Automatic selection feeding system of injection molding machine for automotive interior trim parts and control system thereof

A technology for auto interior parts and automatic selection, which is applied in the field of automatic selection and feeding system of injection molding machines and its control system, can solve the problems of no specific disclosure of PLC control system, product scrapping, and no automatic selection of feeding materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

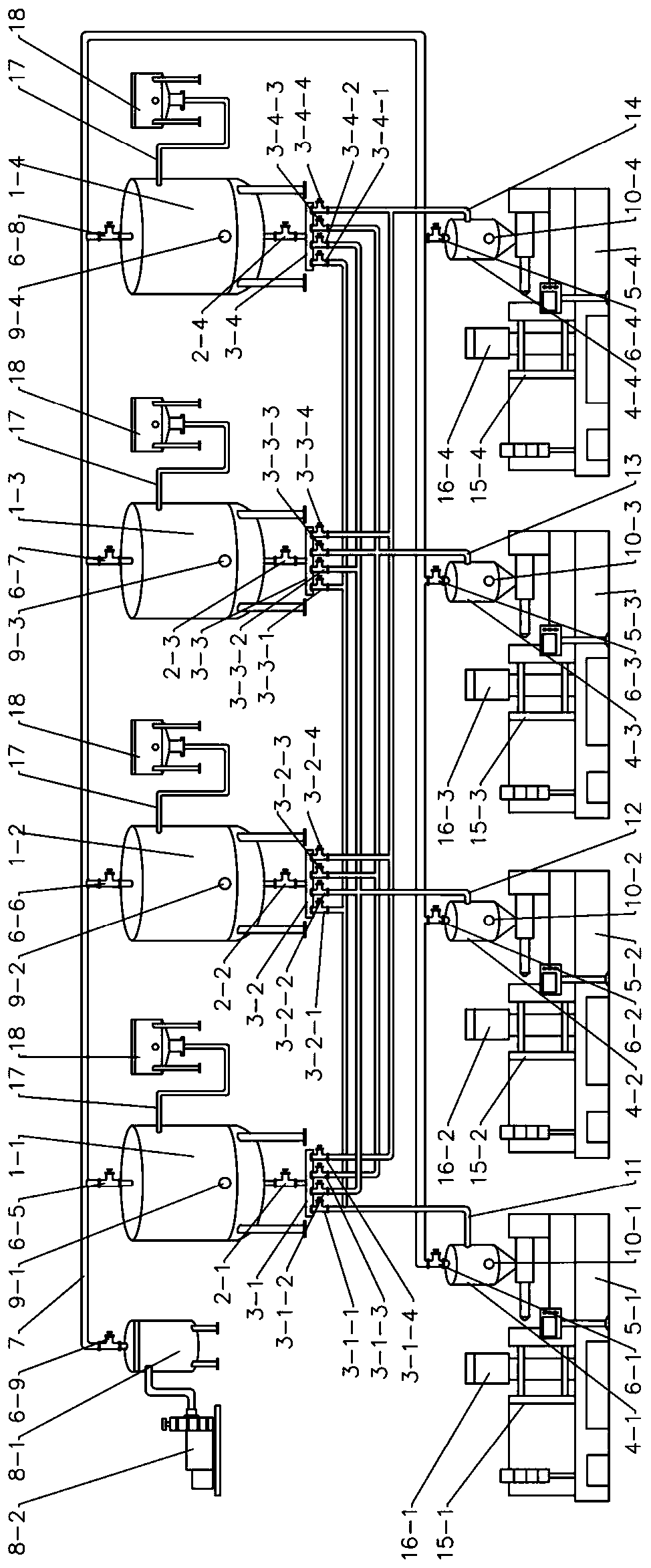

[0139] Such as figure 1Shown, the present invention is used for the automatic selection feeding system of the injection molding machine of automotive interior parts and comprises the first drying material tank 1-1, the second drying material tank 1-2, the 3rd drying material tank 1-3 and the 4th drying material tank. Material tank 1-4, a first drying material tank feed valve 2-1 is installed at the bottom of the first drying material tank 1-1, and a second drying material tank 1-2 is installed at the bottom of the second drying material tank 1-2. Drying material tank feed valve 2-2, a third drying material tank feeding valve 2-3 is installed at the bottom of the third drying material tank 1-3, and a third drying material tank feeding valve 2-3 is installed at the bottom of the fourth drying material tank 1-4. The fourth dry material tank feed valve 2-4 is installed, and the first dry material tank feed valve 3-1 is connected to the lower end of the first dry material tank feed...

