Patents

Literature

43results about How to "Shattered fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crusher

InactiveCN102941143AReduce power consumptionSmall particlesFeeding-stuffGrain treatmentsPulverizerEngineering

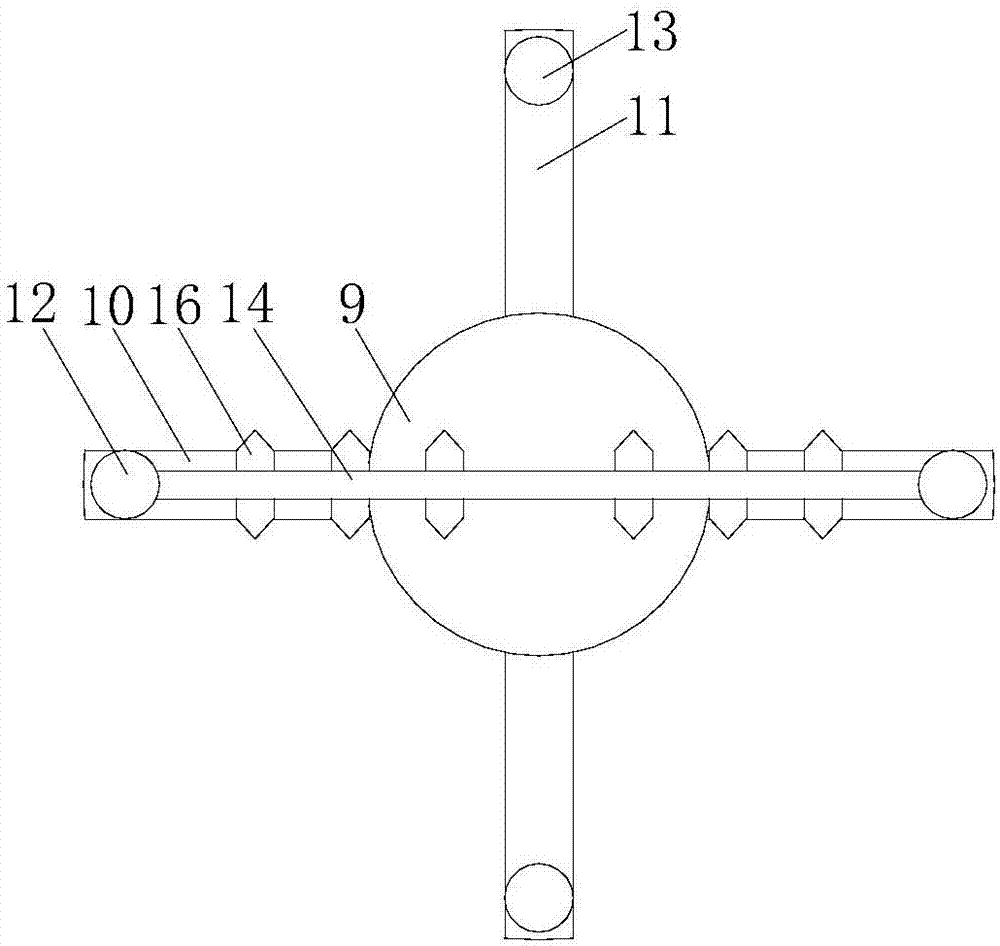

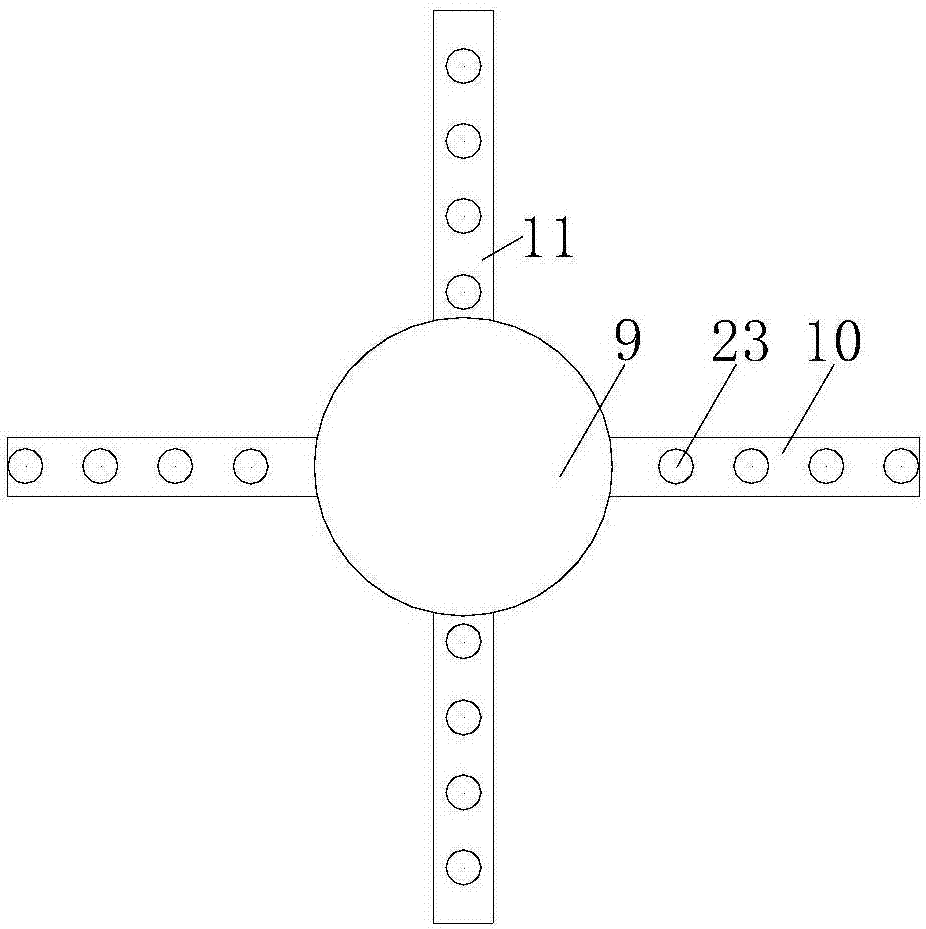

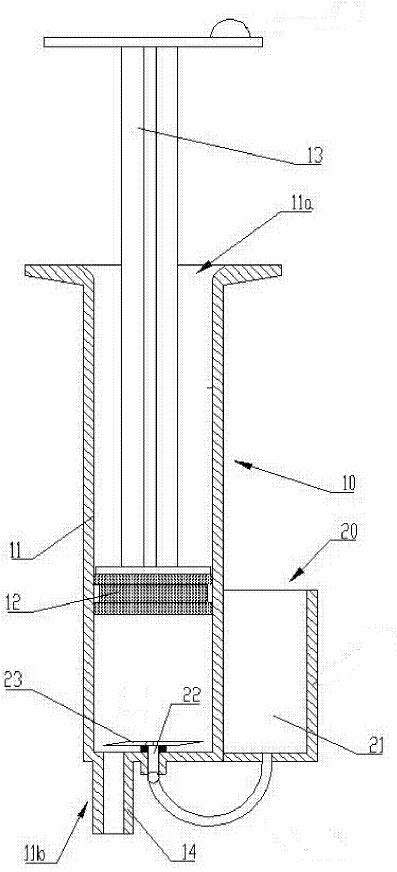

The present invention provides a crusher, which comprises a cabinet, a base, a motor and a main shaft, wherein the cabinet and the motor are fixedly arranged on the base, the main shaft penetrates through the cabinet, a roller and a fixed cutter are arranged inside the cabinet, the roller comprises end covers, a hanging rod and hammer sheets, the number of the end covers is two, the two end covers are fixed on the main shaft, the hanging rod is arranged between the two end covers, both ends of the hanging rod are fixedly connected to the end covers, the hanging rod is provided with a plurality of the hammer sheets, one end of the hammer sheet is rotatably connected with the hanging rod, the fixed cutter is fixed on a fixed cutter shaft inside the cabinet, is arranged just below the roller, and is staggedly matched with the hammer sheet on the bottom of the roller, one side of the cabinet is provided with an air inlet, and the air inlet is communicated with the cabinet. The present invention provides a crusher with characteristics of small crushed particles, low power consumption, simple structure and high efficiency.

Owner:溧阳市正申饲料机械厂

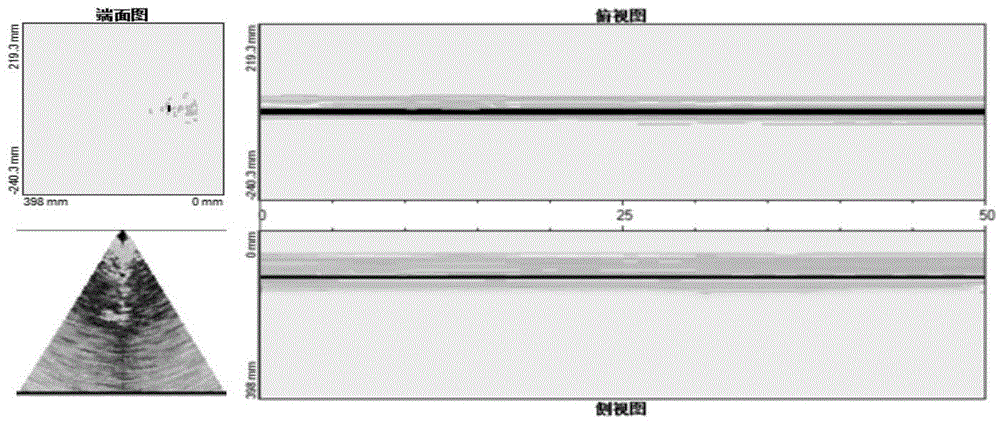

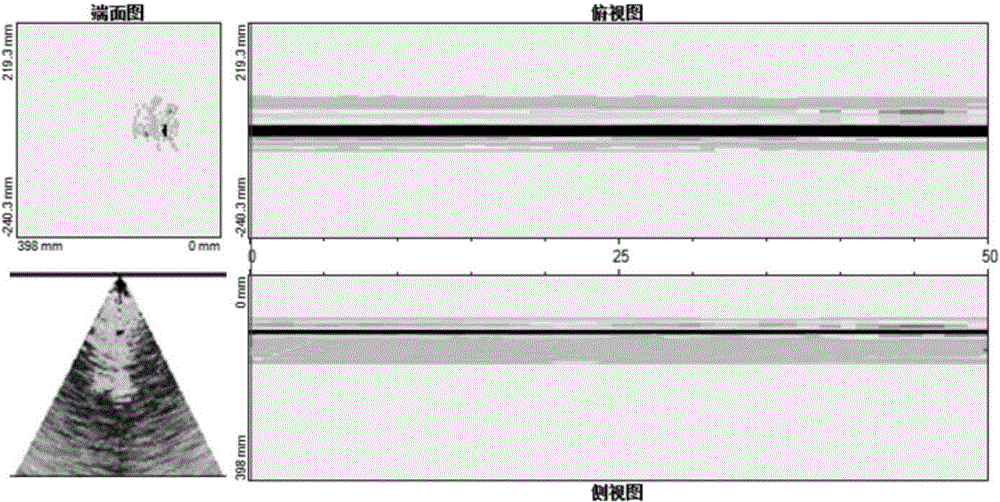

Ultrasonic flaw detection grading method for internal defects of steel ingot

InactiveCN104807884AEasy to operateHelp to chooseAnalysing solids using sonic/ultrasonic/infrasonic wavesOperabilityIngot

The invention discloses an ultrasonic flaw detection grading method for internal defects of a steel ingot. Flaw detection is carried out on the steel ingot from one end of the steel ingot to the other end of the steel ingot at an S interval, the operability is high, research is performed in the combination of actual flow detection conditions, and the flaw detection conditions of the steel ingot are divided into five grades from 0 to 4, so that the internal defects of the steel ingot are classified more comprehensively, accurately and visually, and a favorable judgment basis is provided for final judgment of defect grading management. The flaw detection grades corresponding to the defects can be obtained, and then the grade and shape characteristics of the defects are obtained. An accurate forecasting basis is provided for the quality evaluation of the steel ingot, the processing card design of forging, the mechanical property of the product and the like, and effective quality guarantee are also provided for how to eliminate an all-purpose forging processing card in the subsequent forging process. The steel ingot is taken as a raw material for forging, defects are accurately detected at an as-cast condition, reasonable selection of forging technology is facilitated, as-cast crystal particles are sufficiently smashed, and a condition that a forging piece is free of defect is guaranteed.

Owner:NANJING DEV ADVANCED MFG

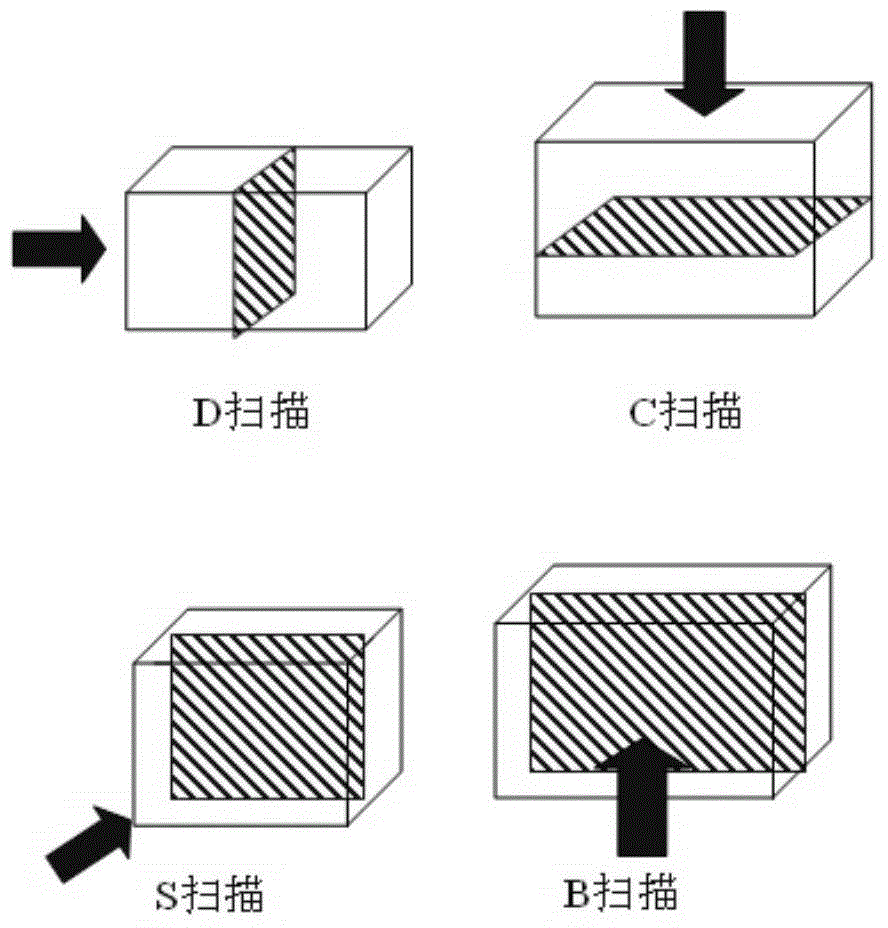

Ultrasonic B+C+D+S scanning identification method of internal defect of steel ingot

ActiveCN104792873AStrong maneuverabilityAccurate description of spectral featuresAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringUltrasound scan

The invention discloses an ultrasonic B+C+D+S scanning identification method of an internal defect of steel ingots. The steel ingots are scanned by utilizing an ultrasonic B scanning method, an ultrasonic C scanning method, an ultrasonic D scanning method and an ultrasonic S scanning method to obtain an ultrasonic B+C+D+S scanning defective map; the maneuverability is high, the map characteristic description is relatively correct, comprehensive, the detection results are intuitionistic and reliable and the defective profile characteristic classification is clear, so that the intuitionistic determination evidence is provided for the final determination of quantification, qualitative property and positioning of the defects. By utilizing an ultrasonic B+C+D+S scanning function, a projection characteristic map of ultrasonic defects of the steel ingots in all directions of a Descartes three-dimensional coordinate can be acquired, so that the relatively-intuitionistic positions and the shape characteristics of the defects can be acquired. The accurate and intuitionistic prediction evidence is provided for quality evaluation of the steel ingots, forging operation card design and mechanical property evaluation of products; the effective quality guarantee is provided for a subsequent forging process and the elimination of universal forging operation cards.

Owner:NANJING DEV ADVANCED MFG

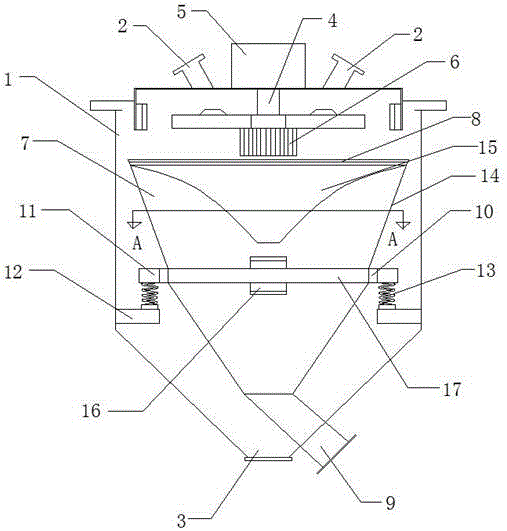

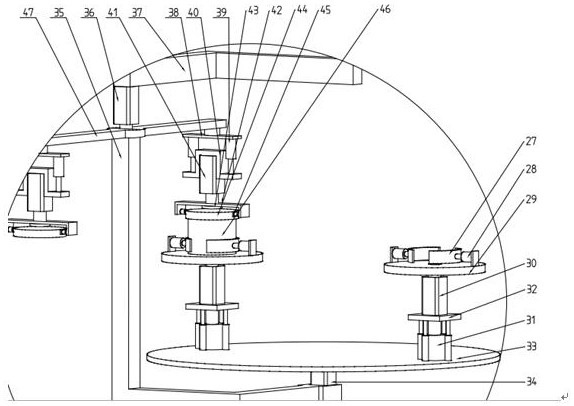

Tapered beater for machine-made sand

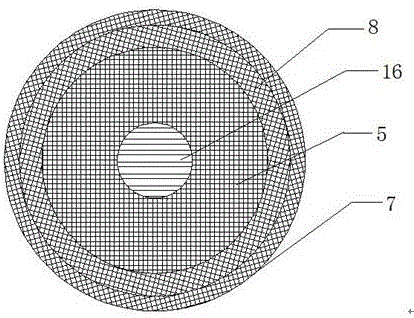

ActiveCN105935621AAvoid deformationGuarantee job stabilitySievingGas current separationImpellerStructural engineering

The invention discloses a tapered beater for machine-made sand. The tapered beater for the machine-made sand comprises feed inlets formed in the upper portion of an outer tapered shell and a fine material port formed in the lower portion of the outer tapered shell. A connecting shaft is arranged on the middle portion of the outer tapered shell. One end of the connecting shaft is in transmission connection with a power unit; and the other end of the connecting shaft is in rotary connection with a wind wheel. The lower end of the wind wheel is provided with a screening unit; a feed port is formed in the upper portion of the screening unit; and a coarse material port is formed in the lower portion of the screening unit. A tight tensioning sleeve is arranged on the side face of the screening unit; and a pair of lug parts is symmetrically arranged on the tight tensioning sleeve. A supporting part is arranged on the inner wall of the outer tapered shell. The lug parts and the supporting part are connected in a matched mode through a pressure ring. By modifying the structure of the screening unit, the screening unit can elastically move up and down to absorb impact force of materials; the screening unit is prevented from deforming and blocking of sieve holes by the materials is prevented; the work stability of the screening unit is guaranteed; complete separation of fine materials and coarse materials is achieved; at the same time, a rotary impeller is arranged so that the materials are smashed more sufficiently, and the beating efficiency of the beater is improved.

Owner:国家电投集团江西中业兴达电力实业有限公司

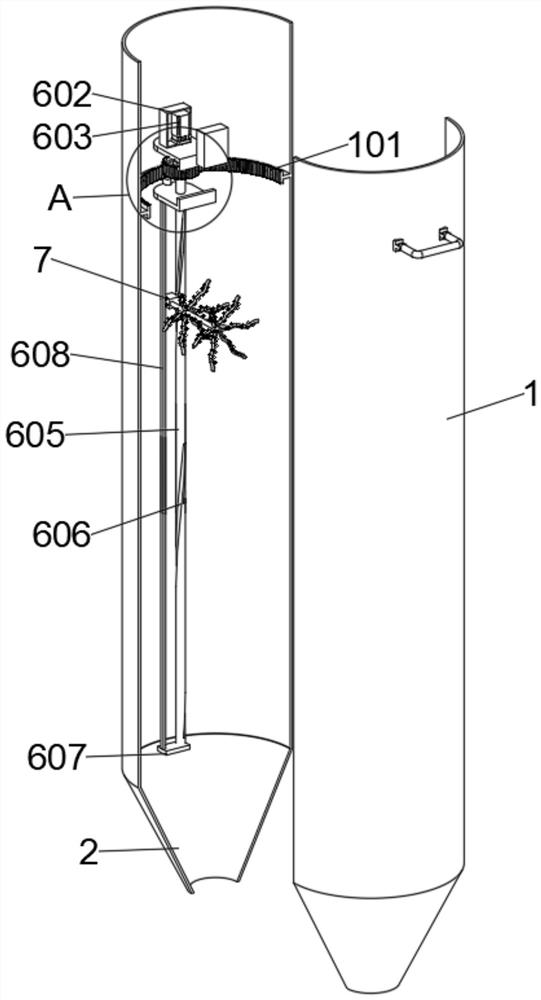

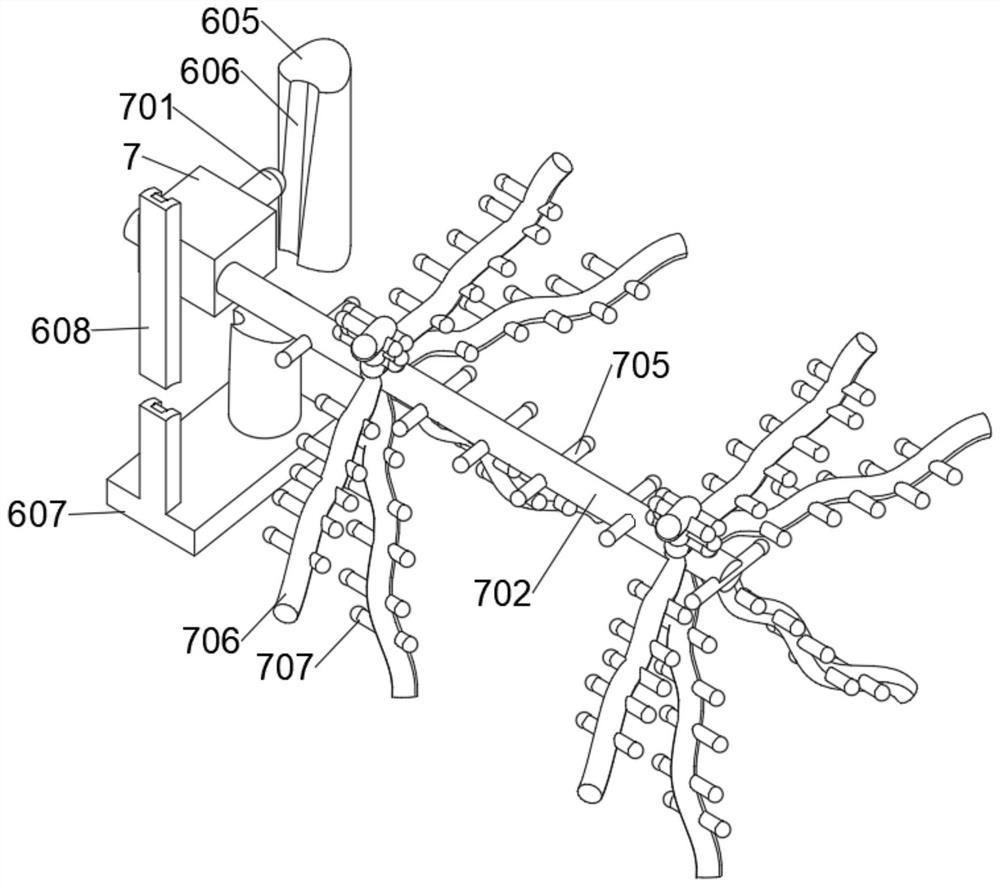

Meat and pearl separation equipment

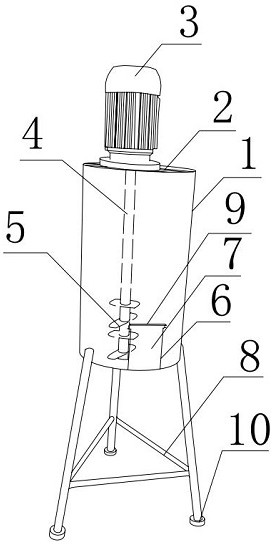

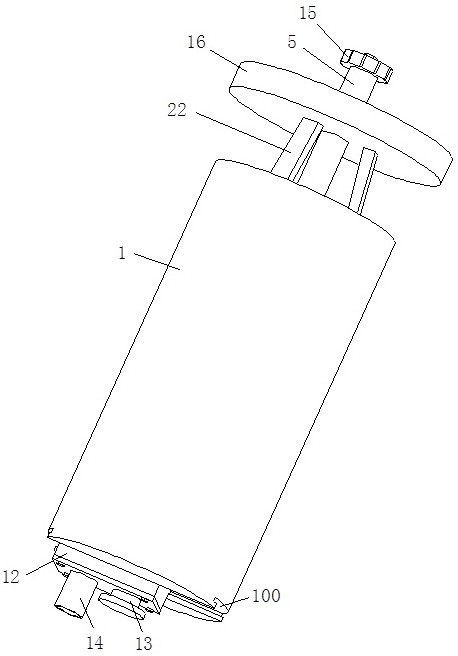

PendingCN112535130AEasy to put inEfficient separationClimate change adaptationPisciculture and aquariaAnimal scienceElectric machine

The invention discloses meat and pearl separation equipment which comprises a barrel body used for loading pearl oyster meat. A fixing rod is transversely arranged in the middle of a barrel opening ofthe barrel body, a motor is arranged on the fixing rod, the motor is arranged at the left side of the fixing rod, and a space at the right side is reserved, so that a large amount of pearl oyster meat is conveniently put in; the motor is connected with a power supply through a power line, a rotating shaft of the motor aligns to the bottom of the barrel body and is connected with a transmission rod, a stirrer is arranged outside the bottom of the transmission rod, the motor is started to drive the transmission rod to rotate, and the pearl shell meat is smashed through the stirrer; the side surface of the barrel body is provided with a discharge port for discharging pearl mother liquor and pearls, and the discharge port is provided with a gate for controlling opening and closing; and a support frame is arranged at the bottom of the barrel body. The meat and pearl separation equipment has the characteristics of efficient separation of a large amount of pearl oyster meat and the pearls, small occupied area and convenience in daily use, and reduces the labor investment.

