Closed slurry extruding type stirring device and seedling culture slurry machine with same

A stirring device and paddle-type technology, which is applied to mixers with rotating stirring devices, mixer accessories, mixers, etc., can solve the problems of waste of raw materials and low mud quality, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

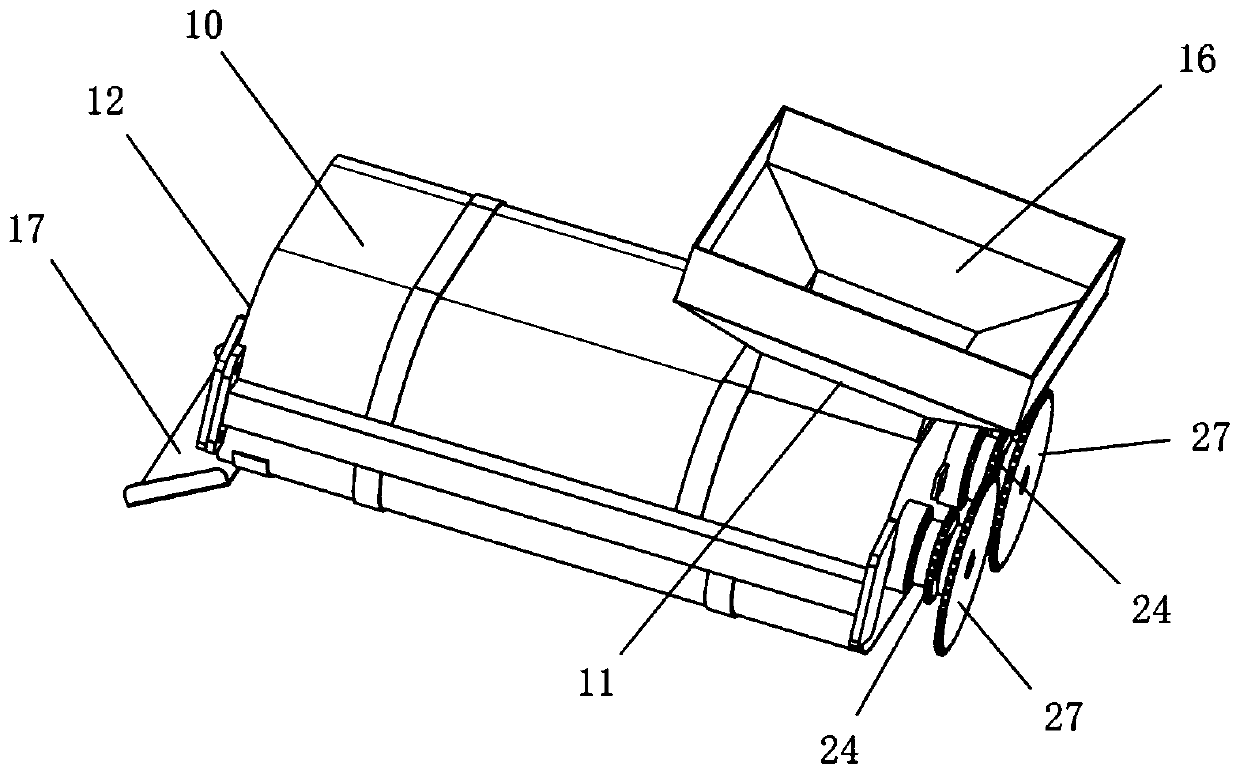

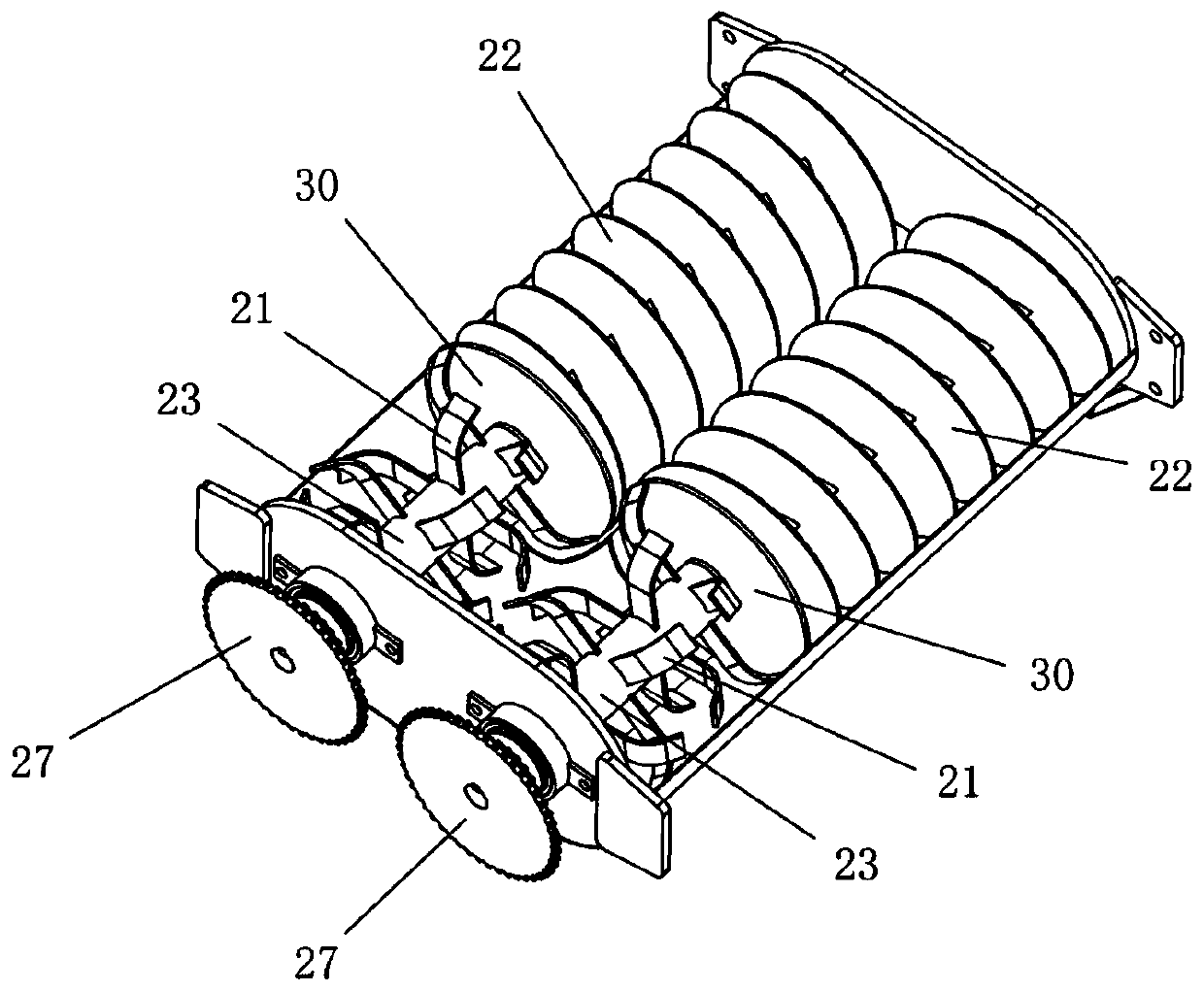

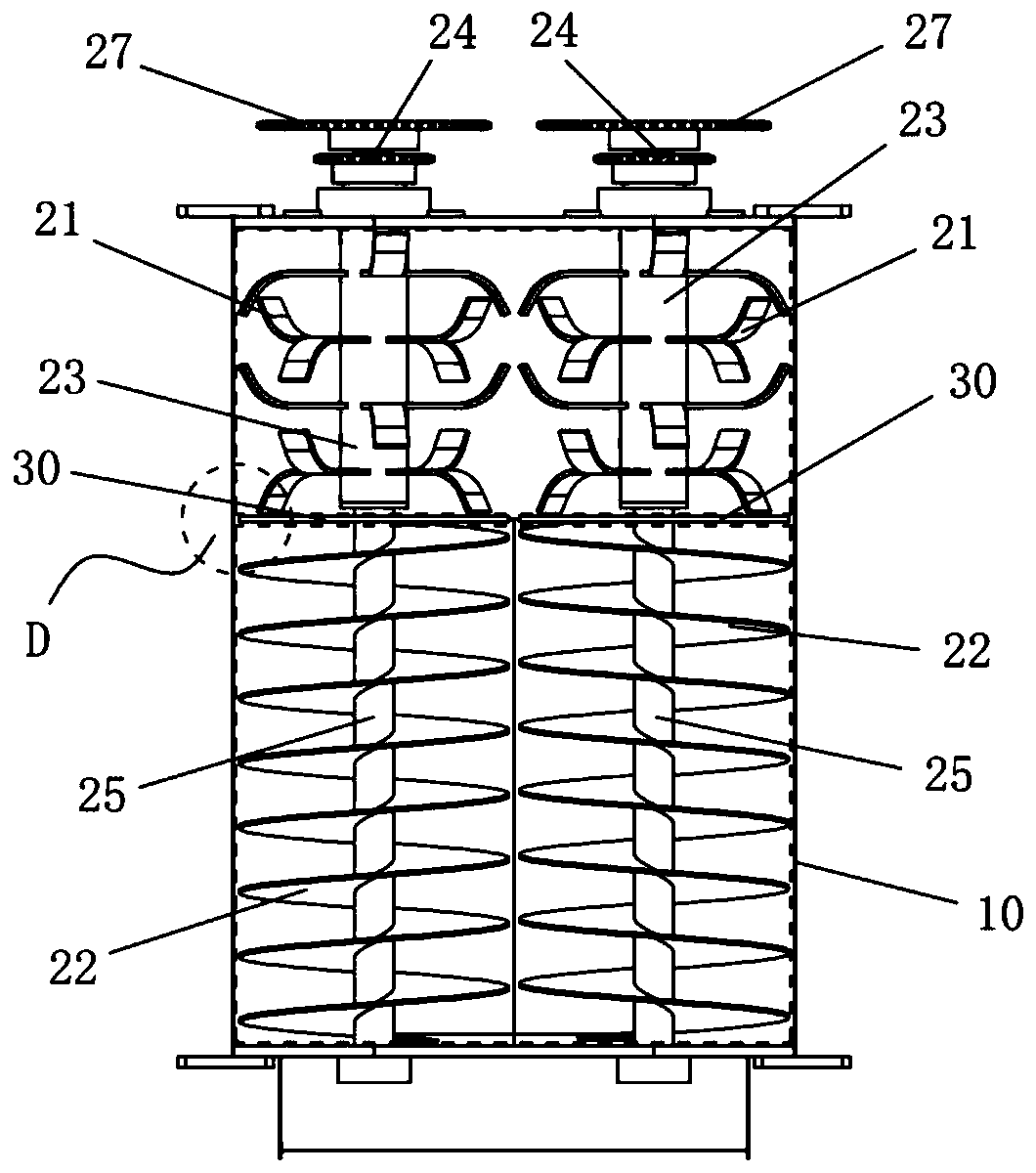

[0038] see Figure 1 to Figure 9 , a closed paddle stirring device according to an embodiment of the present invention, the closed paddle stirring device mainly includes a stirring device housing 10 , a stirring shaft 20 and a disk baffle 30 . Wherein, one end of the stirring device housing 10 is provided with a feed port 11, and the other end of the stirring