Preparation method of two-dimensional high-heat-conductivity graphite membrane/aluminum composite material

A technology of high thermal conductivity graphite and aluminum composite materials, which is applied in the field of preparation of two-dimensional high thermal conductivity graphite film/aluminum composite materials, can solve the problems of long preparation time, high reaction temperature, serious interface reaction between graphite film and aluminum matrix, etc., and achieve The effect of high preparation efficiency, high density and excellent thermophysical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

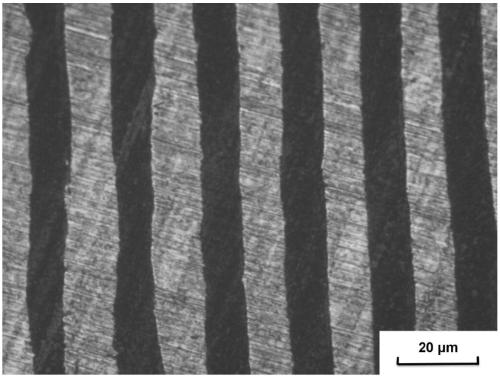

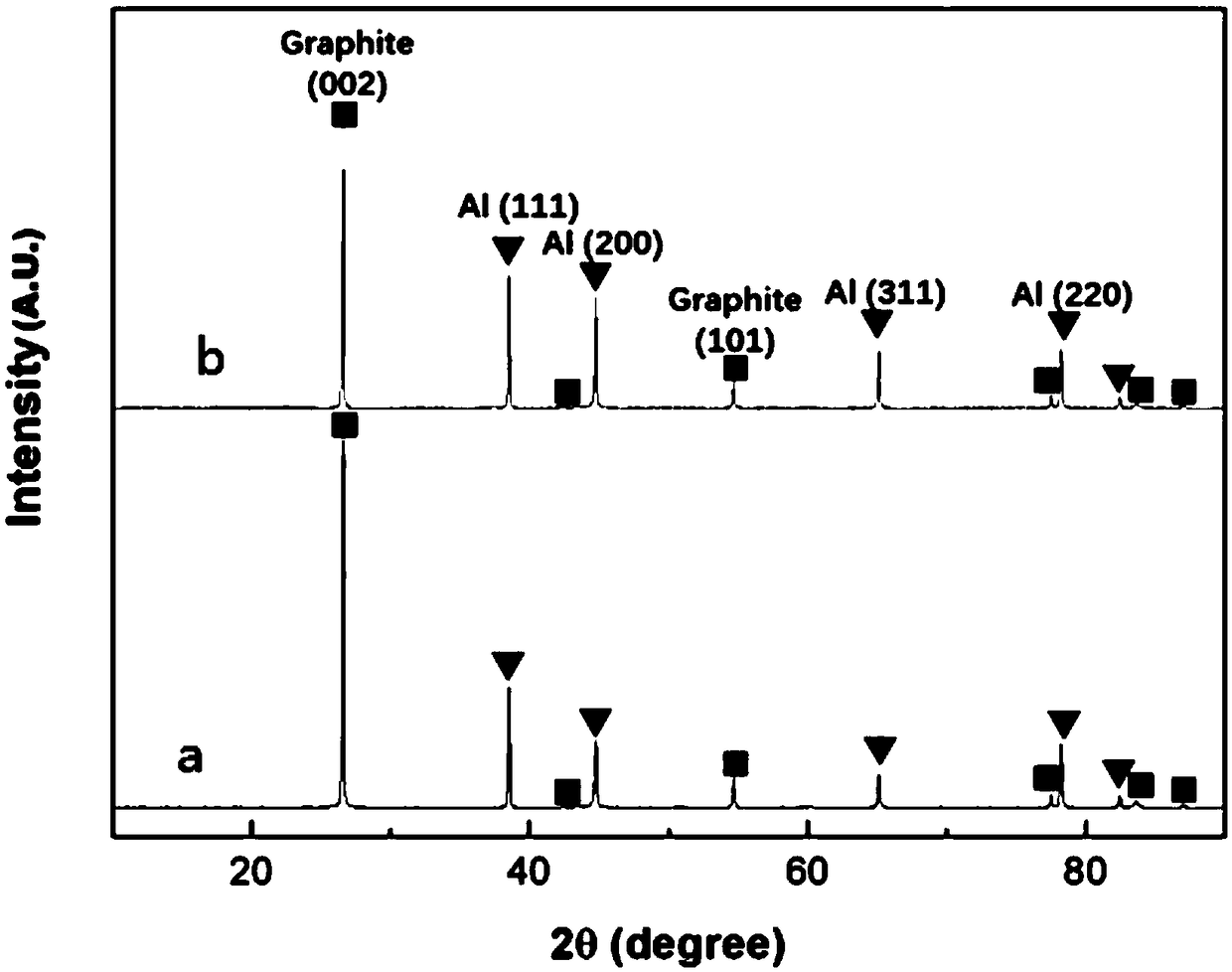

[0020] Embodiment 1: In this embodiment, a method for preparing a two-dimensional high thermal conductivity graphite film / aluminum composite material is carried out according to the following steps:

[0021] 1. Pretreatment graphite film and aluminum foil

[0022] Remove the residual organic matter on the surface of the graphite film, and then put it in an electric blast drying oven to dry for 5 to 10 minutes. After drying, wipe off the amorphous graphite powder on the surface of the graphite film to obtain a pretreated graphite film; remove the oxidation on the surface of the aluminum foil layer, and then put it into a vacuum drying oven to dry for 30-60 minutes to obtain a pretreated aluminum foil;

[0023] 2. Preparation of prefabricated body

[0024] Lay the pretreated graphite film and aluminum foil cross-stacked to obtain a prefabricated block, and then put it into a graphite mold to obtain a graphite film aluminum foil prefabricated body; wherein, the volume fraction o...

specific Embodiment approach 2

[0033] Specific embodiment two: this embodiment differs from specific embodiment one in that: the graphite film is a high crystallinity graphite film in step one, the thickness of the graphite film is 0.012~0.1mm, and the thermal conductivity is 600~1900W / (m· K). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum foil in step 1 is 1050, 1060, 1070, 1100, 1145, 1200, 1235, 2A11, 2A12, 3003, 3A21, 4A13, 5A02, 5052, 5082, 5083, 8006, 8011, 8011A or 8079 aluminum foil, the thickness of the aluminum foil is 0.016 ~ 0.2mm. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com