Owner:广东尊鼎珍珠有限公司

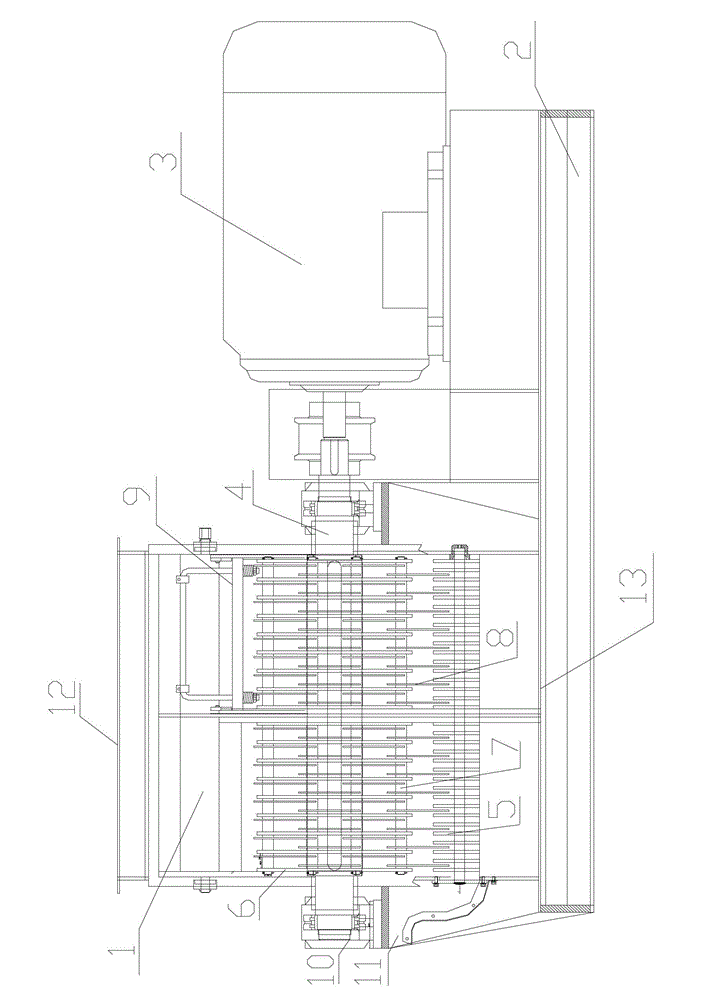

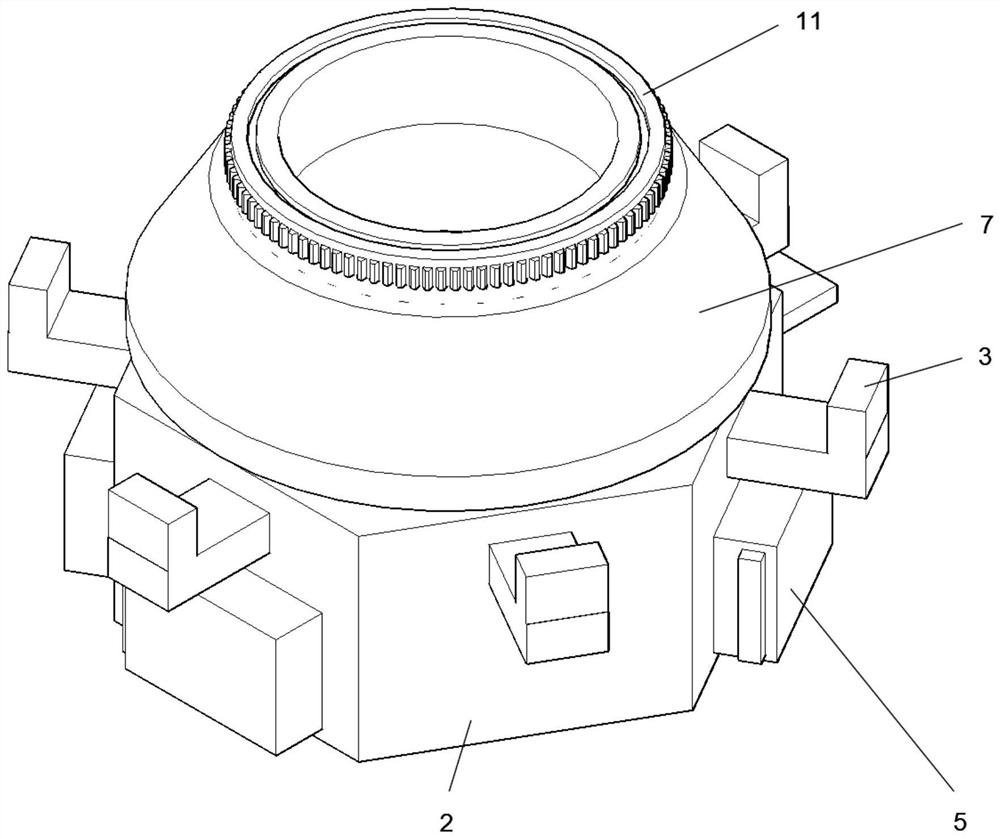

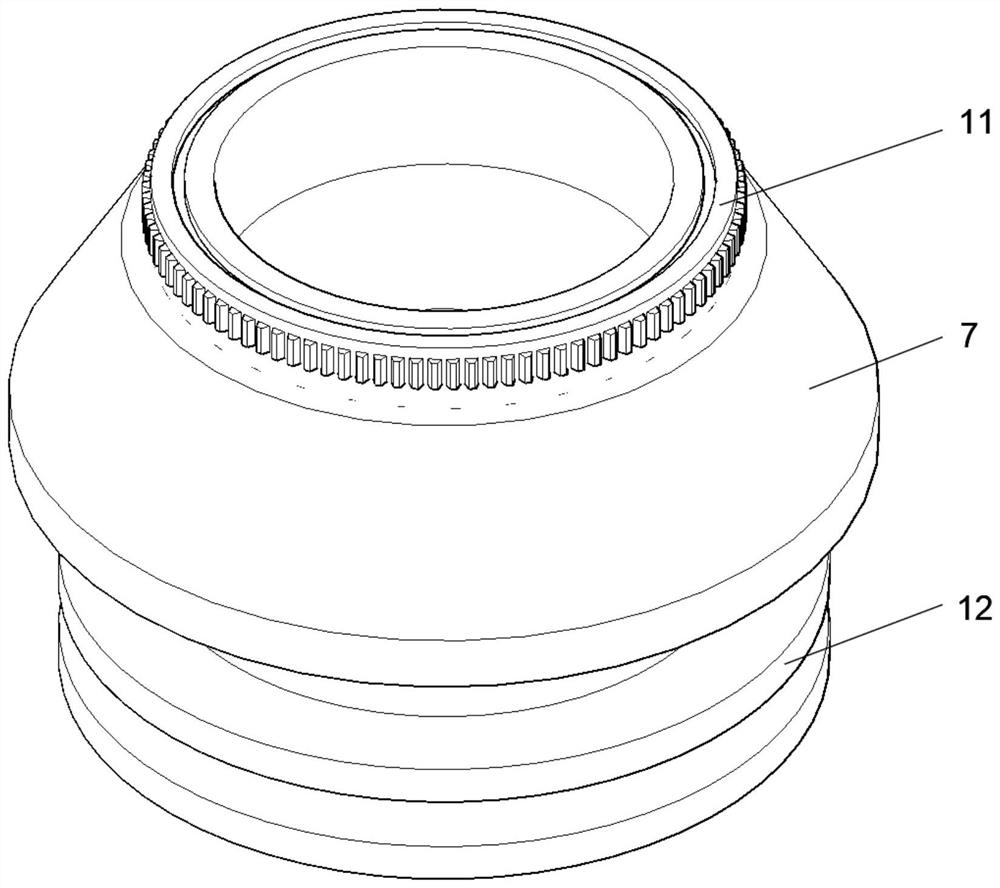

Granulating device for sintered ferrite magnet dry pressing

The invention discloses a granulating device for sintered ferrite magnet dry pressing, belonging to the technical field of granulating devices. The device is characterized by comprising a bench, wherein a granulating cavity is formed on the bench, a stirring mechanism is arranged at the bottom in the granulating cavity and connected with a first drive device; a granulating blade is arranged on the internal wall of the granulating cavity and connected with a second drive device; a granulating outlet is formed on the lower side of the inner wall of the granulating cavity and is provided with a valve; and the valve is provided with an open / close device, and a screening mechanism is communicated with the lower side of the granulating outlet. The invention aims at providing the granulating device with high automatic degree, uniform granulation and high powder screening rate, which is used for powder granulation of sintered ferrite magnet dry pressing.

Owner:MAGNETIC MATERIAL FACTORY MEIZHOU CITY GUANGDONG PROV

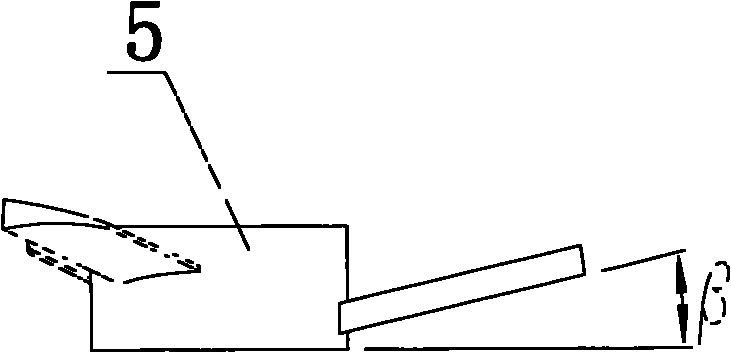

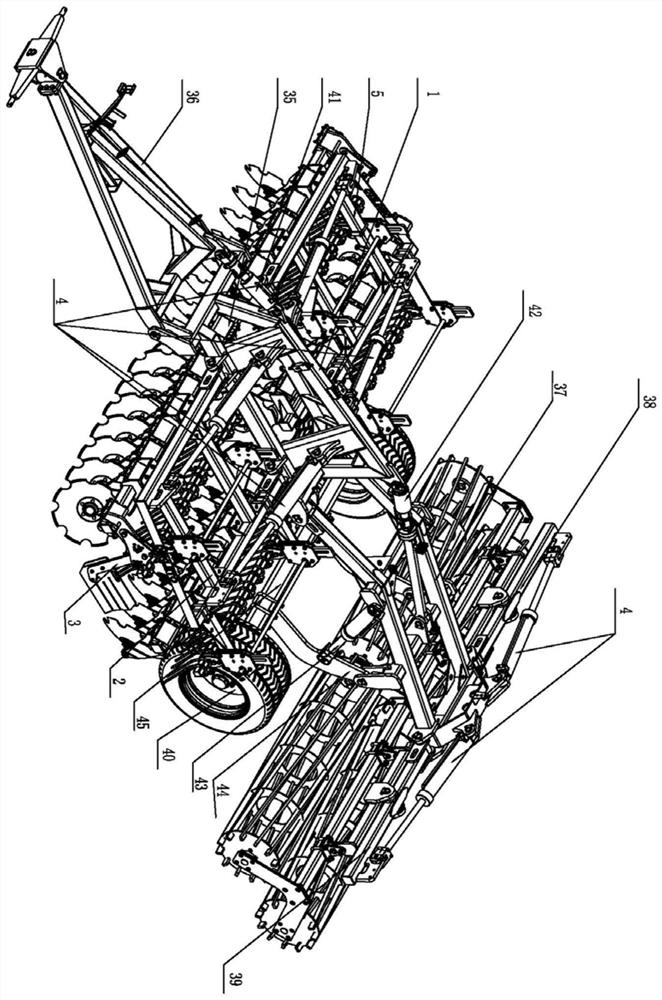

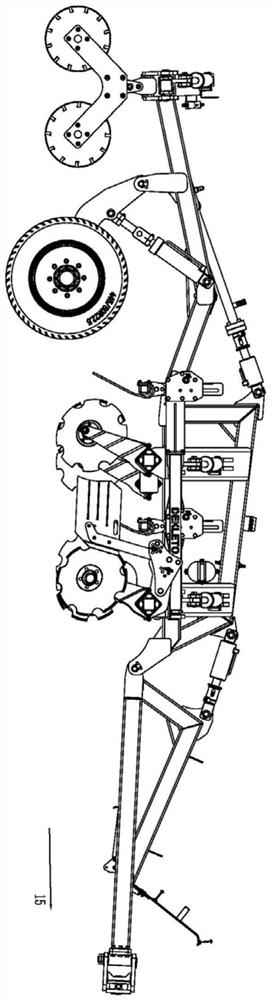

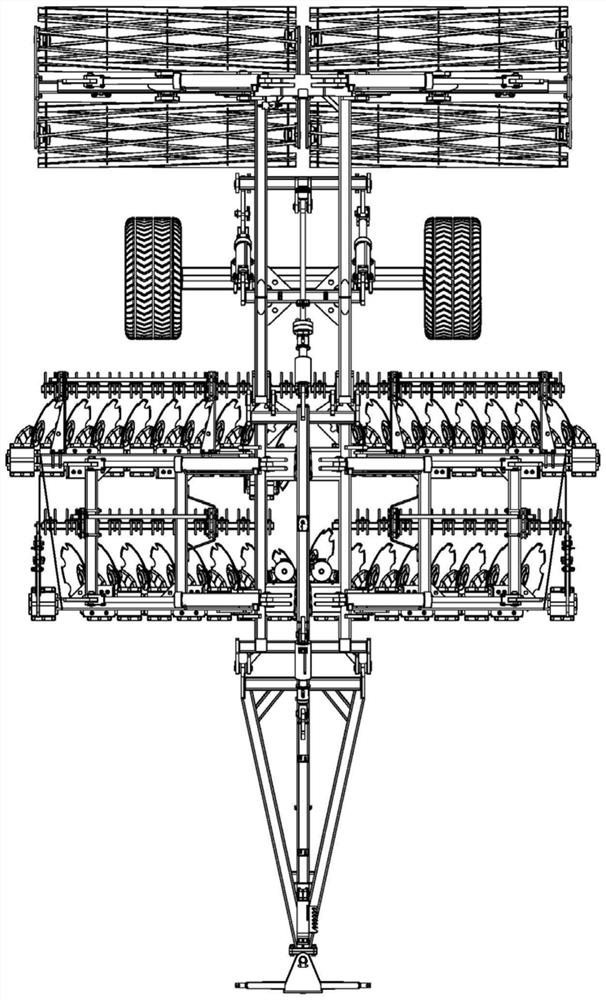

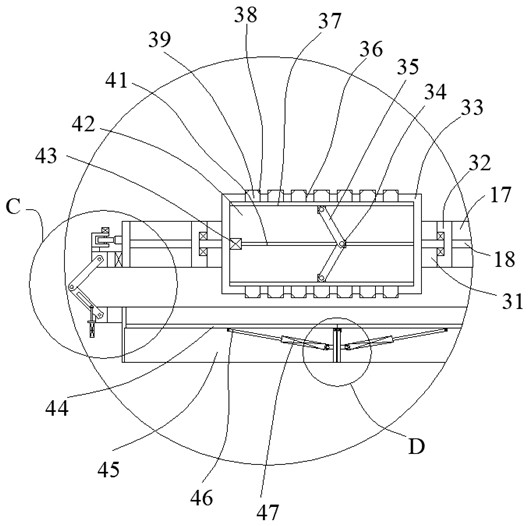

High-speed stubble cleaning harrow

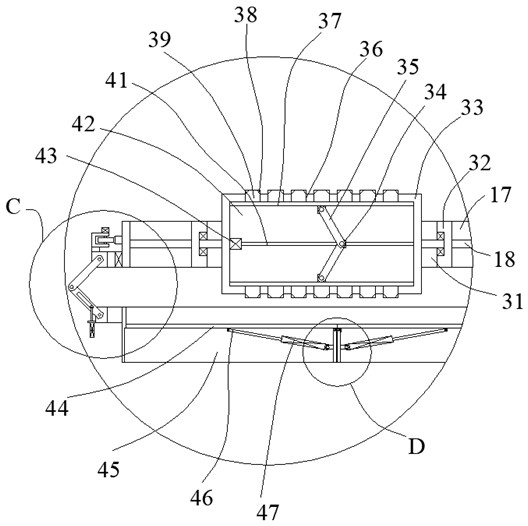

The invention discloses a high-speed stubble cleaning harrow. The high-speed stubble cleaning harrow comprises a main harrow frame assembly, a middle harrow frame assembly, a left folding harrow frameassembly and a right folding harrow frame assembly, wherein the left folding harrow frame assembly and the right folding harrow frame assembly are connected to the left side and the right side of themain harrow frame assembly in a foldable mode, and the rear end of the main harrow frame assembly is movably connected with a rear adjusting tailstock assembly; a left folding press roller assembly and a right folding press roller assembly are connected to the left side and the right side of the rear portion of the rear adjusting tailstock assembly respectively, two walking wheels are connected to the lower end of the rear adjusting tailstock, the two walking wheels are connected through an axle, and the axle is connected with the rear adjusting tailstock through a connecting arm; and the harrow blades on the left-right harrow frame and the front-back harrow frame are symmetrically designed, lateral traction force is avoided, power is exerted more sufficiently, and oil consumption is reduced.