device housing 10 is provided with a discharge port 12; A blanking trough 17 is provided; the stirring shaft 20 is rotatably installed in the stirring device housing 10, the end of the stirring shaft 20 near the feed port 11 is provided with a soil cutter 21, and the end of the stirring shaft 20 near the discharge port 12 is provided with a stirrer. Dragon blade 22; Disc baffle plate 30 is installed on the stirring shaft 20, and is positioned between soil cutting knife 21 and auger blade 22, stays between the outer edge of disc baffle plate 30 and the inner wall of stirring device housing 10 Gap 40 for the passage of mud...

Embodiment 2

[0047] see Figure 1 to Figure 11 , a seedling raising mud machine according to an embodiment of the present invention, the seedling raising mud machine mainly includes a frame 60, a stirring motor 70 and a closed squeezing type stirring device. Wherein, the stirring motor 70 and the closed pulping type stirring device are all arranged on the frame 60, and the output end of the stirring motor 70 is connected with a soil cutting shaft driving sprocket 80 and an auger shaft driving sprocket 90 through a transmission mechanism. The shaft drive sprocket 80 is connected with the soil cutting shaft driven sprocket 24 by a chain, and the auger shaft drive sprocket 90 is connected with the auger shaft driven sprocket 27 by a chain. The enclosed squeezing stirring device in this embodiment is the same as the closed squeezing stirring device in Embodiment 1, and will not be repeated here.

[0048] Above-mentioned seedling raising mud machine, by setting disc baffle 30 between soil cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com