Work piece press fitting mechanism

A press-fit and workpiece technology, applied in the field of special equipment, can solve the problems of slow assembly speed, low efficiency, operator injury, etc., and achieve the effect of fast operation speed, simple press-fit operation process, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

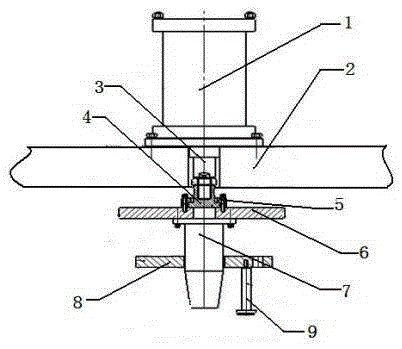

[0013] This embodiment provides a workpiece press-fit mechanism, characterized in that: the workpiece press-fit mechanism includes a drive cylinder (1), a beam (2), a telescopic cylinder (3), a connector (4), and a fixing bolt (5) , Indenter mounting plate (6), indenter (7), limit plate (8), limit rod (9);

[0014] Among them: the drive cylinder (1) is fixed on the beam (2) of the fuselage frame, and the telescopic cylinder (3) of the drive cylinder (1) is connected to the connector (4) through the beam (2) and connected to the press by the fixing bolt (5). The head mounting plate (6) is fixedly connected to the pressure head (7) on the mounting plate (6), and the front end of the pressure head (7) is installed with a limit rod (9) through a limit plate (8).

[0015] The lowest end of the limiting rod (9) is lower than the lowest end of the pressure head (7), no more than two centimeters.

[0016] The drive cylinder (1) is a hydraulic cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com