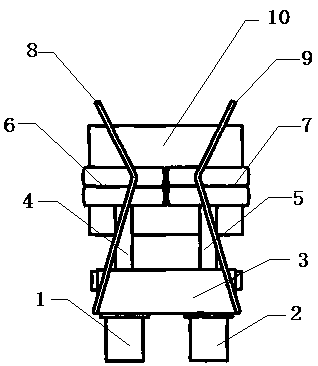

Tyre clamping mechanism for vehicle production line

The invention discloses a tyre clamping mechanism for a vehicle production line, and belongs to the field of vehicle assembling workshop mechanized transportation. The tyre clamping mechanism comprises a base, wherein a driving device is fixedly connected to the base; a clamp holder is also hinged to the base; the driving device and the clamp holder are connected through a push-pull rod; the driving device, the clamp holder and the push-pull rod form a slider-crank mechanism. The tyre clamping mechanism is characterized in that a guiding wheel which is horizontally arranged is arranged at the bottom end of a supporting seat of a push rod of the driving device; a guiding plate which can be cooperated with the guiding wheel is arranged on the base; the guiding wheel is tangent with the inner side wall of the guiding plate. According to the tyre clamping mechanism disclosed by the invention, the structure is simple, the clamp holder is driven by the driving device in the horizontal direction, so that a vehicle front wheel can be stably clamped, and the accurate clamping and positioning of a vehicle in a service position of an automatic production line is realized safely and efficiently.

Owner:武汉东研智慧设计研究院有限公司

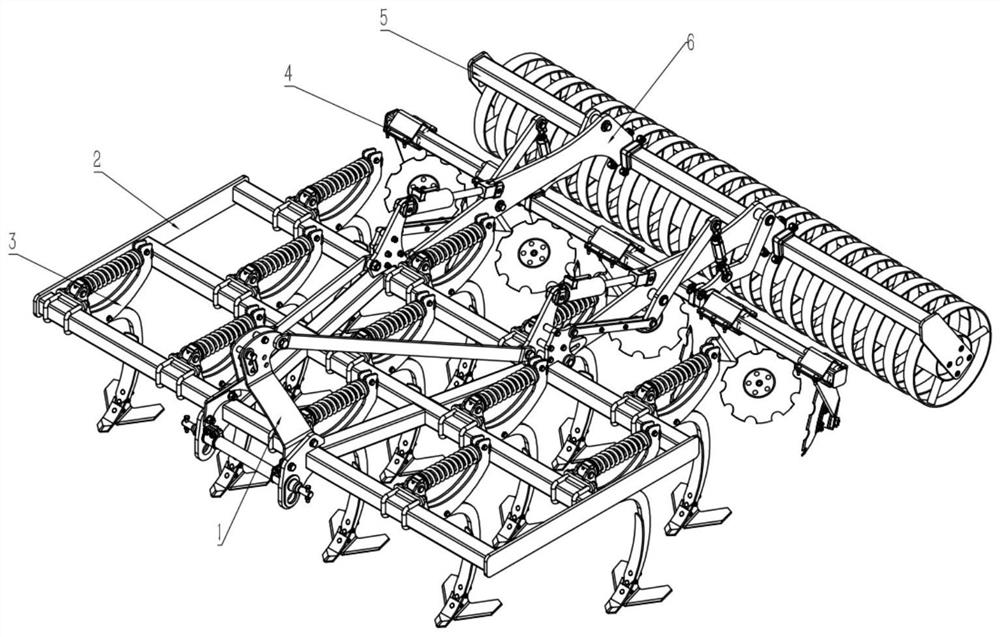

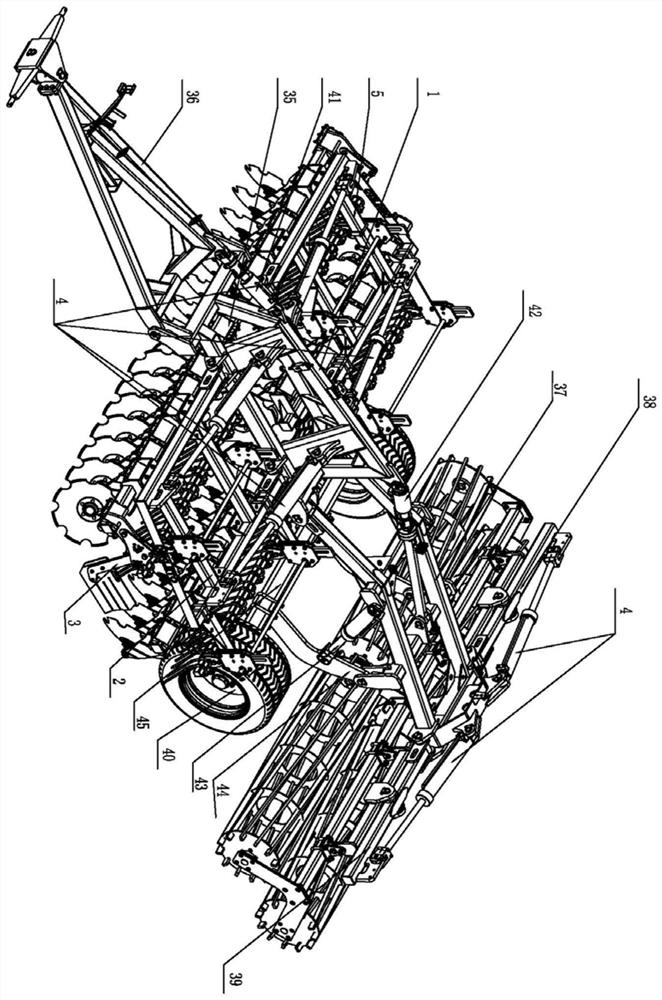

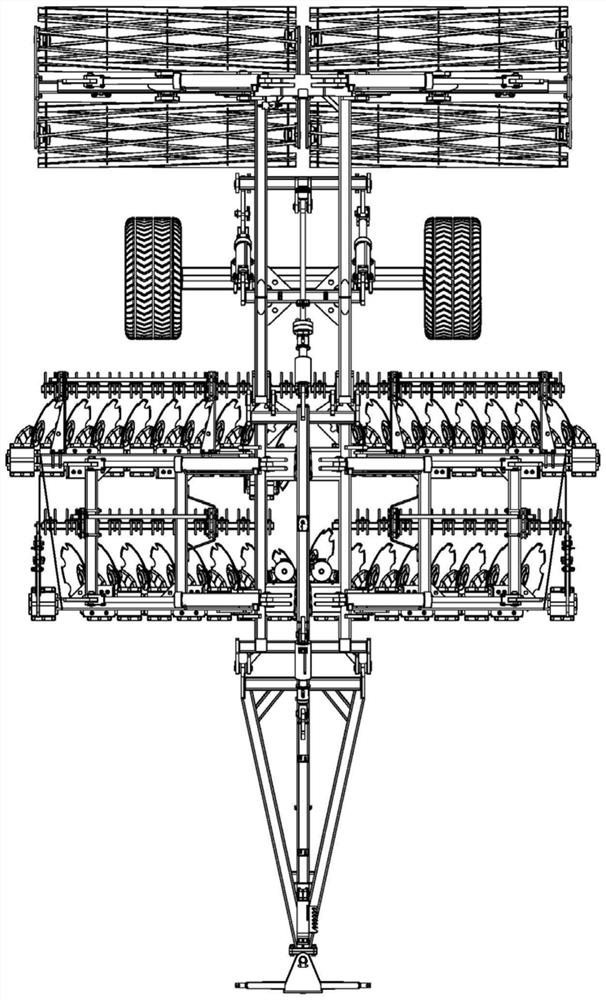

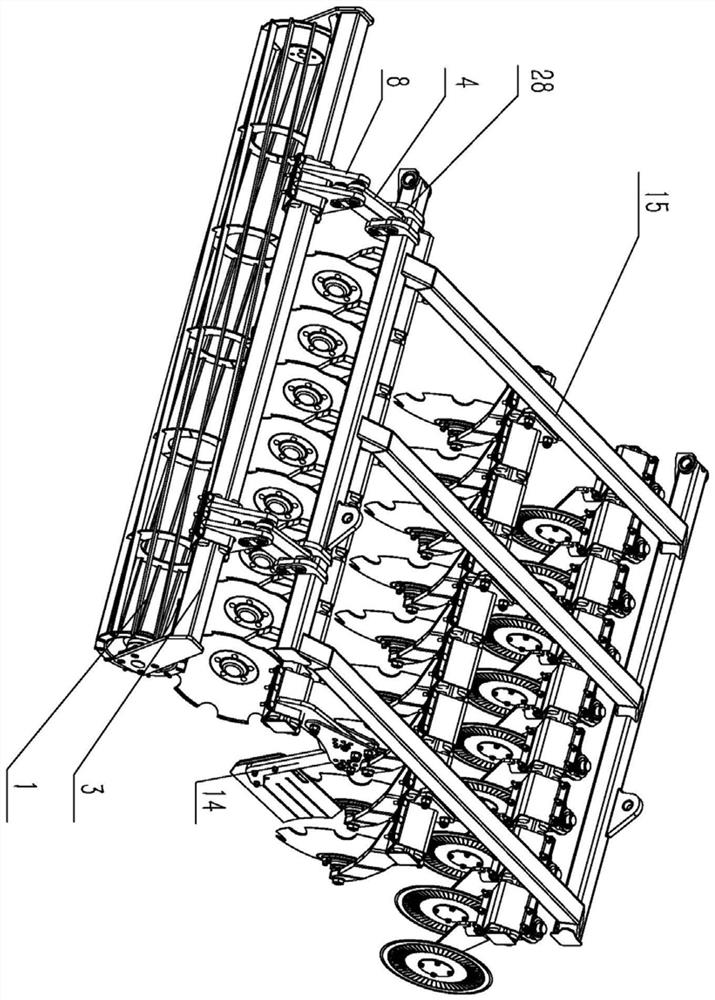

Deep scarification combined land preparation machine and operation method

PendingCN113711710AAdjust working depthSave secondary adjustment timeSpadesAgricultural machinesAgricultural engineeringTraction frame

The invention discloses a deep scarification combined land preparation machine and an operation method. The deep scarification combined land preparation machine comprises a traction frame, a tooth frame beam, a deep scarification tooth assembly, a harrow group and a pressing roller, wherein the traction frame is connected with the tooth frame beam, the deep scarification tooth assembly is hung at the lower end of the tooth frame beam, the harrow group comprises a harrow group cross beam and harrow pieces, the pressing roller comprises a pressing roller cross beam and a pressing roller body hung at the lower end of the pressing roller cross beam, the harrow group is located at the front end of the pressing roller body, and the harrow group cross beam and the pressing roller cross beam are connected with the tooth frame beam through the same depth-limiting leveling mechanism. The operation depth of the deep scarification tooth assembly and the operation depth of the harrow group can be synchronously adjusted, and on the basis that the operation depth of the deep scarification tooth assembly and the operation depth of the harrow group are synchronously adjusted, the operation depth of the harrow group can be further independently adjusted.

Owner:宜兴博登泰科工业装备有限公司

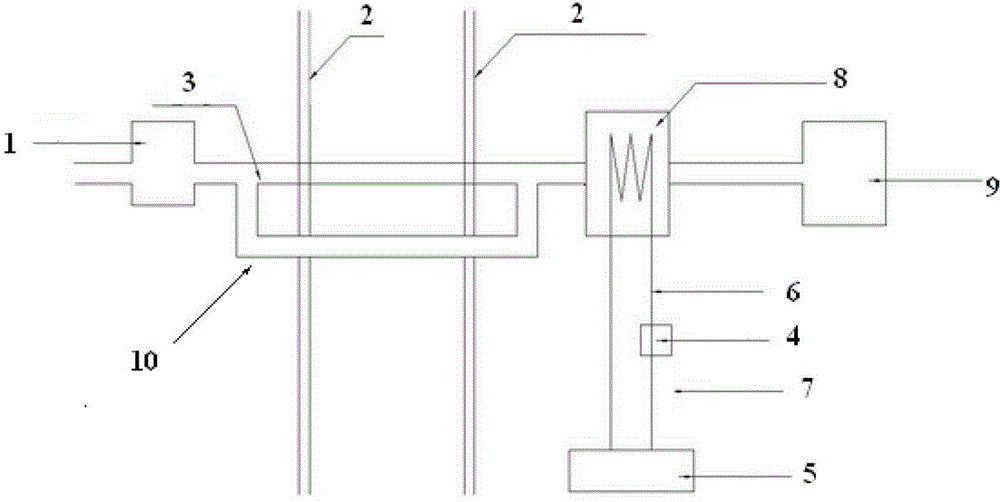

Automobile gasoline carburetor and operation method thereof

InactiveCN104100412ALow ignition pointBurn fasterInternal combustion piston enginesExhaust apparatusPollutant emissionsGasoline

The invention discloses an automobile gasoline carburetor and an operation method of the automobile gasoline carburetor. According to the automobile gasoline carburetor, an inlet of an oil transmission copper pipe (3) is connected with an oil transmission hole of an oil delivery pump (1), and an outlet of the oil transmission copper pipe (3) is connected with an input hole of a carburetor (9); two through holes are formed in the same side wall of the front end of the oil transmission copper pipe (3); the two ends of an oil transmission branch pipe (10) are respectively welded on the two through holes; a square shape is formed by the oil transmission branch pipe and the oil transmission copper pipe; an automobile exhaust pipe (2) passes through the square shape, and clings to the oil transmission copper pipe (3) and the oil transmission branch pipe (10); a loop is formed by a storage battery (5), a switch (4) and an electric stove wire (8) through an electric wire (6); an insulating layer (7) is wound outside the electric wire (6); the oil transmission copper pipe (3) is wound by the electric stove wire. After the automobile gasoline carburetor and the operation method are used, the combustion efficiency is increased, and the pollutant discharge is reduced.