Owner:宜兴博登泰科工业装备有限公司

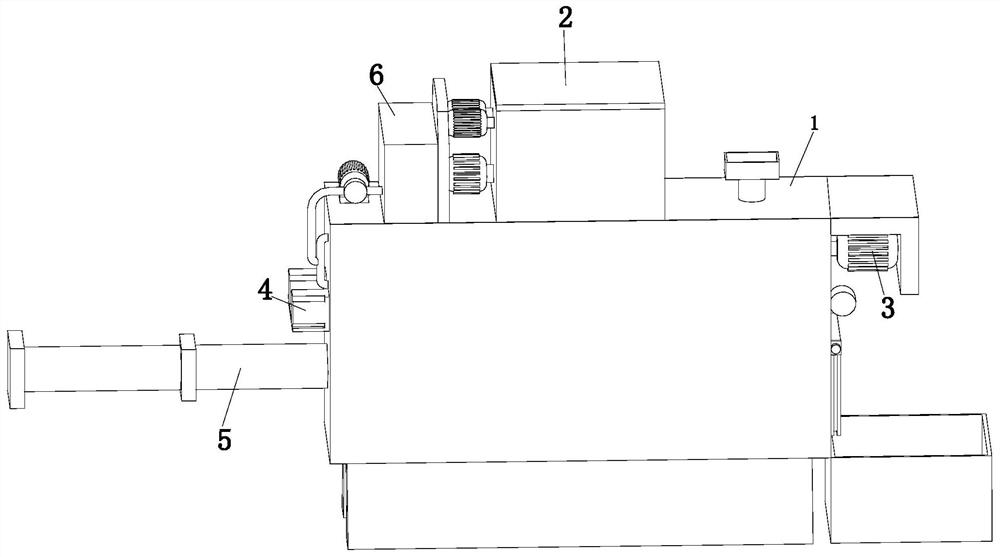

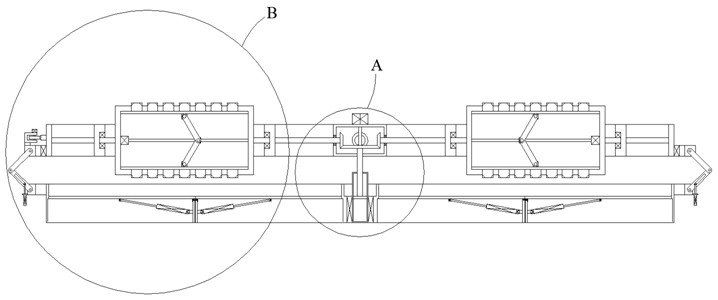

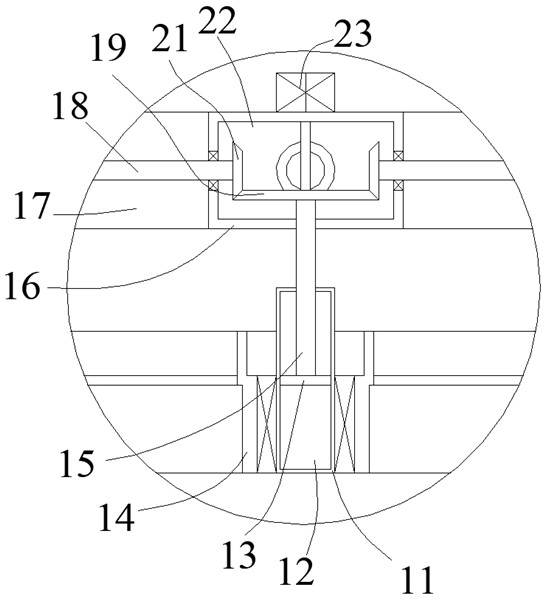

Collagen raw material extruding and stirring device

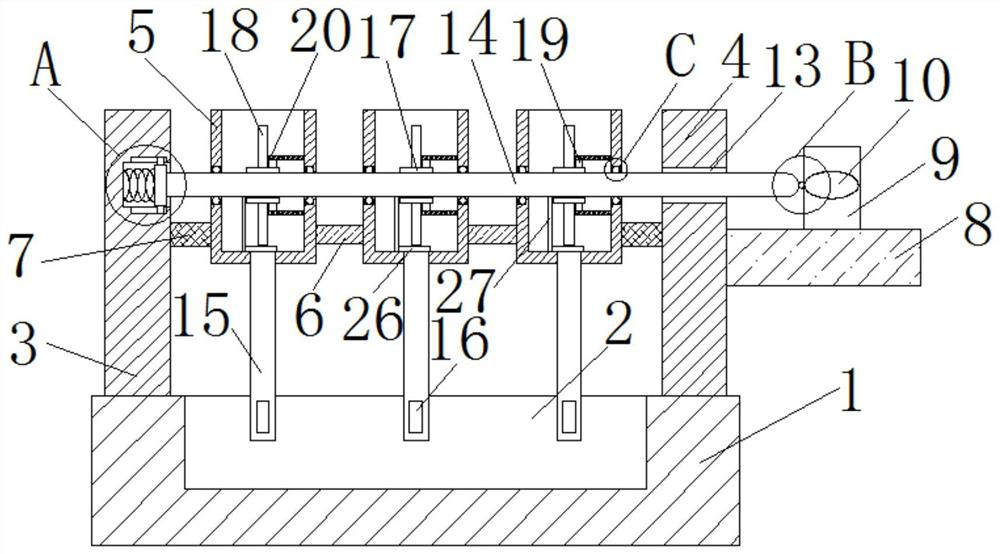

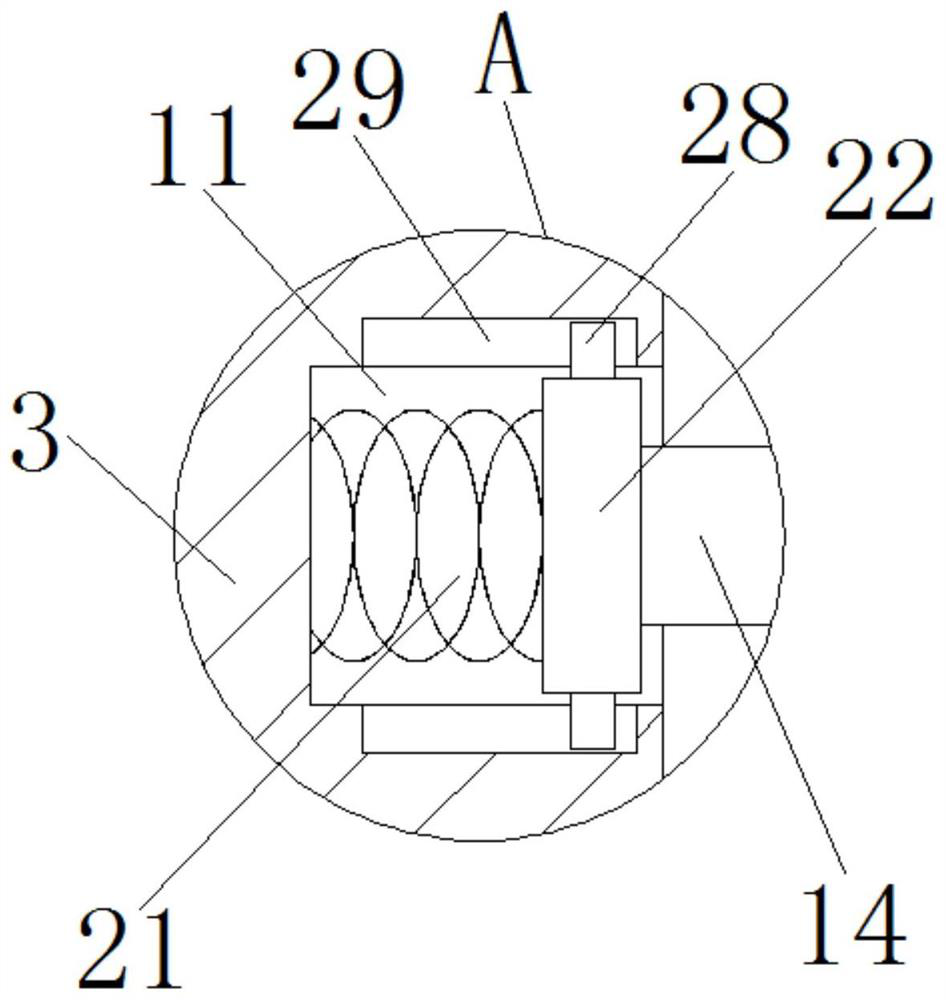

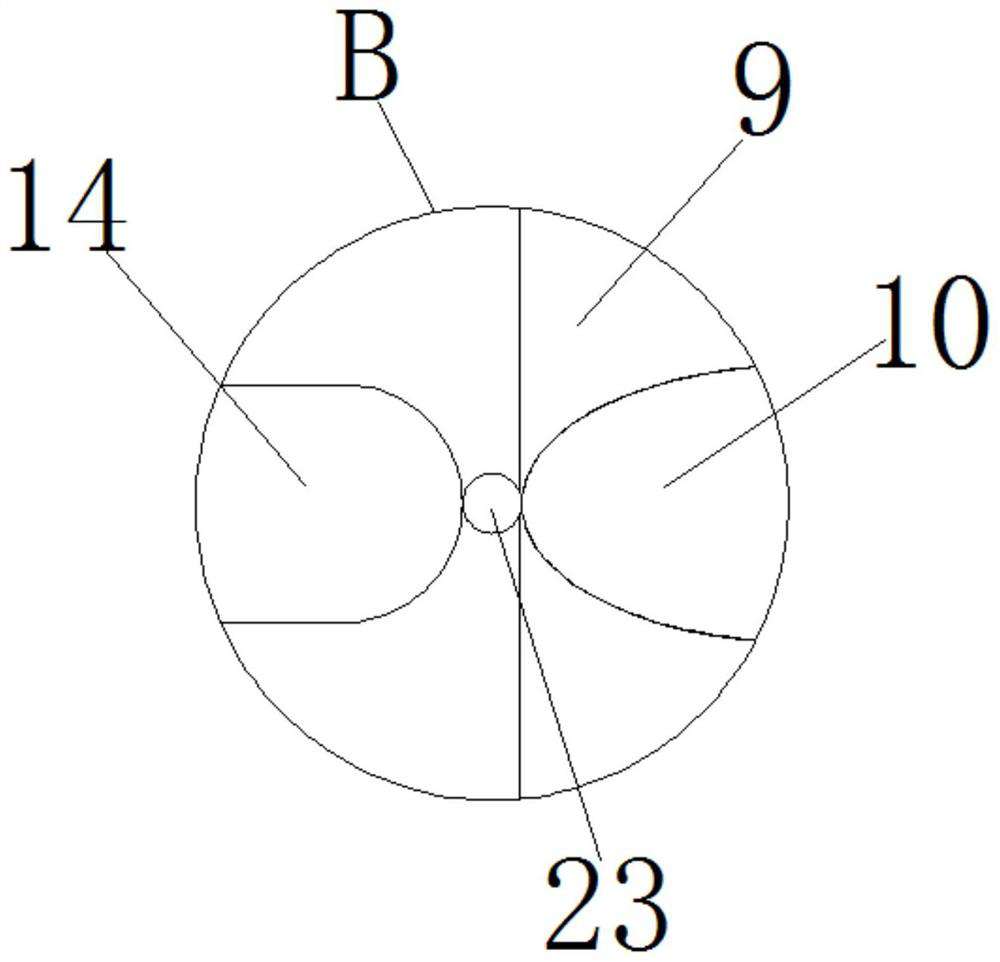

InactiveCN111889012AShattered fullyBroken finelyTransportation and packagingMixer accessoriesProcess engineeringManufacturing engineering

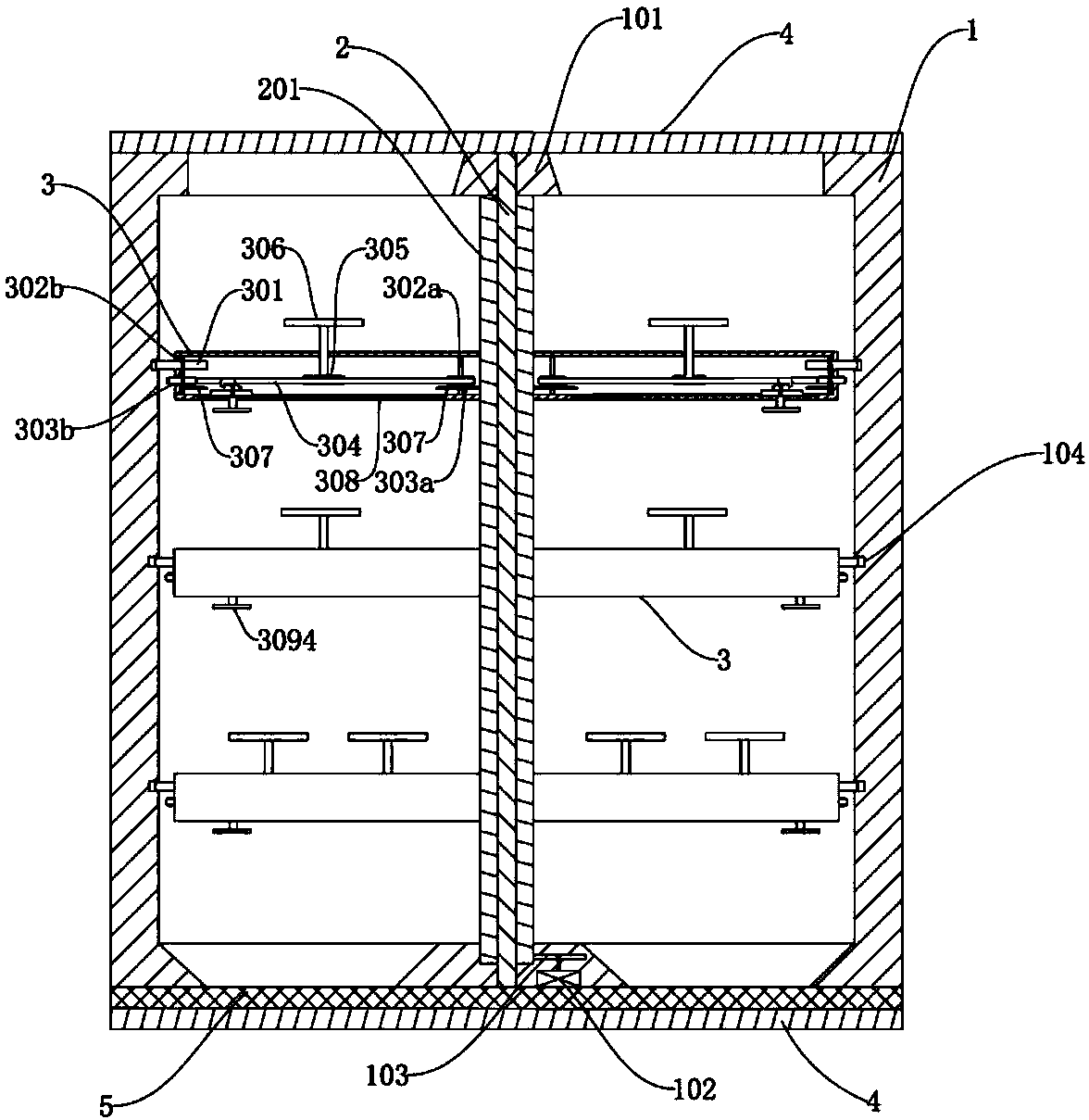

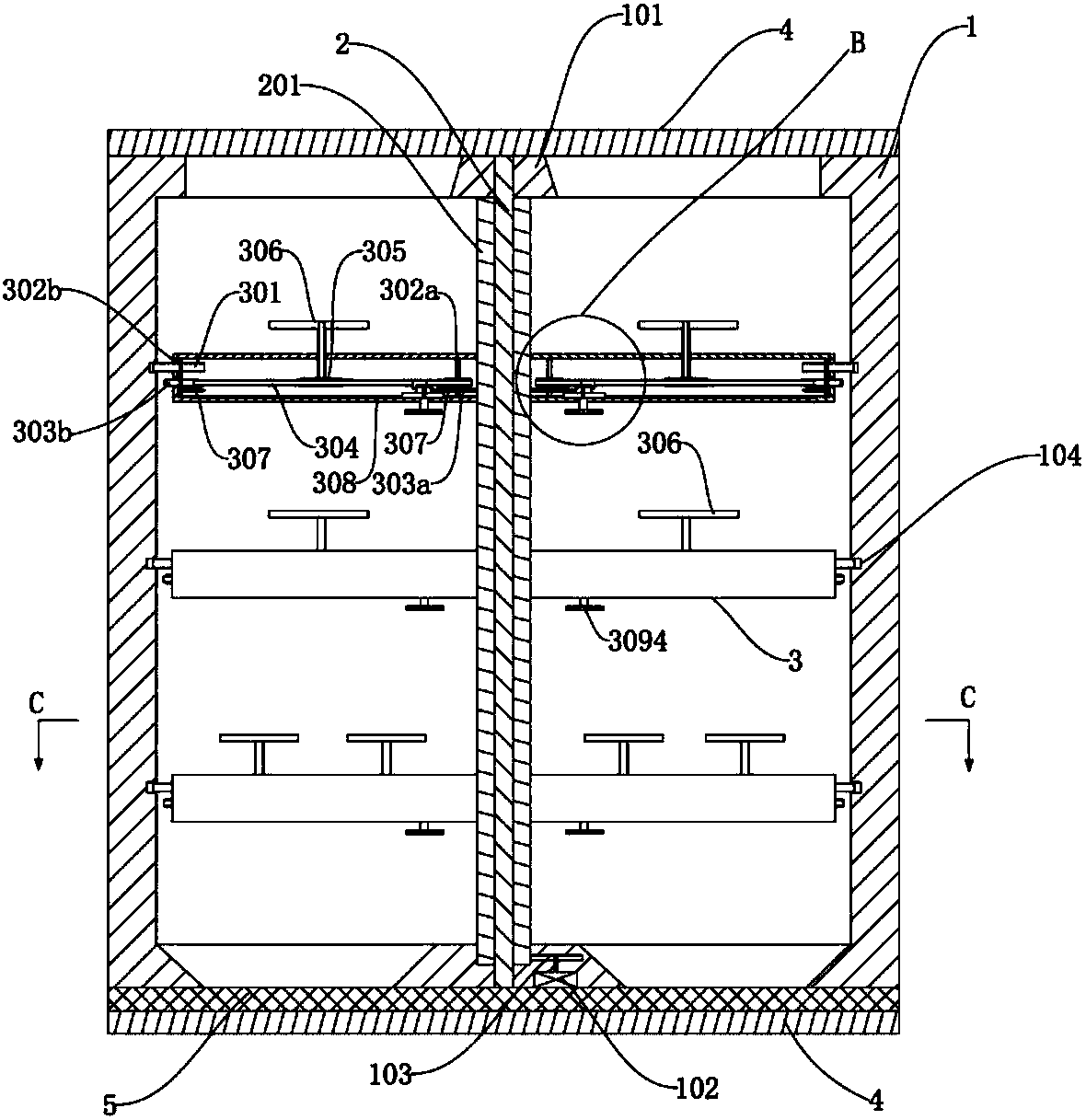

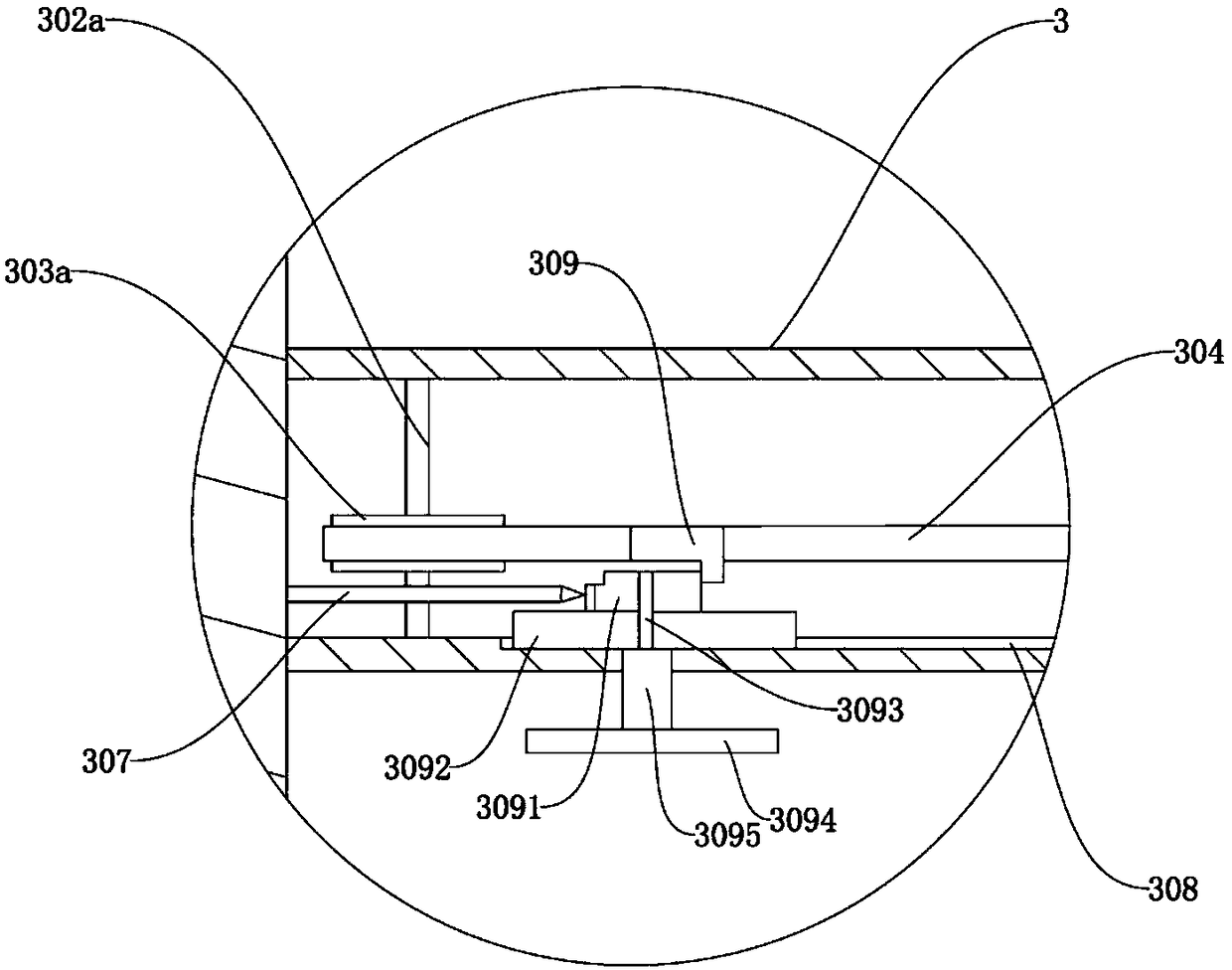

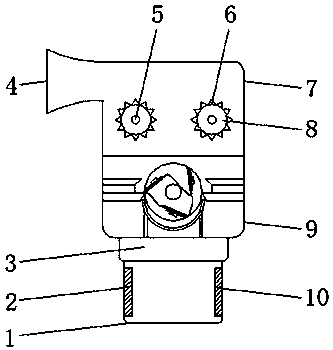

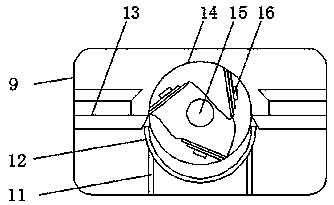

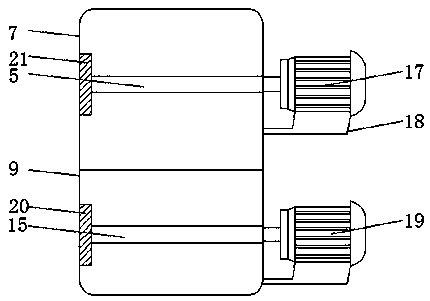

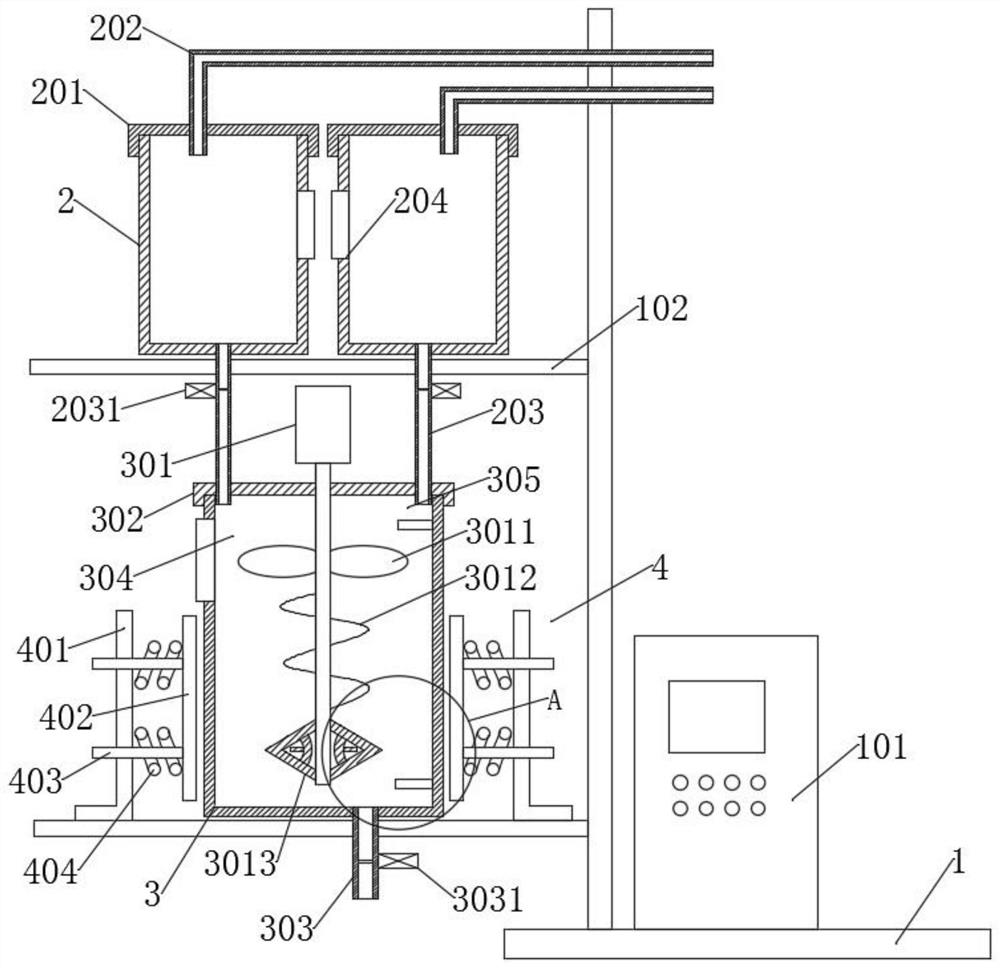

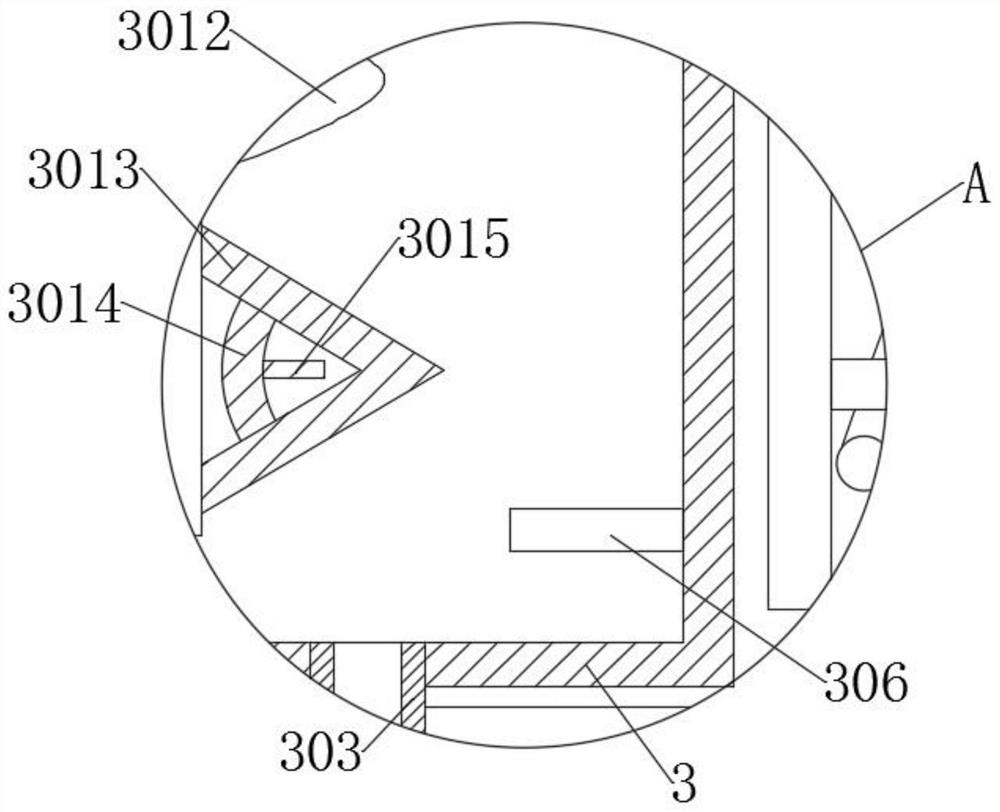

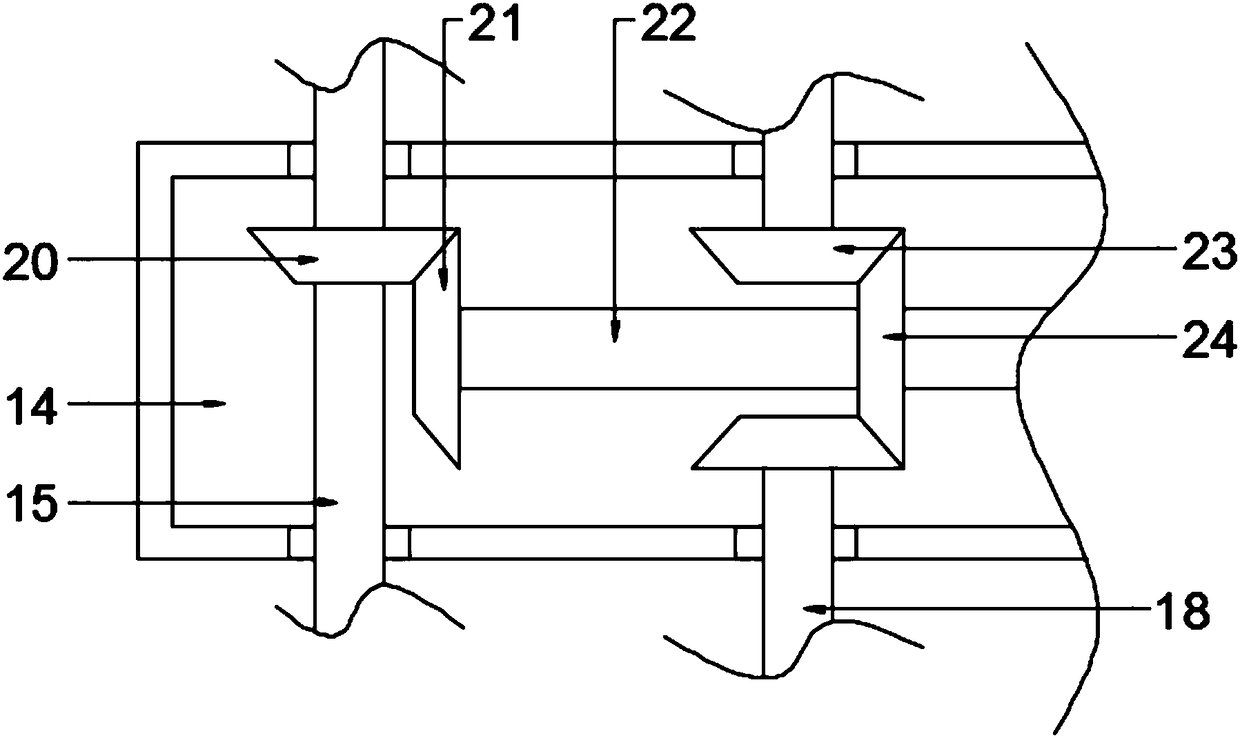

The invention discloses a collagen raw material extruding and stirring device. The invention belongs to the technical field of biological extraction equipment. The device comprises a mixing and stirring box, a crushing device, a stirring device, a grinding and scraping device, a pushing device and a cleaning device; the crushing device is arranged above the mixing and stirring box; the crushing device is communicated with the mixing and stirring box; the stirring device is arranged above one side of the mixing and stirring box; the pushing device is arranged below one side of the mixing and stirring box; the grinding and scraping device is arranged in the middle of one side of the mixing and stirring box; the cleaning device is arranged on one side of the mixing and stirring box. Accordingto the collagen raw material extruding and stirring device provided by the invention, the technical problems that in the prior art, residual materials are prone to being accumulated in a box body, the workload of manual scrubbing is large, cleaning is not easy, the secondary use effect is affected, the operation is tedious, and time and energy are wasted are solved.

