Closed mechanical-seal pump ring and shaft-seal flushing system with same

A technology of mechanical sealing and flushing system, applied in mechanical equipment, non-variable-capacity pumps, components of pumping devices for elastic fluids, etc. Achieve the effect of improving the mechanical seal performance, increasing the flow area, and lengthening the fluid flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

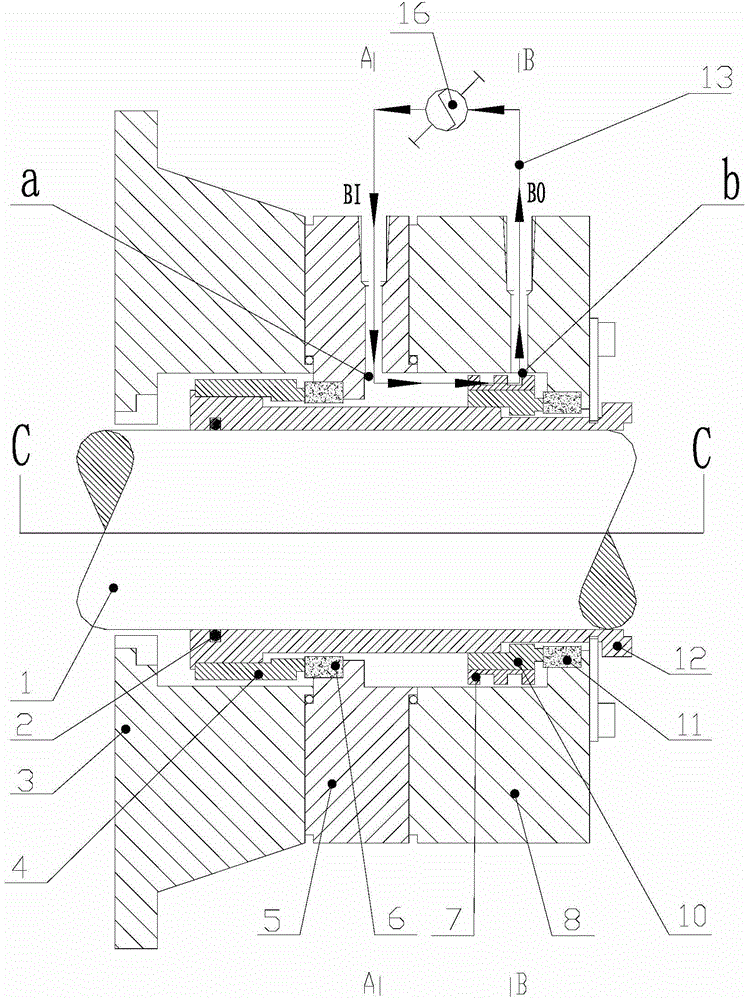

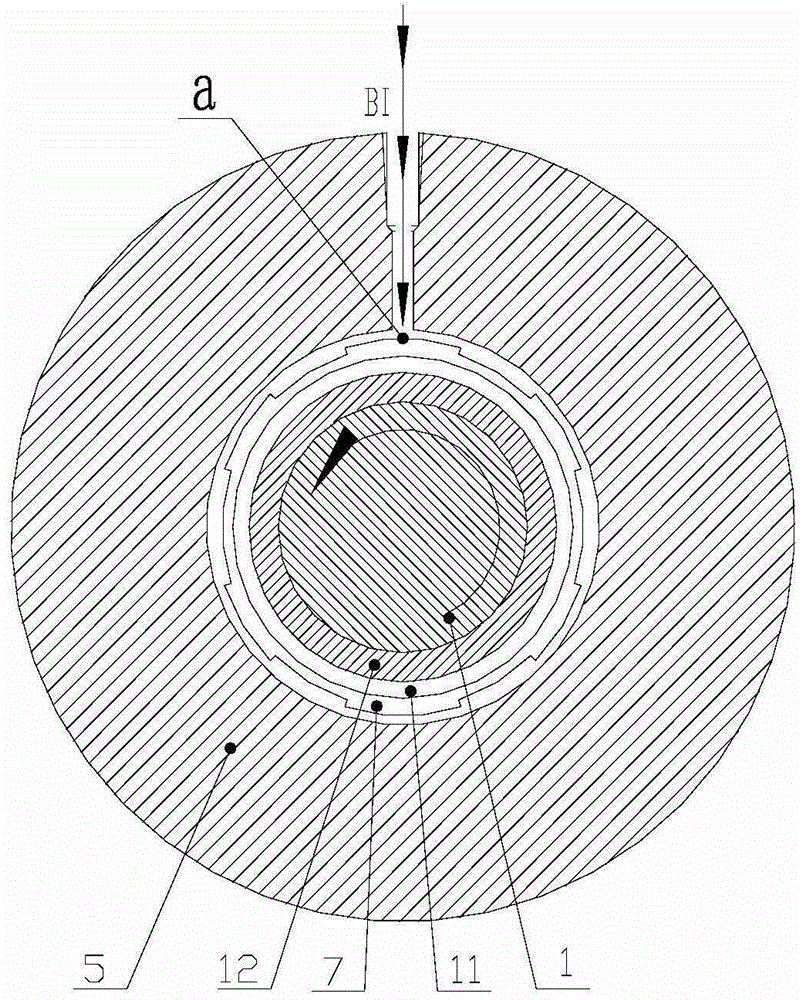

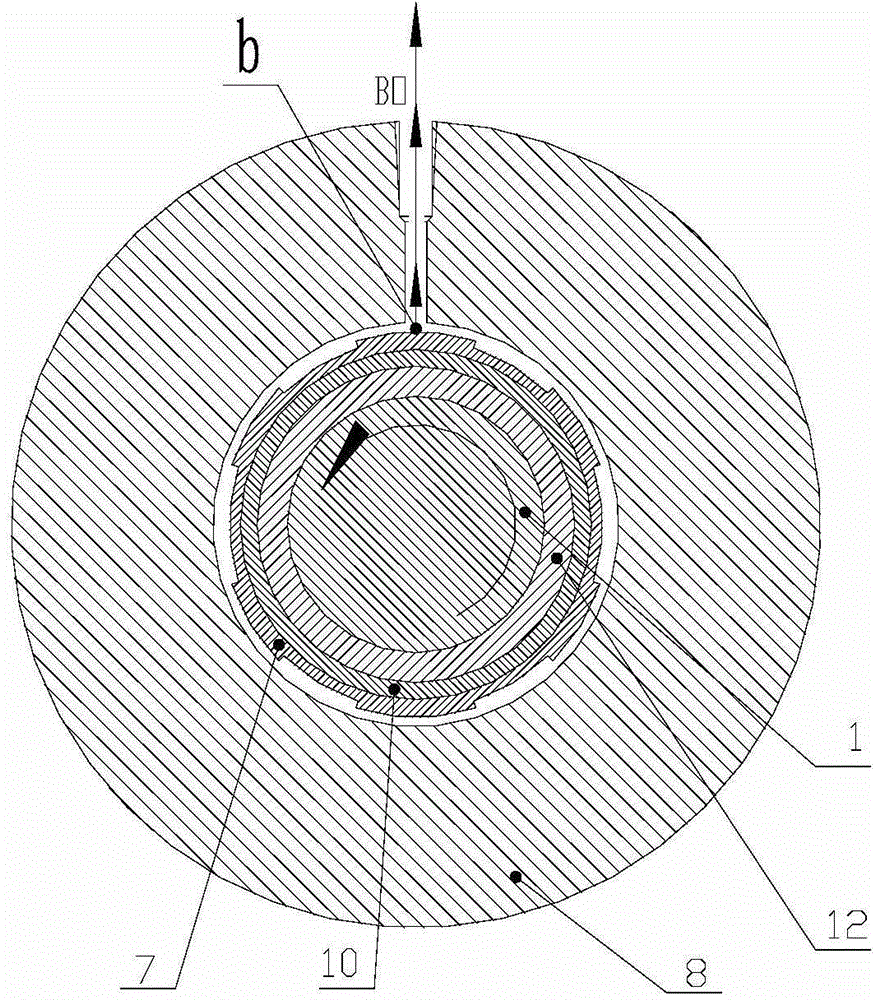

[0099] The closed mechanical seal pump effect ring and the shaft seal flushing system with the pump effect ring of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0100] The closed mechanical seal pump effect ring and the shaft seal flushing system with the pump effect ring of the present invention are firstly a pump effect ring with a closed channel and can provide reliable and stable head and flow rate fluid, and the pump effect ring can not only provide stable acceleration for the fluid , and increase the acceleration distance of the liquid, and make the directionality of the fluid flow velocity strong to reduce useless work. It can not only allow most of the liquid in the sealed cavity to participate in the flow, but also lengthen the fluid flow path and increase the flow area. In API682, the shaft seal system standard for pumps, 2CW-CW cartridge double-contact wet seal with buffer fluid and 3CW-FB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com