specific Embodiment approach 2

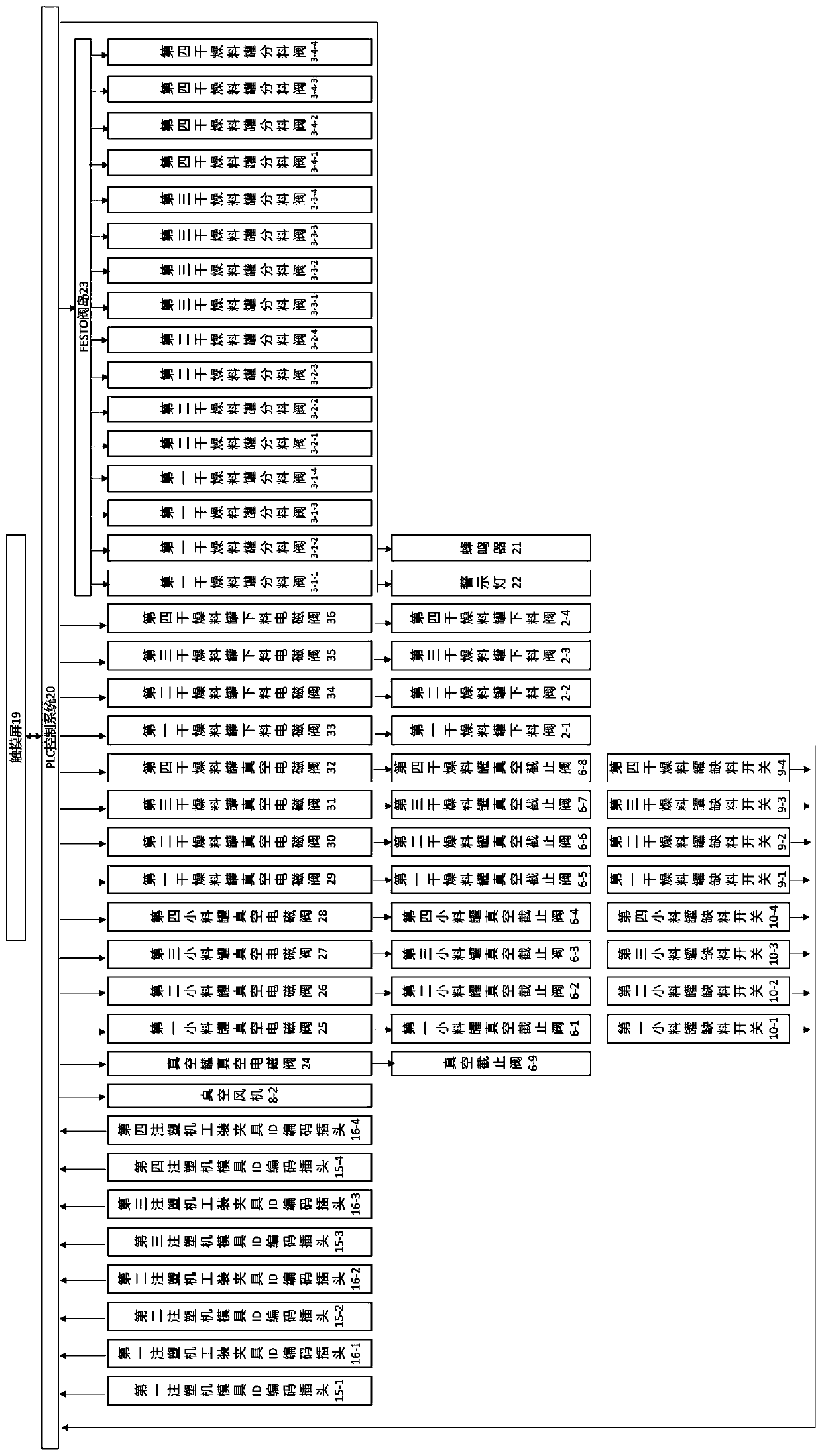

[0145] Such as figure 2 As shown, the present invention is used for the control system of the automatic selection feeding system of the injection molding machine of automobile interior parts comprising PLC control system 20, the touch screen 19 that is bidirectionally connected with PLC control system 20, the vacuum tank vacuum electromagnetic that is connected with PLC control system 20 Valve 24, the first small material tank vacuum solenoid valve 25, the second small material tank vacuum solenoid valve 26, the third small material tank vacuum solenoid valve 27, the fourth small material tank vacuum solenoid valve 28, the first drying material tank vacuum solenoid valve Valve 29, second drying material tank vacuum solenoid valve 30, third drying material tank vacuum solenoid valve 31, fourth drying material tank vacuum solenoid valve 32, first drying material tank discharge solenoid valve 33, second drying material tank bottom Material electromagnetic valve 34, the third dry...