Owner:程红梅

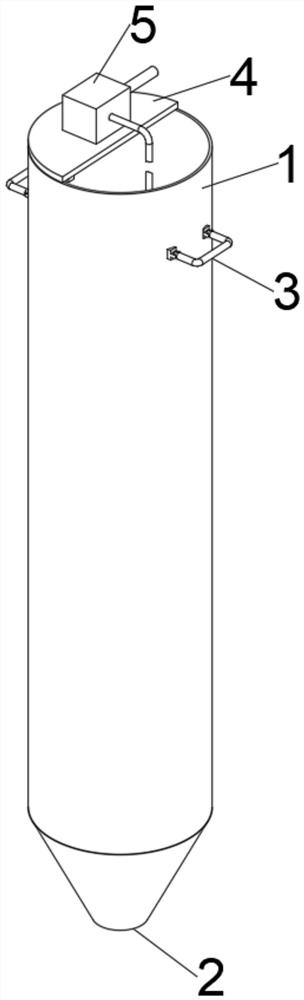

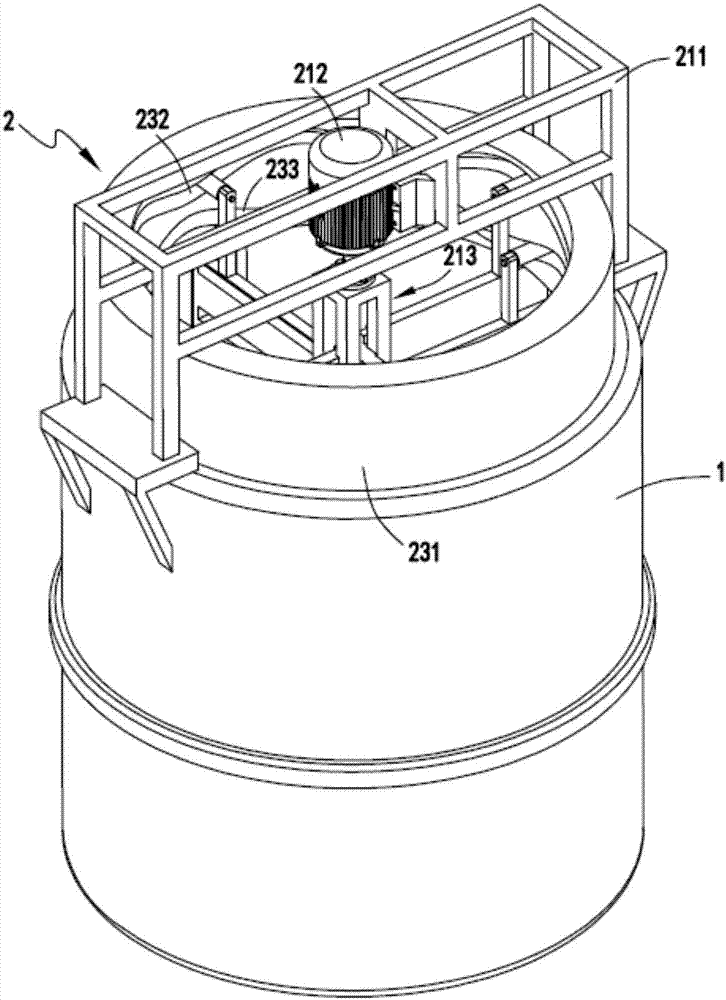

Vortex air flotation device

PendingCN113461096ALarge diameterReduce the number of bubblesWater/sewage treatment by flotationElectric machineryAir pump

The invention discloses a vortex air flotation device, and belongs to the technical field of air flotation. The vortex air flotation device comprises a pipe barrel, the pipe barrel is communicated with a conical water gap, and two handles are symmetrically arranged at the upper end of the circumferential outer wall of the pipe barrel. A semicircular plate is arranged above the pipe barrel, and an air pump is arranged in the middle of the upper portion of the semicircular plate. A U-shaped fixing block is arranged on the upper side in the pipe barrel, and two limiting columns are symmetrically and fixedly arranged in the middle of the outer side in the U-shaped fixing block. A mechanical box is arranged at the outer end of the upper part of the U-shaped fixing block, a motor is fixed in the mechanical box through a screw, and the output end of the motor penetrates through the outer wall of the U-shaped fixing block, extends into the U-shaped fixing block and is sleeved with a gear A. Through close fit of the structures, the device moves up and down to perform air flotation treatment on wastewater. Meanwhile, the internal wastewater can be stirred through revolution to break bubbles. The problems that bubbles generated by many air flotation devices used at present are large in diameter and small in number, the contact time of the bubbles and suspended solids is short, and the air flotation effect is poor are effectively solved.

Owner:汪洋

Biomass recovery equipment

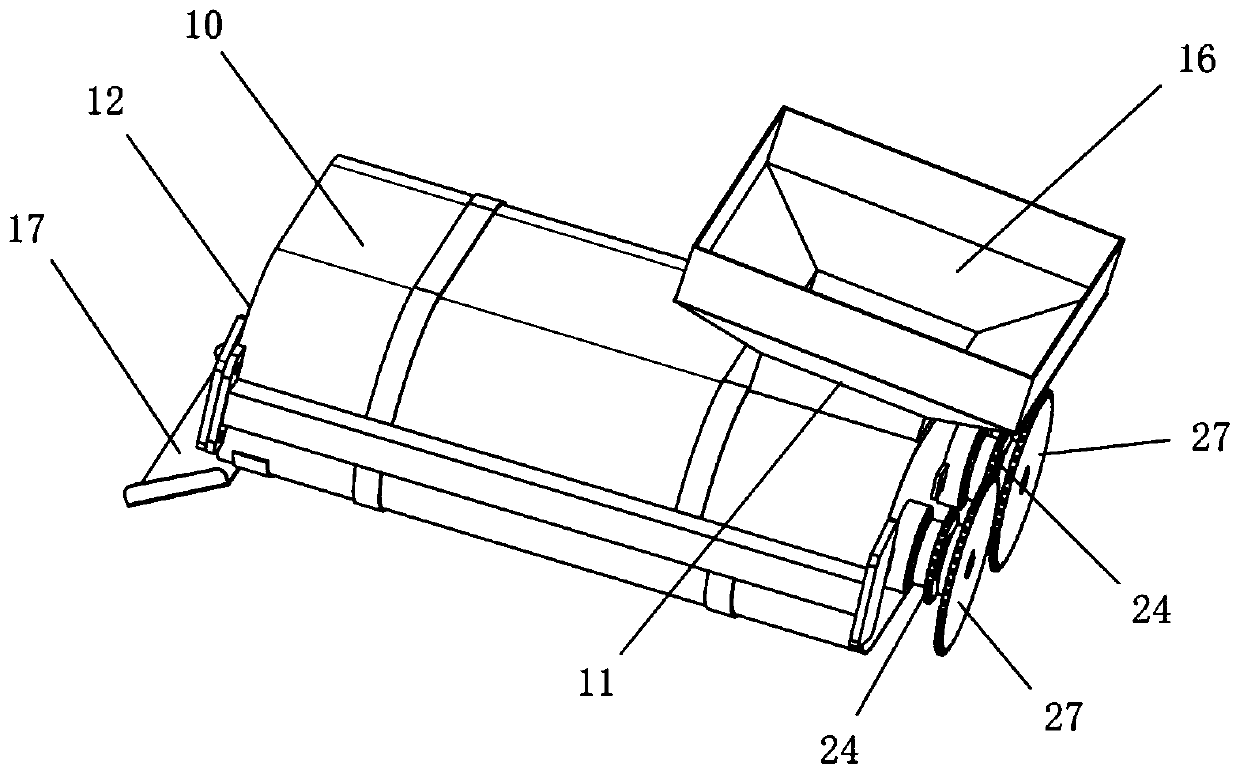

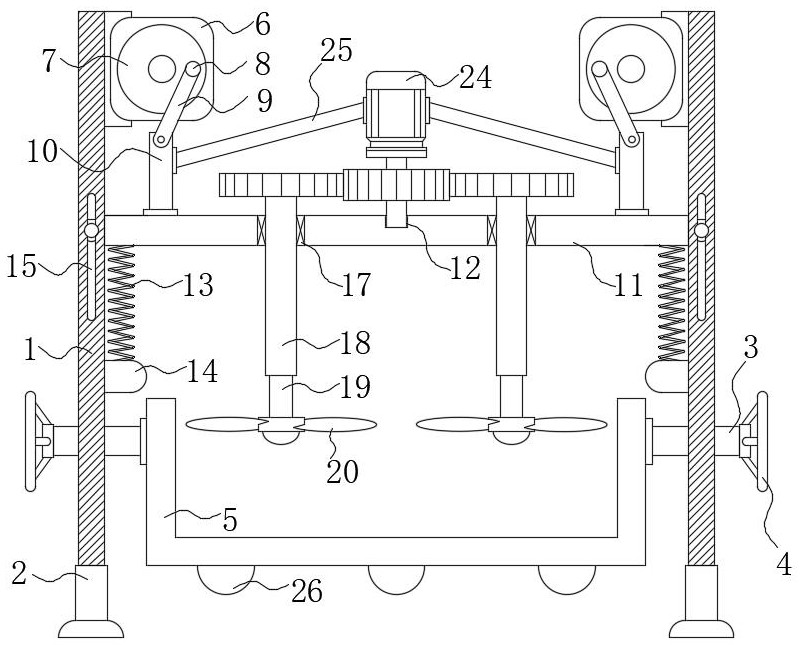

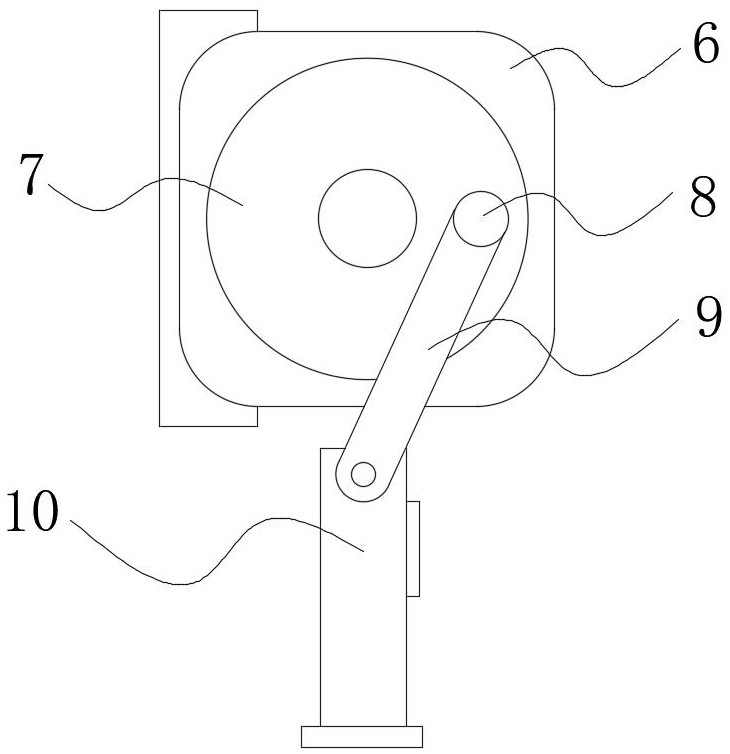

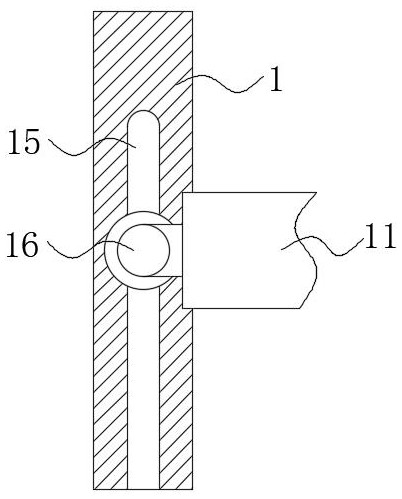

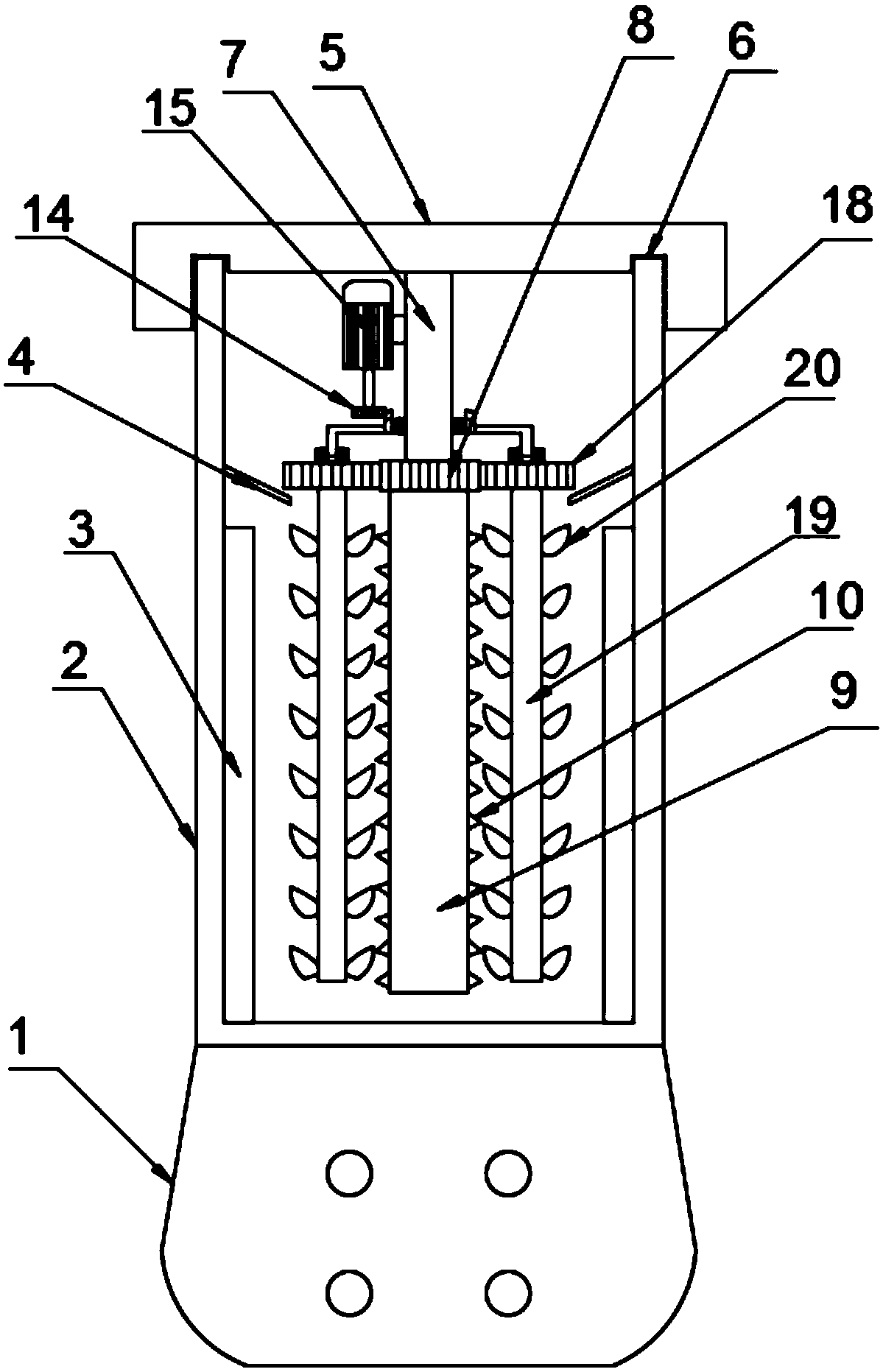

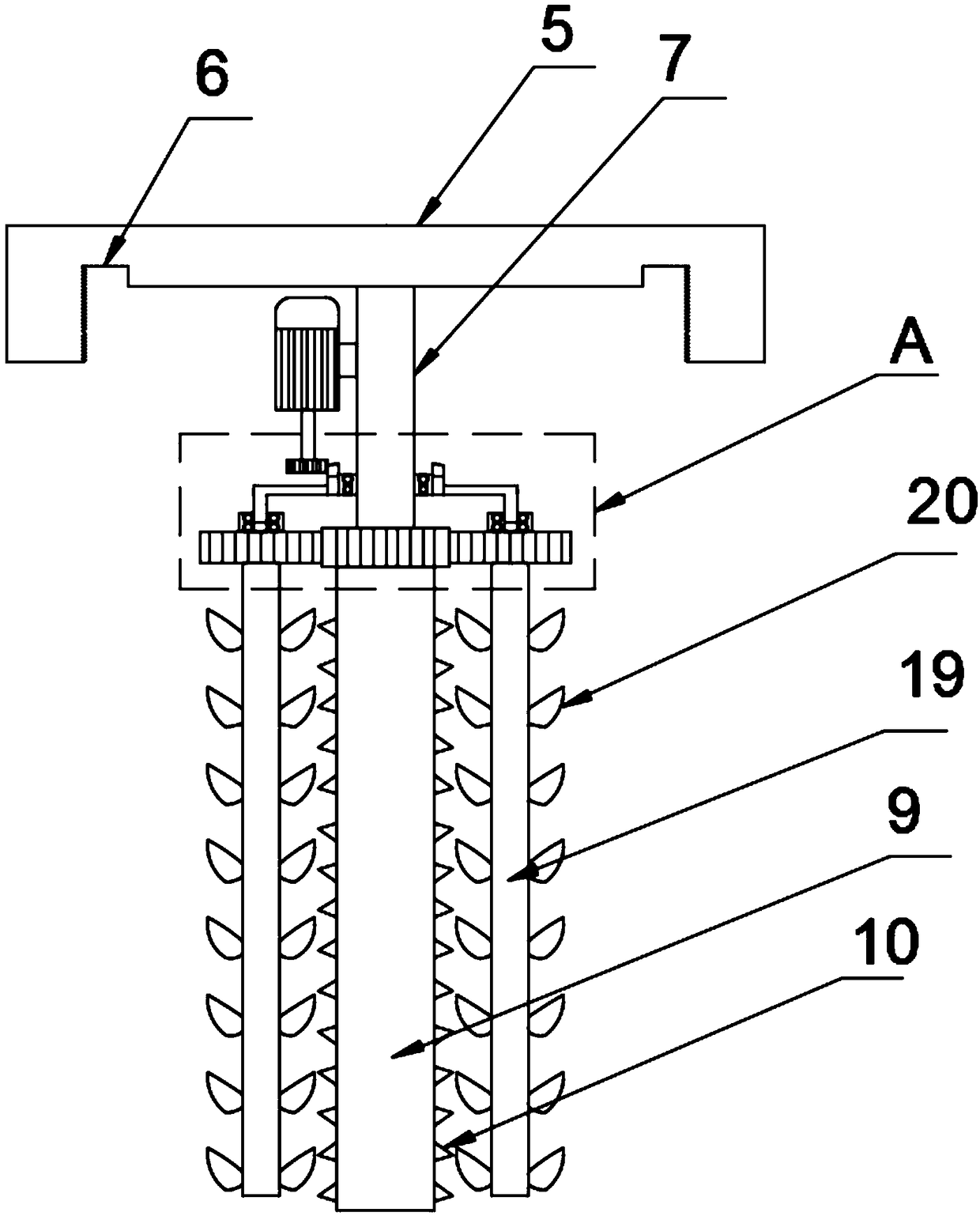

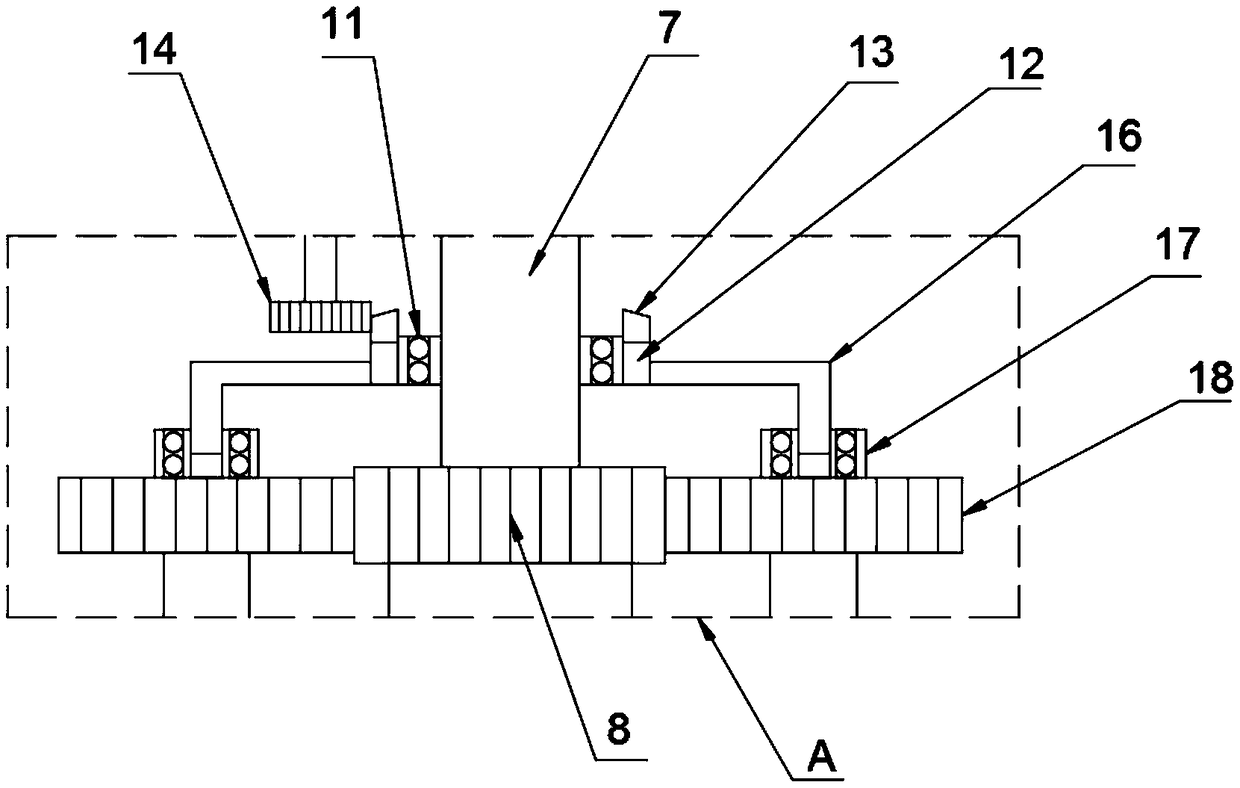

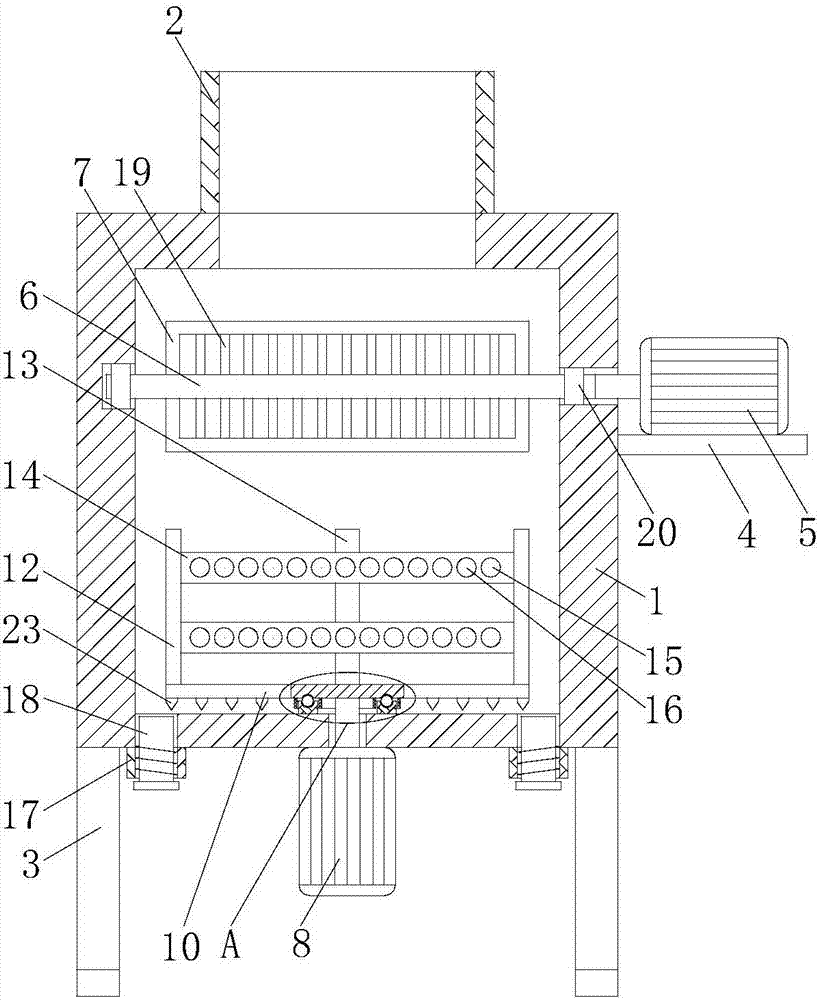

ActiveCN111871523AShattered fullySmash efficientRenewable energy machinesCuttersEngineeringProcess engineering

The invention discloses biomass recovery equipment which comprises a bottom box body. A top box body is arranged on the upper side of the bottom box body, a containing and discharging device used forcontaining biomass raw materials and facilitating discharging of the biomass raw materials out of the equipment is arranged in the bottom box body, and a top rotating ring is rotationally arranged onthe outer side of the top box body; and a distance adjusting device for changing the distance between the top box body and the bottom box body is arranged between the top rotating ring and the bottombox body, and a driving device for driving the top box body to rotate is arranged on one side of the top rotating ring. The biomass recovery equipment is simple in structure; according to the equipment, the manner that the heights of an upper machine body and a lower machine body of the equipment can be adjusted is adopted, in the adjusting process, the upper machine body can rotate to fully smashthe biomass raw materials, and the interior of the equipment can be adjusted according to a smashing area; and the equipment can efficiently smash the materials with different heights and different distribution conditions.