Owner:斯养武 +1

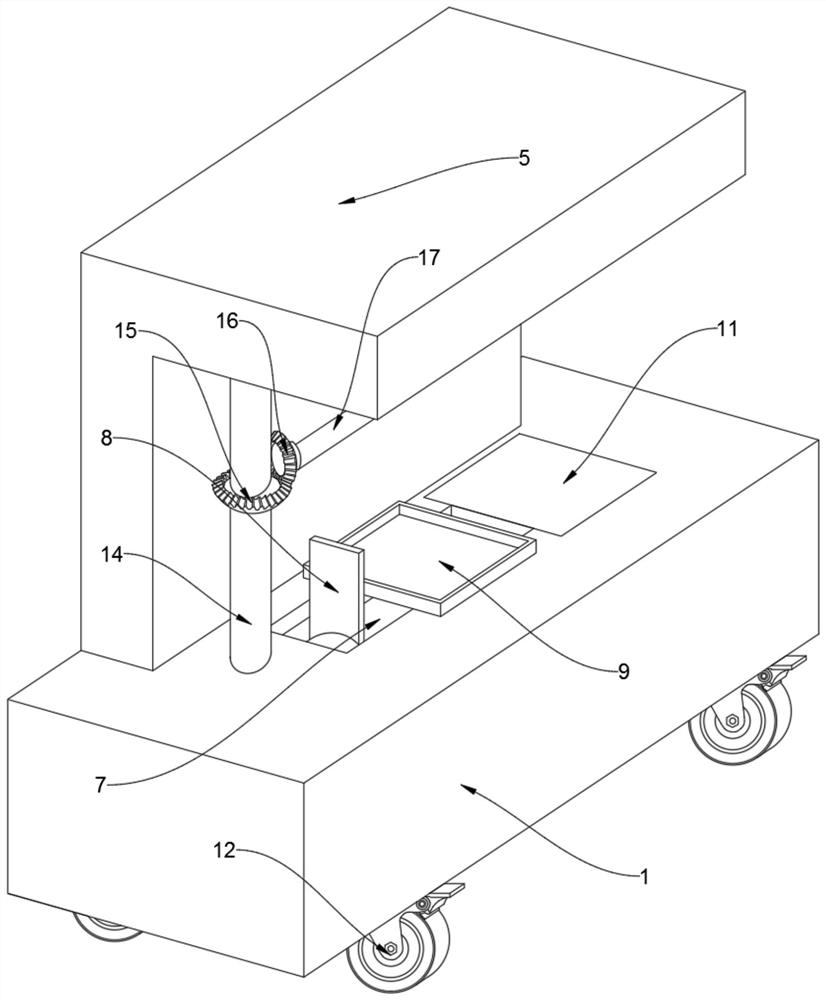

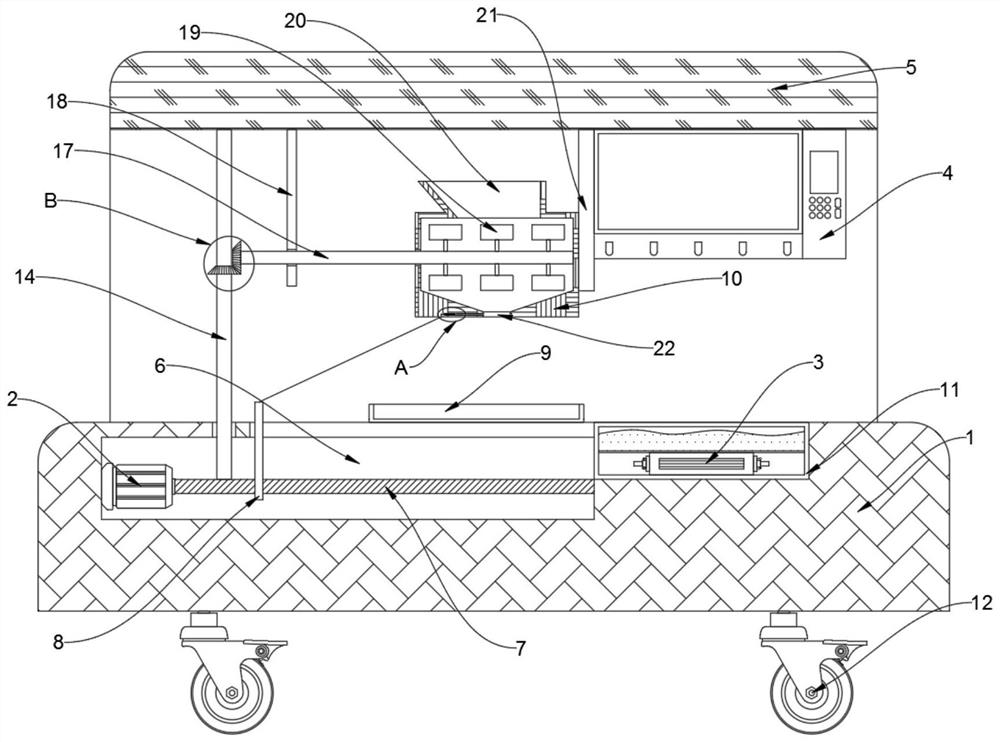

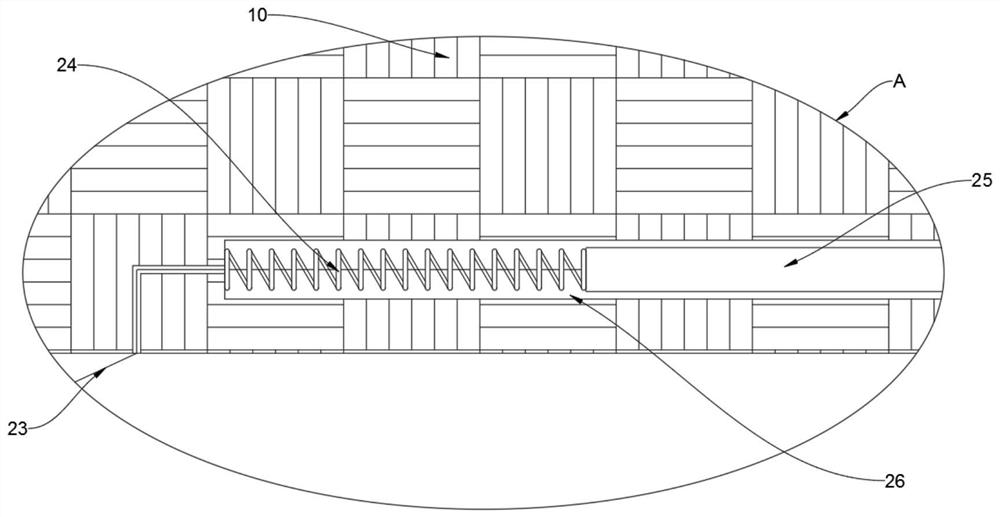

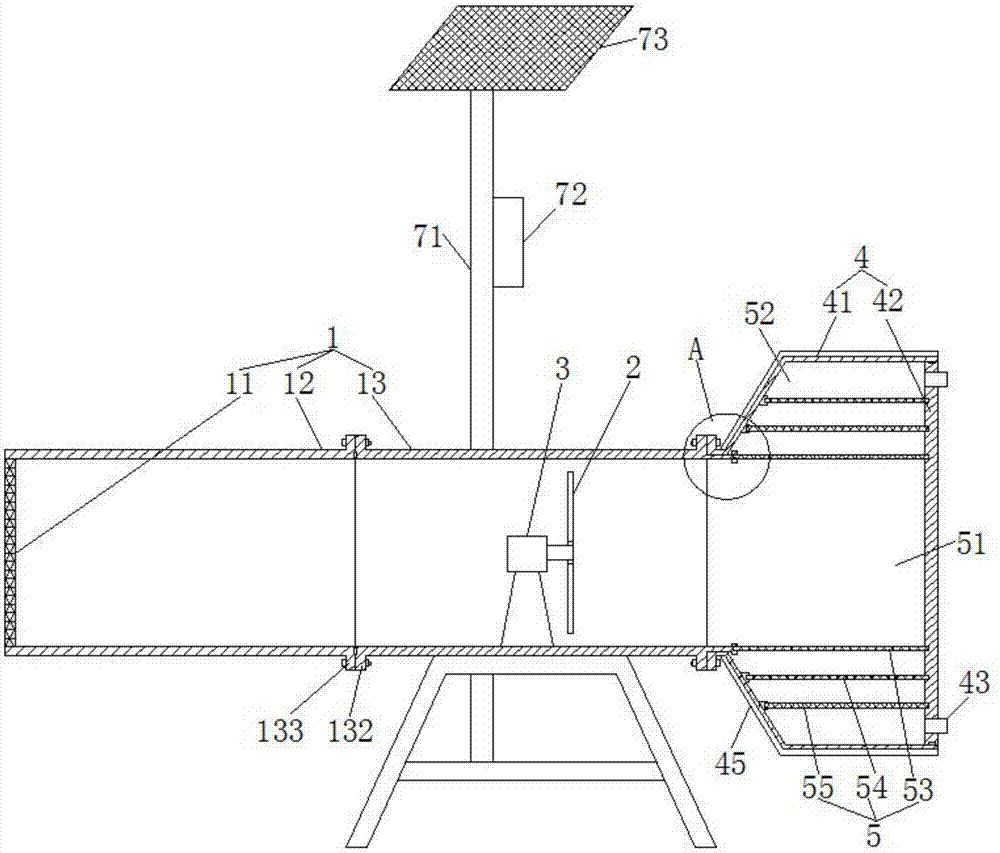

Auxiliary device for material performance spectrum detection

PendingCN112113907ARealize automatic openingAchieve closureColor/spectral properties measurementsOptical spectrometerEngineering

The invention discloses an auxiliary device for material performance spectrum detection. The device comprises a base, a servo motor, a heater and a spectrograph; universal wheels are fixedly connectedto the bottom of the base, a circular groove is formed in the top of the base, the inner side wall of the circular groove is fixedly connected with the outer side wall of the servo motor, a threadedrod is fixedly connected to an output shaft of the servo motor, the end of the threaded rod is rotationally connected with the inner side wall of the circular groove, a sliding plate is in threaded connection with the outer side of the threaded rod, and a switching mechanism is fixedly connected to the top of the sliding plate. A discharging port is driven to open automatically through the rotation of the servo motor; sufficient power is provided for stirring of the liquid and the powder, so that the liquid and the powder can be stirred better and more sufficiently; the discharging groove is pushed by the sliding plate to move to the top of the heating box, so that the heating box can heat the liquid in the mixed liquid conveniently, rapid volatilization of the liquid in the mixed liquid is facilitated, time is saved, and the working efficiency is improved.

Owner:NANYANG INST OF TECH

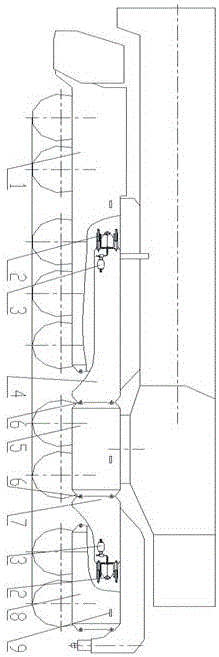

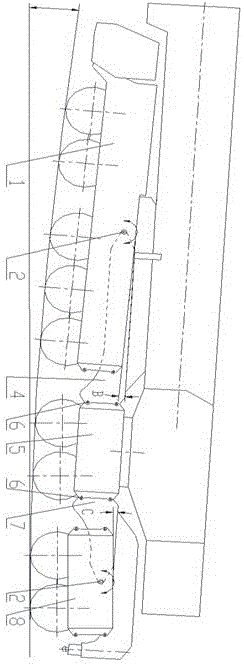

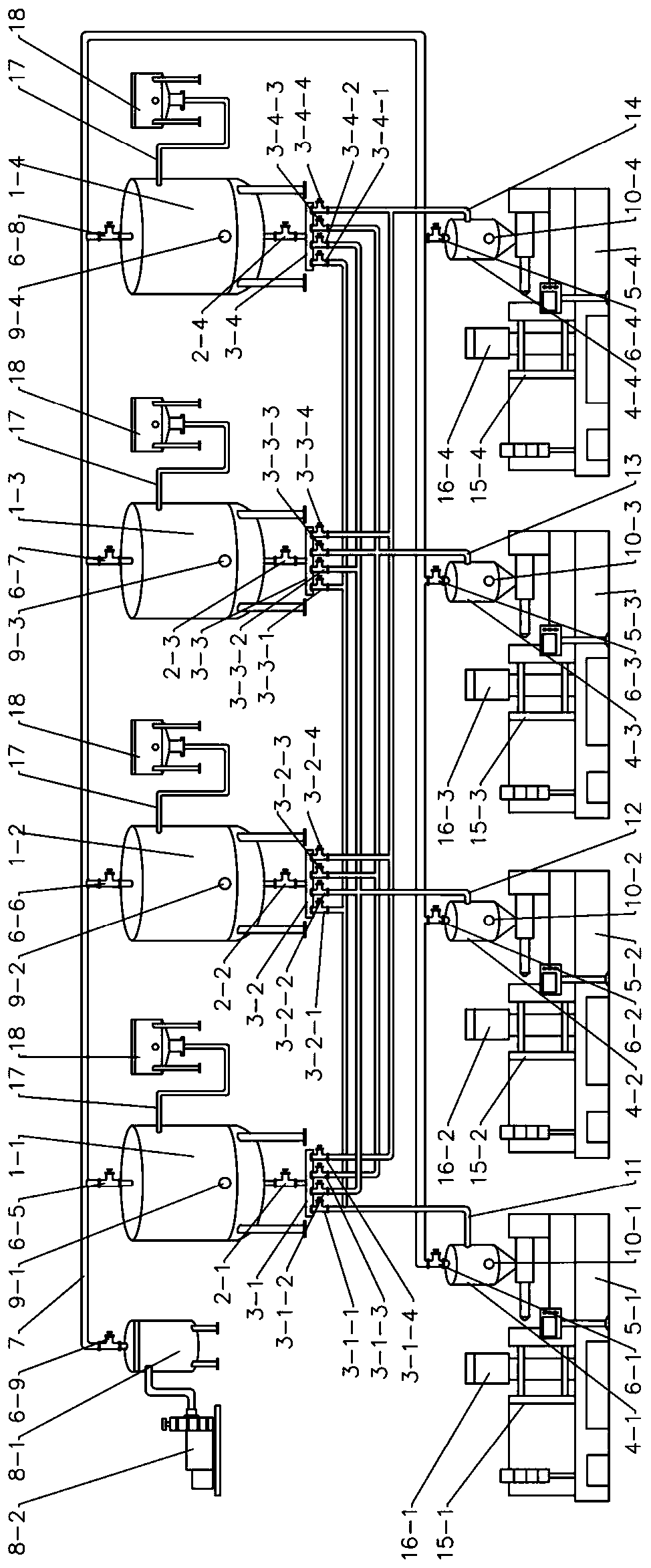

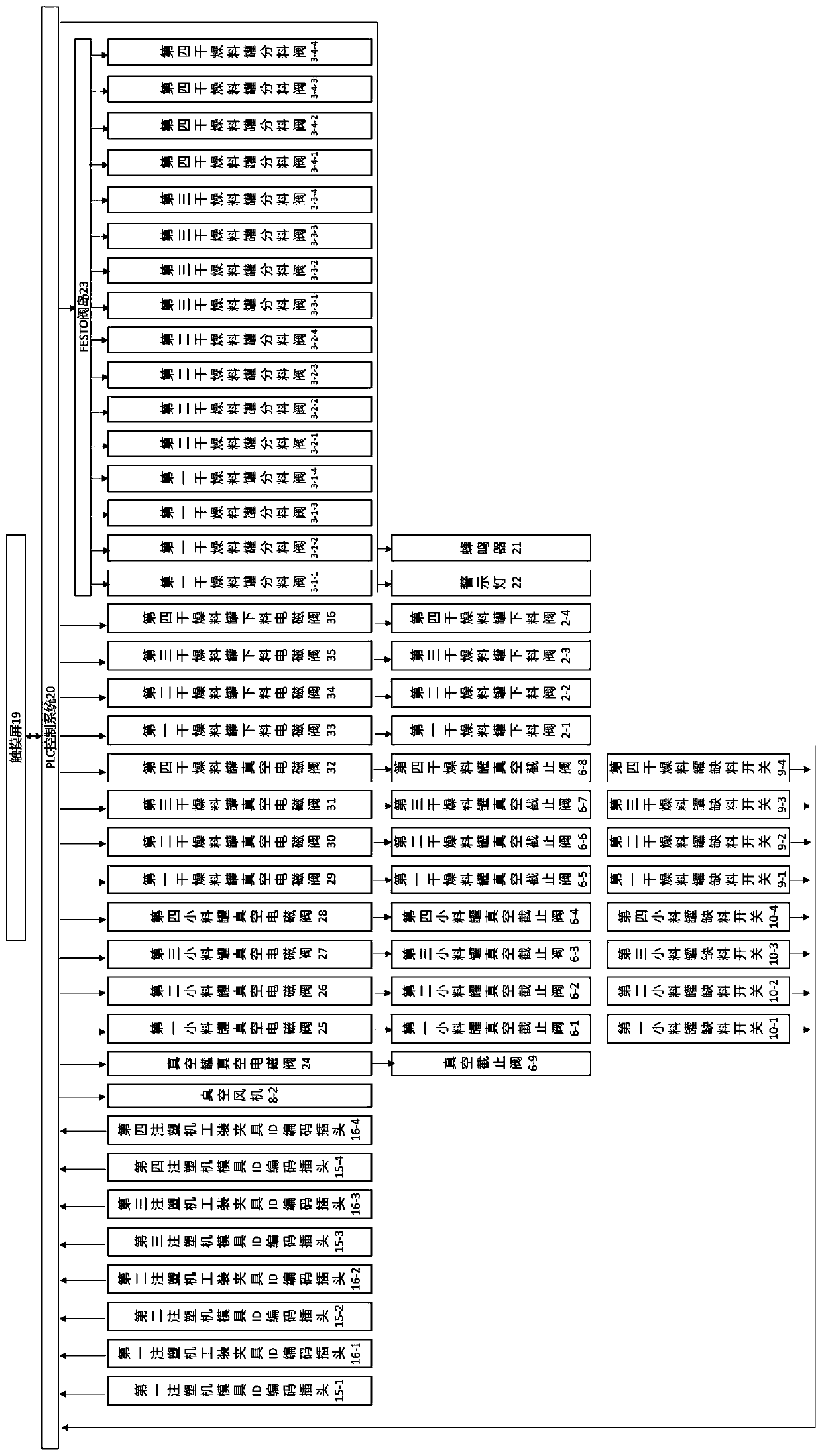

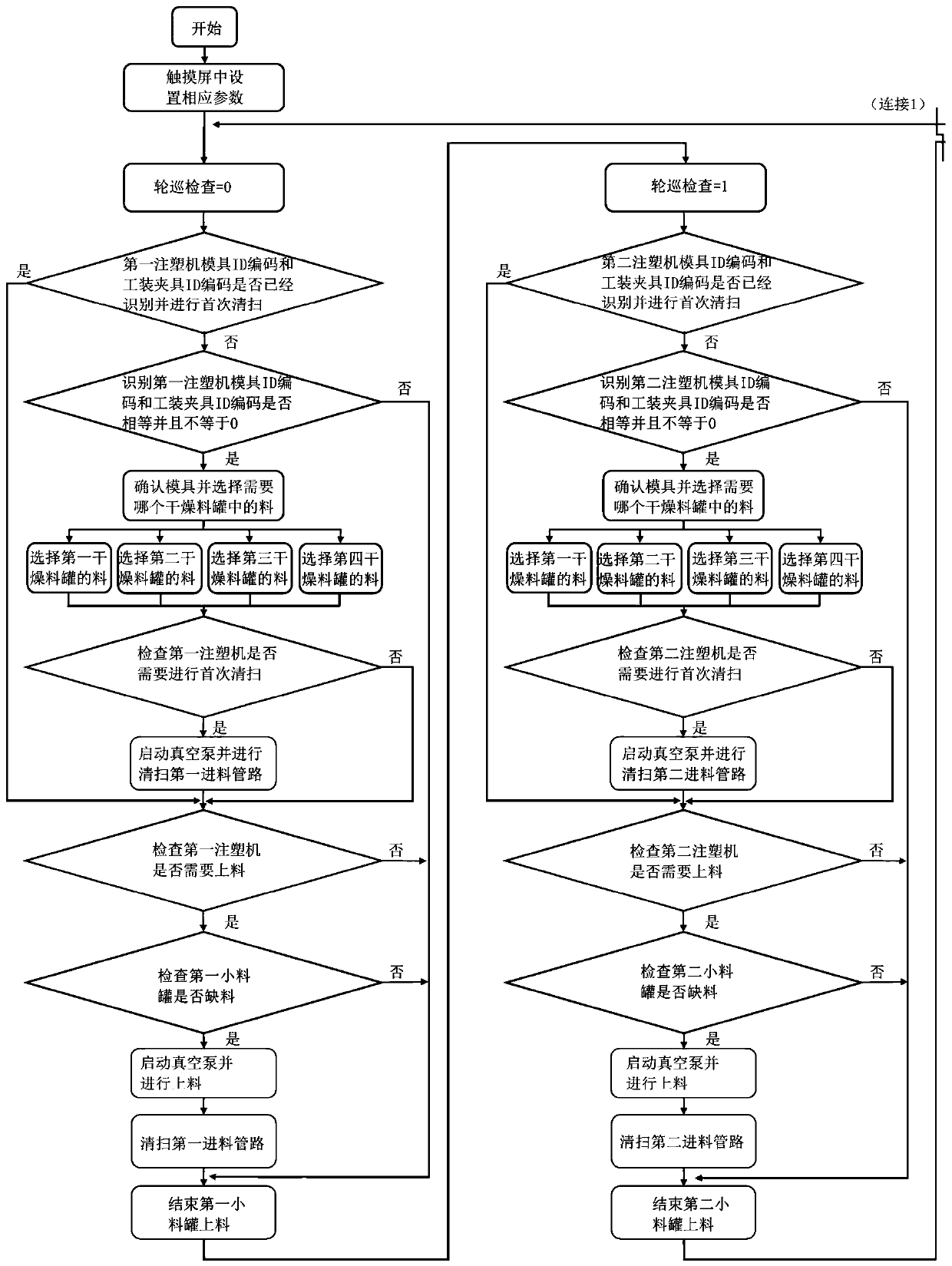

Automatic selection feeding system of injection molding machine for automotive interior trim parts and control system thereof

