An internal fuse making machine

A technology for making machines and internal fuses, applied in fuse manufacturing and other directions, can solve the problems of inability to adjust the length of the three-strand twisted part, poor equipment versatility, and low production efficiency, and achieve good consistency of fusing characteristics, stable acceleration, and improved The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

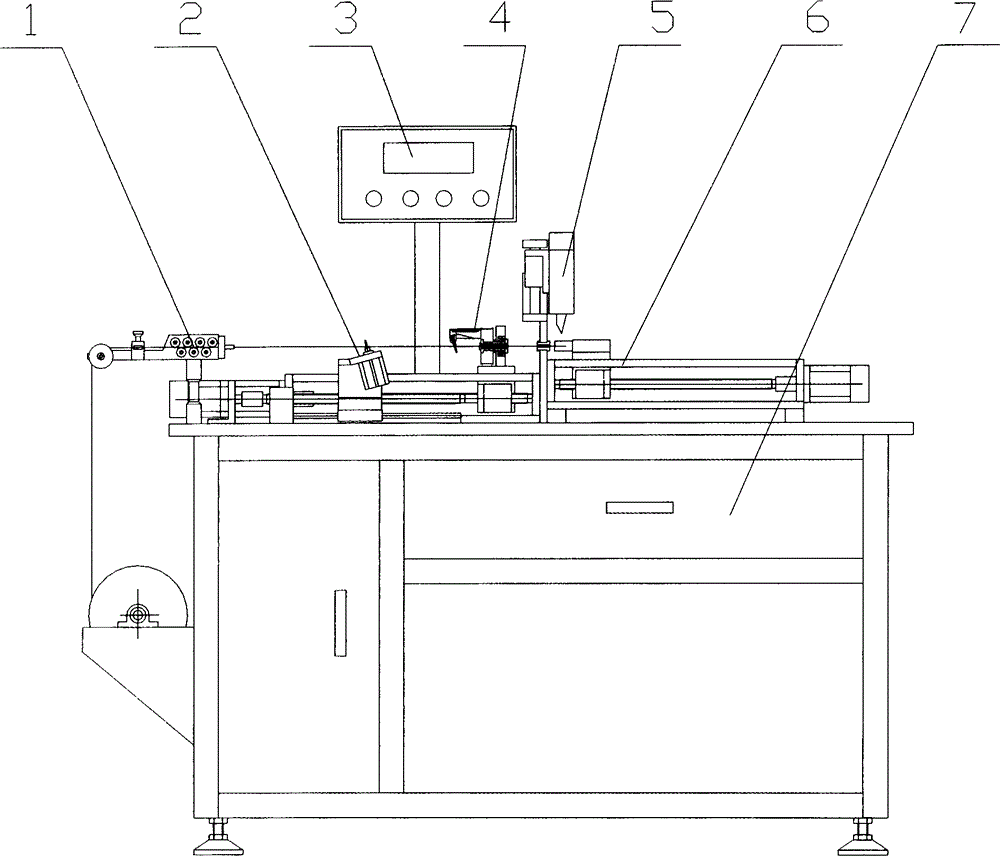

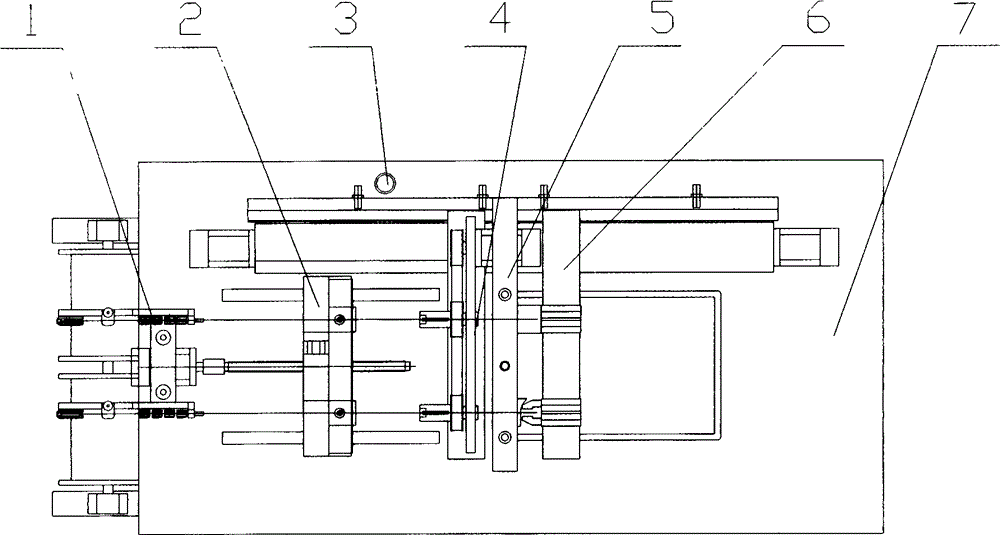

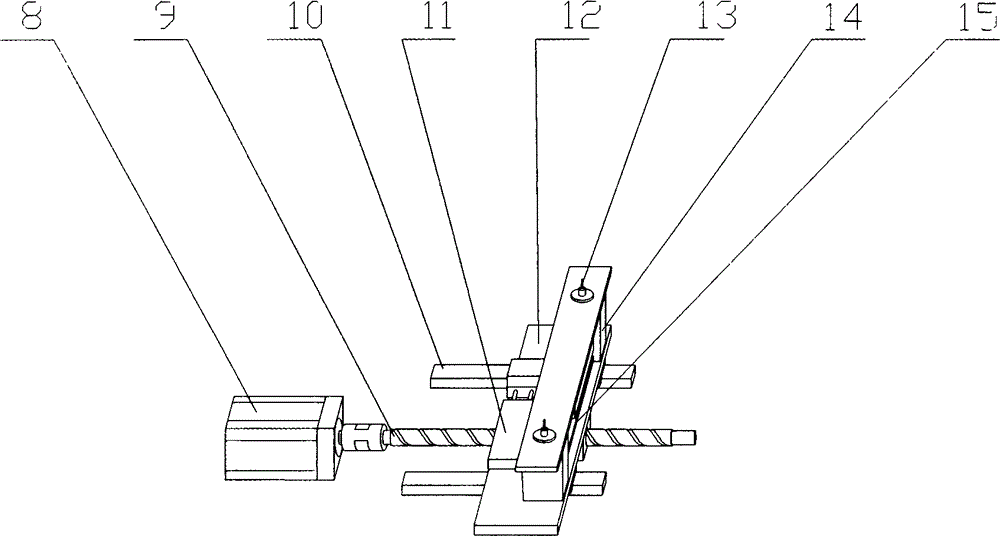

[0041] like Figure 1 ~ Figure 2Shown: a kind of internal fuse making machine, including frame 7 and control system 3, on the top surface of frame 7 from left to right, there are straightening mechanism 1 for straightening alloy copper bare wire, for A coil forming mechanism 2 for winding the wire into a loop, a twisting mechanism 4 for twisting the wire, a cutting mechanism 5 for cutting the prepared fuse and a wire outlet mechanism 6 for pulling out the fuse; The fixed winding needle 13 in the straightening mechanism 1, the knitting mechanism 2, the winding wheel 21 in the winding mechanism 4, the winding arm 19, the movable winding needle 20, the pneumatic scissors 23 of 5 in the cutting mechanism, and the silk The pneumatic finger clips 24 in the mechanism 6 can be arranged in multiple sets in parallel.

[0042] Among them, the loop forming mechanism and twisting mechanism can realize four functions of automatic adjustment of loop length, loop winding, twisting, and needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com