Owner:博兴兴博投资有限公司

Sullage eliminating treatment plug device

InactiveCN108379894AEasy to operateImprove efficiencyGrain treatmentsStationary filtering element filtersLarge mouthDrive motor

The invention belongs to the technical field of water treatment, and in particular relates to a sullage eliminating treatment plug device, aiming at solving the problems that the existing sullage eliminating method is high in difficulty, low in efficiency and not thorough in cleaning. The sullage eliminating treatment plug device is characterized in that the device comprises a water pipe; the water pipe is in a hollow cylindrical shape and comprises a fixed pipe wall with a notch; the fixed pipe wall is provided with a movable pipe wall with a shape matched with that of the notch; the two endsof the water pipe are separately provided with a partition board, and a large-mouth filter screen is arranged at the inner side of one of the two partition boards; two water pipe diversion plates arerespectively fixed at the two ends of the central axis of the water pipe, and a drive motor is installed on one of the two water pipe diversion plates; a transmission shaft of the drive motor is connected with a drive gear; a fixed shaft is connected between the two water pipe diversion plates; a shaft sleeve capable of rotating around the fixed shaft is installed on the fixed shaft; the outer surface of the shaft sleeve is provided with a gear groove matched with the drive gear; the shaft sleeve is provided with at least one rotating body.

Owner:ZHEJIANG XIAYUAN INFORMATION TECH CO LTD

Glass membrane crushing dust-collecting machine

InactiveCN108554574AAchieve the effect of preliminary tearing and breaking into piecesShattered fullyDirt cleaningGrain treatmentsRotational axisEngineering

The invention discloses a glass membrane crushing dust-collecting machine, which comprises a dust-collecting box, a primary crushing box and a secondary crushing box. Two rotating shafts are installedinside the primary crushing box. One end of the rotating shaft is rotatably installed inside a second shaft sleeve, and the other end of the rotating shaft penetrates through the back end face of theprimary crushing box to be rotatably connected to a first motor. A roller body is fixed on the rotating shaft, and a gear knife set is welded on the surface of the roller body. Stationary knives arefixed on two sidewalls of the secondary crushing box. A rotating shaft is installed inside the secondary crushing box. One end of the rotating shaft is rotatably installed inside the first shaft sleeve, and the other end of the rotating shaft penetrates through the back end face of the secondary crushing box to be rotatably connected to a second motor. A moving cutter head is welded on the rotating shaft, and no less than three moving cutters are installed on the moving cutter head. A discharge plate electrode and a dust-collecting plate electrode are respectively fixed on two sidewalls of thedust-collecting box. By the utilization of electrostatic principle, dust-collecting recycling work can be achieved efficiently.

Owner:庄粉香

Glue preparation device capable of automatically preparing glue

InactiveCN112263936AStir wellEvenly mixedRotary stirring mixersTransportation and packagingElectric machineryProcess engineering

The invention discloses a glue preparation device capable of automatically preparing glue, and relates to the technical field of glue preparation devices. The device comprises a support frame, dry rawmaterial barrels, a stirring tank and a clamping assembly; a control box is arranged on the support frame; a plurality of supporting plates are fixedly connected to one side of the supporting frame;barrel covers are fixed at the openings of the raw material barrels; a feeding pipe is fixed in each barrel cover; a discharge pipe is fixed at the bottom of each raw material barrel; a stirring assembly is arranged in the stirring tank; a tank cover is fixed at the top of the stirring tank; a discharging pipeline is arranged at the bottom of the stirring tank, and a second electromagnetic valve is arranged in the discharging pipeline; the stirring assembly comprises a motor; a stirring rod is fixedly mounted at the output end of the motor; and stirring blades are fixedly connected to the upper end of the stirring rod. Through the effects of the supporting frame, the raw material barrels, the stirring tank and the clamping assembly, the problems that the glue preparation proportion is difficult to control accurately, stirring is insufficient and the labor intensity is high due to the fact that manual glue preparation is adopted in existing glue preparation are solved.

Owner:TIANNENG BATTERY WUHU

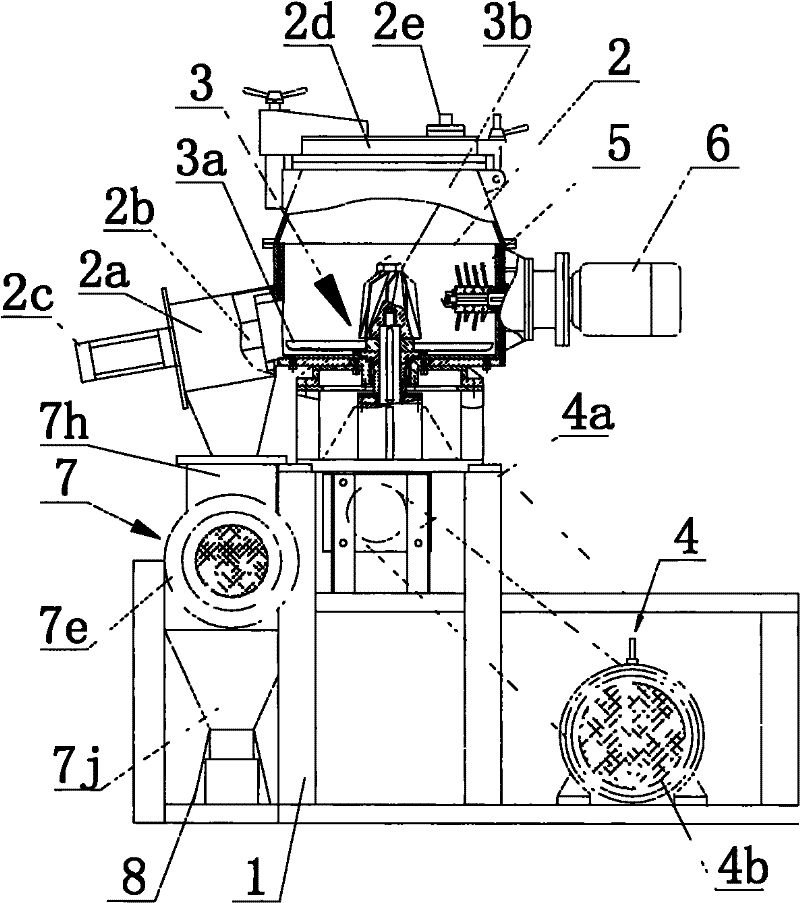

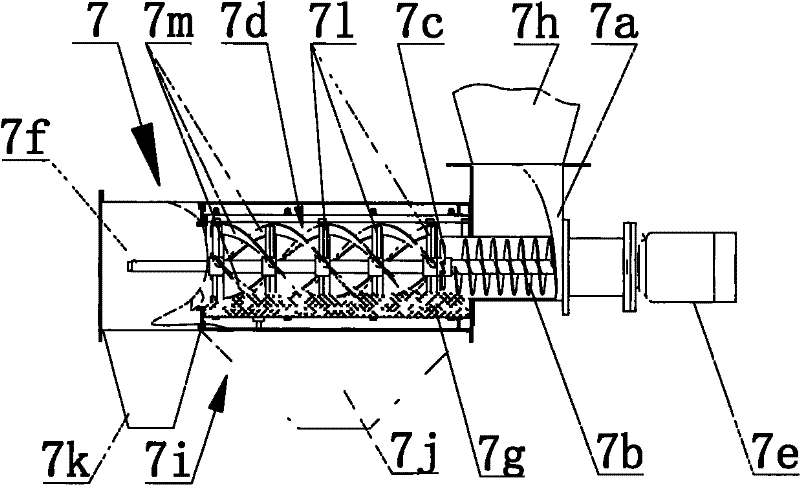

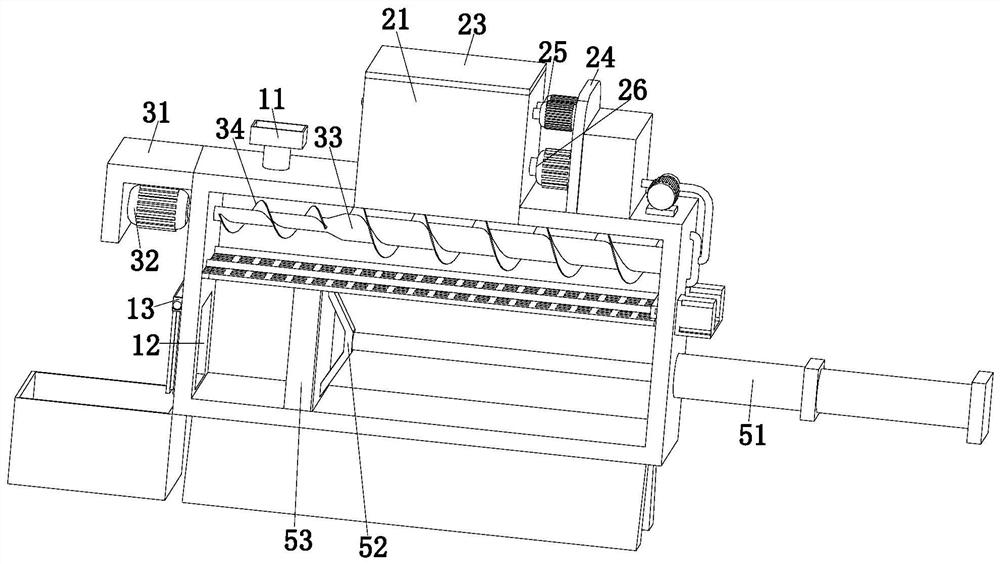

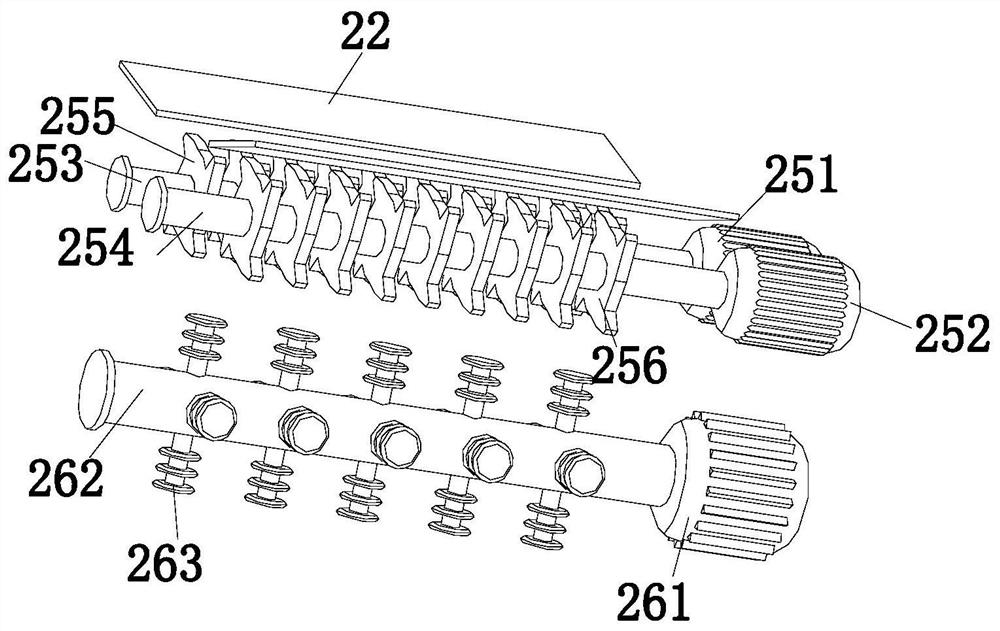

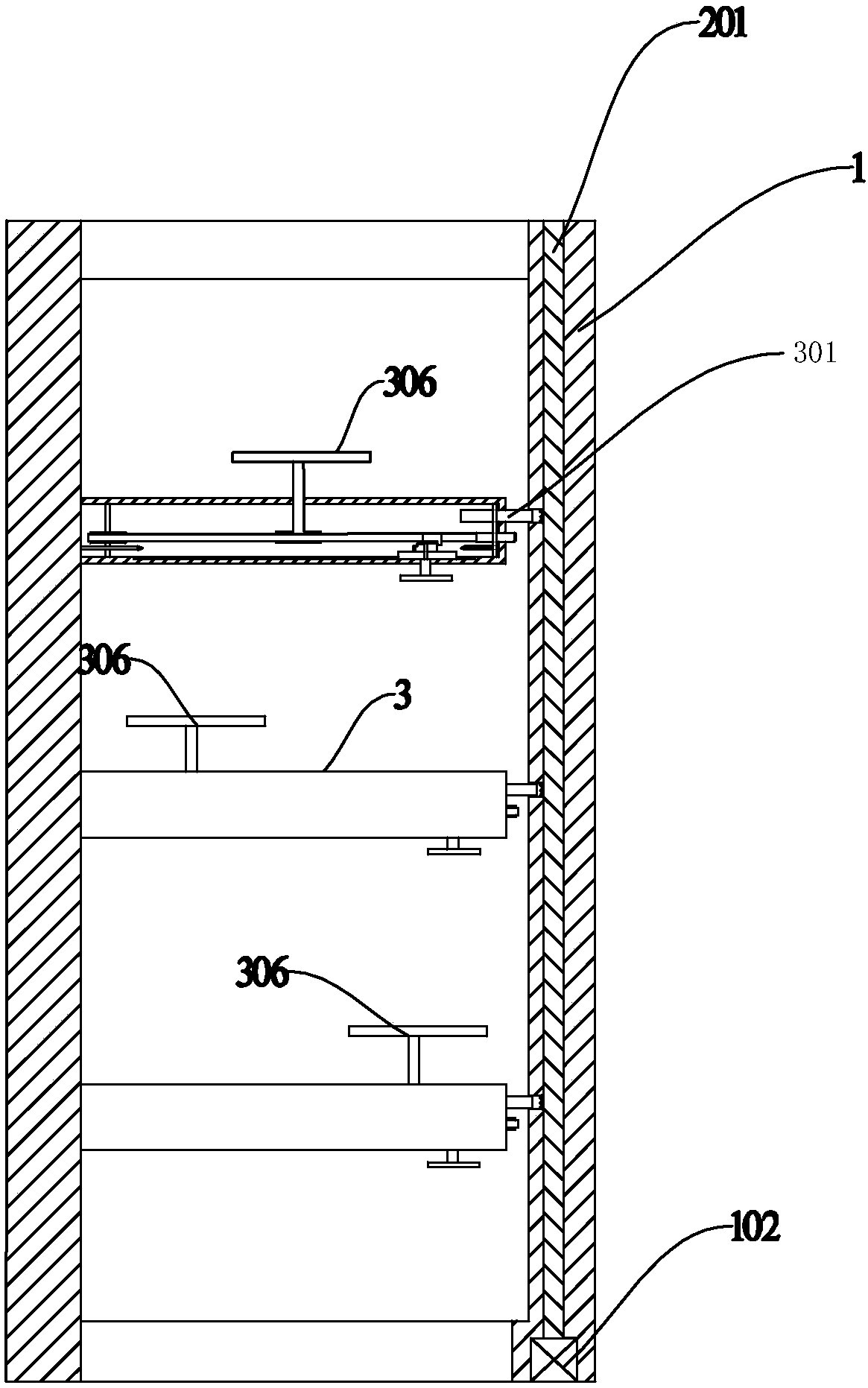

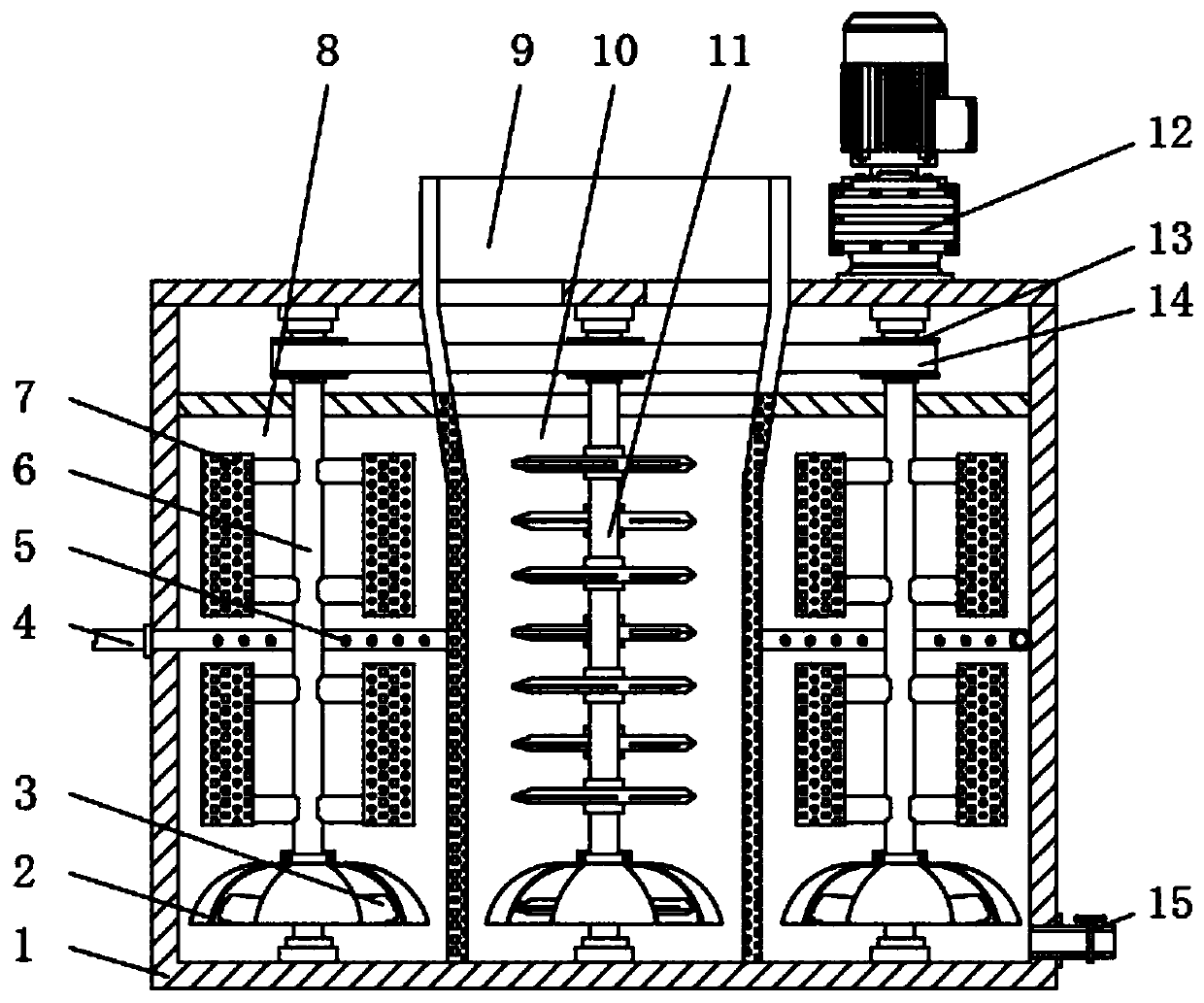

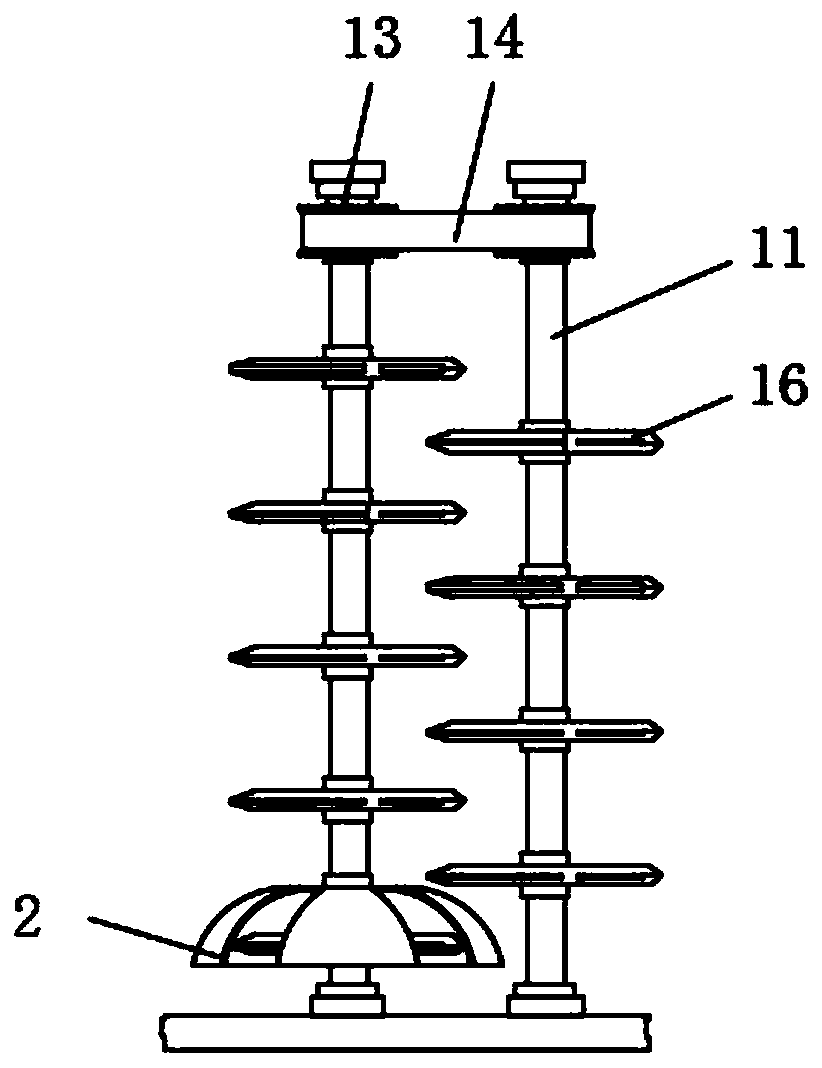

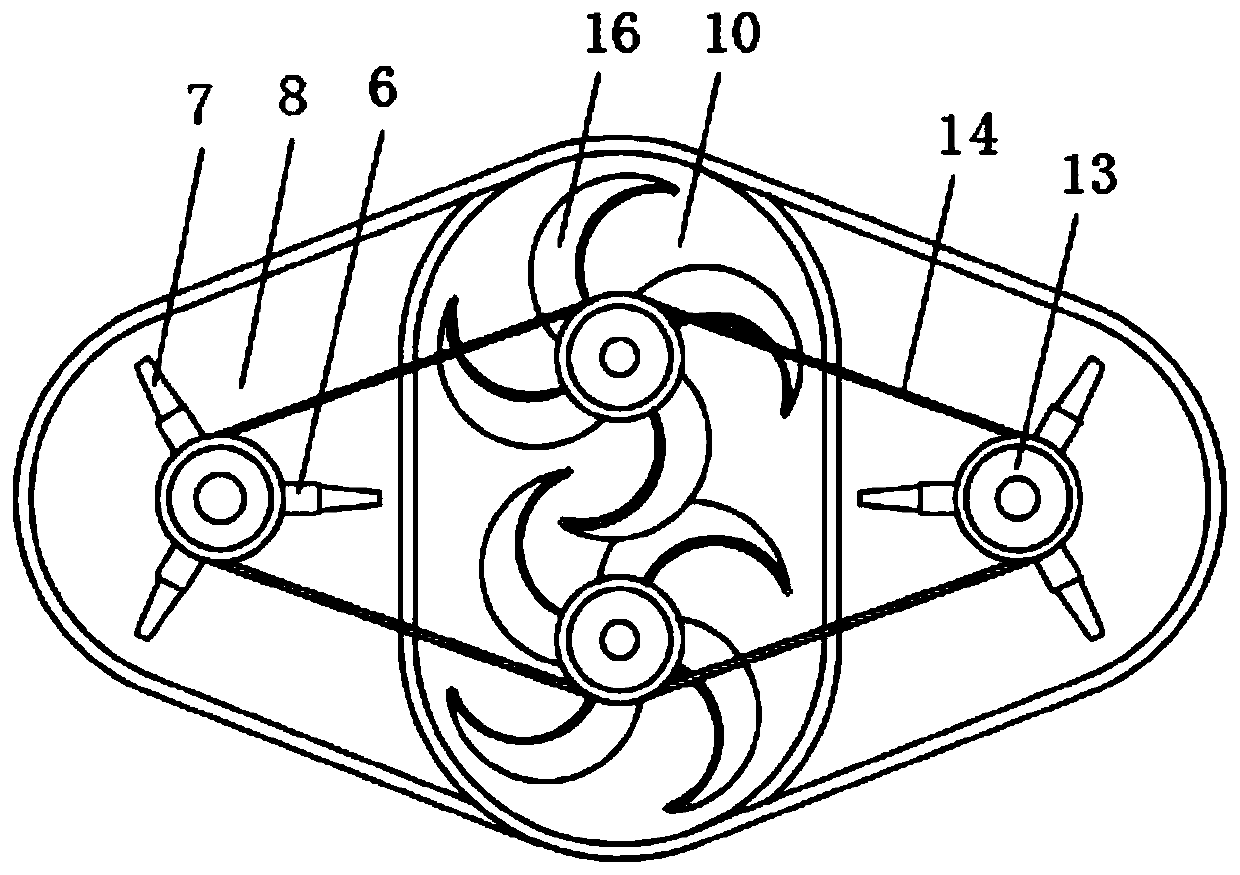

Closed slurry extruding type stirring device and seedling culture slurry machine with same