The invention discloses an automatic selection feeding system of an injection molding machine for automotive interior trim parts and a control system thereof. The automatic selection feeding system ofan injection molding machine for automotive interior trim parts and the control system thereof solve the problems that in the prior art, automatic selection of raw materials cannot be carried out, the material changing process is too long in time consumption and low in efficiency, material changing errors are prone to occurrence, then products are scrapped, and the yield and quality are affected.The automatic selection feeding system of the injection molding machine for the automotive interior trim parts and the control system thereof are characterized in that a plurality of drying materialtanks are connected with small material tanks of a plurality of injection molding machines through material distributing valves and feeding pipelines, a mold ID coding plug and a tool clamp ID codingplug are installed at the mold installation end of each injection molding machine, and a PLC control system checks whether the injection molding machines and the drying material tanks lack materials or not in a sequential inspection mode and conducts feeding. The automatic selection feeding system of the injection molding machine for the automotive interior trim parts and the control system thereof have the beneficial effects that flexibility of the feeding mode is achieved, automatic raw material selection is achieved, manual operation is reduced, generation of mistaken selection of the raw materials of the injection molding machines are effectively prevented, continuous production and monitoring functions are achieved, the product production efficiency and the product quality are improved, the feeding mode is flexible, energy is saved, the consumption is reduced, single-time material changing time is saved, and the production efficiency is high.

Owner:SHENYANG JINBEI YANFENG AUTOMOTIVE INTERIOR SYST CO LTD

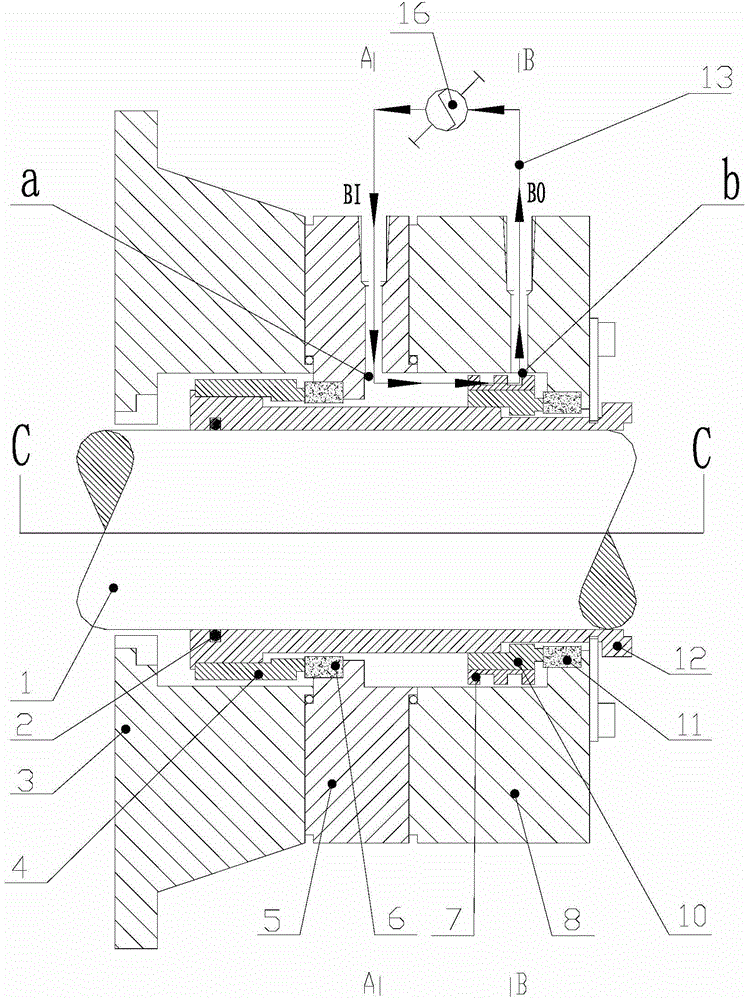

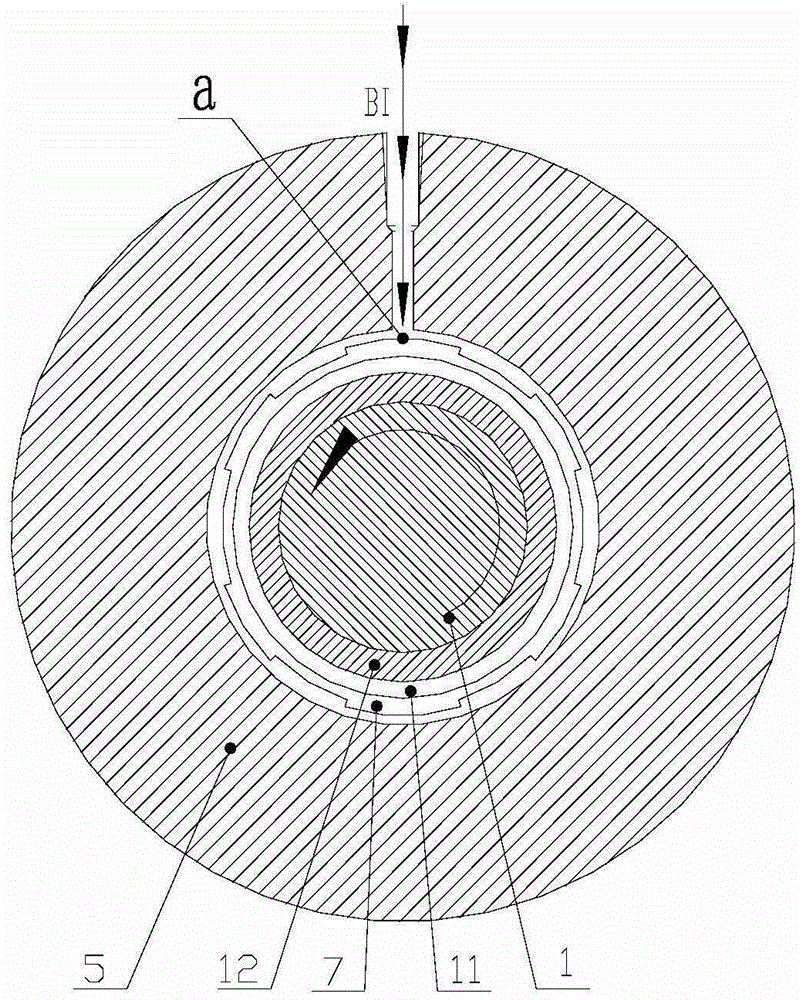

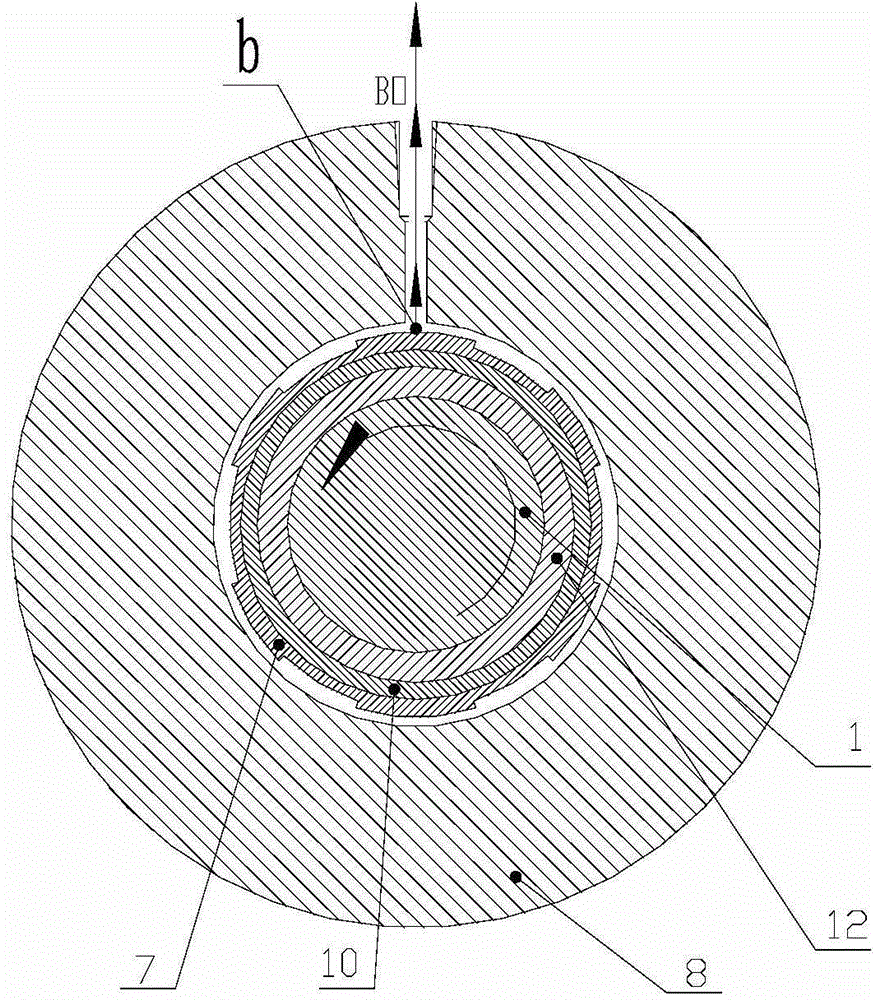

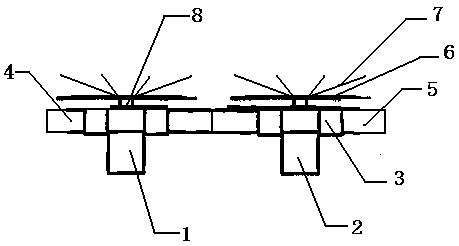

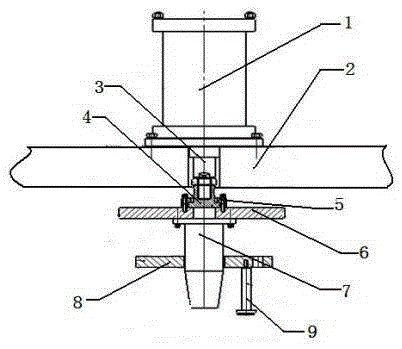

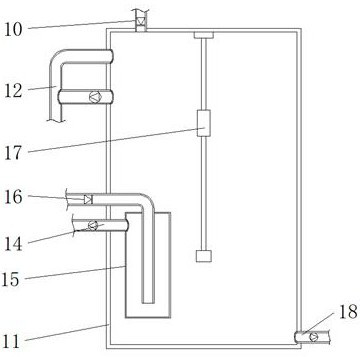

Closed mechanical-seal pump ring and shaft-seal flushing system with same

ActiveCN104696269AStable accelerationIncrease distancePump componentsPumpsEngineeringMechanical engineering

Disclosed are a closed mechanical-seal pump ring and a shaft-seal flushing system with the same. The pump ring is provided with an annular left pump ring side plate and an annular right pump ring side plate which are parallel to each other, inner circumferences of the left pump ring side plate and the right pump ring side plate sleeve the outer circumferential surface of a shaft sleeve of a centrifugal pump, the outer circumferential edges of the left pump ring side plate and the right pump ring side plate are connected with a sealing gland of the centrifugal pump at an interval, a plurality of blades in rotatable and radial arrangement are arranged between the left pump ring side plate and the right pump ring side plate and are perpendicular to the left pump ring side plate and the right pump ring side plate, an end opening formed by closing ends of the radial blades corresponds to a liquid outlet of the shaft sleeve, and an end opening formed by edges of radial ends of the radial blades corresponds to a liquid inlet of a liquid outlet passage formed on the sealing gland. The closed mechanical-seal pump ring has the advantages that liquid accelerating distance is increased, and idle work is reduced; most liquid in a seal cavity can be enabled to flow, and a fluid flowing path can be lengthened to widen the flow area.