specific Embodiment approach 3

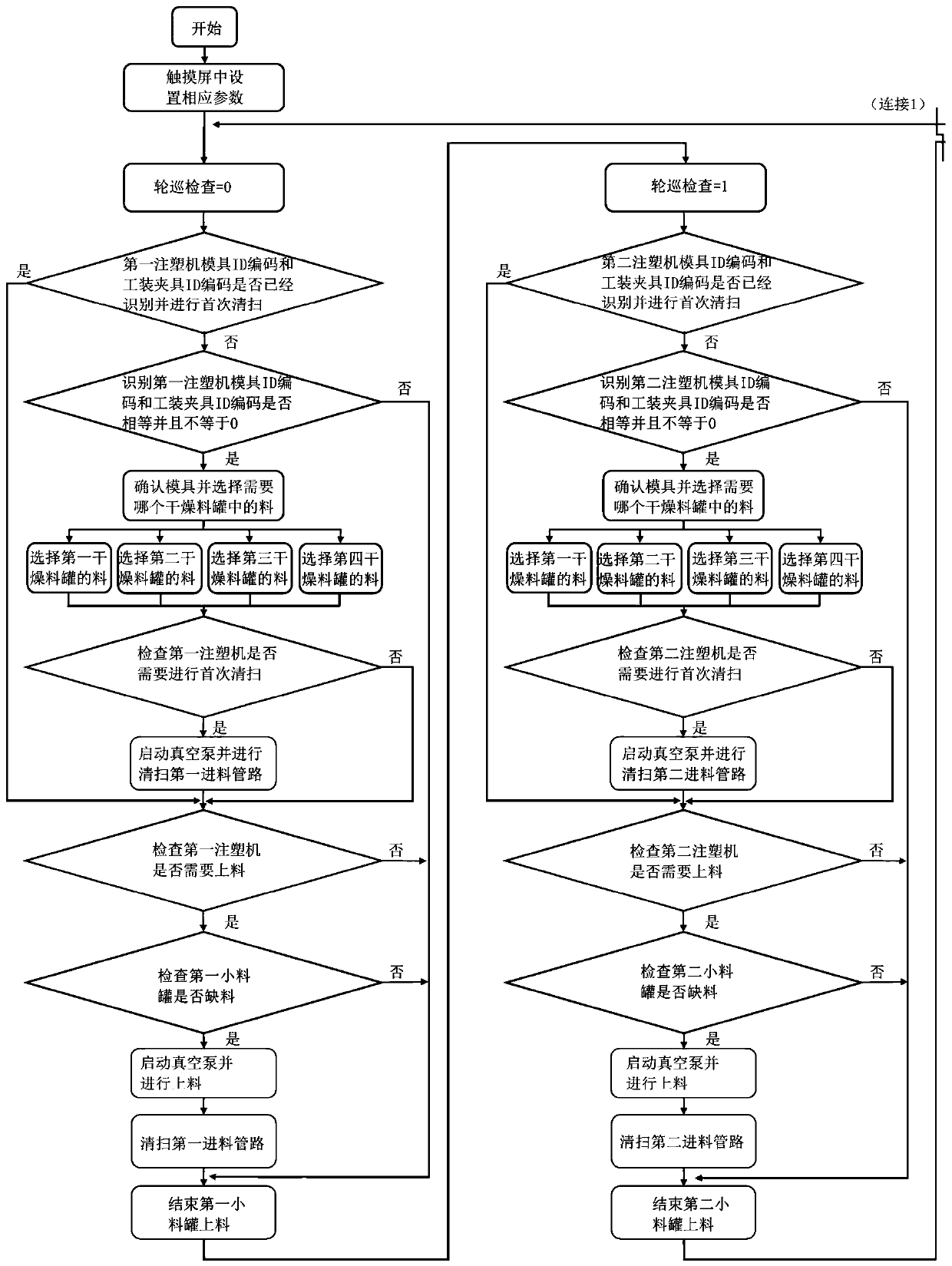

[0149] The present invention is used for the operation process of the control system of the injection molding machine automatic selection feeding system of automobile interior parts as follows image 3 The steps shown are carried out, the image 3 Consists of 4 pages of interconnected drawings:

[0150] When the operation starts, set the corresponding control parameters for the PLC control system on the touch screen, and then start the patrol inspection from 0 to 7,

[0151] When the patrol inspection is equal to 0, check whether the mold ID code of the first injection molding machine and the fixture ID code of the first injection molding machine have been identified and perform the first cleaning;

[0152] When checking whether the mold ID code of the first injection molding machine and the ID code of the fixture of the first injection molding machine have been identified and the first cleaning is performed, if the mold ID code of the first injection molding machine and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com