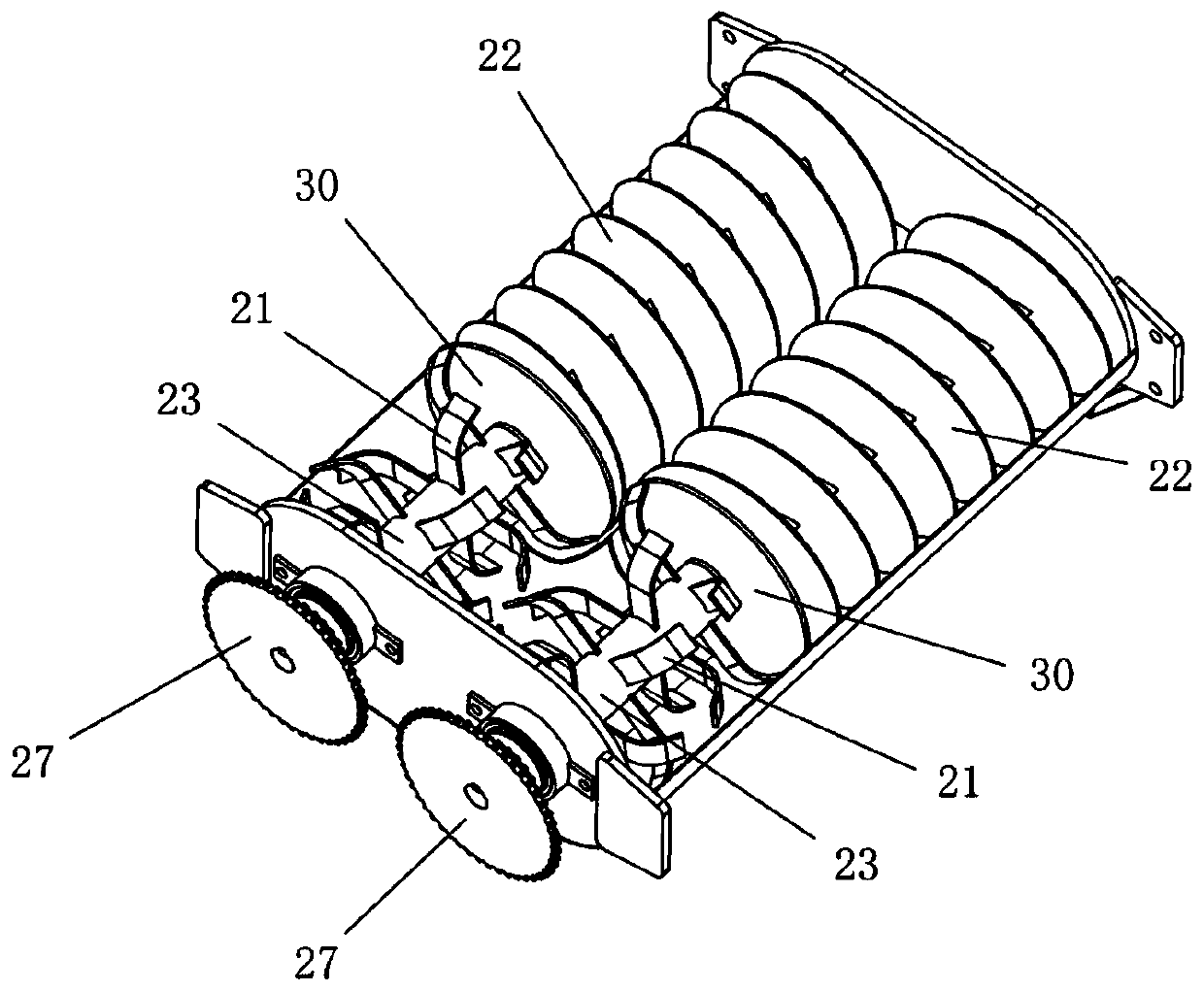

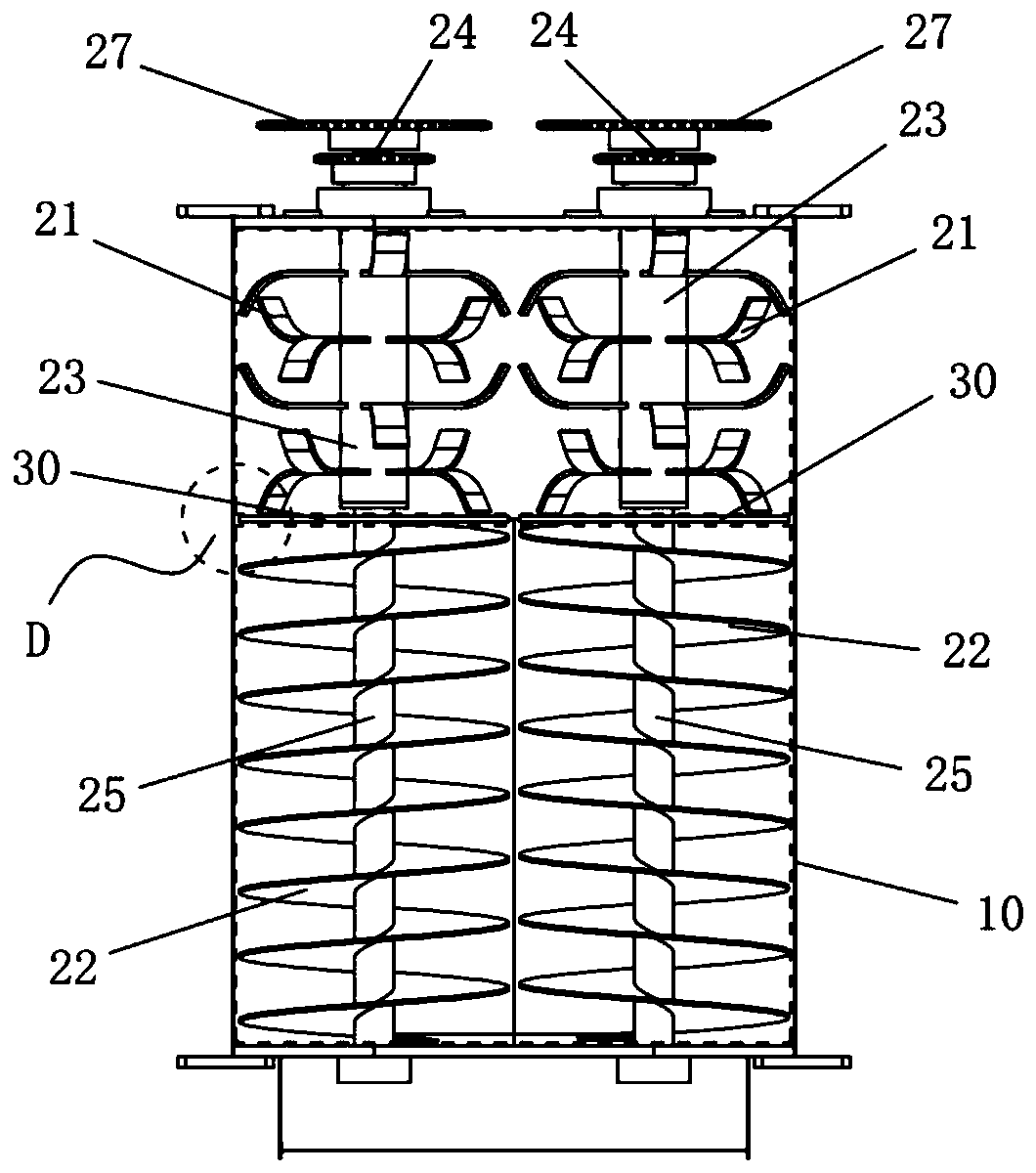

ActiveCN110663508AQuality improvementShattered fullyTransportation and packagingRotary stirring mixersEngineeringSlurry

The invention discloses a closed slurry extruding type stirring device and a seedling culture slurry machine with the same. The closed slurry extruding type stirring device comprises a stirring deviceshell, stirring shafts and disk baffle plates, a feeding port is formed in one end of the stirring device shell, a discharging port is formed in the other end of the stirring device shell, the stirring shafts are rotatably mounted in the stirring device shell, soil cutting knives are arranged at one end, close to the feeding port, of each stirring shaft, screw conveyer blades are arranged at oneend, close to the discharging port, of each stirring shaft, the disk baffle plates are mounted on the stirring shafts and positioned between the soil cutting knives and the screw conveyer blades, gapsare reserved between the outer edges of the disk baffle plate and the inner wall of the stirring device shell, and slurry passes the gaps. According to the closed slurry extruding type stirring device and the seedling culture slurry machine, the disk baffle plates are arranged between the soil cutting knives and the screw conveyer blades, gaps are formed between the outer edges of the disk baffleplate and the inner wall of the stirring device shell, slurry with qualified particle diameter passes the gaps, soil can be sufficiently crushed, and the quality of the slurry is improved.

Owner:HUNAN AGRICULTURAL UNIV

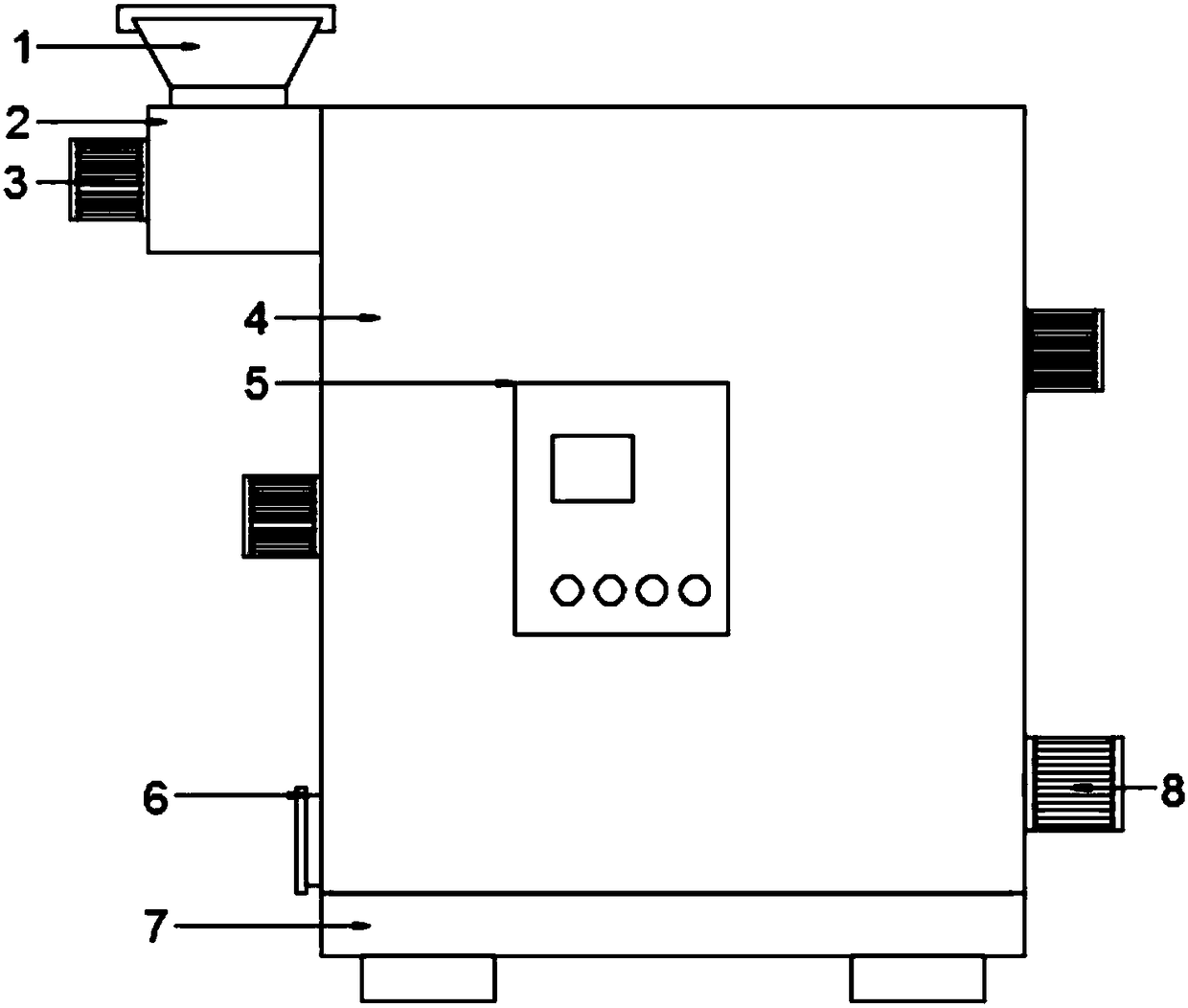

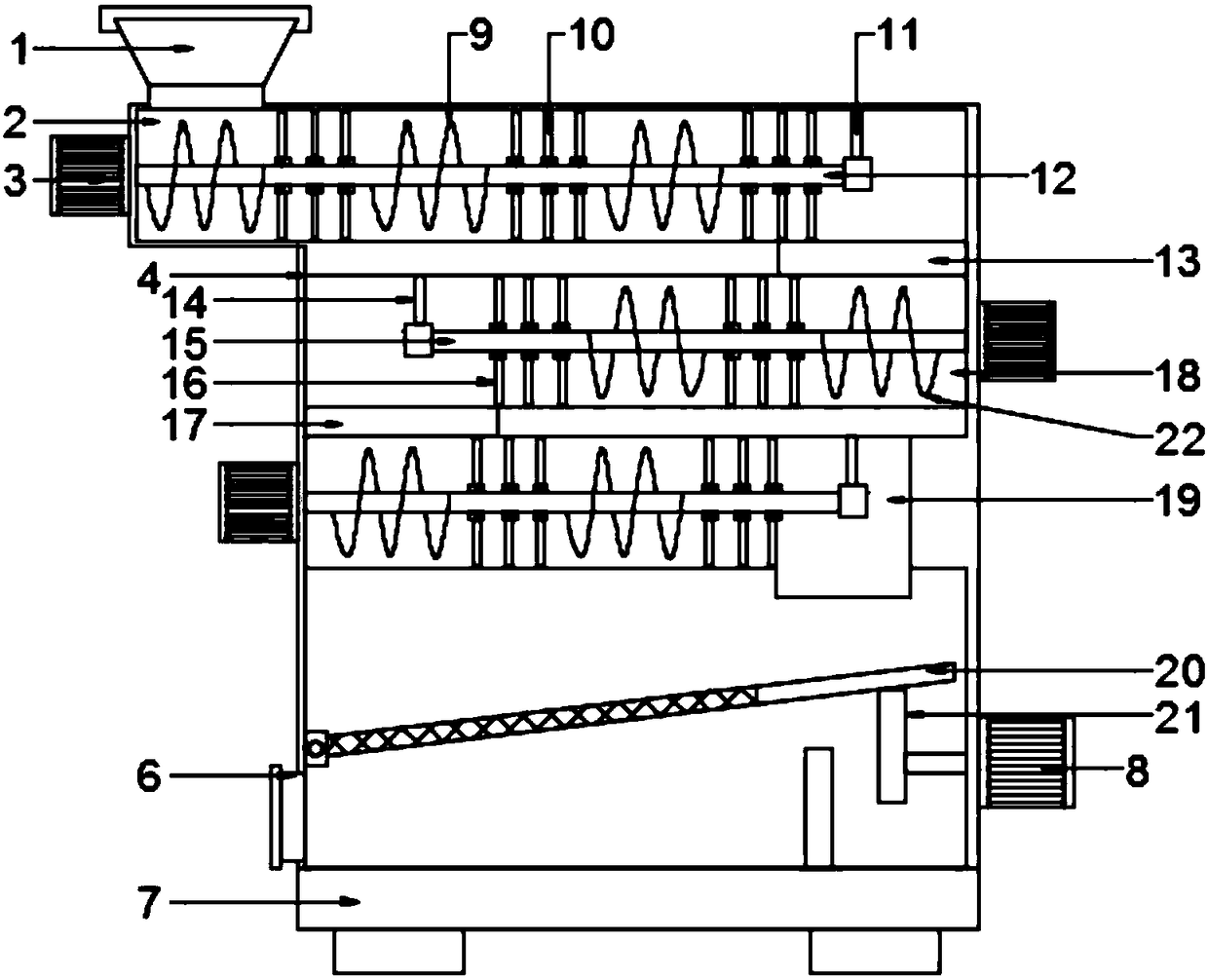

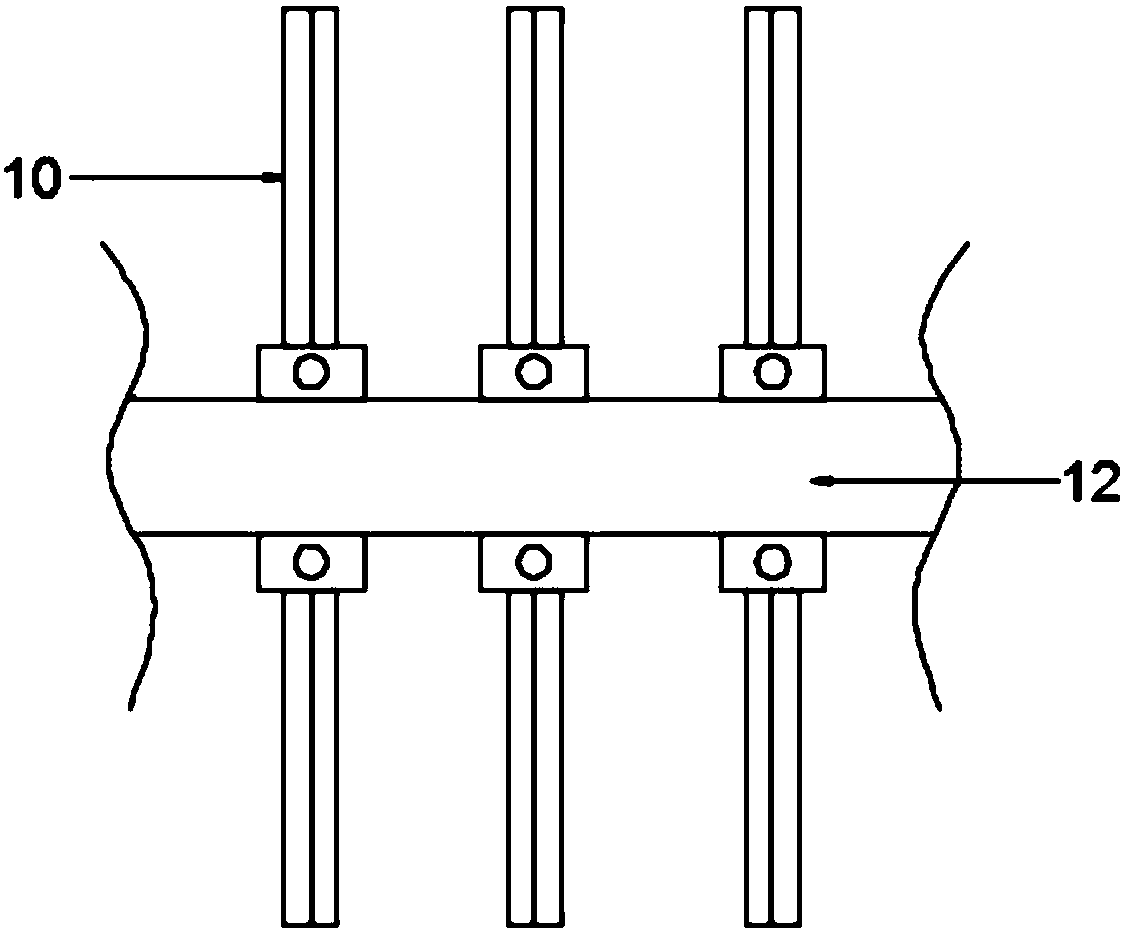

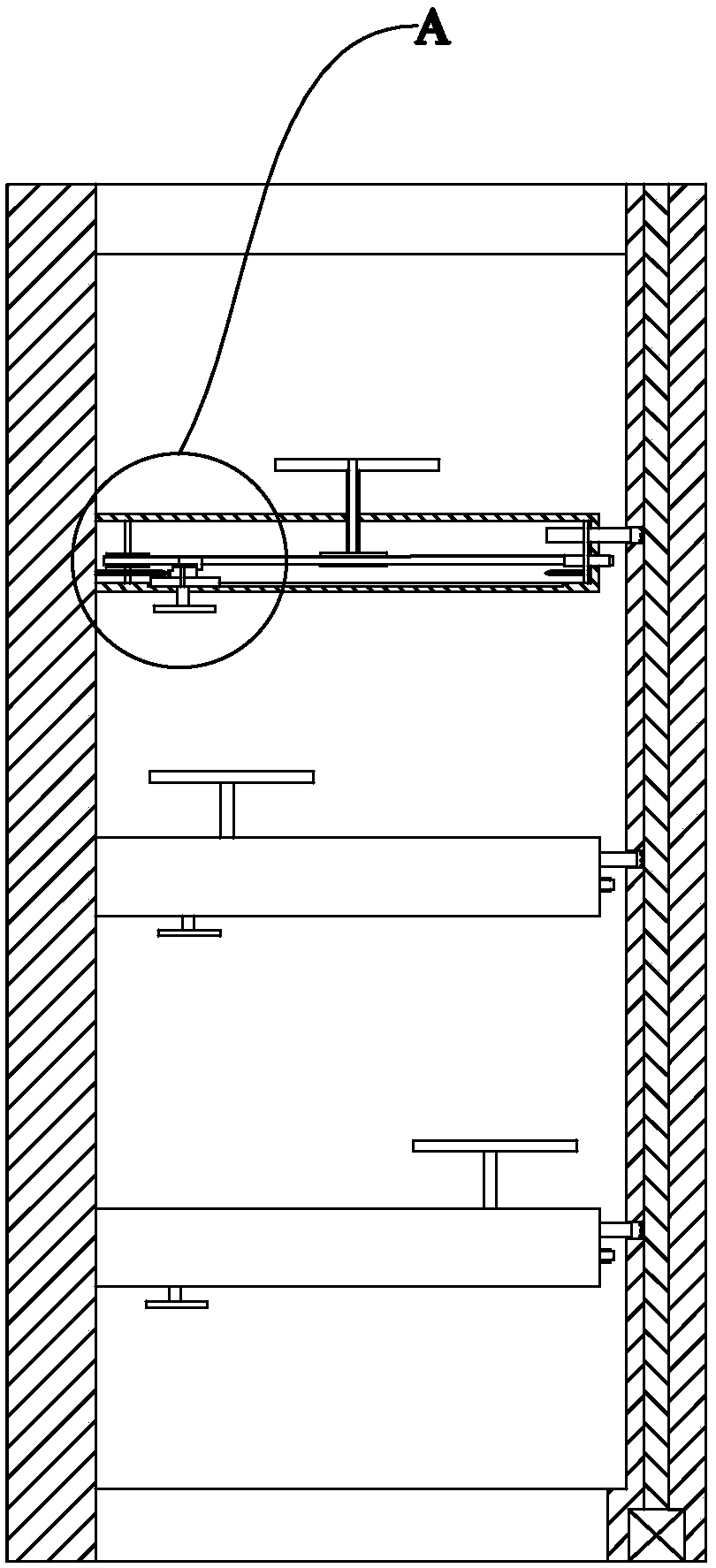

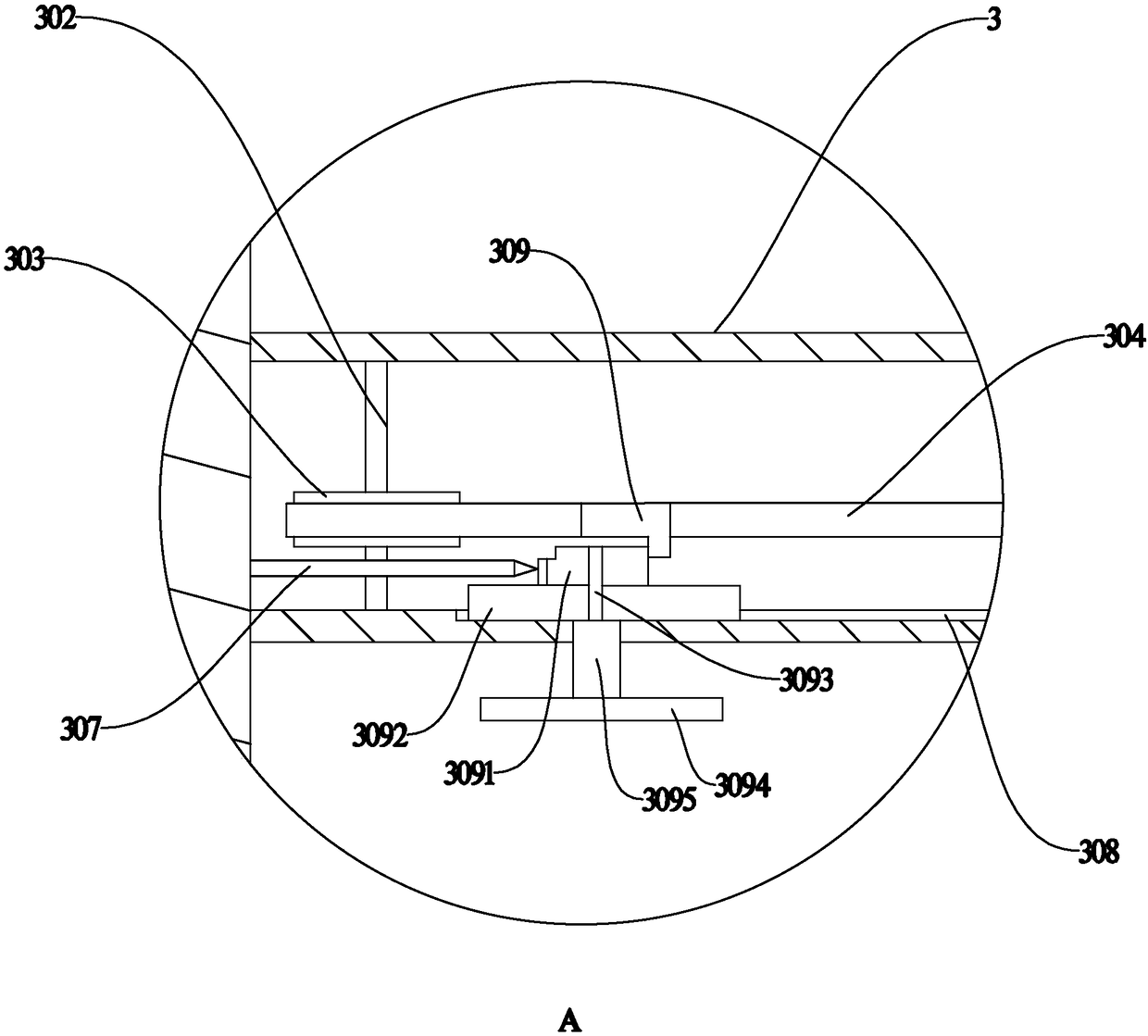

Continuous smashing device for forage grass in animal husbandry

InactiveCN108541465ASmash evenlyShattered fullyAnimal feeding devicesCuttersAnimal ForagingEngineering

The invention discloses a continuous smashing device for forage grass in animal husbandry. The continuous smashing device comprises a feeding and smashing device, a first smashing device, a second smashing device and a screening plate, wherein the feeding and smashing device is inserted into the top of the device body of the device in a penetrating mode, the first smashing device is inserted intothe device body at the lower side of the feeding and smashing device, the first smashing device and the feeding and smashing device are communicated through a first feeding pipe, the second smashing device is inserted into the device body at the lower side of the first smashing device, the second smashing device and the first smashing device are communicated through a second feeding pipe, the screening plate is arranged on the device body at the lower side of the second smashing device, and a discharging pipe is arranged on the left side wall of the device body on the lower side of the screening plate. According to the forage grass continuous crushing device for the animal husbandry, the forage grass is crushed through three-time continuous transmission, the forage is uniformly and sufficiently smashed, the effect is good, the efficiency is high, and eating and digestion of animals are facilitated.