Owner:天津长瑞大通流体控制系统有限公司

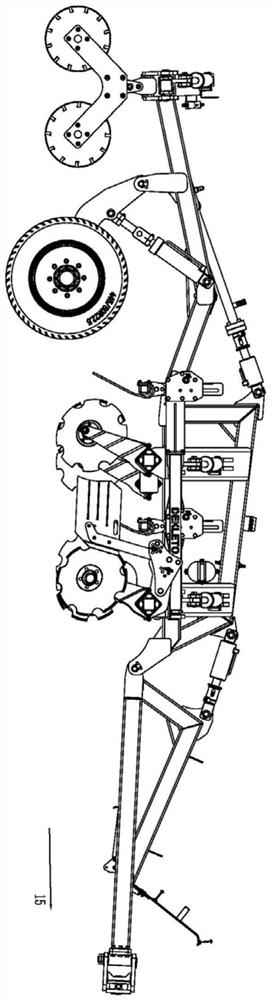

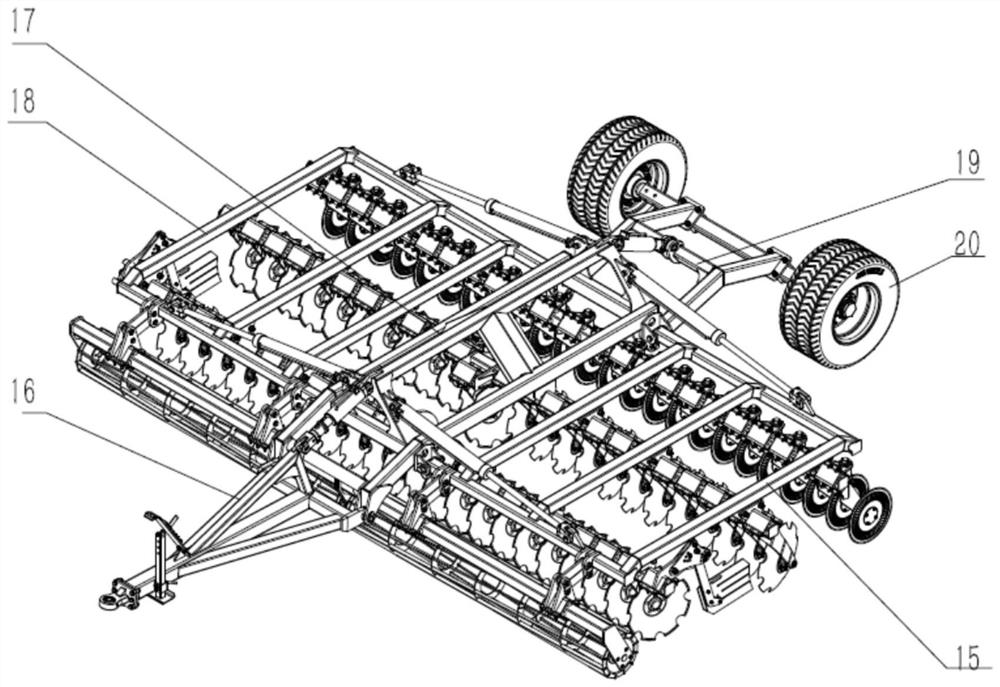

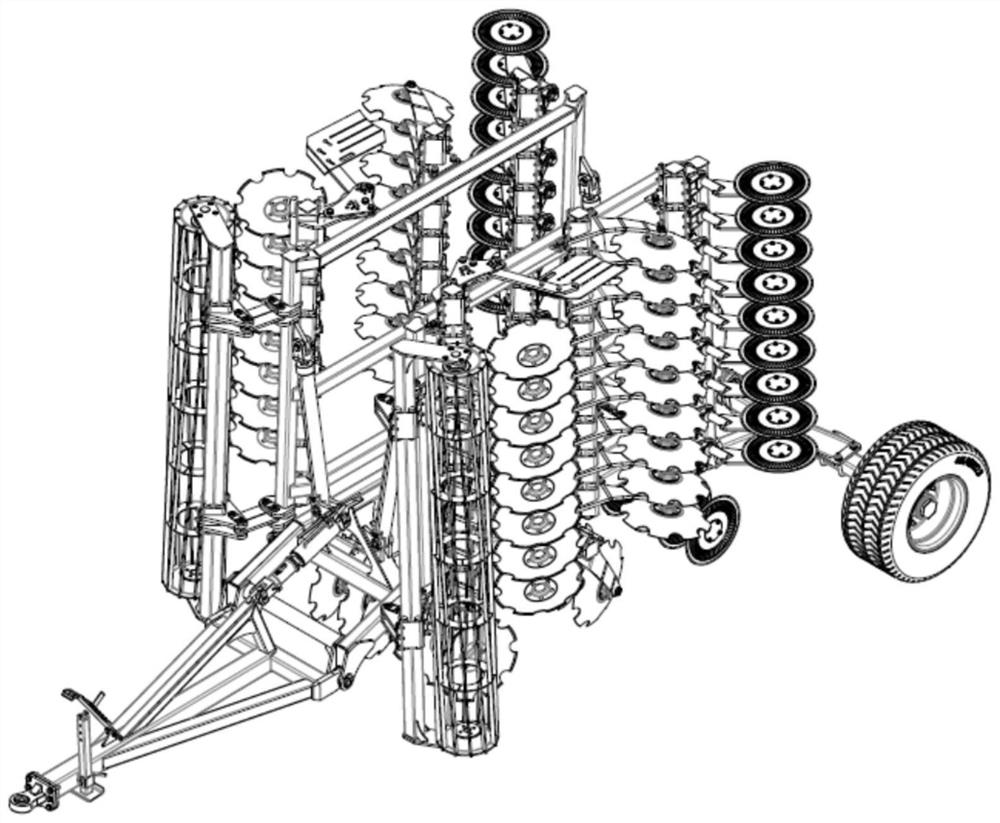

High-speed stubble cleaning harrow

The invention discloses a high-speed stubble cleaning harrow. The high-speed stubble cleaning harrow comprises a main harrow frame assembly, a middle harrow frame assembly, a left folding harrow frameassembly and a right folding harrow frame assembly, wherein the left folding harrow frame assembly and the right folding harrow frame assembly are connected to the left side and the right side of themain harrow frame assembly in a foldable mode, and the rear end of the main harrow frame assembly is movably connected with a rear adjusting tailstock assembly; a left folding press roller assembly and a right folding press roller assembly are connected to the left side and the right side of the rear portion of the rear adjusting tailstock assembly respectively, two walking wheels are connected to the lower end of the rear adjusting tailstock, the two walking wheels are connected through an axle, and the axle is connected with the rear adjusting tailstock through a connecting arm; and the harrow blades on the left-right harrow frame and the front-back harrow frame are symmetrically designed, lateral traction force is avoided, power is exerted more sufficiently, and oil consumption is reduced.

Owner:宜兴博登泰科工业装备有限公司

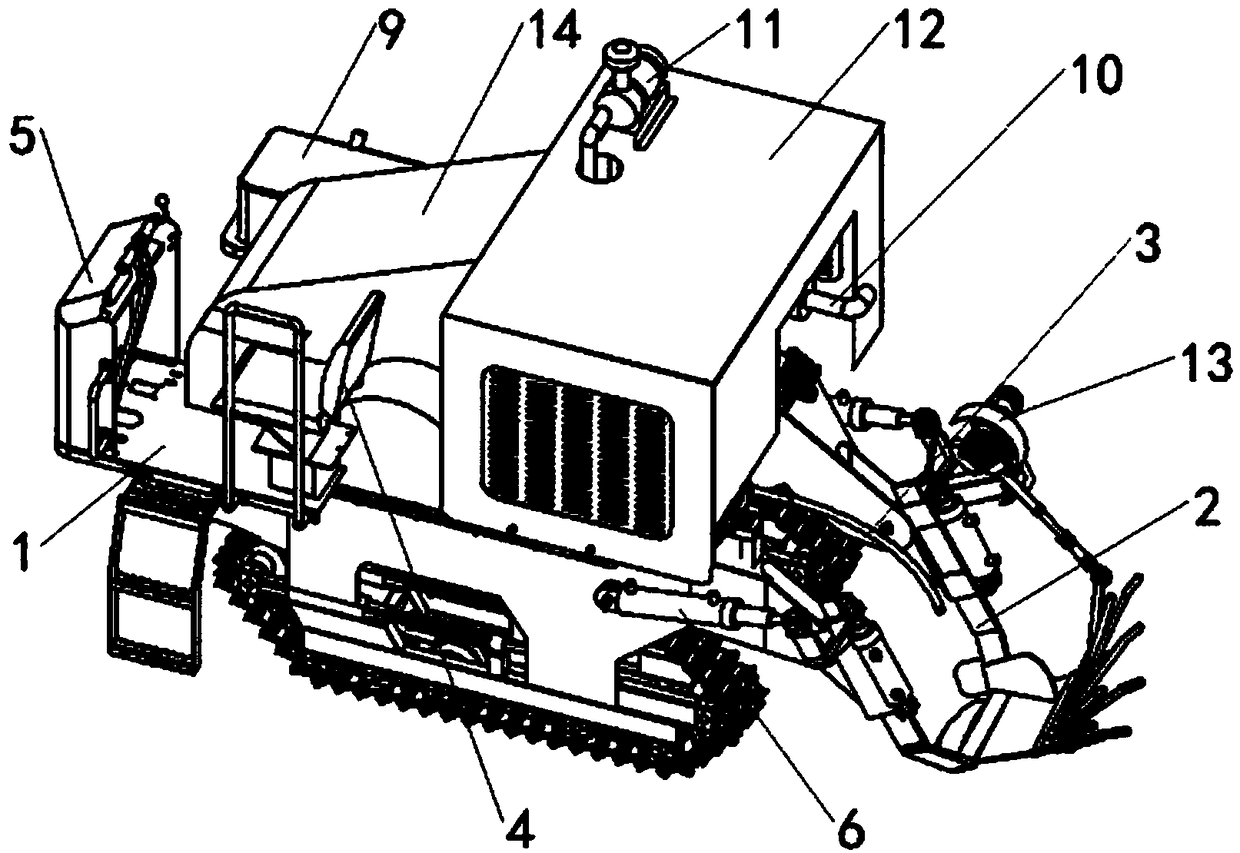

A modular flexible chassis, its application and its crane

ActiveCN106698210BFully dynamicAvoid power lossServomotorsServometer circuitsModularityComputer module

The invention discloses a modular flexible chassis, its application and its crane, which belong to the field of crane equipment. The chassis is composed of a plurality of modules with different functions, and different combinations and connection methods are adopted between the modules to realize the flexibility and modularization of the vehicle body , the assembled chassis is highly self-adaptive to the ground; the chassis includes a drive control travel module located at the forward end, a support bearing module connected to the drive control travel module, a crane operation module arranged between the support load bearing modules, and a driven travel module located at the end module; the support bearing module includes a front support bearing module and a rear support bearing module, the crane operation module is located between the front and rear support bearing modules, the driving control travel module is connected with the front support bearing module, and the driven The driving module is connected with the rear support bearing module. Compared with the existing structure, the modularized flexible chassis of the present invention has multiple functions such as strong ground self-adaptation, wide application of the chassis, convenient maintenance and strong power.

Owner:XUZHOU HEAVY MASCH CO LTD

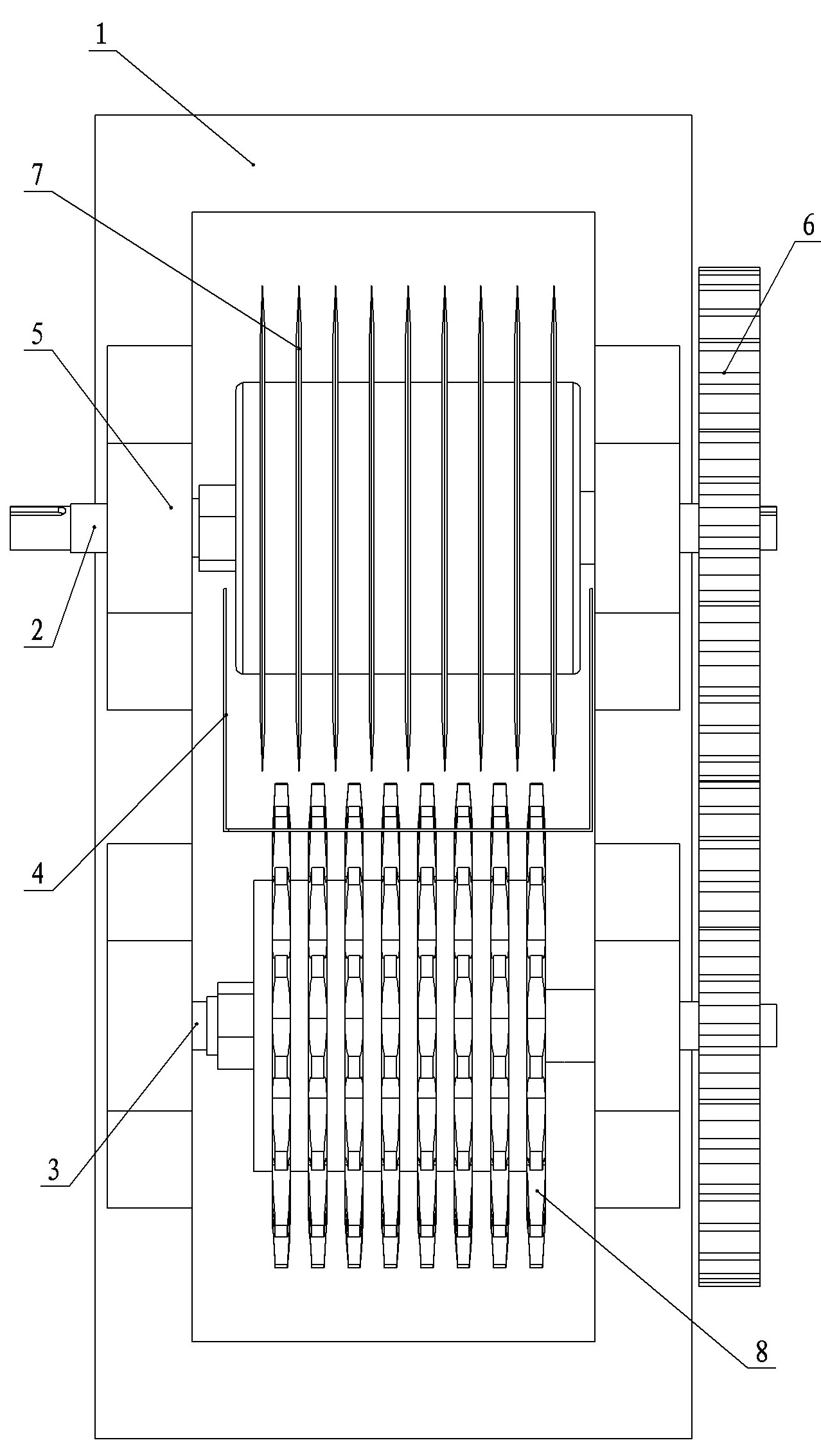

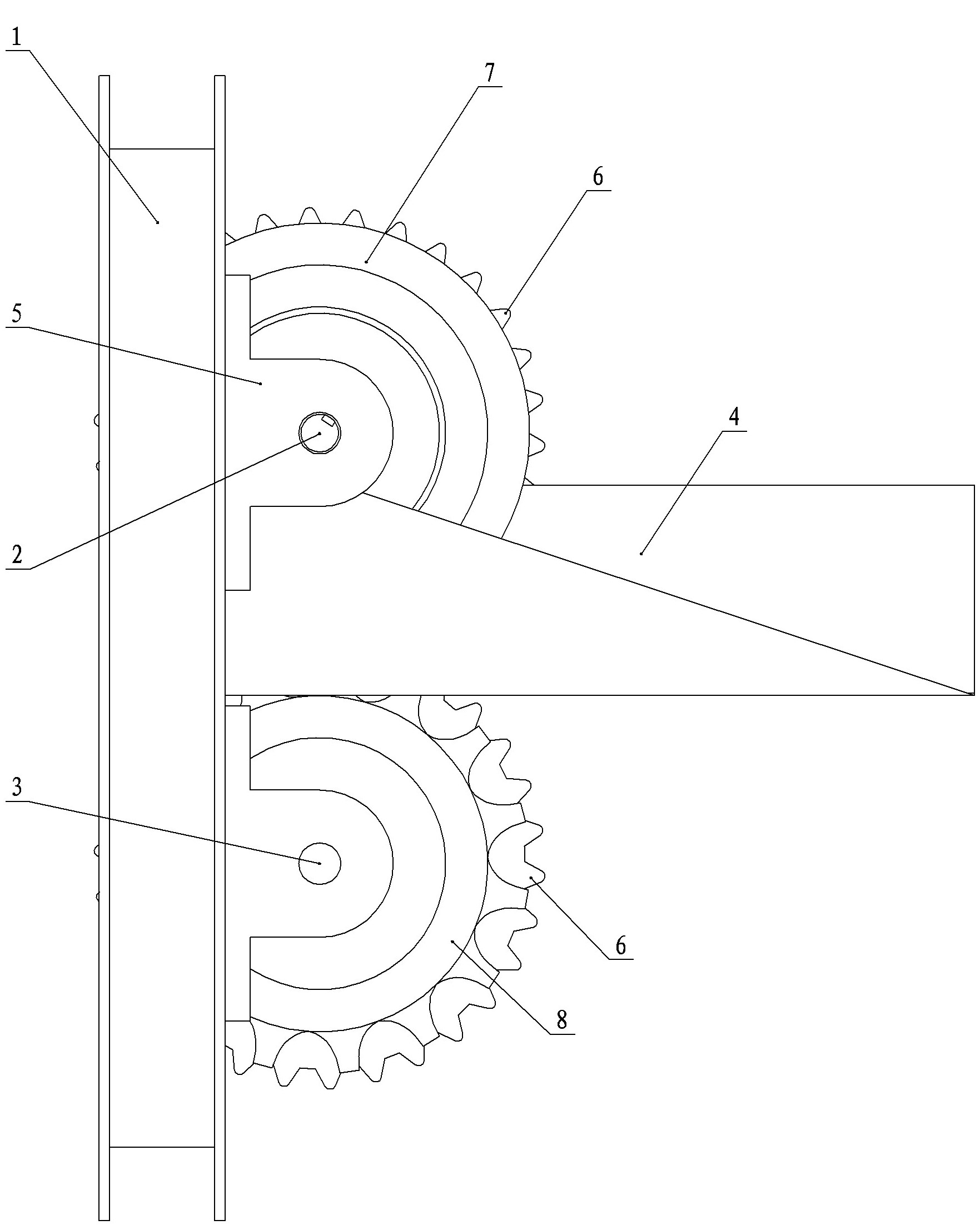

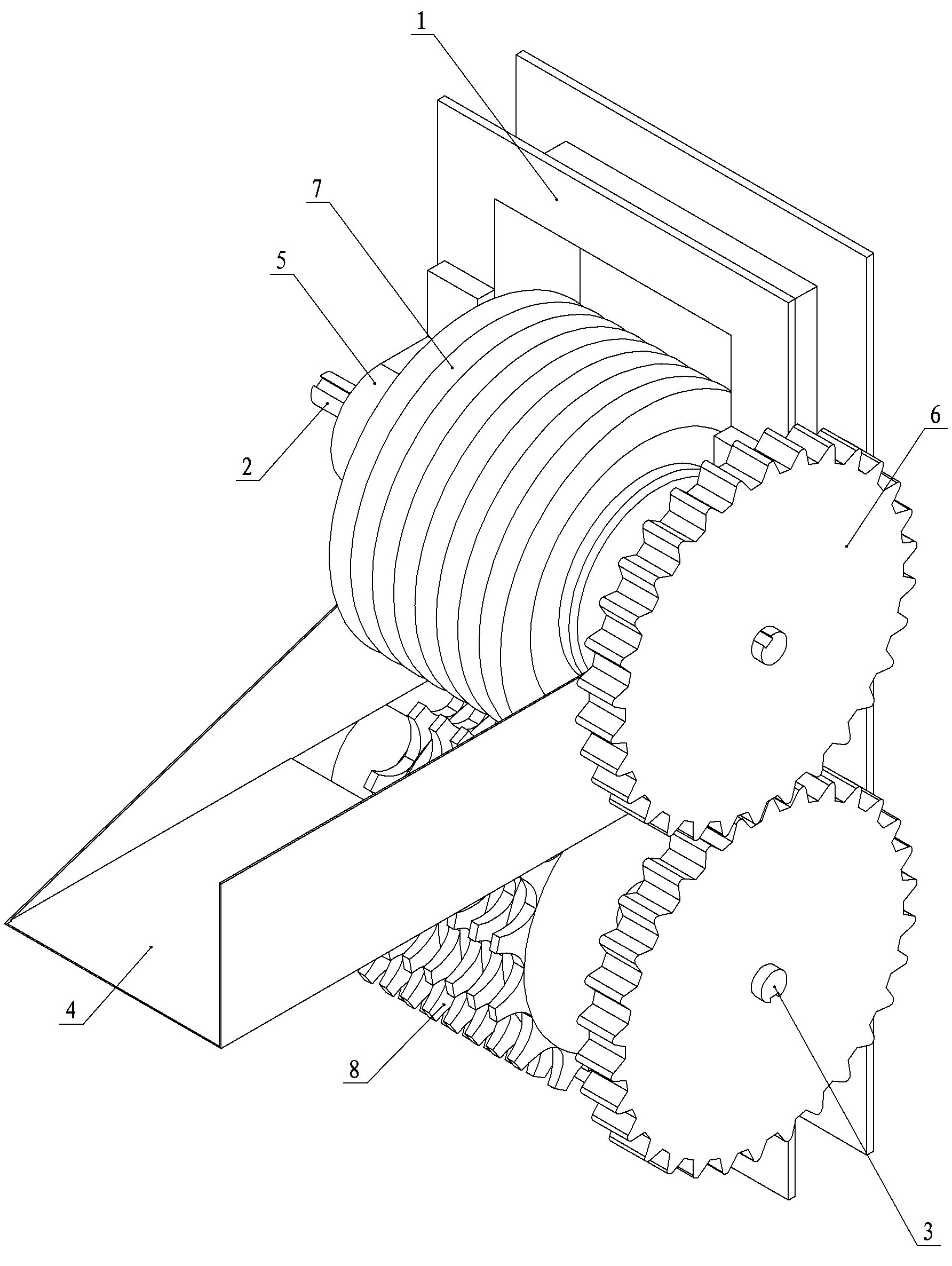

Tobacco bundle untying device

The invention provides a tobacco bundle untying device. The tobacco bundle untying device comprises a hopper, a frame body, a cutter head shaft and a gear shaft, wherein the cutter head shaft and the gear shaft are arranged on the frame body in parallel; multiple cutter heads are overlapped on the cutter head shaft; multiple gears are overlapped on the gear shaft, and a certain spacing is formed between adjacent cutter heads and between adjacent gears; the cutter heads and the gears are arranged in a staggered way; mutually engaged gears are mounted at the ends of the cutter head shaft and the gear shaft; and the hopper is arranged on the frame body, with the hopper bottom directly facing the position between the cutter heads and the gears. According to the tobacco bundle untying device provided by the invention, the tobacco bundle is held and extruded towards the cutter heads by the teeth of the gears on the gear shafts, and then the tobacco leaves around the tobacco bundle can be cut, and the purpose of untying the tobacco bundle is achieved. The device is provided with the tobacco bundle hopper as the accessory only. The device is simple in structure, sufficient in power, high in untying efficiency, and high in practicability; by mounting on related equipment and with power supplied, the device can be applied to manually untie the bundle (with an additional handle) and untie the bundle during threshing, redrying and spreading the tobacco as well as selectively untying bundle.

