Tapered beater for machine-made sand

A technology for dispersing machine and machine-made sand, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of deformation of the screening device, abnormal screening, low stability of the screening device, etc., to ensure the stability of work, Guarantee work reliability and improve the effect of dispersing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

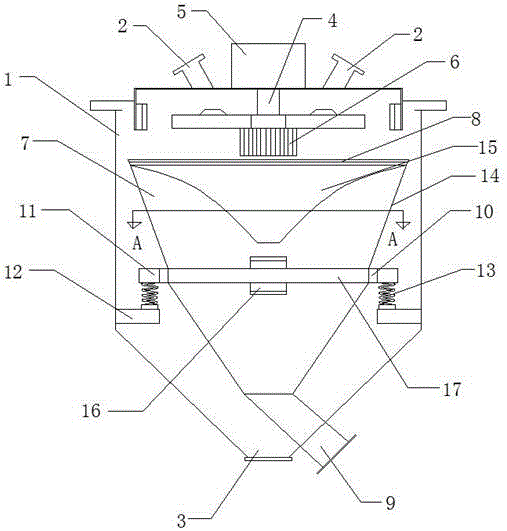

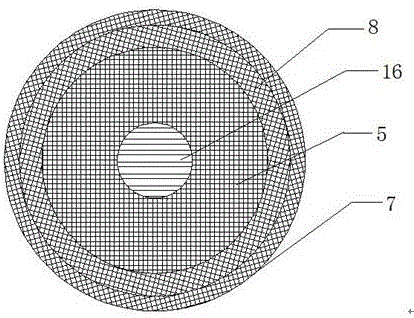

[0018] like figure 1 and figure 2 As shown, a machine-made sand cone breaker includes a feed port 2 located on the upper part of the outer cone shell 1, a fine material port 3 located at the lower part of the outer cone shell 1, and a middle part of the outer cone shell 1. There is a connecting shaft 4, one end of the connecting shaft 4 is driven and connected to the power unit 5, the other end of the connecting shaft 4 is rotated and connected to the wind wheel 6, the lower end of the wind wheel 6 is provided with a screening device 7, and the upper part of the screening device 7 is provided with a feeding 8, the lower part is provided with a coarse material port 9, the side of the screening device 7 is provided with a tight hoop 10, a pair of ears 11 are symmetrically arranged on the tight hoop 10, and the inner wall of the outer cone shell 1 is provided with a supporting part 12, The ear portion 11 and the support portion 12 are connected by a pressure spring 13, and the ...

Embodiment 2

[0024] Embodiment 2 is the same as Embodiment 1, except that the self-lubricating aluminum alloy material is composed of the following components by mass percentage: Fe is 3.4%, Cu is 4.7%, Si is 0.5%, Mg is 1.1%, Cr is 1.5%, Sn is 1.3%, Nb is 0.3%, Bi is 2.0%, the impurity content is not more than 1%, and the balance is aluminum.

Embodiment 3

[0026] Embodiment 3 is the same as Embodiment 1 and Embodiment 2, except that the self-lubricating aluminum alloy material is composed of the following components by mass percentage: Fe is 3.8%, Cu is 5.1%, Si is 0.7%, Mg 1.3% for Cr, 1.5% for Sn, 1.7% for Sn, 0.5% for Nb, 2.2% for Bi, the impurity content is not more than 1%, and the balance is aluminum.

[0027] The self-lubricating aluminum alloy rotating impeller obtained in the above examples is tested and detected, and the Vickers hardness of the self-lubricating aluminum alloy rotating impeller reaches 43-48, the radial crushing strength reaches 185.4-196.7MPa, and the oil content reaches 22%. , has good comprehensive mechanical properties and can meet the requirements of working conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com