Owner:朱建国

Stasis removal water treatment fixable apparatus

InactiveCN108499165AShattered fullySettling tanks feed/dischargeSedimentation settling tanksEngineeringFan blade

The invention relates to a stasis removal water treatment fixable apparatus. The stasis removal water treatment fixable apparatus comprises a water pipe wall, a driving apparatus, and a first crushingmechanism, wherein the upper part of the water pipe wall is provided with a material inlet; the driving apparatus comprises a rotating shaft and a motor fixedly arranged on the water pipe wall, and the rotating shaft is provided with an outer gear; and the first crushing mechanism comprises a rotating cavity, a first gear, a gear shaft, a chain gear a, a chain gear b and a chain, the rotating cavity is arranged in the radial direction of the water pipe wall, two ends of the gear shaft are rotatably arranged in the rotating cavity, the two gear shafts are arranged on the two ends of the rotating cavity, the first gear is coaxially arranged on the gear shaft close to the rotating shaft, the gear shaft is engaged with the outer gear on the rotating shaft, the chain gear a is coaxially arranged on the gear shaft, the chain gear b is rotatably arranged in the rotating cavity by virtue of two ends of the rotating shaft, one end of the rotating shaft extends to the outer side of the rotatingcavity and is connected with a fan blade, and the chain is engaged with the chain gear a and the chain gear b. The rotating cavity of the apparatus has a double crushing effect, so that more sufficiency in crushing can be realized.

Owner:ZHEJIANG XIAYUAN INFORMATION TECH CO LTD

High-efficiency processing device for herbage of animal husbandry

The invention discloses a high-efficiency processing device for herbage of animal husbandry. The device comprises a device main body, a lifting rod and a transmission pipe; a screen mesh is fixedly arranged in the device main body, the upper end of the lifting rod is fixed to a lifting rotating shaft through a sleeve, the left end of the lifting rotating shaft is fixed to an output shaft of a first motor, a second motor is fixedly arranged on the left side of the upper end of the transmission pipe, and a main rotating shaft is fixedly arranged on an output shaft of the second motor; main breaking blades are distributed on the main rotating shaft in an array, a first conical gear is mounted on the portion, in the transmission pipe, of the main rotating shaft, a second conical gear is meshedwith the right side of the first conical gear and fixed to a transmission rotating shaft, a fourth conical gear is mounted on a main body of the transmission rotating shaft and meshed with third conical gears, the third conical gears are fixed to secondary rotating shafts, and secondary breaking blades are distributed on the secondary rotating shafts in an array. According to the high-efficiencyprocessing device for the herbage of the animal husbandry, the herbage is broken uniformly and completely, the effect is good, the efficiency is high, and convenience is provided for animals in eatingand digestion.

Owner:朱建国

Construction waste crushing device capable of crushing large amount of construction waste

InactiveCN111617845ASimple and convenient unloadingEasy to liftGrain treatmentsElectric machineryServo

The invention discloses a construction waste crushing device capable of crushing large amount of construction waste. The device comprises a supporting frame, bases, moving rods, rotating handles and astorage box, wherein the bases are fixedly connected to the lower end of the supporting frame, the moving rods are inserted into the inner wall of the supporting frame, the rotating handles are fixedly connected to the left ends of the moving rods, the right ends of the moving rods penetrate through the supporting frame and are fixedly connected to the side faces of the storage box, and first servo motors are fixedly connected to the upper side of the inner wall of the supporting frame. According to the device, during use, through cooperative use of structures such as the moving rods and balancing weights, the effect of simple and convenient discharging is achieved; through cooperative use of structures such as rotating discs and fixing seats, the effect of convenient lifting is achieved;through cooperative use of structures such as the rotating discs and the fixing seats, the effect of sufficient crushing is achieved; and through cooperative use of structures such as springs and sliding wheels, the effect of automatic returning is achieved.

Owner:张雷昌

Small-size meat grinder for kitchen

ActiveCN109008683AExtended service lifeImprove efficiency and qualityKitchen equipmentEngineeringGRINDING TOOTH

The present invention provides a small-size meat grinder for a kitchen. The grinder comprises an engine base, the top portion of the engine base is provided with a barrel, the inner wall of the barrelis provided with fixed baffles, the top portions of the fixed baffles are provided with a ring baffle, the top portion of the barrel is provided with a barrel cover, the bottom wall of the barrel cover is provided with a chute, the bottom portion of the barrel cover is provided with a fixed link, a first gear is fixedly arranged at the bottom end of the fixed link, a first grinding rod is fixedlyarranged at the bottom portion of the first gear, the outer wall of the first grinding rod is provided with grinding teeth, the outer wall of the fixed link is sleeved with a first bearing, the outerwall of the first bearing is provided with a connection ring, and a second gear is fixedly arranged at the top end of the connection ring. The small-size meat grinder for the kitchen is provided withgrinding blades from bottom to top to perform rolling of meat raw materials from bottom to top to allow the meat raw materials to continuously perform rolling and flow in the barrel and allow the meat products to be fully smashed and grinded so as to improve the efficiency and the quality when the meat products are grinded.

Owner:中山市小榄镇威的电器有限公司

Efficient chemical raw material mixing device

InactiveCN107335379AShattered fullyEfficient mixingRotary stirring mixersTransportation and packagingRaw materialChemical engineering

The invention discloses an efficient chemical raw material mixing device which comprises a shell, wherein a feeding port is fixedly mounted at the top of the shell; support legs are fixedly connected with both sides of the bottom of the shell; a holding plate is fixedly connected with the right side of the shell; a motor I is fixedly connected with the top of the holding plate; the rotating shaft of the motor I extends into the shell and is fixedly connected with a transverse rod; the transverse rod is moveably mounted inside the shell. Due to adoption of the motor I, a transverse rod, a crushing rod, a motor II, a circular block, a connecting rod I, a connecting rod II, a stirring rod I, a stirring rod II, a stirring plate, through holes and the fixing block I, an efficient material mixing effect is achieved, raw materials can be sufficiently crushed and are further partitioned and mixed under the cooperation of the through holes and the fixing block I, then the raw materials are further refined, a uniform material mixing effect is achieved, the material mixing time is shortened, the material mixing working efficiency is improved, and convenience is brought to people to use the device.

Owner:张家港华翊电工有限公司

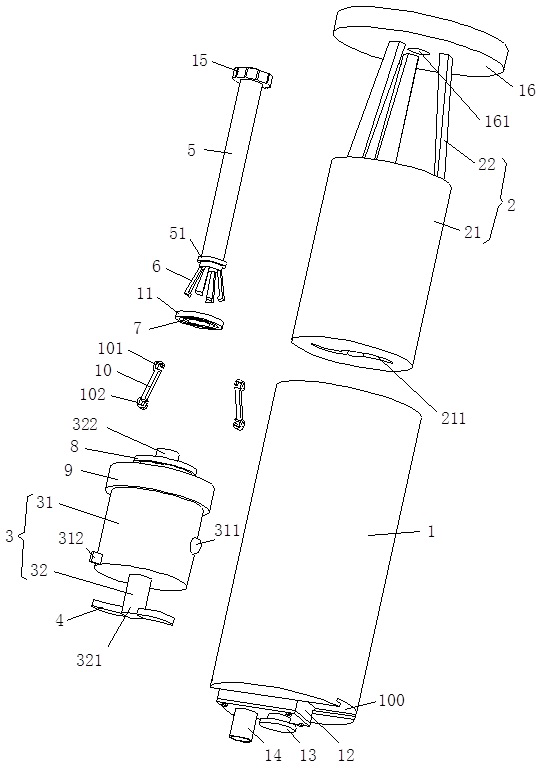

Parathyroid gland homogenate breaker

InactiveCN112169933AResidue reductionImproving Experimental Measurement AccuracyInfusion syringesVeterinary instrumentsElectric machineryEngineering

The invention relates to the technical field of medical instruments, in particular to a parathyroid gland homogenate breaker. The parathyroid gland homogenate breaker comprises a syringe, a piston, amotor, a blade and a driving mechanism. The piston comprises a piston body and a push-pull rod, the piston body is used for being in circumferential sealing fit with the inner wall of the syringe, andthe push-pull rod is used for driving the piston body to axially move along the inner wall of the syringe; an accommodating groove is formed in one end of the piston body, and a penetrating through hole is formed in the bottom surface of the accommodating groove; the motor comprises a machine body and a motor shaft arranged on the machine body, and one end of the motor shaft is used for penetrating through the through hole and is connected with the blade; and the driving mechanism is used for driving the machine body to move relative to the piston body to drive the blade to extend or retractinto the accommodating groove, and when the blade retracts into the accommodating groove, the blade is in circumferential sealing fit with the groove wall of the accommodating groove. According to thetechnical scheme, when parathyroid gland homogenate is injected, the piston can be pushed to the bottom of the syringe, and therefore residues of the parathyroid gland homogenate in the syringe can be reduced.

Owner:谷昌德

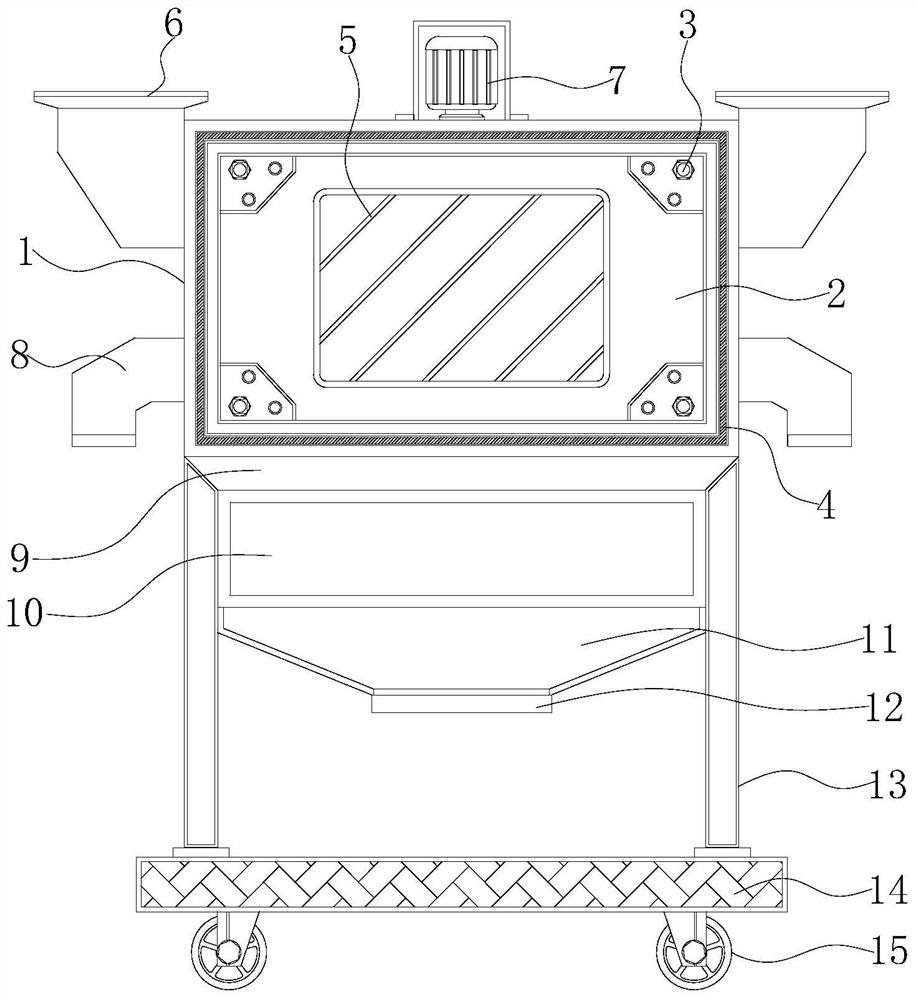

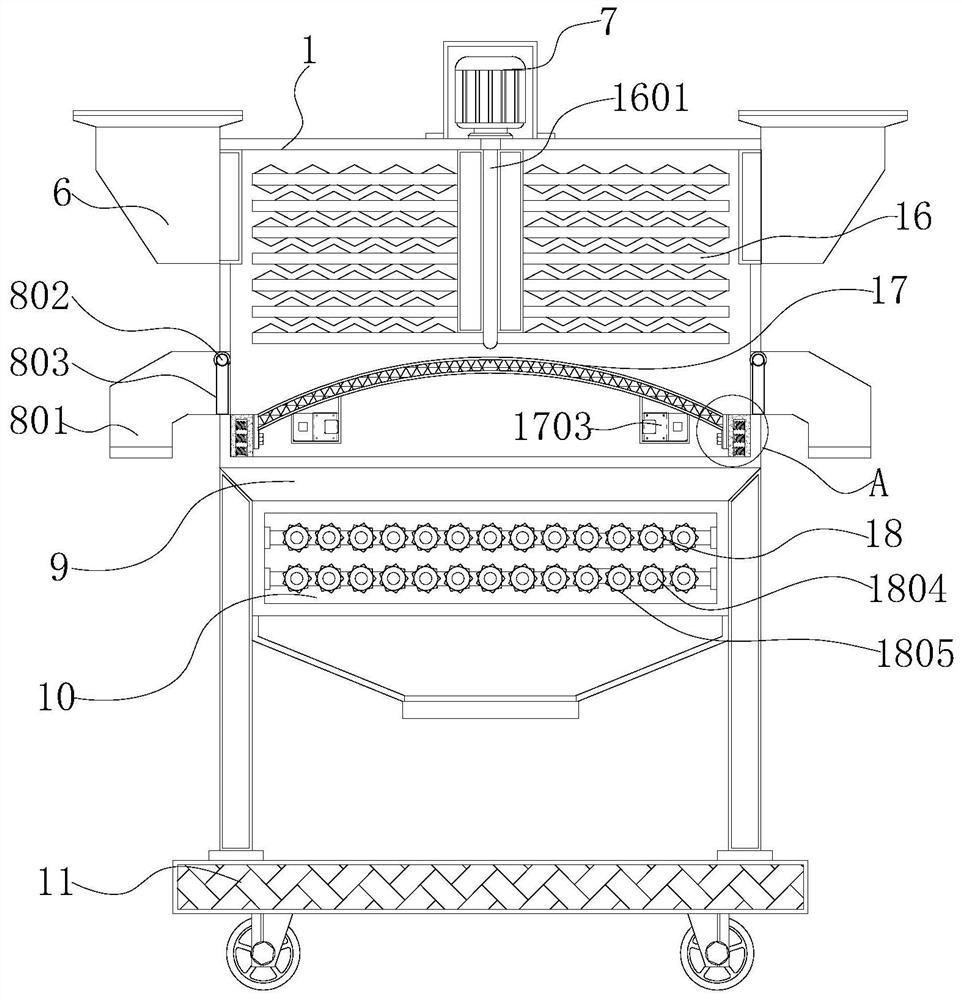

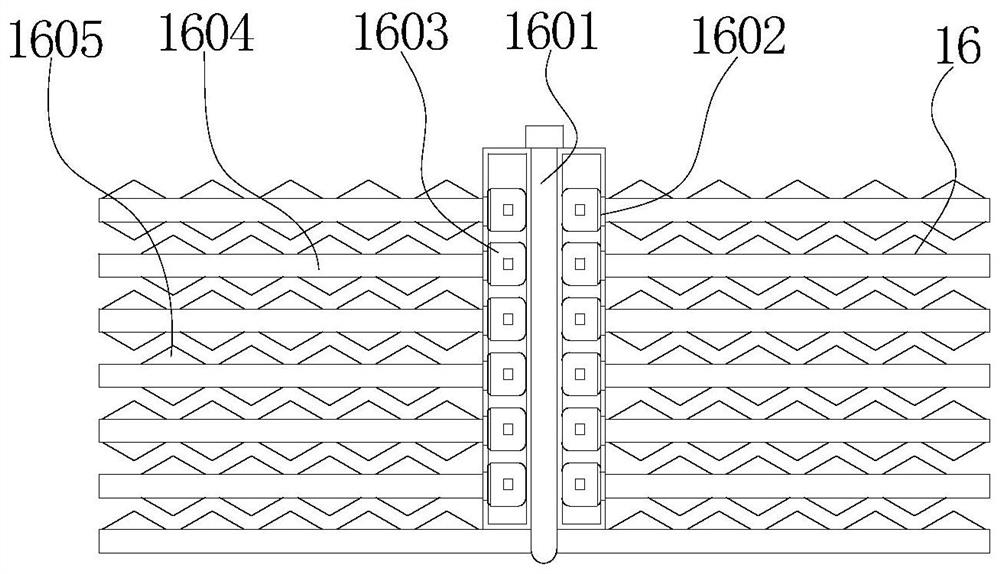

Vacuum cup processing crusher capable of uniformly crushing materials and provided with screening structure

InactiveCN112452513AEasy to moveEasy maintenanceSievingScreeningStructural engineeringManufacturing engineering

The invention discloses a vacuum cup processing crusher capable of uniformly crushing materials and provided with a screening structure, and relates to the technical field of crushers for vacuum cup processing. The crusher comprises a coarse material crushing box, a fine material crushing box and a screening mechanism, wherein a mounting outer plate is fixed to the outer side of the coarse material crushing box, four corners of the mounting outer plate are fixed to the coarse material crushing box, a sealing layer is fixed to the outer edge of the mounting outer plate, explosion-proof glass isfixed to the middle of the mounting outer plate, feeding hoppers are arranged on the two sides of the upper portion of the coarse material crushing box, a rotating motor is mounted on the upper portion of the middle of the coarse material crushing box, and screening discharging mechanisms are arranged on the two sides of the lower portion of the coarse material crushing box. According to the crusher, materials can be screened through a material screening frame of an arc-shaped arched structure and a metal screen, fine materials with small particles can enter a discharging groove below, and large blocky materials can roll to the two sides of the material screening frame along the material screening frame of the arc-shaped arched structure under the action of gravity, so that the materialscan conveniently enter the screening and discharging mechanisms which are symmetrically distributed on two sides.

Owner:郭文英

A bleaching and beating device for certificate paper production

ActiveCN108842497BImprove processing qualityProcessing quality impactPulp bleachingPulp beating/refining methodsRolling paperProcess engineering

The invention discloses a bleaching and pulping device for producing bond paper. The bleaching and pulping device comprises a device body and bleaching chambers, wherein each bleaching chamber is arranged on one side inside the device body; in addition, stirring paddles are arranged inside the bleaching chambers; paddle plates are fixedly arranged on one side of the stirring paddles through connecting rods; a mesh cap is connected to the lower surface of each stirring paddle through a bearing; besides, screw blades are arranged on the surface of each stirring paddle inside the corresponding mesh cap. In the bleaching and pulping device disclosed by the invention, two beating bars are arranged inside a beating chamber; in addition, a plurality of blades are equidistantly arranged on the surface of each beating rod in a staggered manner, so that paper pulp can be sufficiently smashed; meanwhile, the mesh caps and the blades are arranged below stirring rods; the paper pulp can be sufficiently ground by rotating the blades inside the mesh caps, and become more delicate, so that the processing quality of paper is improved; the side wall of the arranged beating chamber is of a hollowed mesh structure, so that the unbeaten paper pulp can be limited in always being continuously beaten in the beating chamber.

Owner:芜湖韩大防伪科技有限公司

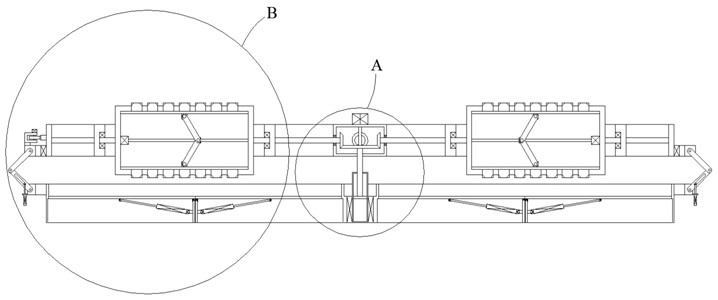

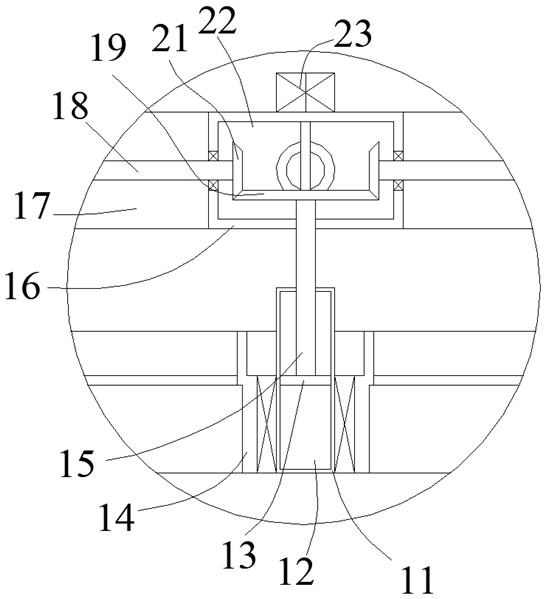

Deep processing equipment for hydraulic modified asphalt

The invention discloses deep processing equipment for hydraulic engineering modified asphalt, and the equipment comprises a first fixed supporting frame, a processing pipe body, an L-shaped supporting fixing plate, a first connecting frame, discharging control valves, a storage and collection disc, a stirring and mixing tank, a second fixed supporting frame, a mixing and cleaning mechanism and a driving control device. The stirring and mixing tank is rotatably mounted in the processing pipe body, the storage and collection disc is fixedly mounted at the upper end of the stirring and mixing tank, the L-shaped supporting and fixing plates are uniformly and fixedly mounted between the processing pipe body and the storage and collection disc, and the discharging control valves are uniformly and fixedly mounted in the middle of the side end face of the processing pipe body. The first fixed support frame is fixedly mounted between the driving control device and the processing pipe body; the second fixed supporting frame is fixedly mounted between the mixing and cleaning mechanism and the processing pipe body, and a rotary adjusting gear ring is fixedly mounted at the upper end of the stirring and mixing tank. In the use process, the added material body and asphalt can be fully mixed.