Owner:BAOFENG REDRYING FACTORY OF TIANCHANG INT TOBACCO CO LTD

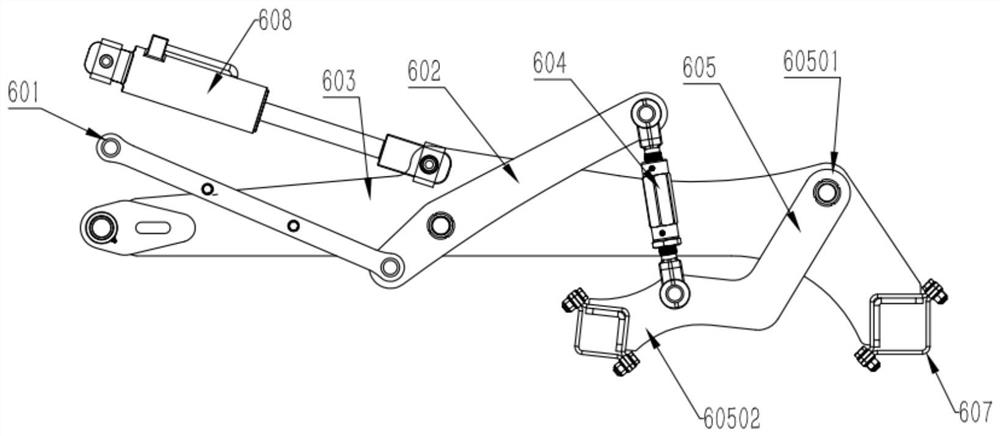

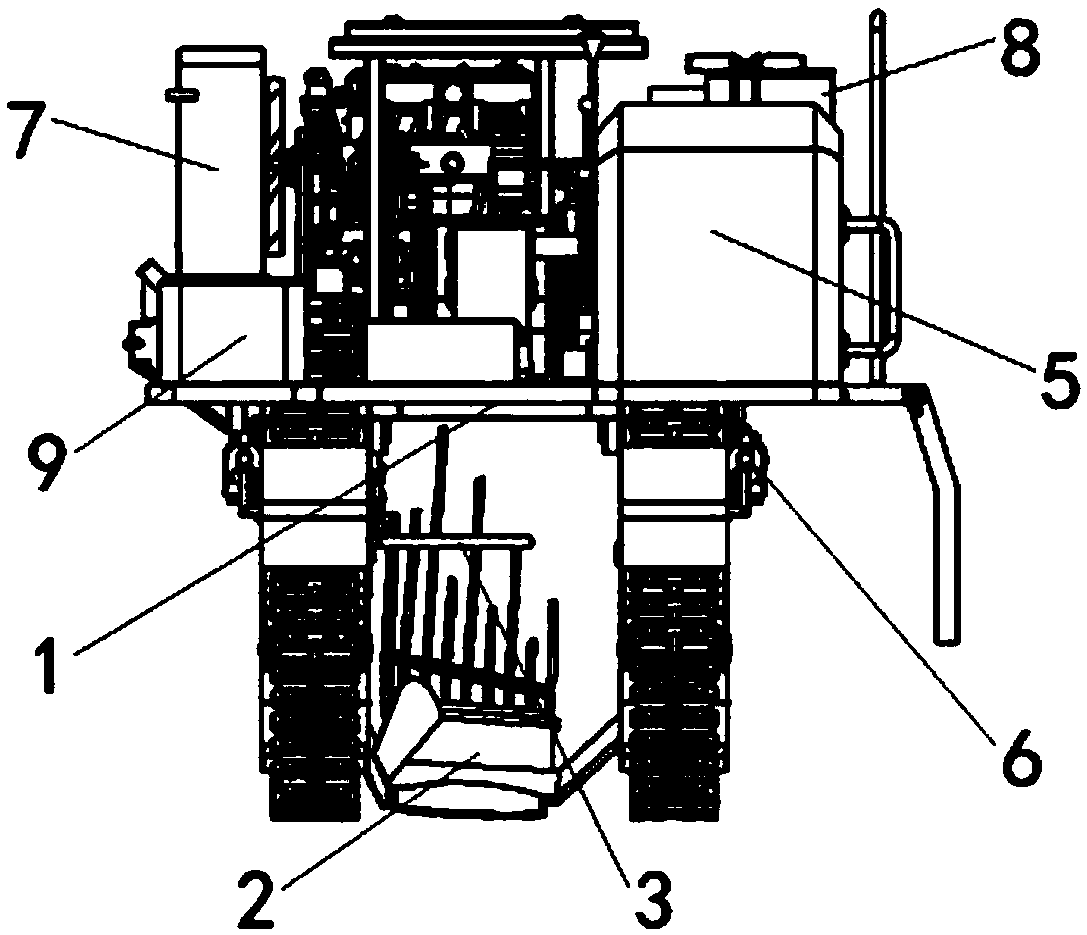

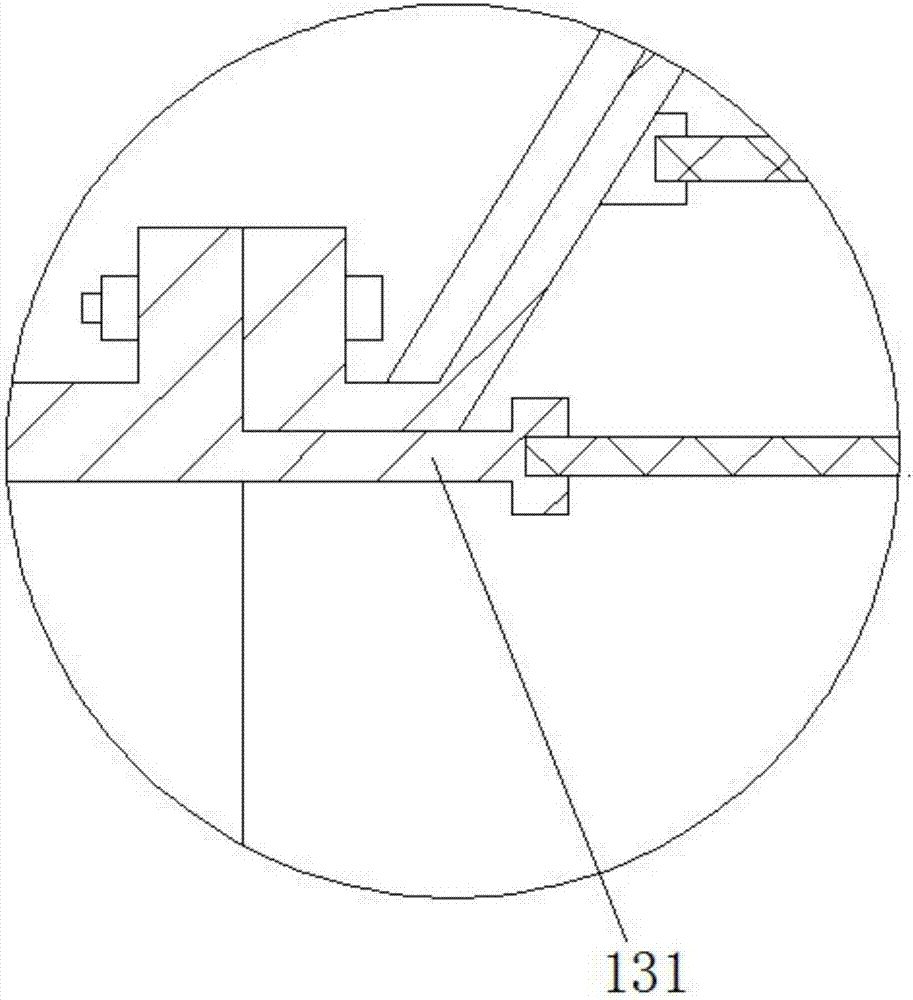

Gravity center adjusting system for high-ground-clearance plant protection machine and adjusting method thereof

PendingCN113419553ASmooth motionFull of powerAttitude controlInsect catchers and killersControl engineeringGravity center

The invention discloses a gravity center adjusting system for a high-ground-clearance plant protection machine and an adjusting method thereof, belonging to the technical field of agricultural mechanical equipment. The invention aims to solve the problems that an existing high-ground-clearance plant protection machine lacks enough stability in field operation and is prone to rollover and thus causes casualties and property loss and affects operation efficiency. The gravity center adjusting system comprises a signal collecting device, a controller and an executing mechanism, wherein the signal collecting device is arranged on the plant protection machine and collects the inclination angle, pressure, liquid level and displacement signals of the plant protection machine; the signal output end of the signal collecting device is connected with the signal receiving end of the controller; the instruction output end of the controller is connected with the instruction receiving end of the executing mechanism; and the executing mechanism adjusts the angles of a left-side angle-adjustable medicine chest frame and a right-side angle-adjustable medicine chest frame. The gravity center adjusting system provided by the invention is used for the high-ground-clearance plant protection machine.

Owner:JILIN AGRICULTURAL UNIV

Corn Emasculation Mechanism Used Especially For Automatic Machine

The invention relates to corn emasculation mechanism used especially for automatic machine, it is characterized that the corn emasculation mechanism used especially for automatic machine includes a first driving machine, a second driving machine, a mounting support, a first gear, a second gear, a horizontal cutter disc, a blade and a rotating shaft; Wherein the mechanism is mainly composed of a driving mechanism and a transmission mechanism, the driving mechanism is a first driving machine and a second driving machine, the first driving machine and the second driving machine can be the same frequency reverse motor or the same frequency reverse hydraulic cylinder or pneumatic cylinder, the first driving machine and the second driving machine are respectively arranged on the mounting support; the power output parts are respectively provided with a first gear and a second gear; the first gear and the second gear are externally tangent and types and diameters are the same, the output end of the rotating shaft of the first and second gears is fixedly provided with a horizontal cutter disc, a plurality of blades are arranged on the horizontal cutter disc, and the blades can be provided with 2 to 4 blades. The invention has the advantages of simple structure, reasonable design, high power, high working efficiency and low production cost, it can be manufactured into large equipment orportable equipment with small size, it has strong practicability, and greatly reduces the labor intensity of people.

