Deep scarification combined land preparation machine and operation method

A land preparation machine and subsoiling technology, applied in agriculture, agricultural machinery, adjustment devices, etc., can solve the problems of cumbersome adjustment operations, etc., and achieve the effects of reducing fuel consumption, sufficient power, and reducing lateral traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

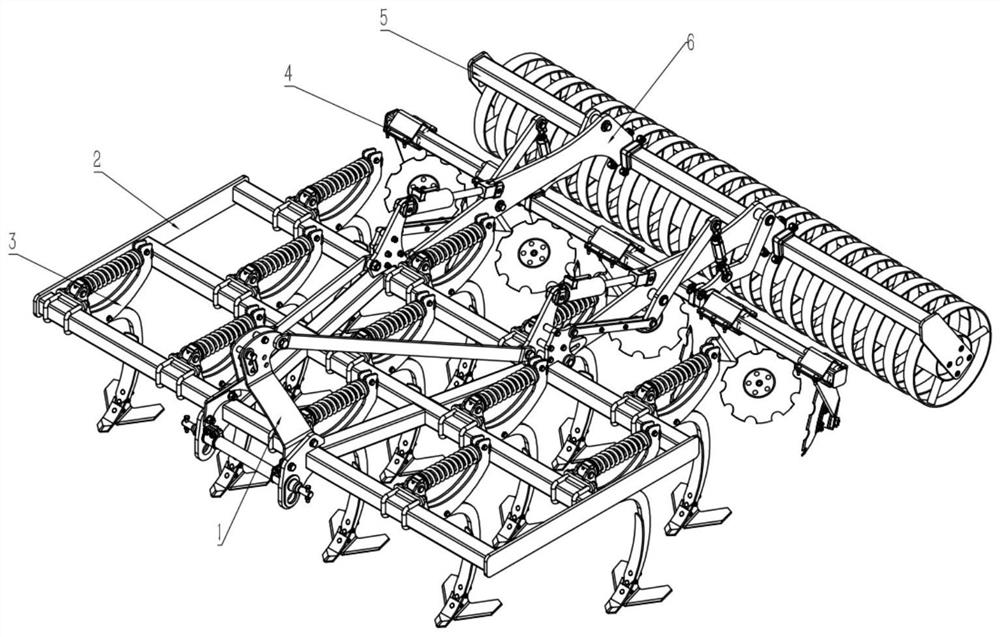

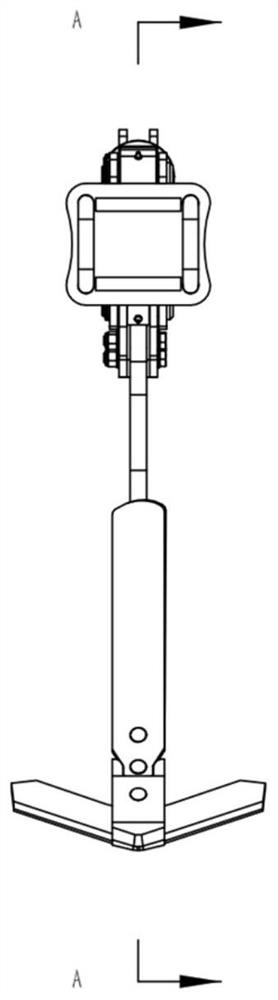

[0029] refer to figure 1 , to further illustrate the subsoiling combined soil preparation machine of the present invention, a subsoiling combined soil preparation machine includes a traction frame 1, a rack beam 2, a subsoiling tooth assembly 3, a rake group 4 and a pressure roller 5, and the traction The rack 1 is connected to the rack beam 2, the deep loose tooth assembly 3 is suspended on the lower end of the rack beam 2, the rake group 4 includes a rake group beam and rake blades, and the pressing roller 5 includes a pressing roller beam and the pressure roller suspended at the lower end of the pressure roller beam, the rake group 4 is located at the front end of the pressure roller 5, and the rake group beam and the pressure roller beam pass through the same depth-limiting leveling mechanism 6 and the rack Beam 2 connection.

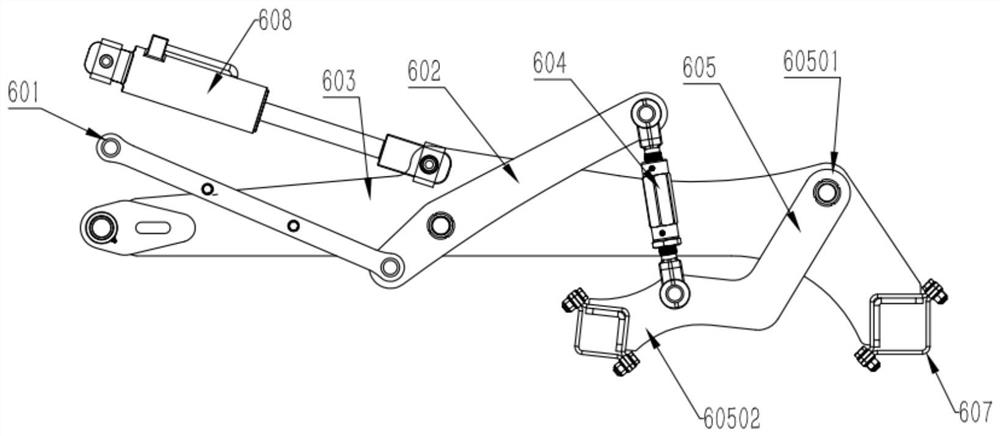

[0030] refer to figure 1 and figure 2 , to further illustrate the depth-limiting leveling mechanism of the present invention, the depth-limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com