Tobacco bundle untying device

A technology of parallel installation of cigarette handles, which is applied in the field of cigarette handle release devices, and can solve problems such as long process lines, heavy devices, and low efficiency of release handles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

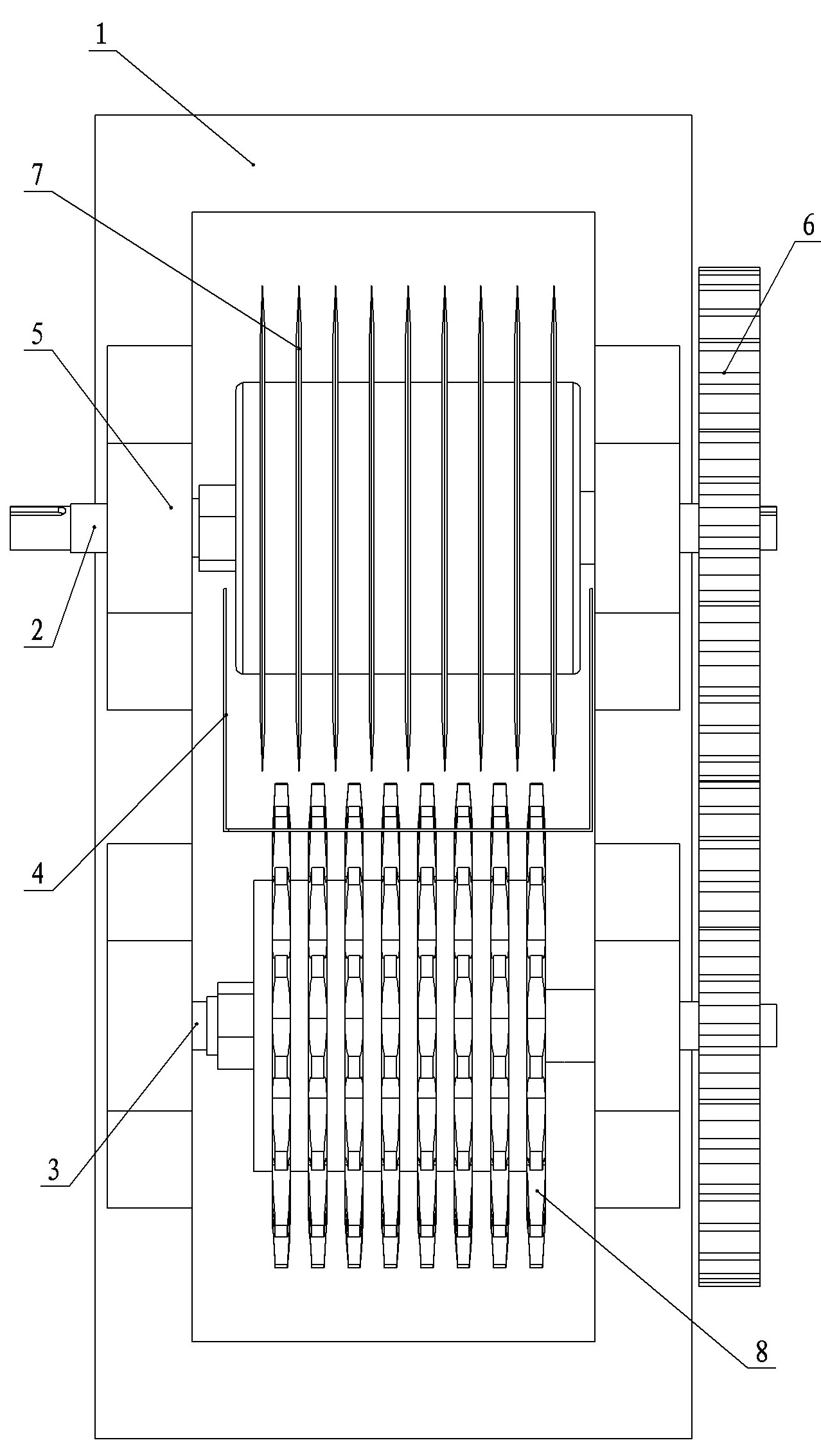

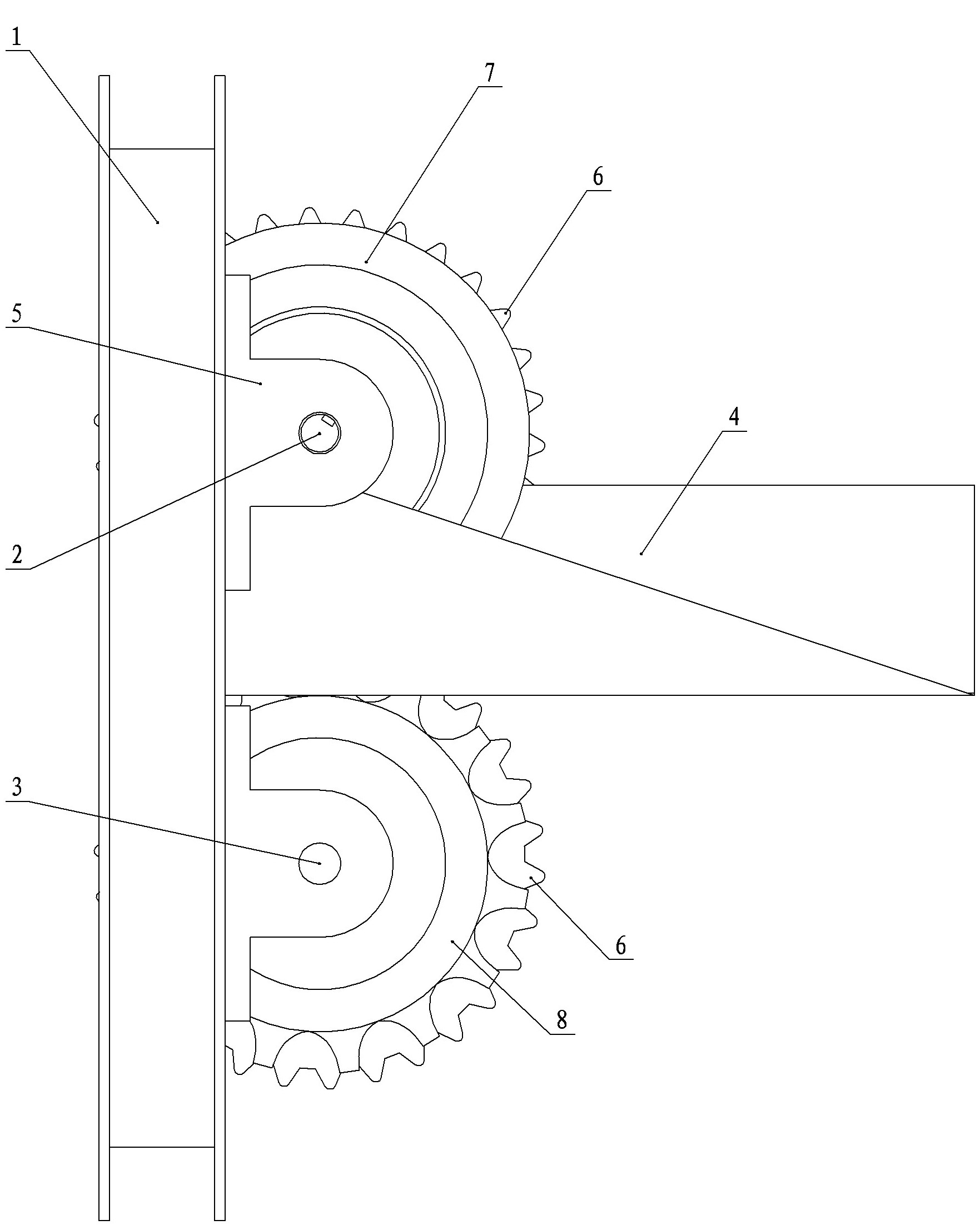

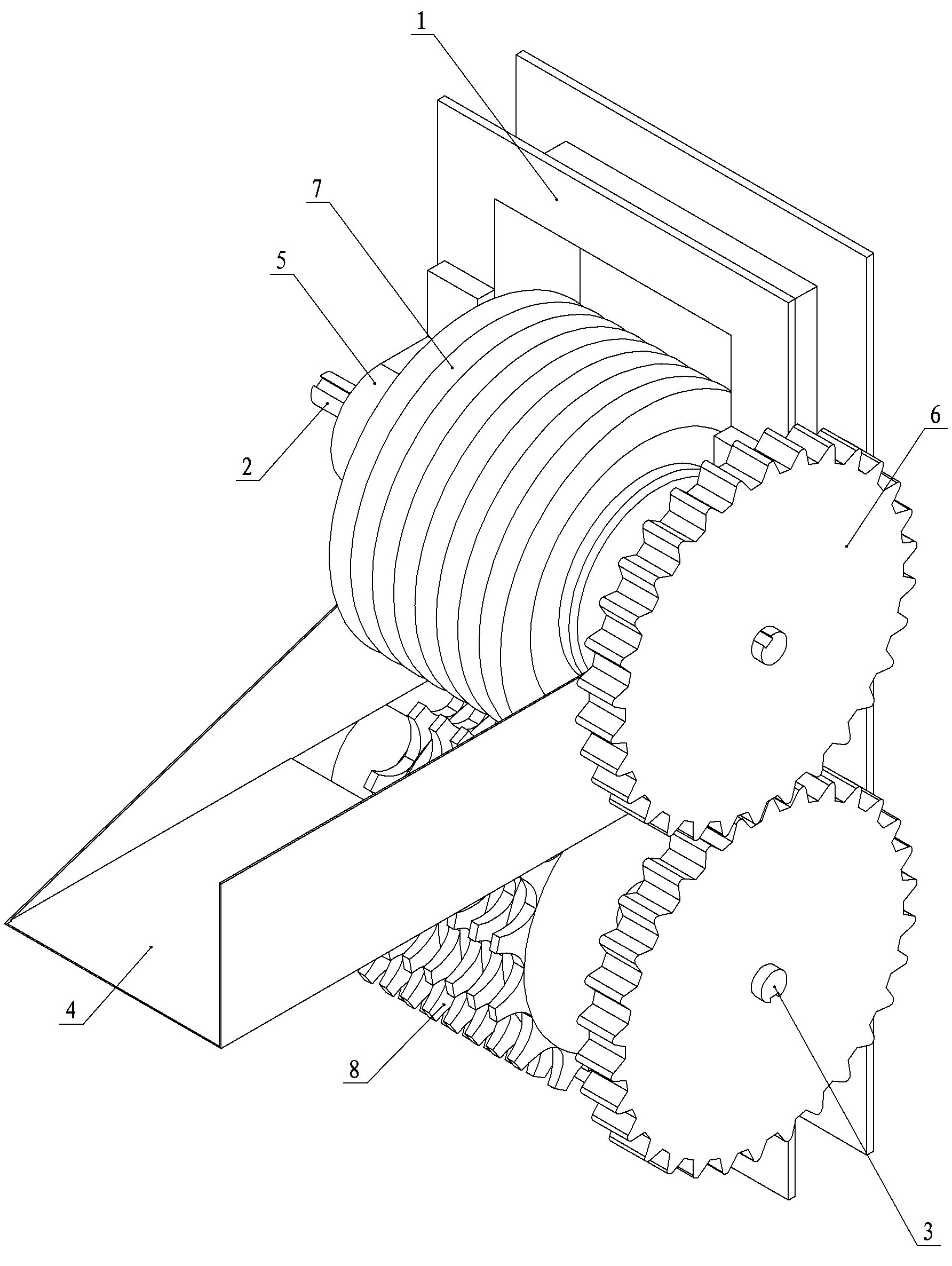

[0014] Example: see Figure 1-Figure 3 In the figure, a device for untying a cigarette handle includes a lower hopper, a frame body, a cutterhead shaft and a gear shaft installed in parallel on the frame body, and several cutterheads are stacked on the cutterhead shaft. Several toothed discs are stacked on the gear shaft, and there is a certain distance between adjacent cutter discs, and there is also a certain distance between adjacent toothed discs. The said cutter discs and the toothed discs are arranged alternately. The ends of the disc shaft and the gear shaft are equipped with mutually meshing gears, and the lower hopper is installed on the frame body, and the bottom of the lower hopper is facing between the cutter head and the toothed disc. Gaskets are arranged between the several cutter heads, and gaskets are also arranged between the several toothed disks. Both the cutter head shaft and the gear shaft are installed on the frame body through the bearing box. The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com