Owner:顾宏娟

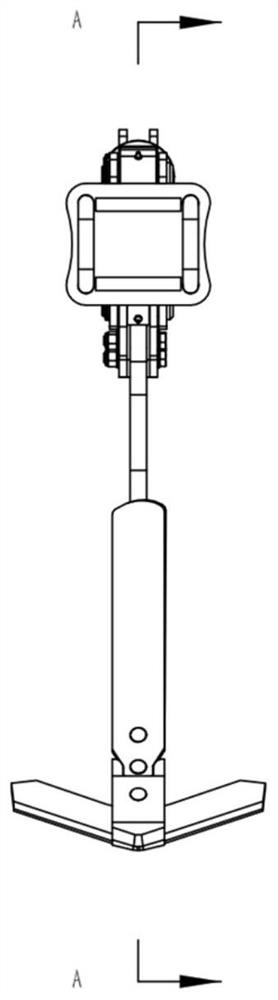

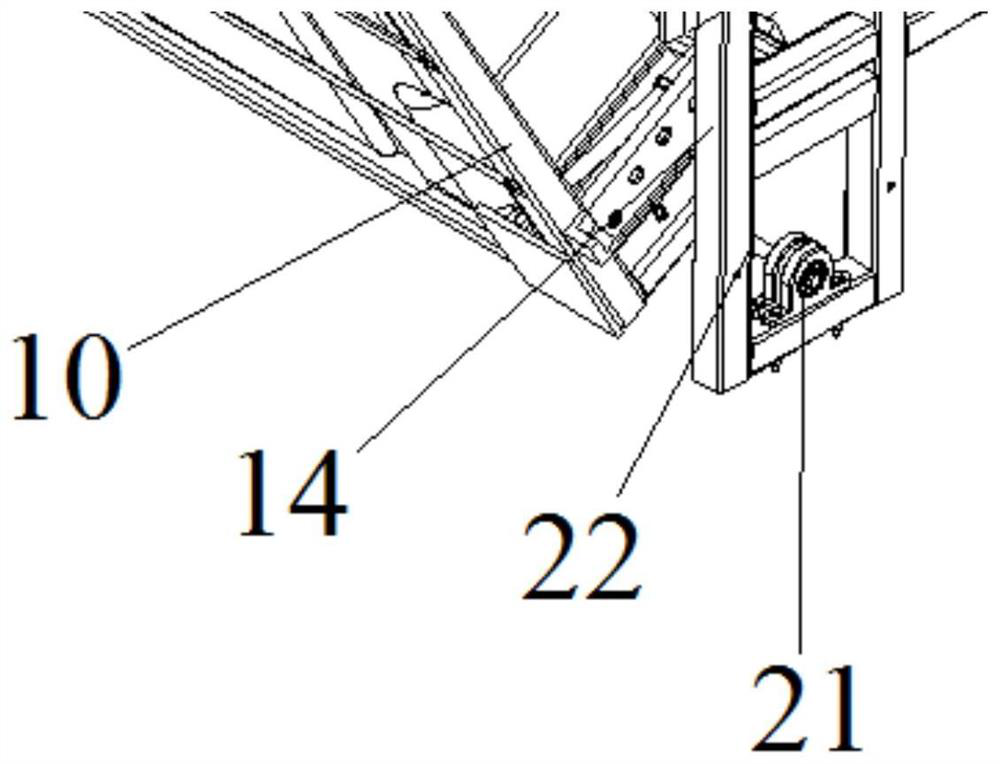

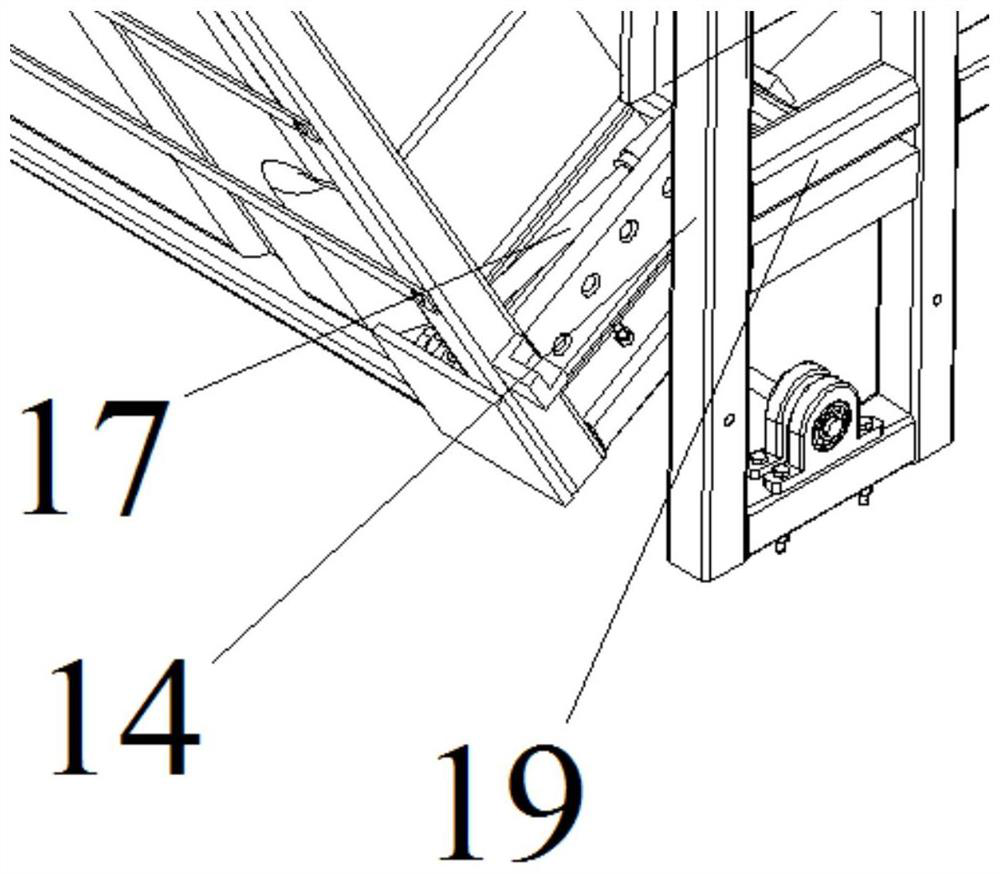

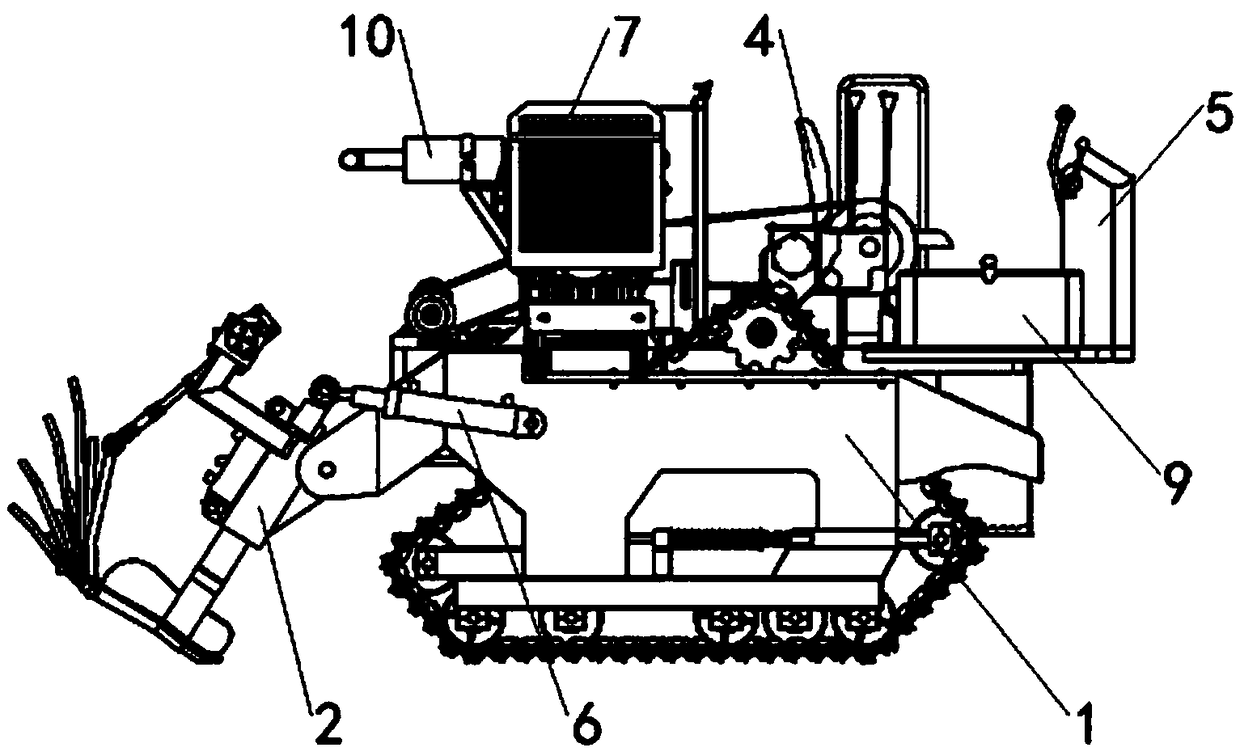

Sectioned type allium fistulosum harvester and harvesting method

PendingCN109429666AImprove the level of harvesting mechanizationFast harvestDiggersEngineeringShovel

The invention relates to a sectioned type allium fistulosum harvester and a harvesting method. The harvester comprises a crawler chassis, a vibration type excavating device which is hinged to the rearend of the crawler chassis through a horizontal hinge shaft, and an allium fistulosum righting rod which is fixedly connected with the crawler chassis; a pushing device which drives the vibration type excavating device to rotate around the horizontal hinge shaft is installed on the crawler chassis and an engine which is used for driving the crawler chassis to move are installed on the crawler chassis, and the allium fistulosum righting rod extends to the side, located on an allium fistulosum passing route, of the vibration type excavating device. The harvester has the advantages that the operational functions of excavating, soil loosening, pulling and laying are achieved, flexible soil clearing and loosening and ordered laying are achieved, an excavating shovel is allowed to moved up anddown according to different working demands, the uniformity of the excavating depth is ensured, a rocking arm is driven by a motor to drive a soil screening net to vibrate, so that soil block pulverizing and soil clearing are achieved, the allium fistulosum gradually moves towards one side, and the ordered laying of the allium fistulosum is achieved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Movable-type reciprocating piston-type internal combustion engine and assembly method and power output mechanism thereof

InactiveCN106014630ASolve technical problems that waste burst energySufficient air intakeMachines/enginesReciprocating motionCrank

The embodiment of the invention discloses a movable-type reciprocating piston-type internal combustion engine and an assembly method and a power output mechanism thereof. The movable-type reciprocating piston-type internal combustion engine comprises a cylinder barrel, a piston which reciprocates in the cylinder barrel and the power output mechanism, wherein the power output mechanism comprises a connection rod, a crank throw and a crank shaft; one end of the connection rod is connected onto the central axis of the piston of the reciprocating piston-type internal combustion engine through a rotary shaft; the other end of the connection rod is rotatably connected with one end of the crank throw; the other end of the crank throw is rotatably connected with the crank shaft; and the crank shaft or the cylinder barrel deflects from the central axis of the piston for a preset distance, so that the crank shaft or the cylinder barrel is not located on the central axis of the piston.

Owner:李殿亮 +2

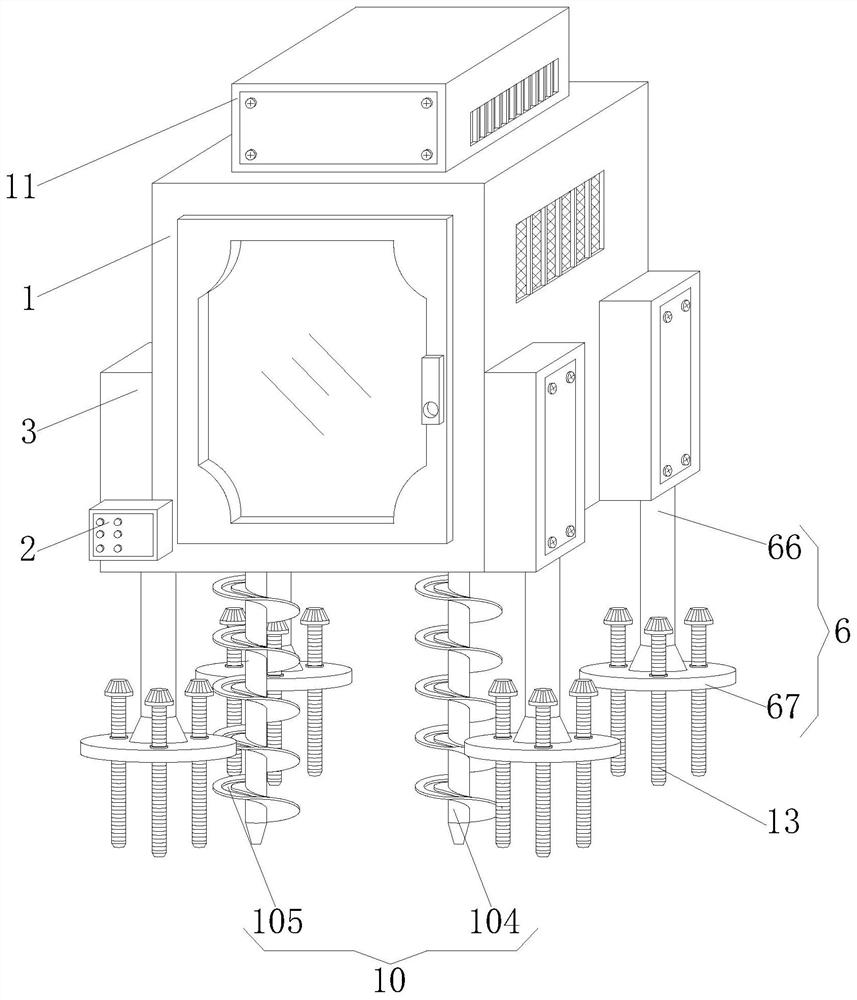

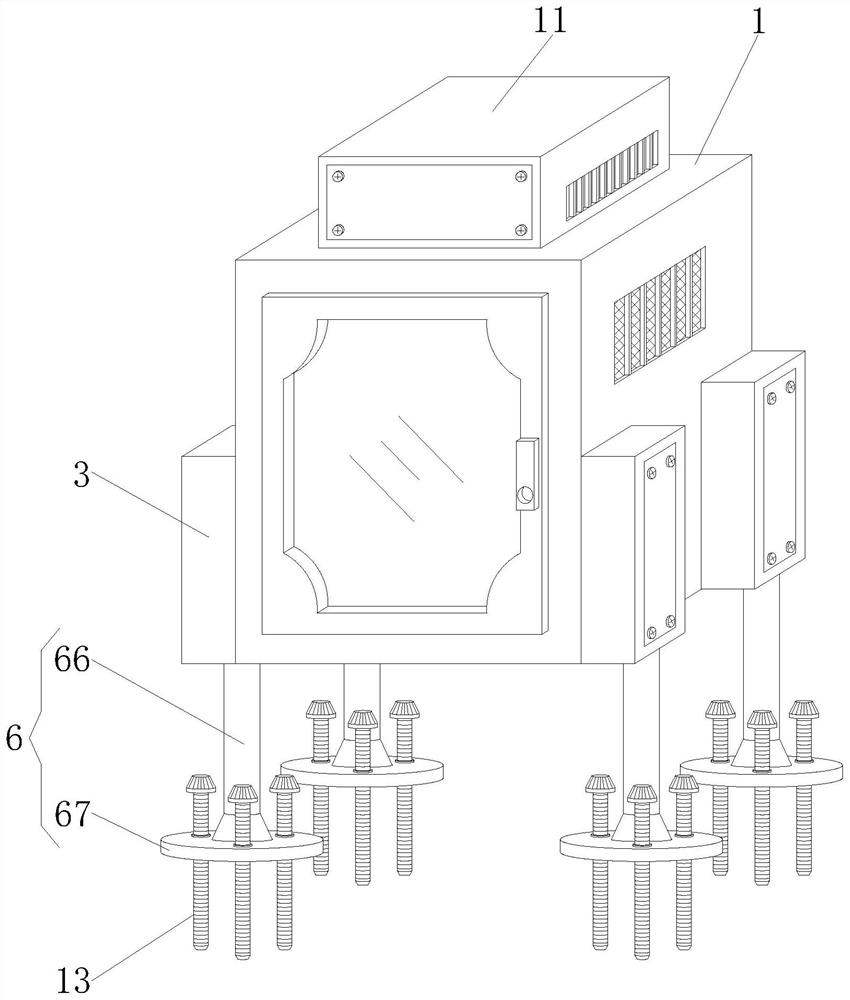

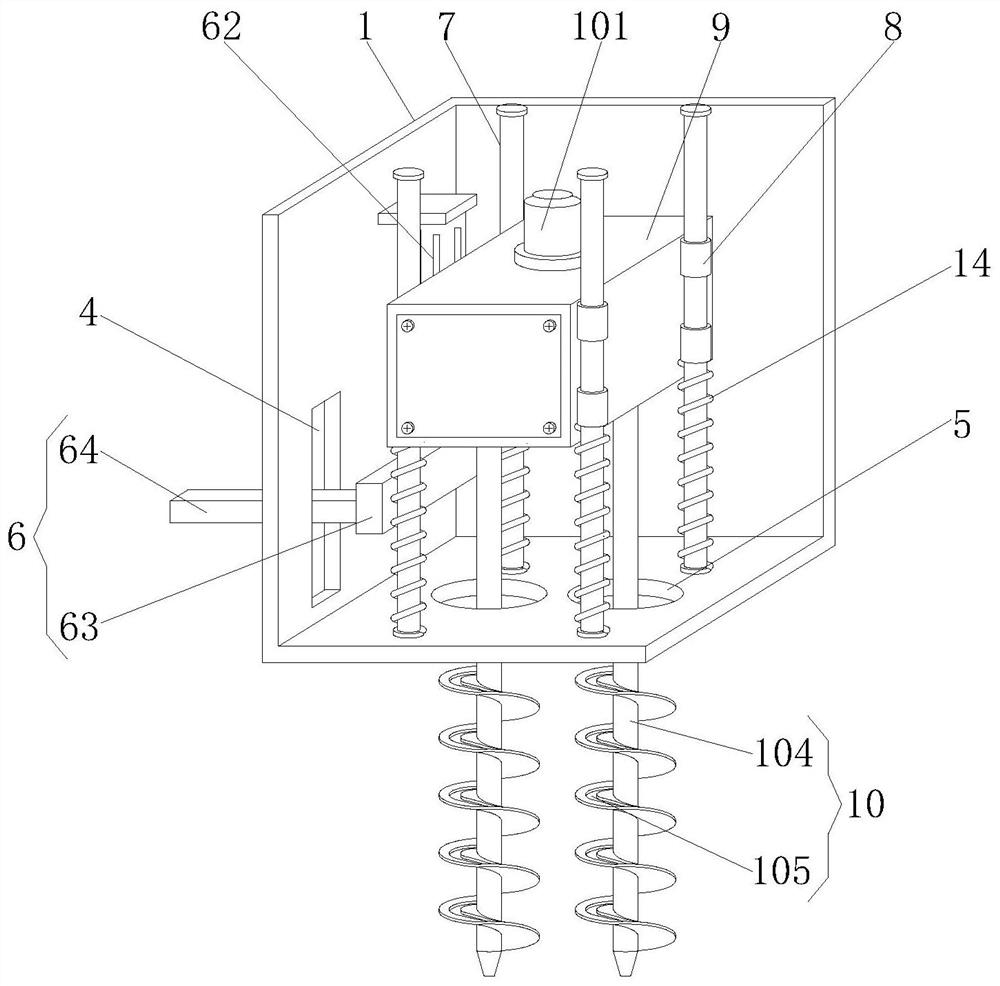

Soil detection device with stratified sampling function

InactiveCN112763258AMeet the needs of depth adjustmentSmall amount of sampleWithdrawing sample devicesEarth material testingSoil scienceGear wheel

Owner:张振斌

Gas turbine engine

InactiveCN108952965ASimple structureEasy to operateTurbine/propulsion fuel valvesGas turbine plantsEngineeringSteel ball

The invention discloses a gas turbine engine. The gas turbine engine comprises an engine body and a gas cavity which is formed in the engine body; a discharge cavity is formed in the left end of the gas cavity; a first cavity is formed in the right end of the gas cavity; a second cavity is formed in the right end of the first cavity in a communicating manner; a third cavity and a fourth cavity which are positioned in the bottom of the gas cavity are formed in the left end of the first cavity from right to left in sequence; elastic steel ball gas inlet mechanisms which are in longitudinal symmetry are arranged between the gas cavity and the discharge cavity; and a compressing pipe which is positioned at the right end of each elastic steel ball gas inlet mechanism and communicates with the elastic steel ball gas inlet mechanism is arranged on the inner wall of the left end of the gas cavity. The gas turbine engine is simple in structure, low in gas loss, high in energy utilization rate,convenient to start, and full of power.