Owner:左重全

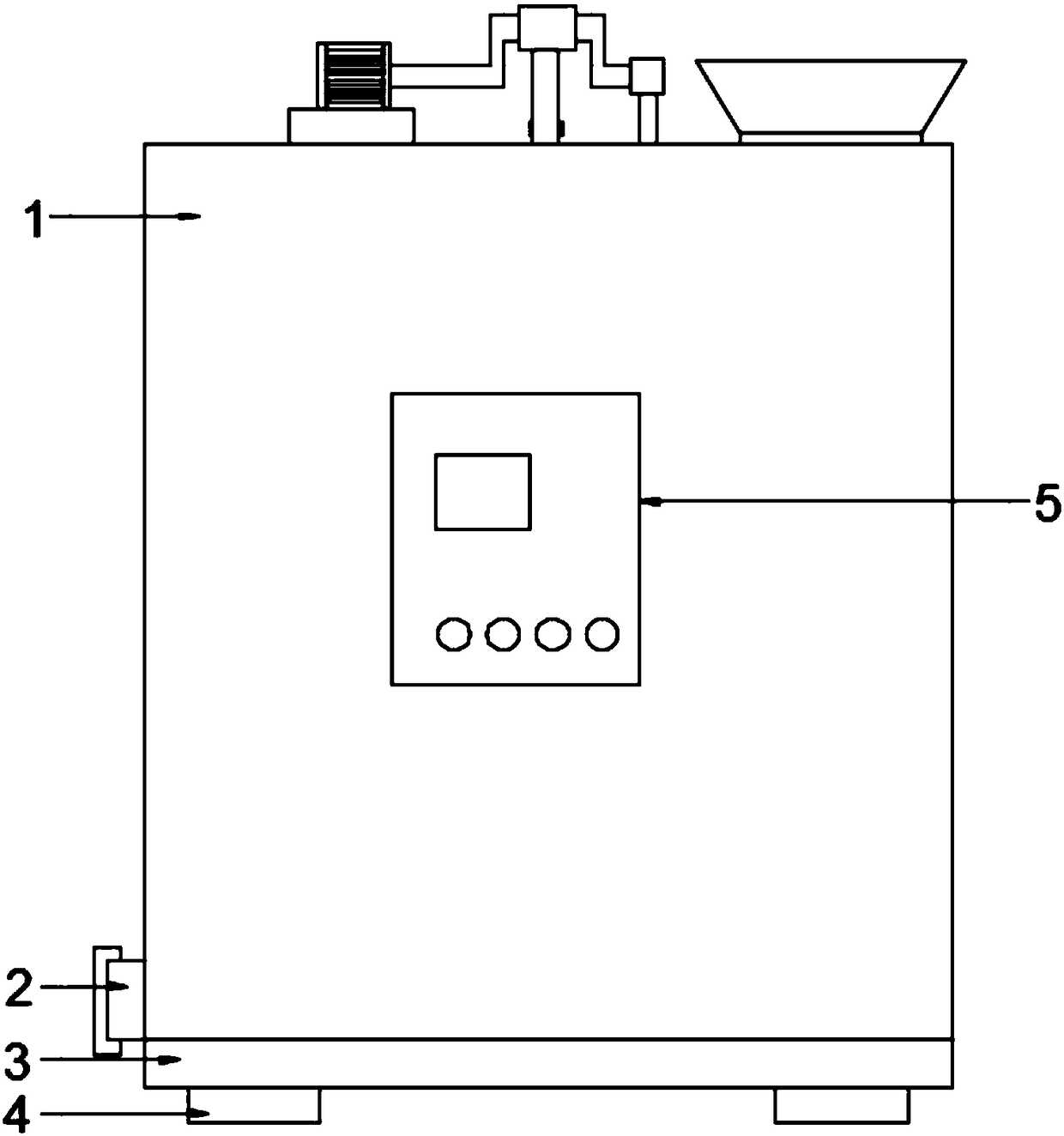

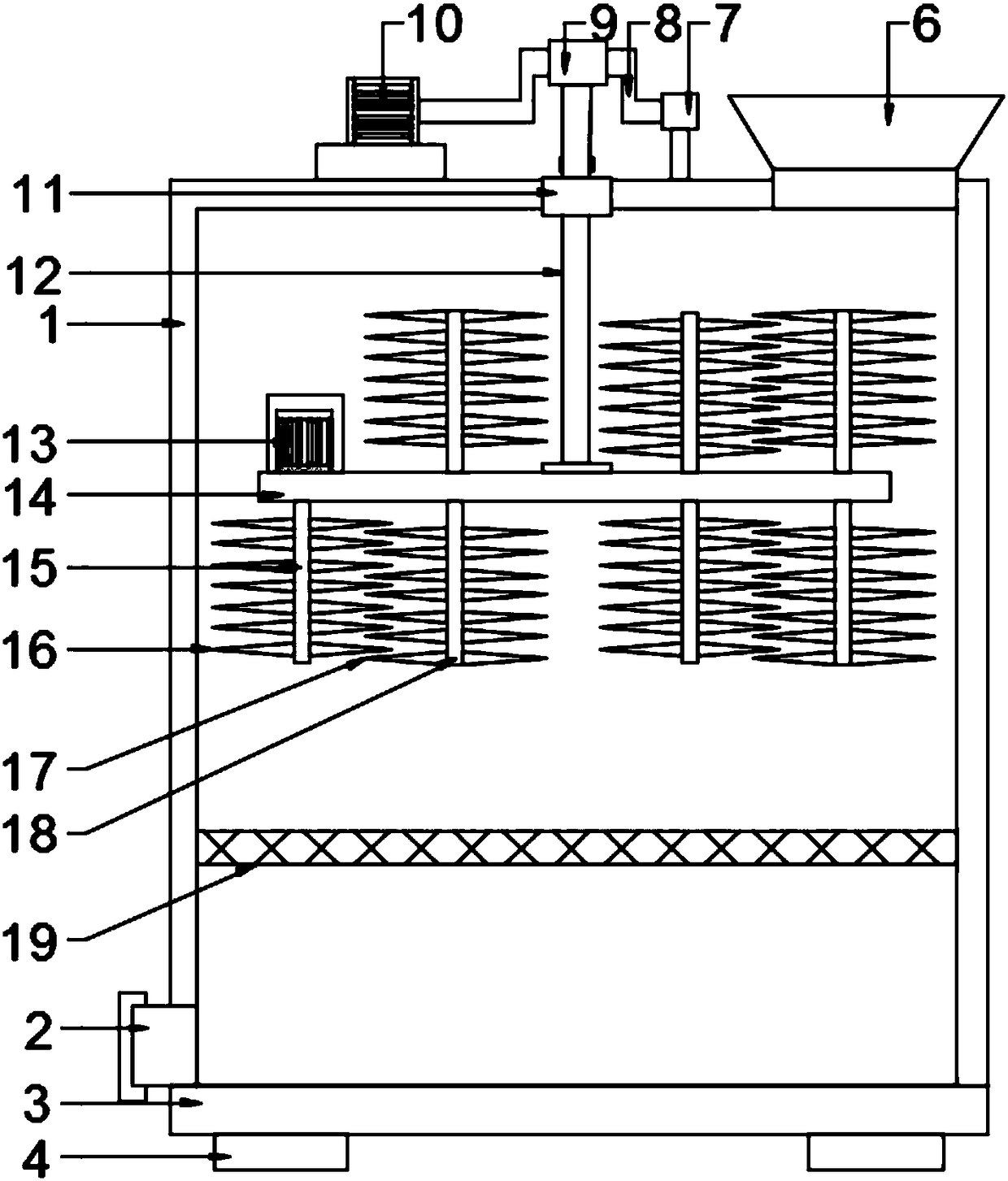

Biomass recovery equipment

ActiveCN111871523BShattered fullySmash efficientRenewable energy machinesCuttersProcess engineeringMechanical engineering

The invention discloses biomass recovery equipment, which comprises a bottom box body, a top box body is arranged on the upper side of the bottom box body, and a storage and discharge device for storing biomass raw materials and facilitating the discharge of equipment is arranged in the bottom box body. A top rotating ring is arranged on the outer side of the top casing, and a distance adjustment device for changing the distance between the top casing and the bottom casing is provided between the top rotating ring and the bottom casing. One side of the rotating ring is provided with a driving device to drive the top box to rotate. The equipment of the present invention has a simple structure. This equipment adopts a method of adjusting the height of the upper body and the lower body of the equipment. The rotation of the machine body fully crushes the biomass raw materials and can adjust the equipment internally according to the crushing area, so that the equipment can efficiently crush materials with different heights and distributions.

Owner:博兴兴博投资有限公司

An automatic feeding equipment for cattle and sheep breeding with accurate feeding

Owner:凤台诺恒农业发展有限公司

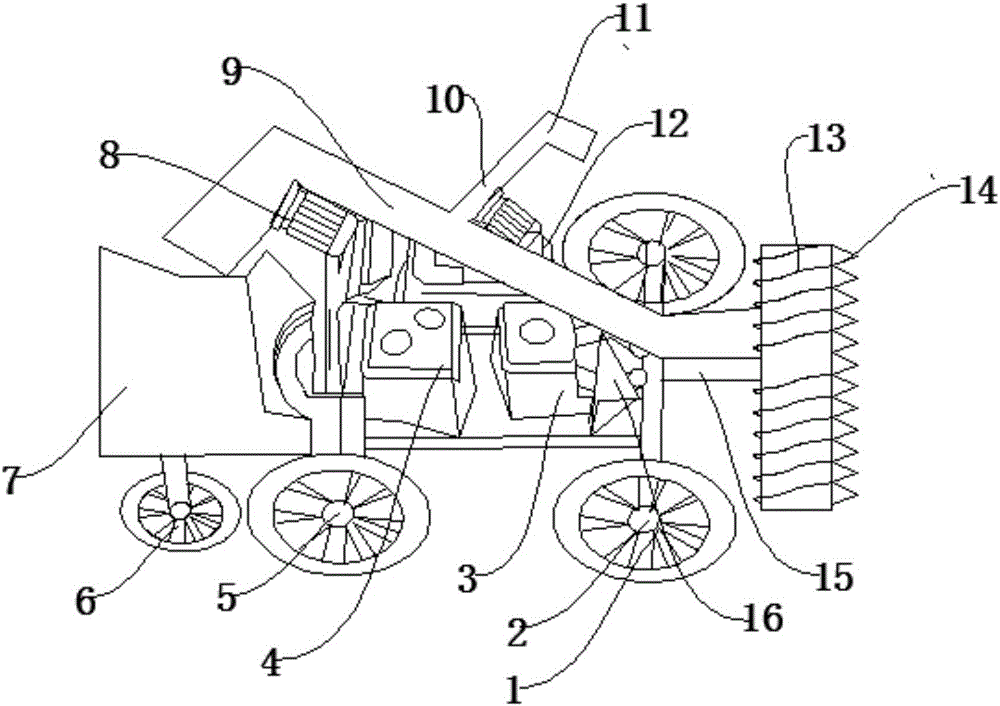

Full-automatic farm-oriented rapeseed harvester

The invention discloses a full-automatic farm-oriented rapeseed harvester. The harvester comprises a guide pulley, a power box, an electric generator and an intelligent controller, wherein a bearing is arranged in the guide pulley, a water tank is arranged at one side of the bearing, the power box is arranged at one side of the water tank, a postposition wheel is arranged at one side of the power box, a supporting wheel is arranged at one side of the postposition wheel, a recycling box is arranged above the supporting wheel, a draught fan is arranged above the recycling box, a transmitting cabin is arranged above the draught fan, an exhaust fan is arranged at one side of the transmitting cabin, a straw discharging cabin is arranged above the exhaust fan, the electric generator is arranged under the straw discharging cabin, a smashing box is arranged at one side of the electric generator, a cutting knife is arranged in front of the smashing box, and a transmission shaft is arranged at one side of the cutting knife. The full-automatic farm-oriented rapeseed harvester has the beneficial effects that the speed of harvesting is greatly improved; straws are smashed completely; rapeseeds and straws are fully separated; the leaving out of rapeseeds is very small; the automation efficiency is high.

Owner:XUZHOU FENGSHUO GREEN AGRI SCI & TECH DEV

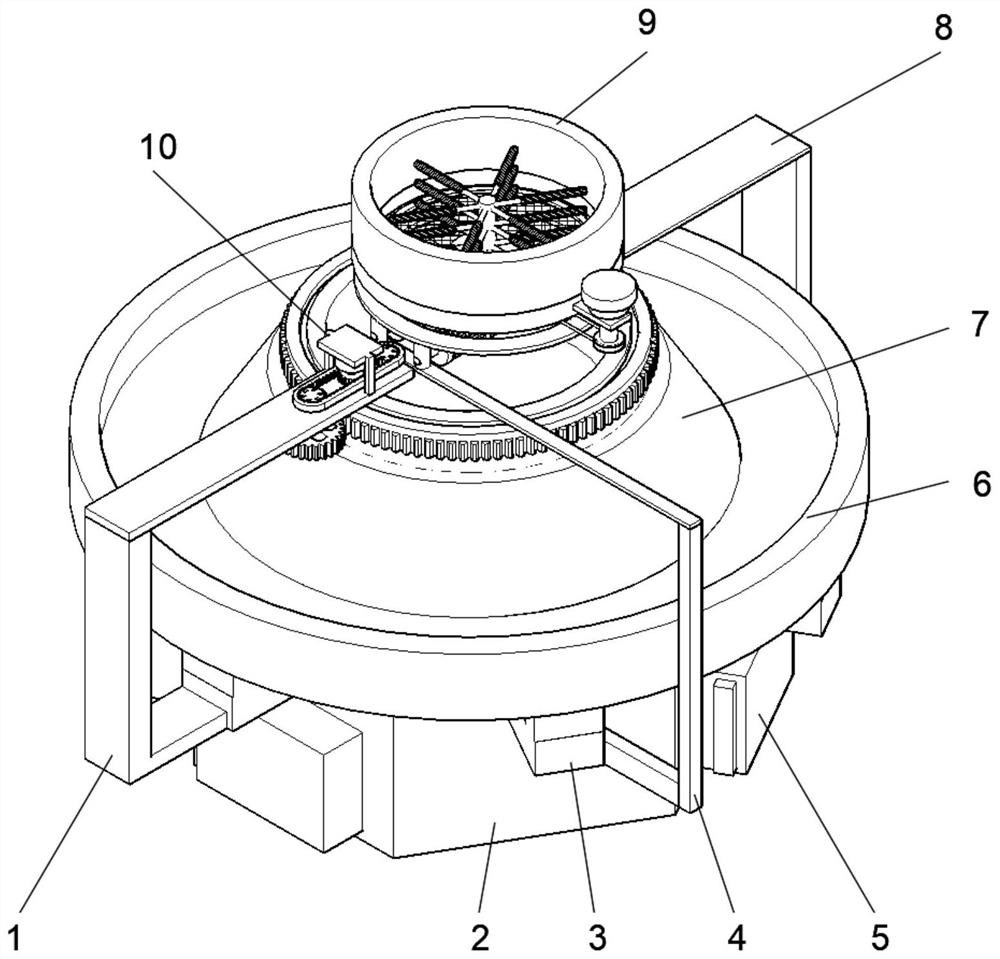

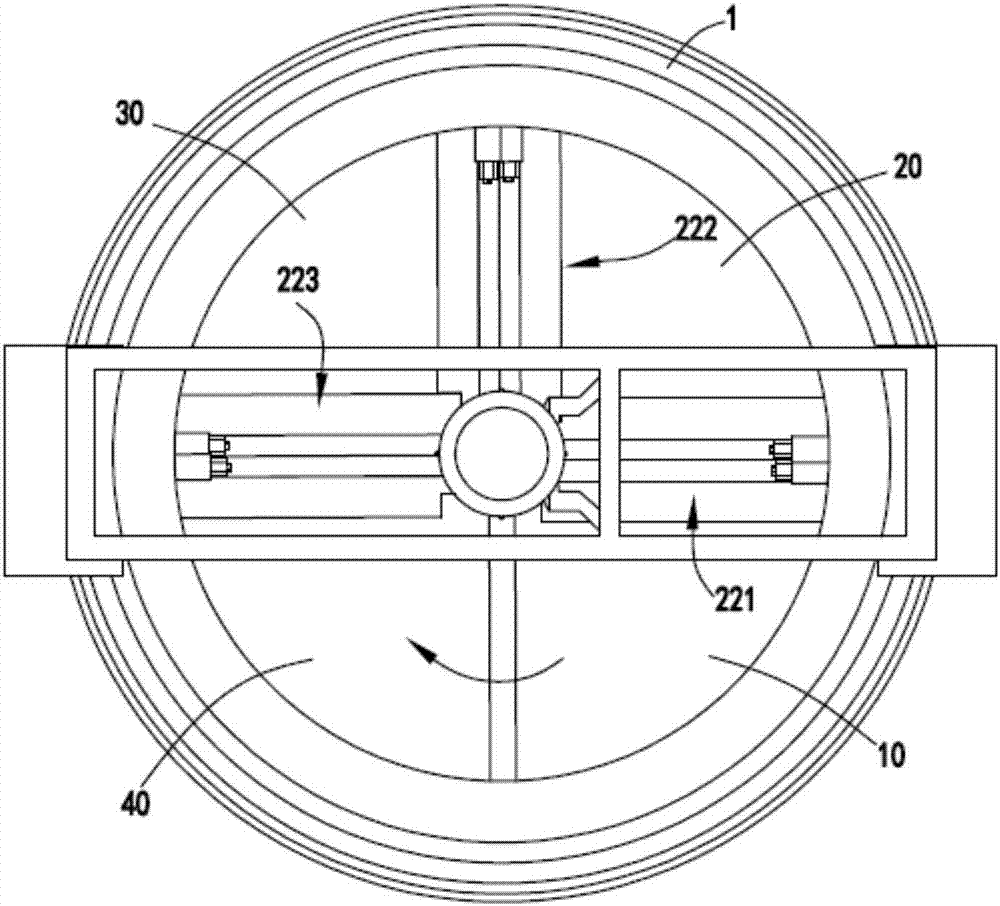

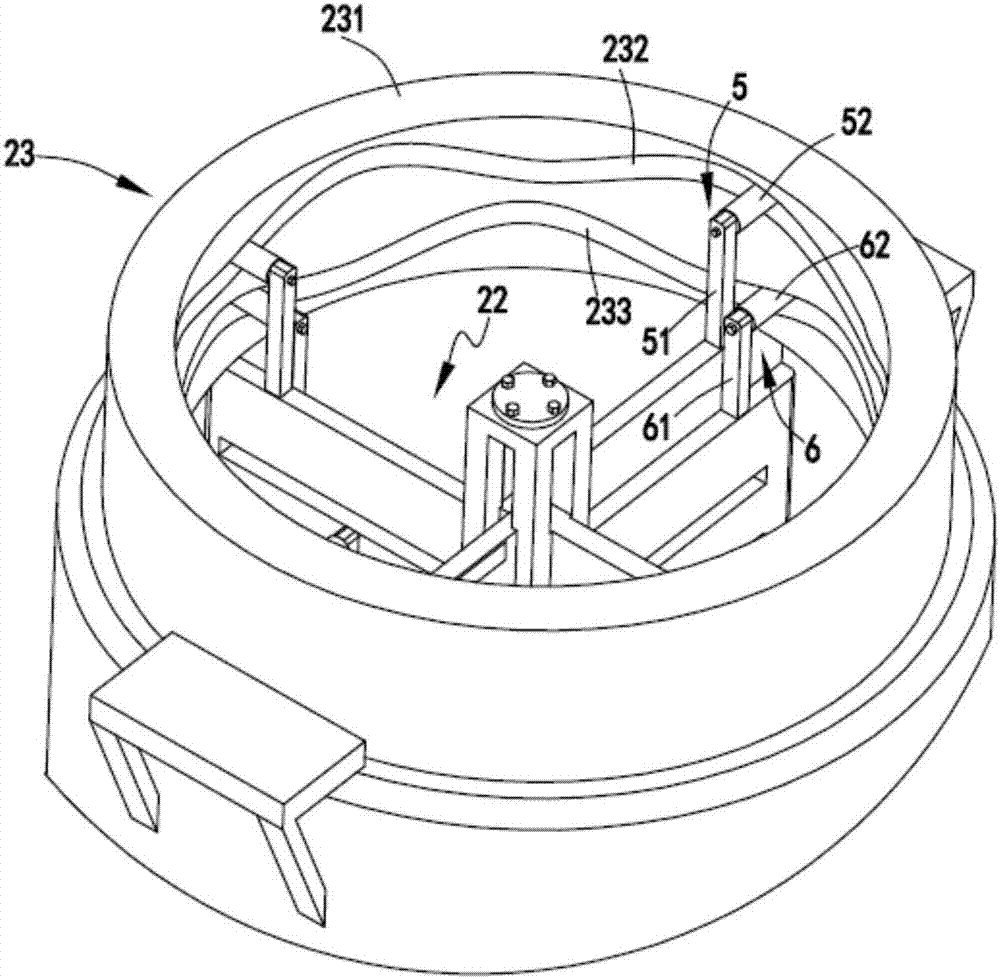

Rotary type size beating device

InactiveCN107185681AEven and fuller smashingQuality improvementGrain treatmentsTreatment effectEngineering

The invention relates to a rotary type size beating device comprising a size tank and a rotary size beating portion. The size tank is used for containing size. The rotary size beating portion comprises a power mechanism, a size beating mechanism and a guiding mechanism. The size tank is divided by the size beating mechanism into an original size area, a primary size area, a secondary size area and a qualified size area. The size beating mechanism is driven by the power mechanism and guided by the guiding mechanism to rotate along the center axis of the size tank and move up and down in a reciprocating manner at the same time so that the size in all the areas of the size tank can be beaten stage by stage. The rotary type size beating device solves the problems that because textile size is not fully beaten, the size treatment effect is poor, and the follow-up use effect is influenced.

Owner:SUZHOU HUACE TEXTILE SCI & TECH

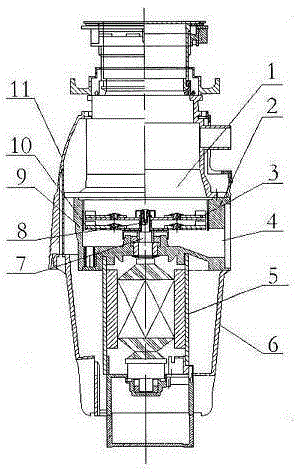

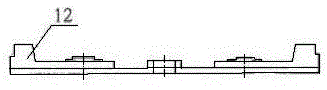

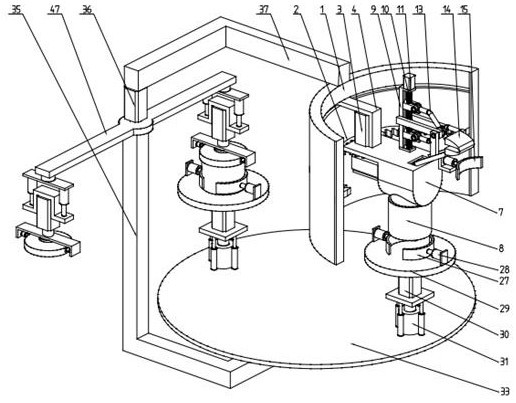

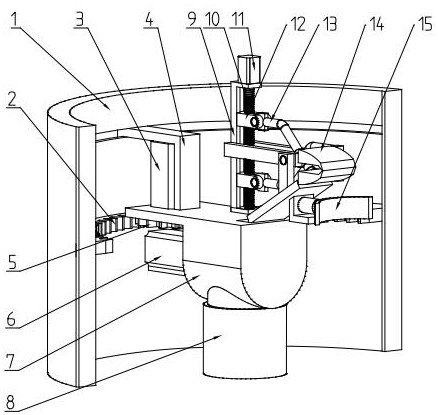

Domestic kitchen garbage smashing machine

The invention discloses a domestic kitchen garbage smashing machine. The domestic kitchen garbage smashing machine mainly has the effect of fully smashing food garbage especially fiber type soft substances and preventing pipeline blockage. The domestic kitchen garbage smashing machine is characterized in that a plurality of cutter plates are installed inside a water storage tank, the food garbage is firstly smashed by smashing blades of the first-stage cutter plate, then the food garbage which is not fully smashed is further smashed by the second-stage cutter plate, and the food garbage which is not smashed by the second-stage cutter plate is smashed by smashing blades of the third-stage cutter plate, the fourth-stage cutter plate until the last-stage cutter plate. The food garbage especially soft fiber garbage can be fully smashed after smashed by the smashing blades of the multiple cutter plates.

Owner:黑龙江万向鹏程科技发展有限公司

A robot for collecting nail shell powder

The invention discloses a robot for collecting nail shell powder, which comprises a ring seat, a ring rack, a rotary frame, a crushing machine shell, a powder tank, a lifting frame, an upper clamp seat, an upper clamp rod, a clamp head, a butt head, and an electric cylinder Support, landslide, landslide connecting seat, lower tong rod, rotary connecting rod, lower tong seat, large saw blade, crushing shaft, crushing pieces, bottle body clamp, bottle changing disc, L-shaped connecting rod, upper connecting rod, motor Swivel base, motor chassis, replacement swivel frame, etc. When the robot is in use, it presses the head against the flesh under the nail, and at the same time, the upper and lower pincers move together to trim the nail shell. The cut nail shell enters the shredder shell along the slope, and the large saw blade and the crushing pieces rotate. Grind the nail shell into powder, the powder leaks into the powder can through the powder hole, then the bottle clip unscrews the powder can, and the large disc rotates to cap the powder can.

Owner:吕家环

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com