Owner:浦江县速达进出口有限公司

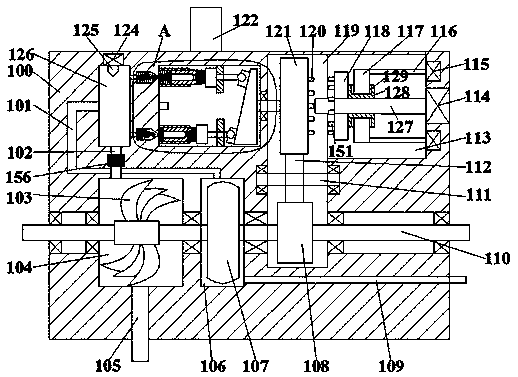

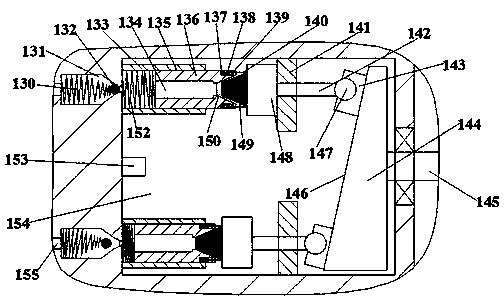

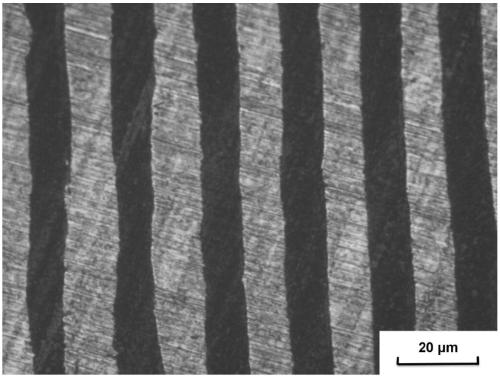

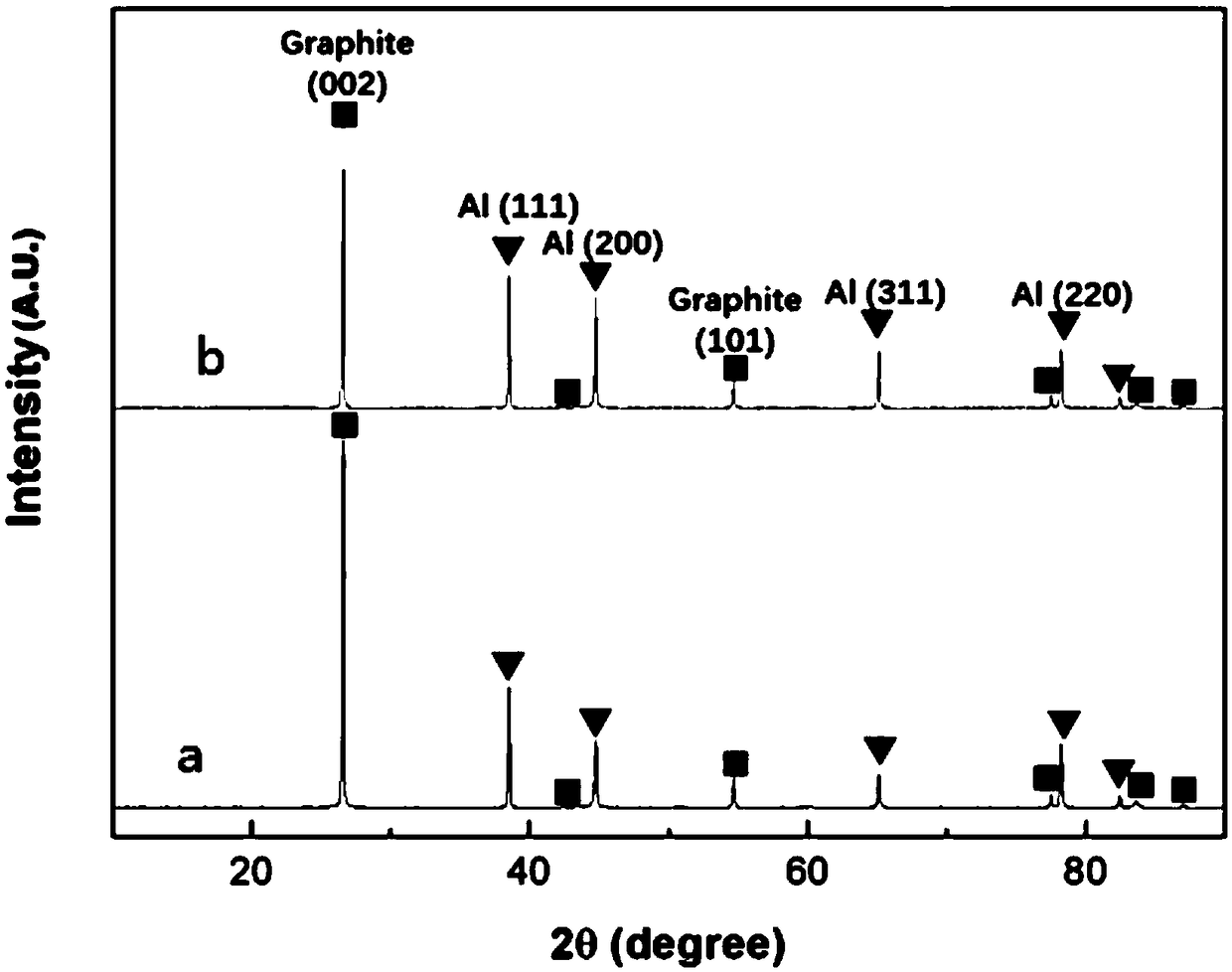

Preparation method of two-dimensional high-heat-conductivity graphite membrane/aluminum composite material

The invention relates to a preparation method of a two-dimensional high-heat-conductivity graphite membrane / aluminum composite material, and aims to solve the problems that a current graphite membrane / aluminum composite material is high in furnace chamber reaction temperature and long in preparation time, and interface reaction between a graphite membrane and an aluminum substrate is severe. The preparation method includes the steps: firstly, pretreating a graphite membrane and an aluminum foil; secondly, preparing a prefabricated body; thirdly, sintering the material by a spark plasma sintering method in an atmosphere protection manner. By the spark plasma sintering method, reaction time is short, so that generation of an Al4C3 phase cannot be detected, and the composite material is highin preparation efficiency, compactness and reliability and excellent in thermo-physical performance. The method is applied to the field of electronic packaging substrates.

Owner:HARBIN INST OF TECH

Work piece press fitting mechanism

InactiveCN106736414AFull of powerThe pressing operation process is simpleVehicle componentsMetal working apparatusTelescopic cylinderEngineering

The invention relates to a work piece press fitting mechanism. The work piece press fitting mechanism is characterized by comprising a driving cylinder, a crossbeam, a telescopic cylinder, a connector, a fixing bolt, a pressure head mounting disk, a pressure head, a limiting plate and a limiting rod, wherein the driving cylinder is fixedly arranged on the crossbeam of a machine body frame; the telescopic cylinder of the driving cylinder is connected with the connector, and penetrates through the crossbeam to be connected with the pressure head mounting disk through the fixing bolt; the pressure head is fixedly mounted on the pressure head mounting disk; the limiting rod is mounted at the front end of the pressure head through the limiting plate; and the lowest end of the limiting rod is lower than that of the pressure head by no more than 2cm. The work piece press fitting mechanism disclosed by the invention has the advantages that driving cylinder type driving press fitting is adopted, so that the work piece press fitting mechanism is full of power, safe and reliable, simple in press fitting operation technology, high in operating speed, high in mechanization degree and high in automation degree, the operating difficulty and the operating strength of staff are reduced, and the working efficiency is improved.

Owner:吴鹏飞

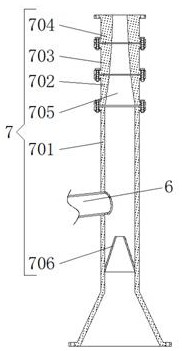

Multistage haze purifier

PendingCN107062417ASimple structureEasy to assemble and disassembleMechanical apparatusDispersed particle filtrationWaste management

The invention relates to a multistage haze purifier which comprises an air inlet barrel assembly, an impeller, a drive device, a filtering shell and a multistage filtering cylinder assembly. The air inlet barrel assembly comprises a hollow air barrel with the two ends open and a netty grating. The netty grating is mounted in an opening in one end of the air barrel. The impeller is coaxially arranged in the air barrel. The drive device is mounted in the air inlet barrel assembly, and the drive end of the drive device is fixedly connected with the impeller. The filtering shell is hollow, and one end of the filtering shell is open. The open end of the filtering shell is necking down and is in sealed connection with the other end of the air barrel in a matched mode. The filtering cylinder assembly is mounted in the filtering shell and internally provided with an air inlet cavity communicating with the air barrel. An air outlet cavity is formed between the multistage filtering cylinder assembly and the inner wall of the filtering shell. A plurality of exhaust outlets are uniformly formed in the position, corresponding to the air outlet cavity, of the closed end of the filtering shell at intervals. The multistage haze purifier has the advantages of being simple in structure, convenient to dismount, mount and use, and good in filtering effect.

Owner:山东速得机电有限公司

Heavy stubble cleaning harrow and stubble cleaning operation method of high-stubble straw

PendingCN111972056AImprove job performanceImprove stubble removal effectMowersHarrowsAgricultural engineeringStructural engineering

The invention discloses a heavy stubble cleaning harrow. The heavy stubble cleaning harrow is characterized by comprising a main harrow frame assembly, a middle harrow frame assembly, a left folding harrow frame assembly and a right folding harrow frame assembly, wherein the left folding harrow frame assembly and the right folding harrow frame assembly are connected to the left side and the rightside of the main harrow frame assembly in a foldable mode; the middle harrow frame assembly is fixedly connected to the lower portion of the main harrow frame assembly; the front end of the main harrow frame assembly is movably connected with a traction frame assembly; the rear end of the main harrow frame assembly is movably connected with a rear adjusting tail frame assembly; walking wheels areconnected to the rear portion of the rear adjusting tail frame assembly; the front end of the left folding harrow frame assembly is connected with a left pressing roller assembly; and the front end ofthe right folding harrow frame assembly is connected with a right pressing roller assembly. According to the heavy stubble cleaning harrow, high-stubble straw is pressed down, the straw is crushed and mixed through the front row of harrow pieces and the rear row of harrow pieces, and straw rhizomes are subjected to secondary cutting through disc slices, so that the straw can be fully crushed, repeated operation of the stubble cleaning harrow on an operated residual stubble field is not needed, and the operation efficiency is improved.

Owner:宜兴博登泰科工业装备有限公司

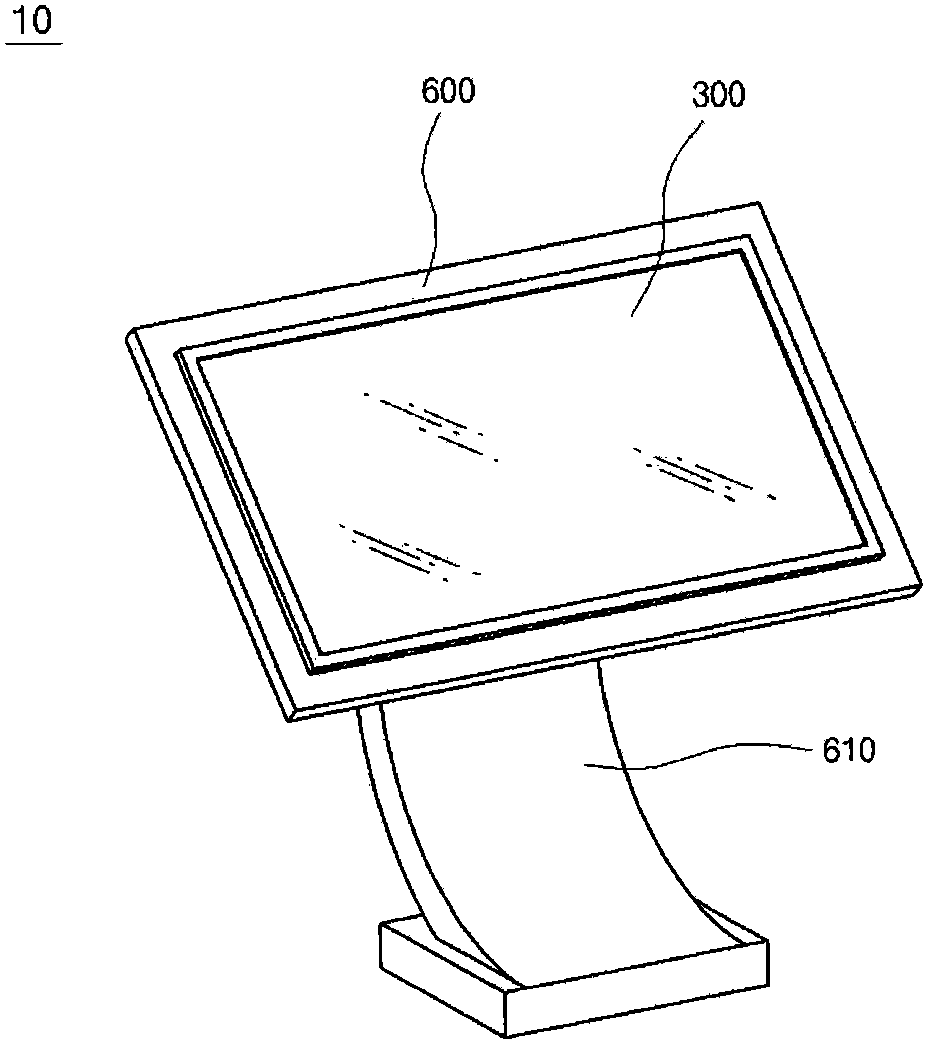

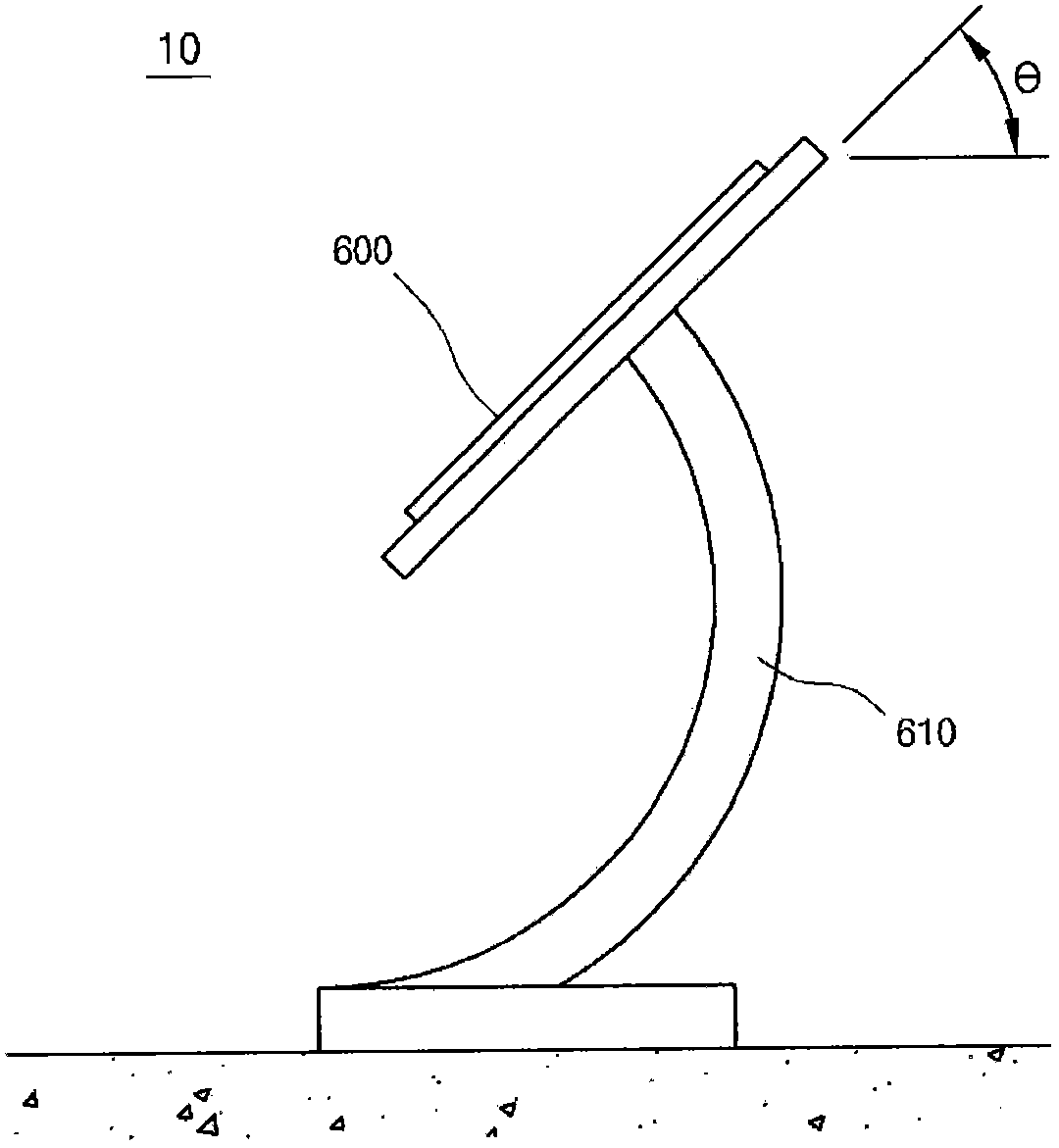

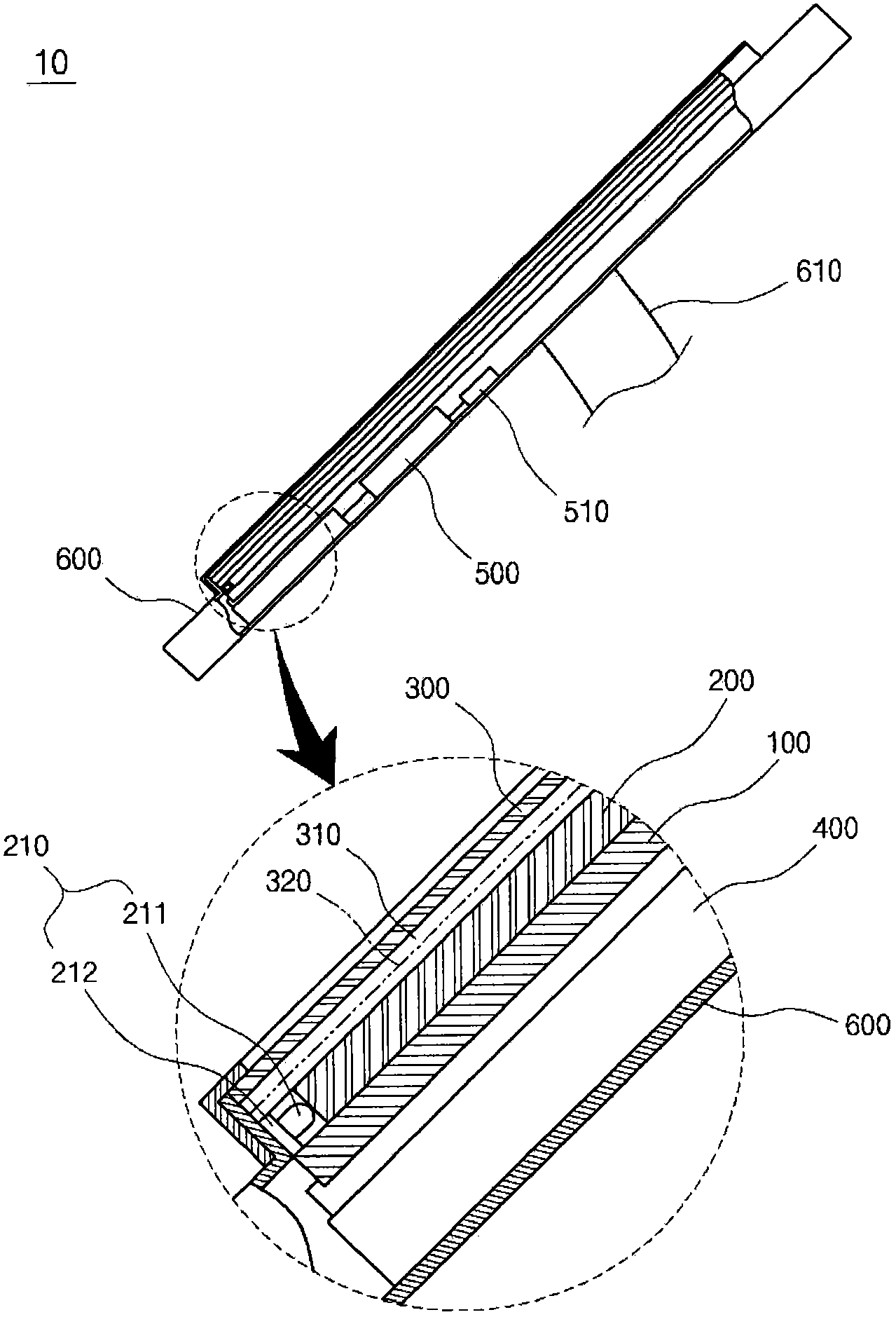

Photovoltaic power guide plate

InactiveCN102844804AFull of powerAesthetically pleasingAdvertisingPhotovoltaic energy generationElectricityLight guide

A solar guide panel is provided to sufficiently generate power and prevent a solar cell from being contaminated by preventing the exposure of the solar cell. A flat pate type solar cell(100) receives sunlight and generates power. A light guide panel(200) uniformly emits light from the outside to the front and solar cell direction. A lighting unit(210) supplies light to the light guide panel through an LED lamp(211). A protection panel(300) is separated from the front of the light guide panel. A battery(400) stores power generated from the solar cell. A controller(500) turns on and off the LED lamp with a signal of a timer.

Owner:NEULPUREUN ADVERTISING IND

Automobile production line tire clamping mechanism

The invention discloses a tyre clamping mechanism for a vehicle production line, and belongs to the field of vehicle assembling workshop mechanized transportation. The tyre clamping mechanism comprises a base, wherein a driving device is fixedly connected to the base; a clamp holder is also hinged to the base; the driving device and the clamp holder are connected through a push-pull rod; the driving device, the clamp holder and the push-pull rod form a slider-crank mechanism. The tyre clamping mechanism is characterized in that a guiding wheel which is horizontally arranged is arranged at the bottom end of a supporting seat of a push rod of the driving device; a guiding plate which can be cooperated with the guiding wheel is arranged on the base; the guiding wheel is tangent with the inner side wall of the guiding plate. According to the tyre clamping mechanism disclosed by the invention, the structure is simple, the clamp holder is driven by the driving device in the horizontal direction, so that a vehicle front wheel can be stably clamped, and the accurate clamping and positioning of a vehicle in a service position of an automatic production line is realized safely and efficiently.

Owner:武汉东研智慧设计研究院有限公司

A method for power grid black start

InactiveCN104716671BReliable recoveryRestoration of power is reliableSingle network parallel feeding arrangementsWind energy generationElectric power systemPower grid

The invention discloses a black-start method for a power grid. The start method comprises the following steps: when an electric power system is powered off due to a fault, judging whether a wind power plant is used as a black-start power supply or not according to the charge state of an energy storage system configured in the wind power plant, if the charge state of the energy storage system is less than 0.2, starting a high-capacity thermal power unit by using the traditional black-start power supply, and externally recovering the power grid step by step. According to the black-start method, wind resources can be adequately utilized and the wind power plant is taken as the black-start power supply for carrying out black-start for the power grid.

Owner:SOUTHEAST UNIV

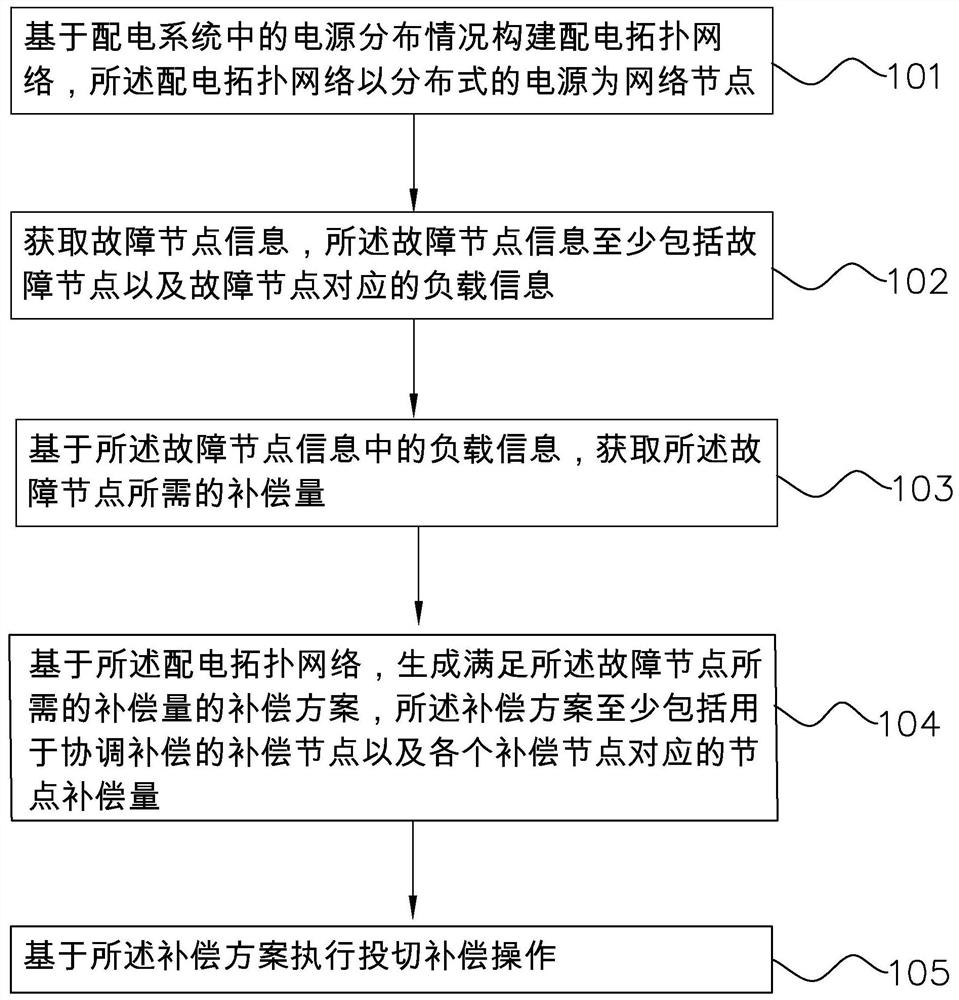

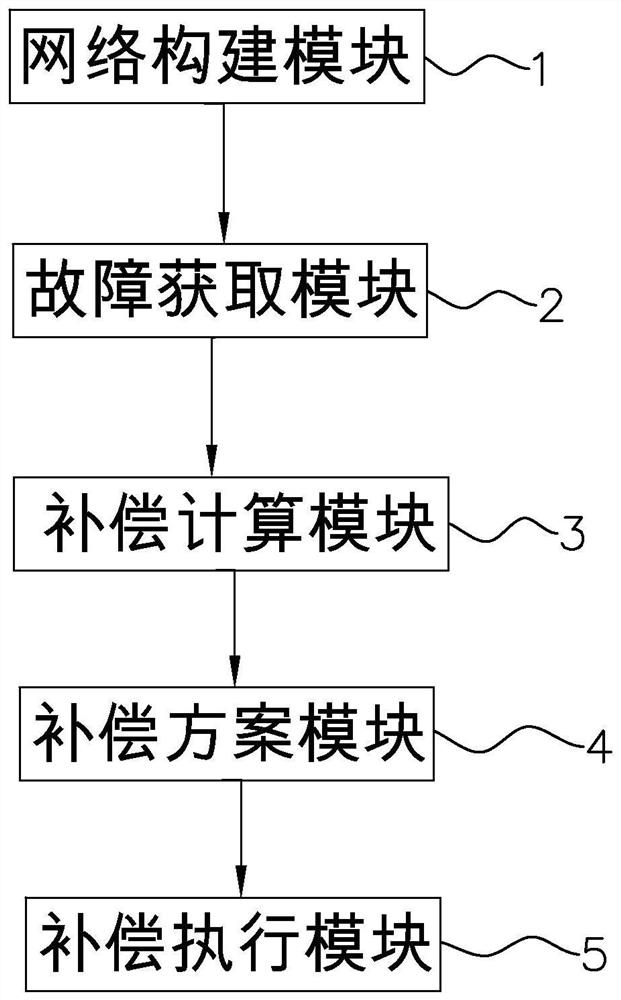

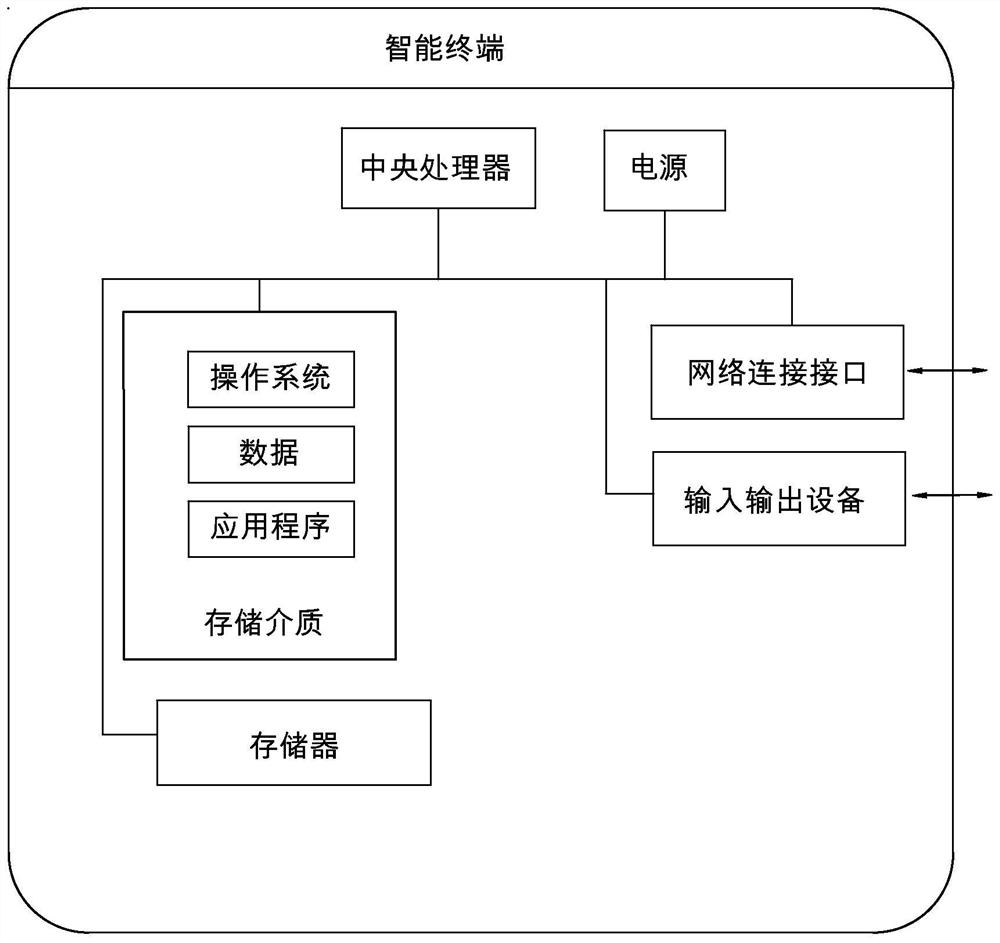

Distributed power supply load power distribution coordination control method and system

PendingCN114447980AConvenient power supplyIncreased likelihood of normal power supplySingle network parallel feeding arrangementsPower oscillations reduction/preventionNetwork generationControl engineering

The invention relates to the technical field of alternating-current and direct-current power distribution, in particular to a distributed power supply load power distribution coordination control method and system, and aims to solve the technical problems that in the prior art, an intelligent power distribution cabinet usually can monitor the working condition of the intelligent power distribution cabinet, and when a fault occurs in a load loop, manual intervention is needed to carry out emergency coordination processing, so that the working efficiency is high. According to the technical scheme, the distributed power supply load power distribution coordination control method comprises the steps that a power distribution topology network is constructed based on the power supply distribution condition in a power distribution system, fault node information is obtained, and the compensation amount needed by a fault node is obtained based on load information in the fault node information; generating a compensation scheme meeting the compensation amount required by the fault node based on the power distribution topology network; and executing the switching compensation operation based on the compensation scheme. The method and the device have the effect of improving the processing efficiency of emergency coordinated power supply of faults.

Owner:苏州市上电中天电力发展有限公司

Hydraulic drive gear tasseling farm device

InactiveCN108112375AFull of powerReasonable structural designHorticulture methodsHeadersBody right sideGear wheel

A hydraulic drive gear tasseling farm device is characterized by comprising a left motor, a right motor, a mounting rack, a left rotating shaft, a right rotating shaft, a left roller, a right roller,a left stirring rod, a right stirring rod and a protective cover, wherein the left motor and the right motor are symmetrically arranged on the left and right sides of the mounting rack, the left and right motors are same-frequency reverse rotating motors, the left and right rotating shafts are installed at the power output ends of the left and right motors and connected with the power output endsrespectively, the left and right rollers are installed on the left and right rotating shafts and connected with the left and right rotating shafts respectively, the left and right stirring rods havinga certain inclination angle are arranged on the left and right rollers, the protective cover is arranged outside the left and right rollers, and the device is of a bilaterally symmetrical structure.The hydraulic drive gear tasseling farm device has the advantages of being sufficient in power, reasonable in structural design, small in occupied space, good in transmission effect, dustproof, environmentally friendly and easy to operate, reducing the labor intensity of famers, replacing a traditional backward operation method and the like.

Owner:李淮滨

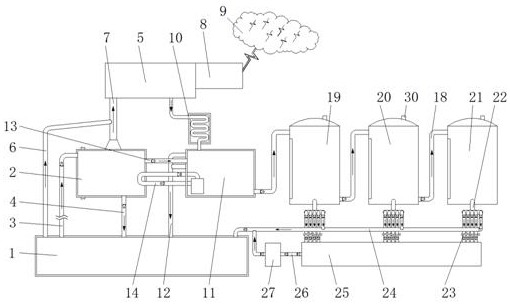

Energy-saving temperature control device for mountain area service area based on terrestrial heat absorption

InactiveCN113565712AGuaranteed water supplyGuaranteed temperature environmentGeothermal energy generationHollow article cleaningWater useEngineering

The invention discloses an energy-saving temperature control device for a mountain area service area based on terrestrial heat absorption. The energy-saving temperature control device comprises a terrestrial heat water tank, a steam turbine module, a power grid module, a backflow tank, a liquid level sensor, a service area water using module and an electric heating element, wherein a heat collection water tank is connected to the outer side of the terrestrial heat water tank, the steam turbine module is arranged on the outer side of the terrestrial heat water tank, a generator module is installed on the outer side of the steam turbine module, the backflow tank is arranged on the outer side of the heat collection water tank, a high-temperature water tank is connected to the tail end of a third inflow pipe, and a feeding hole is formed in the top of the heat collection water tank. For the energy-saving temperature control device for a mountain area service area based on terrestrial heat absorption, energy development and utilization are carried out based on terrestrial heat energy, water supply of various levels of temperatures can be guaranteed for the mountain area service area, water use inside and even outside the mountain area service area can be guaranteed conveniently, cyclic operation can be achieved at the same time, energy waste is reduced, energy saving and temperature control are facilitated, and the temperature environment of the service area is ensured.

Owner:王嘉川

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com